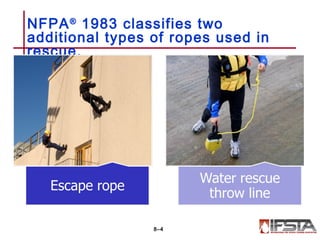

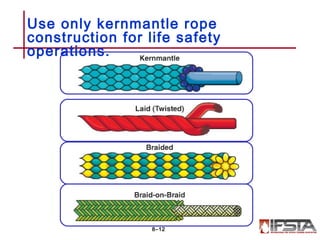

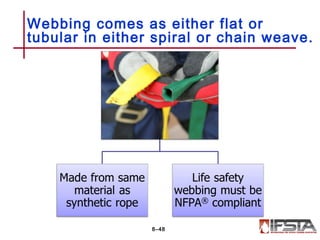

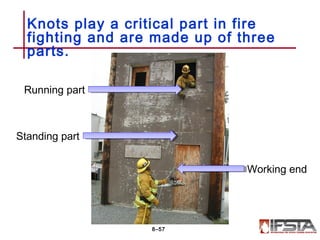

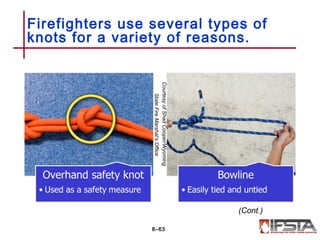

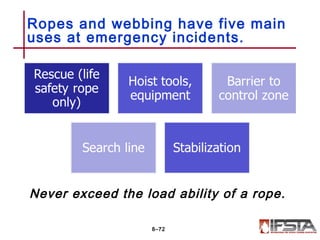

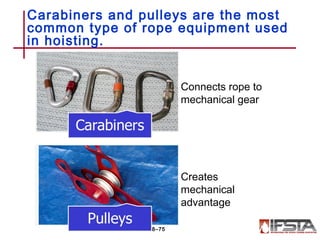

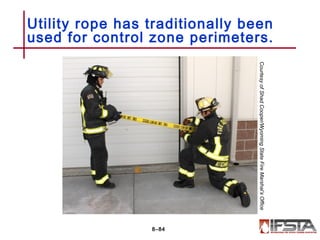

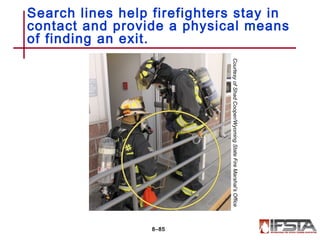

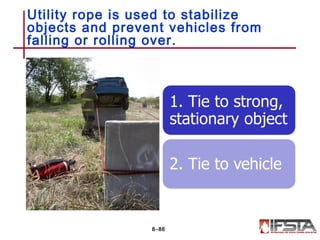

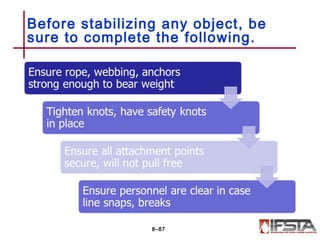

- Firefighters use ropes, webbing, and knots for hoisting tools and equipment, stabilizing objects, designating control zones, performing rescues, and escaping dangerous situations.

