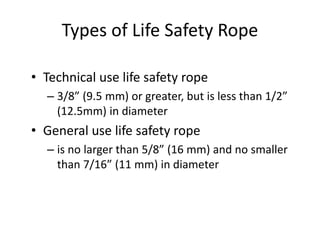

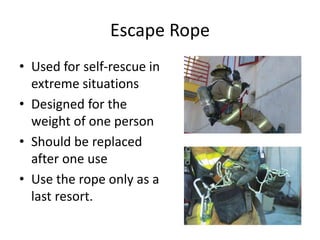

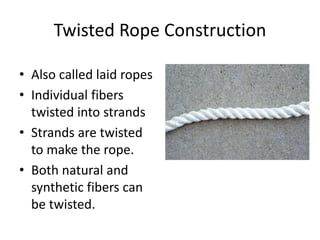

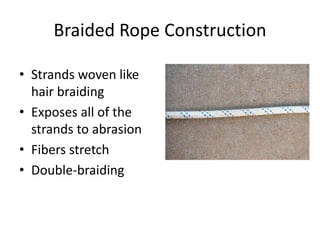

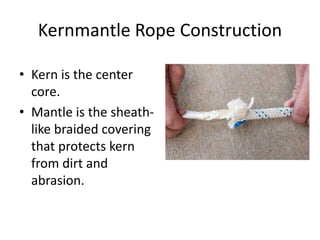

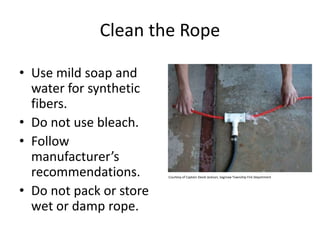

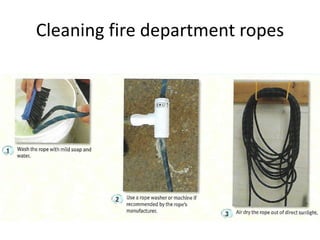

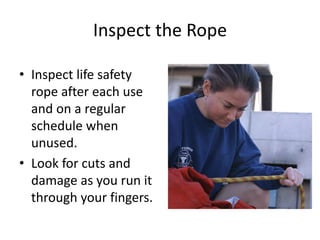

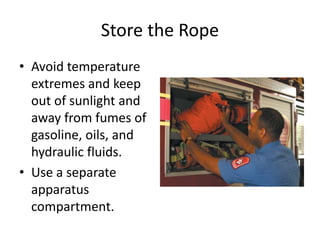

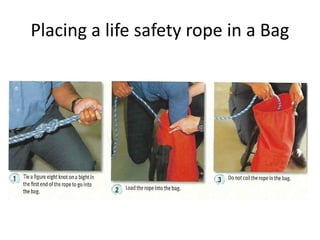

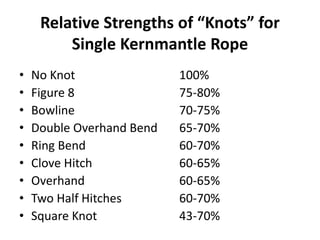

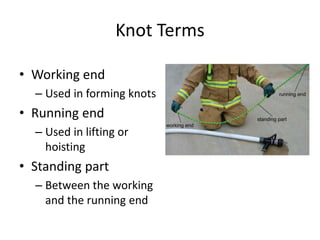

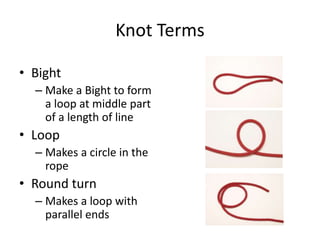

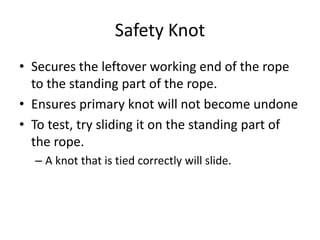

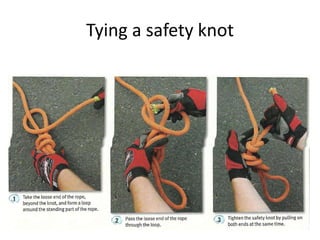

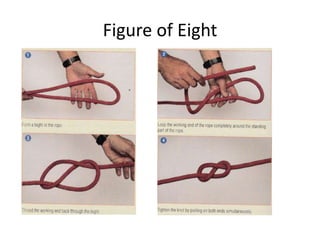

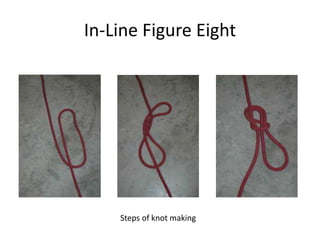

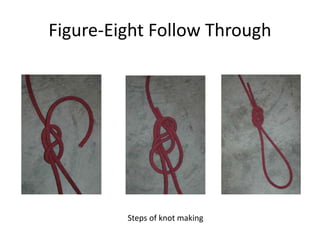

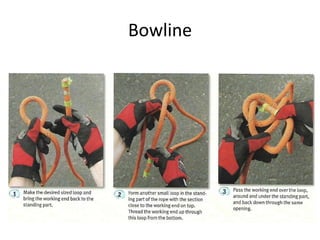

