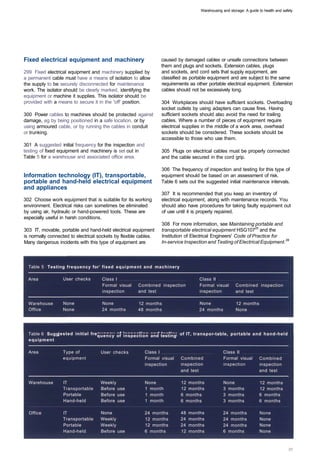

This document provides guidance on health and safety management for the warehousing and storage industry. It identifies manual handling, slips and trips, vehicles, and work at height as priority issues. Effective health and safety management involves identifying risks, controlling them through sensible measures, and protecting employees and others. A written health and safety policy statement is needed if the workplace has five or more employees. Accidents must be reported under RIDDOR regulations.