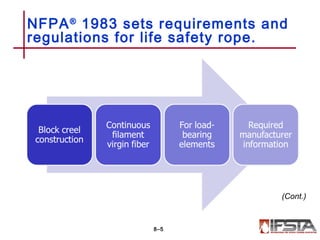

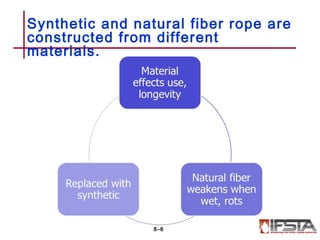

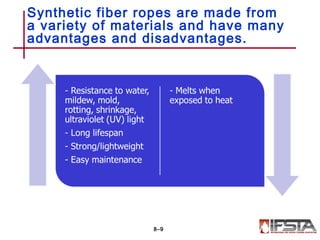

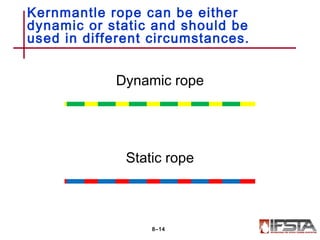

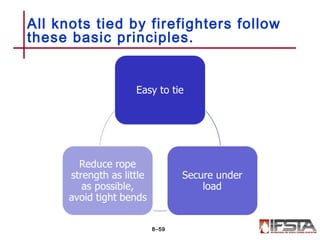

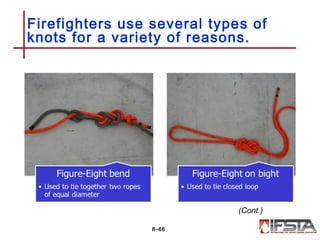

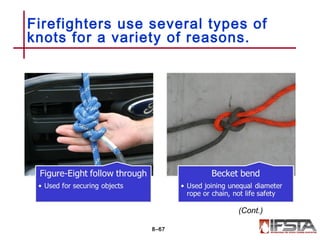

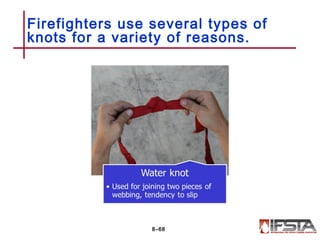

- Proper rope use requires understanding types of ropes, their applications, and tying various knots quickly.