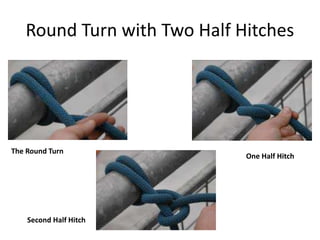

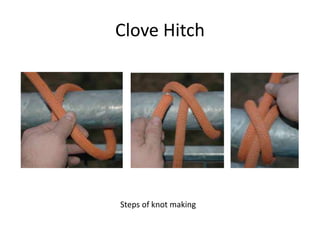

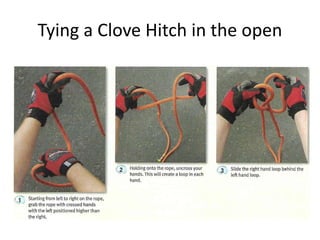

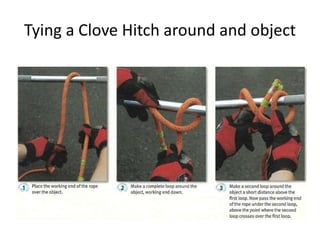

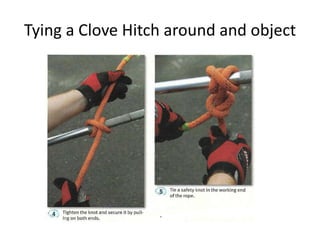

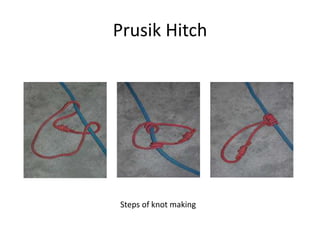

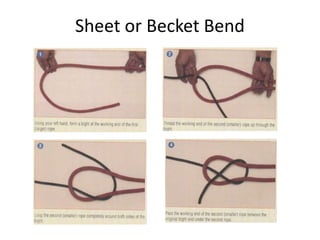

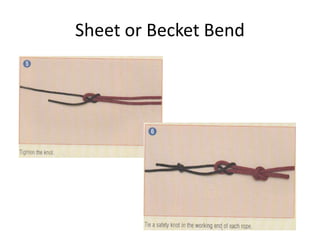

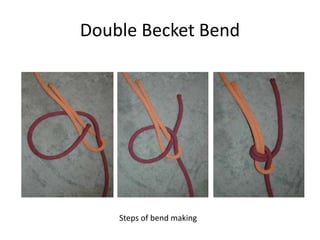

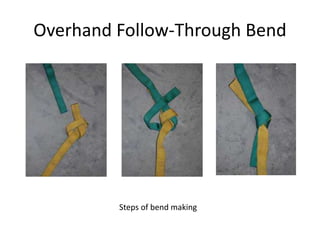

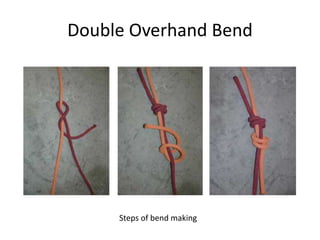

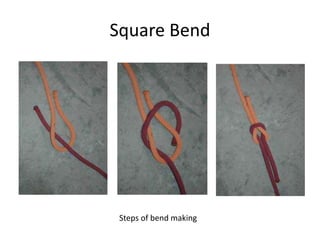

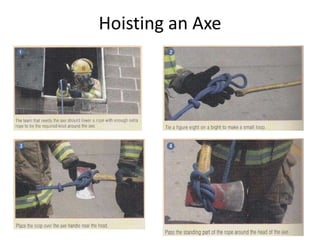

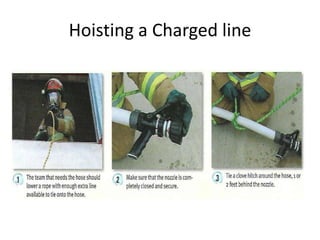

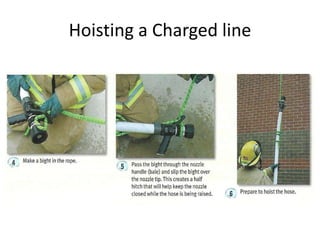

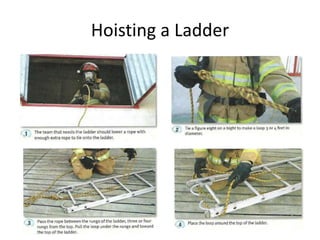

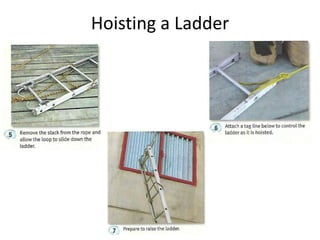

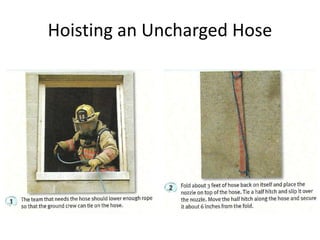

