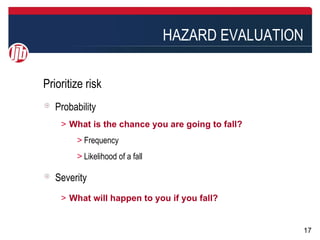

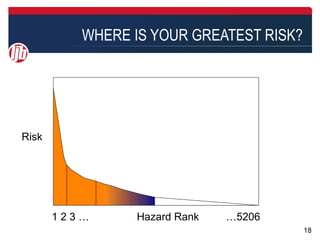

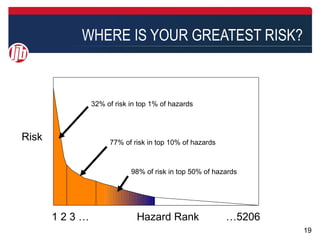

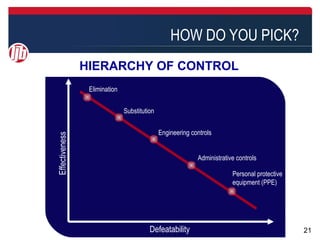

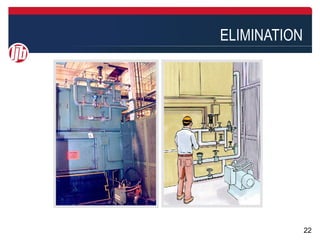

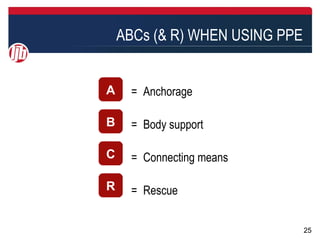

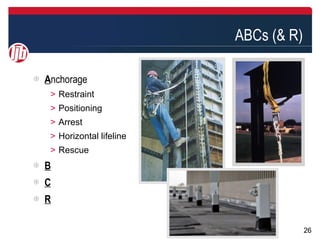

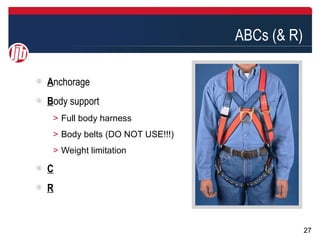

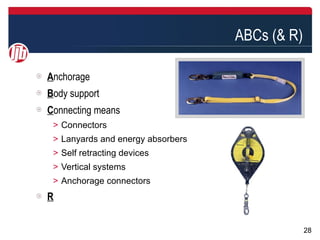

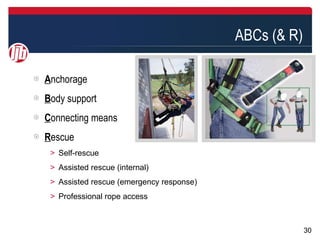

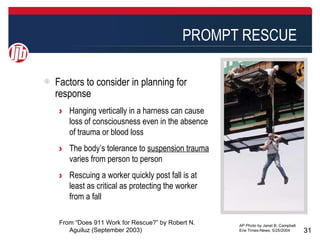

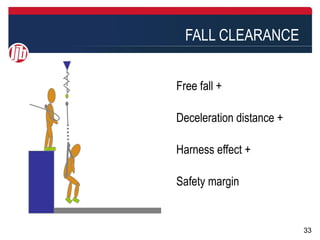

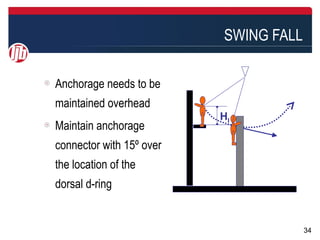

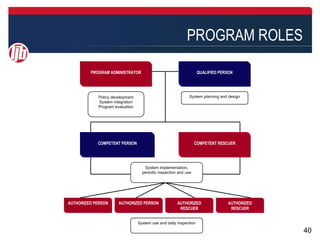

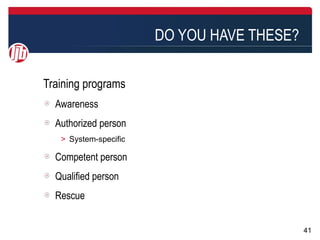

This document outlines essential elements of a managed fall protection program, emphasizing the importance of effective management, employee participation, hazard identification, and training. It discusses evaluating fall hazards, the hierarchy of control for choosing abatement solutions, and training requirements for competent personnel. Additionally, it provides guidelines for equipment standards, inspection, and emergency response considerations to reduce fall risks in the workplace.