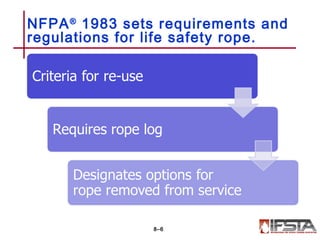

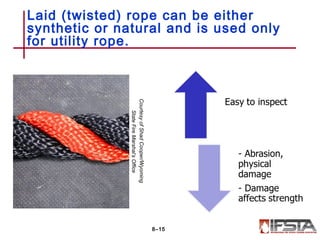

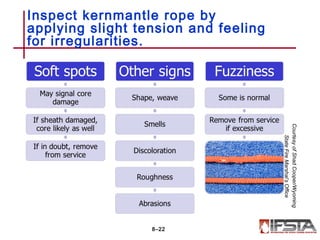

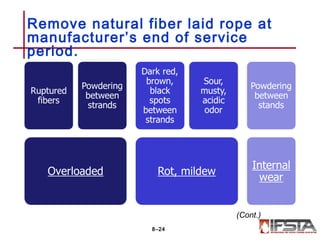

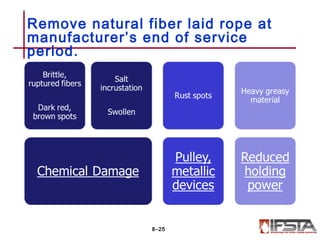

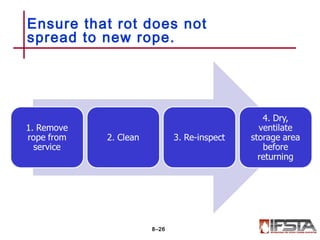

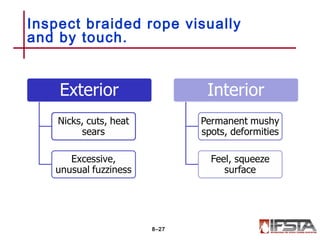

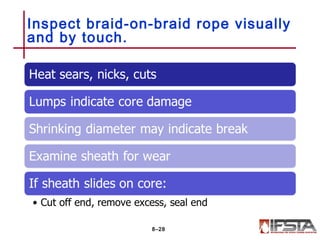

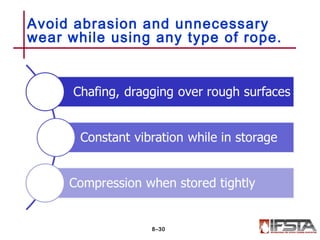

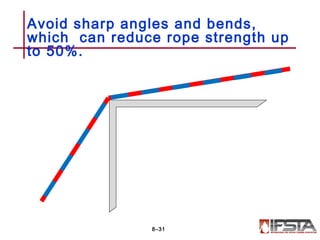

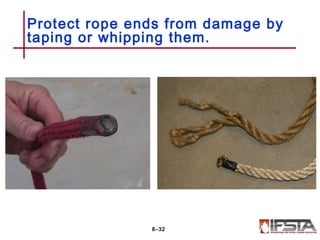

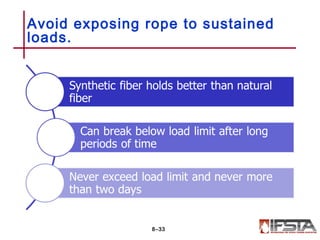

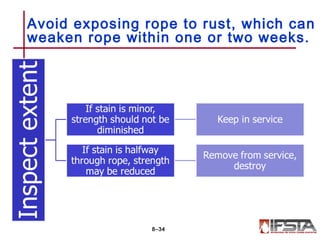

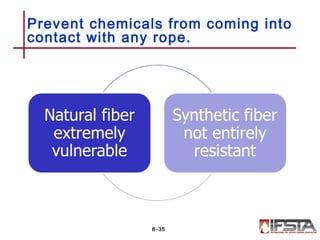

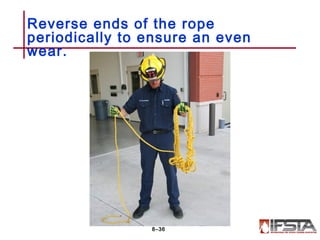

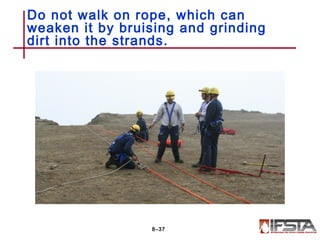

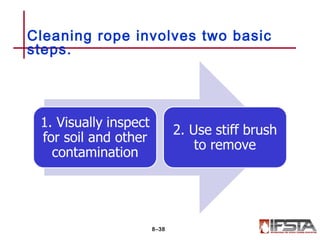

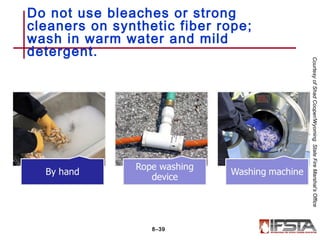

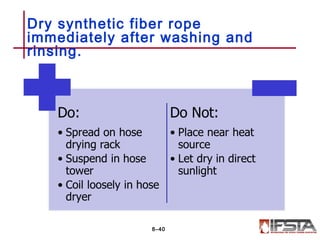

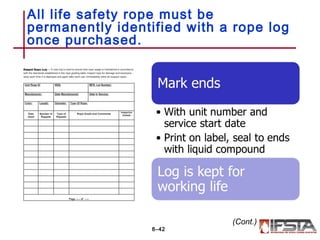

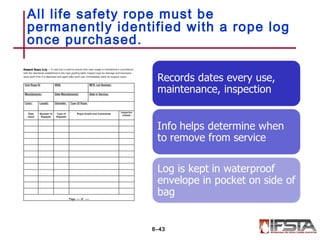

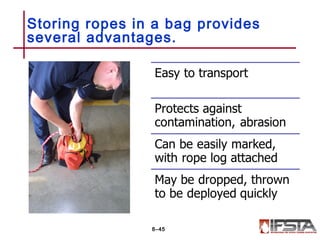

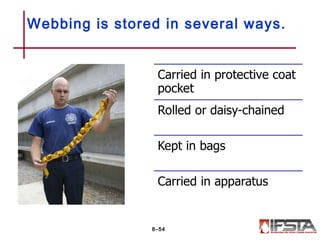

- Ropes and webbing must be regularly inspected, cleaned, maintained, and stored to ensure they are ready for emergencies.