This document discusses hydrogen as a future energy source and outlines methods for its production. It first provides background on hydrogen as the most abundant element in the universe and discusses its properties that make it a promising fuel, such as having the highest energy content per unit mass of all fuels. The document then describes various methods for producing hydrogen, including from water via electrolysis or thermochemical processes, and biologically from biomass. It also outlines countries' and companies' policies supporting research and development of hydrogen fuel cell technologies.

![tons of hydrogen gas can be produced annually from solely tomato and eggplant wastes

in Antalya with the help of solar energy. It is noteworthy to mention that the energy

equivalent is 4365 tons of fossil oil.

* Air pollution problem will also be solved when hydrogen is used as a fuel since H2O is

alone the the reaction product. Furthermore, the condensation of that water, produced

in the system, would also be a partial solution for another environmental problem: the

water supply problem. Thus, a big step will be taken FOR A BETTER LIFE.

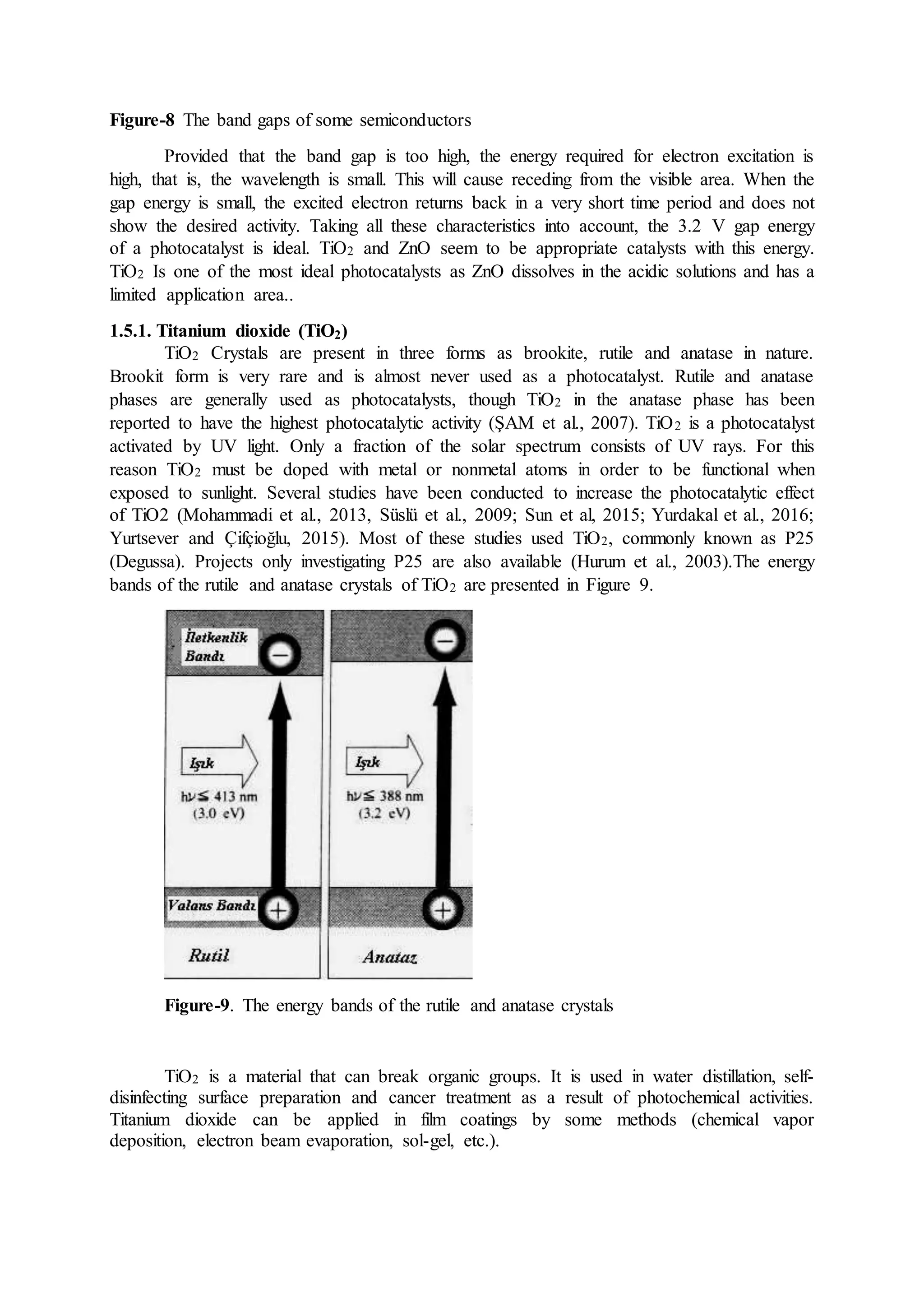

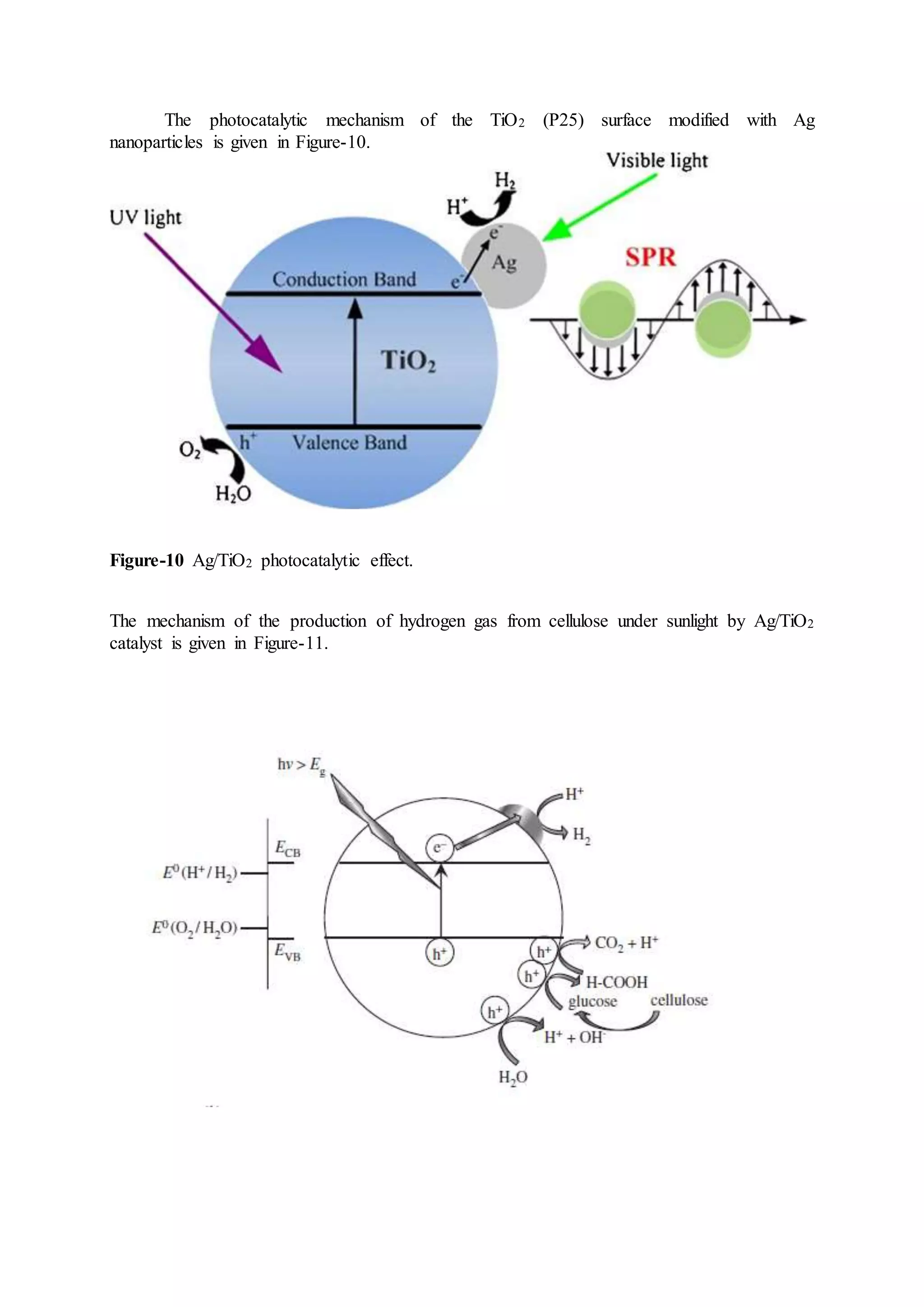

* In previous studies, TiO2 surface was doped with Ag; however, not used for the production

of hydrogen from cellulose. (Ornate, 2013; Yurdakal, 2016). Additionally, TiO2 crystal was

doped with Pt, Pd, Ni and Au, and the experiment was carried out at 60 °C to produce