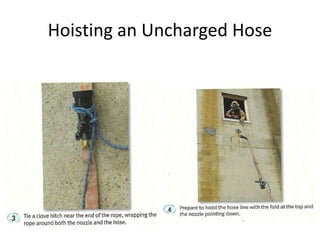

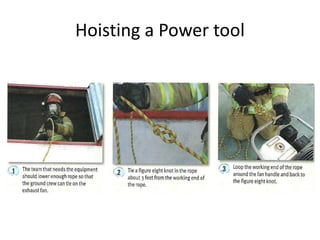

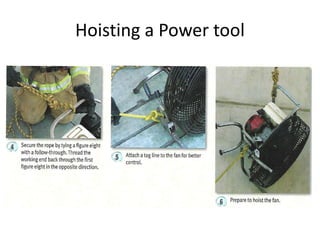

This document discusses knots and rope usage in firefighting. It covers the different types of ropes used - life safety ropes, escape ropes, and utility ropes. It describes various rope materials like synthetic fibers, wire ropes, and natural fibers. It discusses rope construction methods like twisted, braided, and kernmantle. The document provides details on inspecting, cleaning, caring for, and storing ropes. It explains different types of knots like loops, hitches, bends and provides instructions on tying knots like the bowline, clove hitch, figure eight, and prusik hitch. It also shows examples of hoisting tools and equipment using ropes and knots.