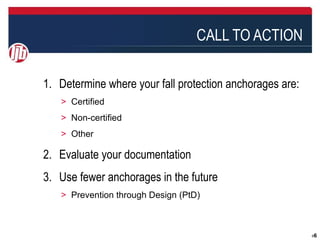

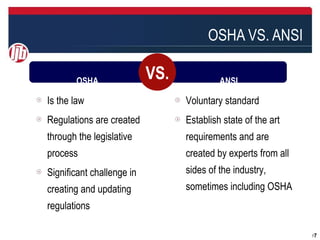

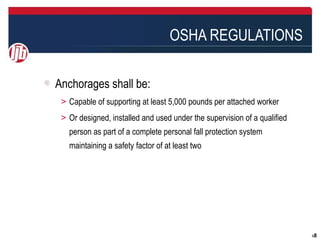

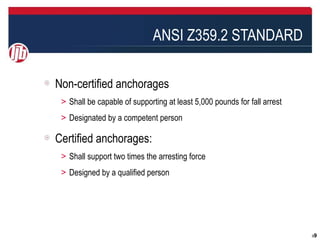

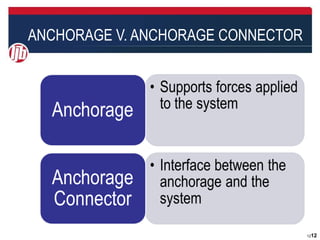

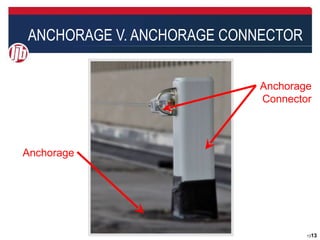

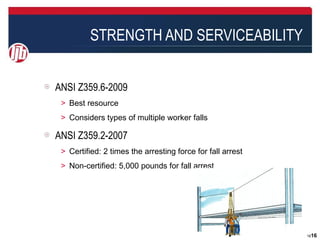

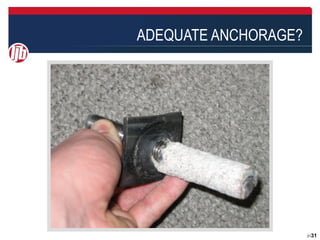

The document discusses fall protection anchorages, highlighting the importance of proper anchorage assessment according to OSHA and ANSI standards. It outlines the various types of anchorages, their required strengths, and the necessity for thorough documentation and evaluation of fall protection systems. Key considerations for improving fall protection at job sites are emphasized, including the need for certified anchorages and the importance of prevention through design.