hydrogen gas from the cellulose (Caravaca, 2016). In our project, on the other hand,

experiments were carried out under room conditions; that is, without additional heating. The

production of hydrogen gas from cellulose with modified Ag/TiO2 surface would be a

pioneering work in the literature.

5. COMMENTS

* The experiment was carried out at 60 °C in the previous studies. We performed the experiment

under room conditions. The effect of temperature can further be investigated by comparing the results

obtained at different temperatures.

* We used % 1 Ag/TiO2 photocatalyst. The effect of photocatalyst can be studied by changing the

Ag/TiO2 ratios.

6. REFERENCES

Anonim, 2016, İnternet haber, (son erişim tarihi: 02.01.2017)

http://www.dunyabulteni.net/haberler/367347/almanyanin-benzinli-otomobil-yasagi-

resmilesti

Amendola S.C., Sharp-Goldman S.L., Janjua M.S., Kelly M.T., Petillo P.J., Binder M., 1999 ,

"An Ultrasafe Hydrogen Generator: Aqueous, Alkaline Borohydride Solutions and Ru

Catalyst",Journal of Power Sources, 85,(2000)186-189

Aslan Ö., 2007, ‘Hidrojen Ekonomisine Doğru’İstanbul Ticaret Üniversitesi Sosyal Bilimler

Dergisi 6(11) ,283-298

Atkinson B., Roth S., Hirscher M., Griinwald W., 2001,’’Carbon nanostructures; An efl]cient

hydrogen storage medium for fuel cells?’Fuel Cells Bulletin,Germany No:38, 9-12

Benli Y., 2014,‘Gümüş İle Doplamış Nano-TiO2’in Özelliklerinin İncelenmesi’(Doktora tezi)](https://image.slidesharecdn.com/hydrogenreport-170515200607/75/SciChallenge2017-Hydrogen-report-22-2048.jpg)