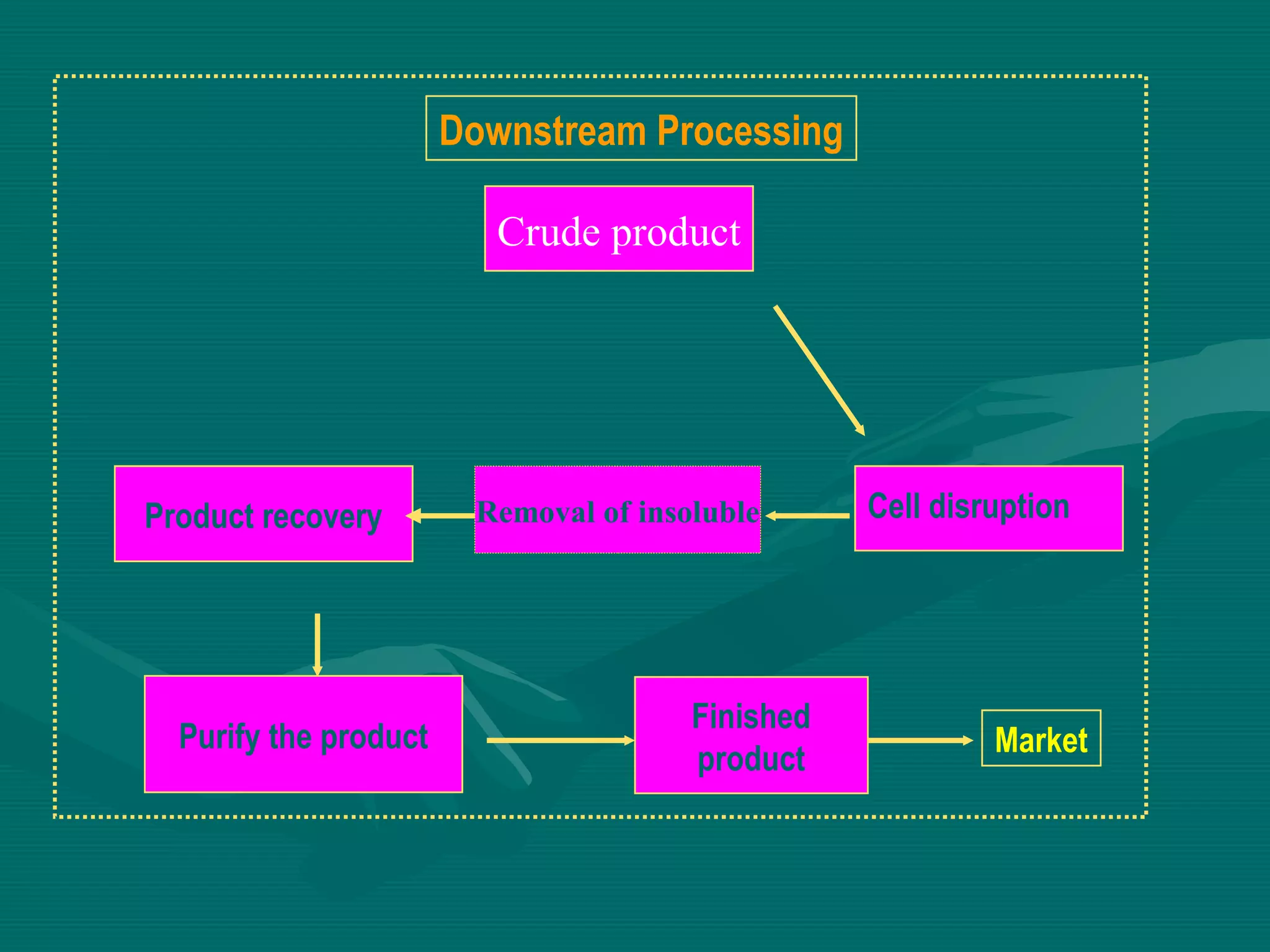

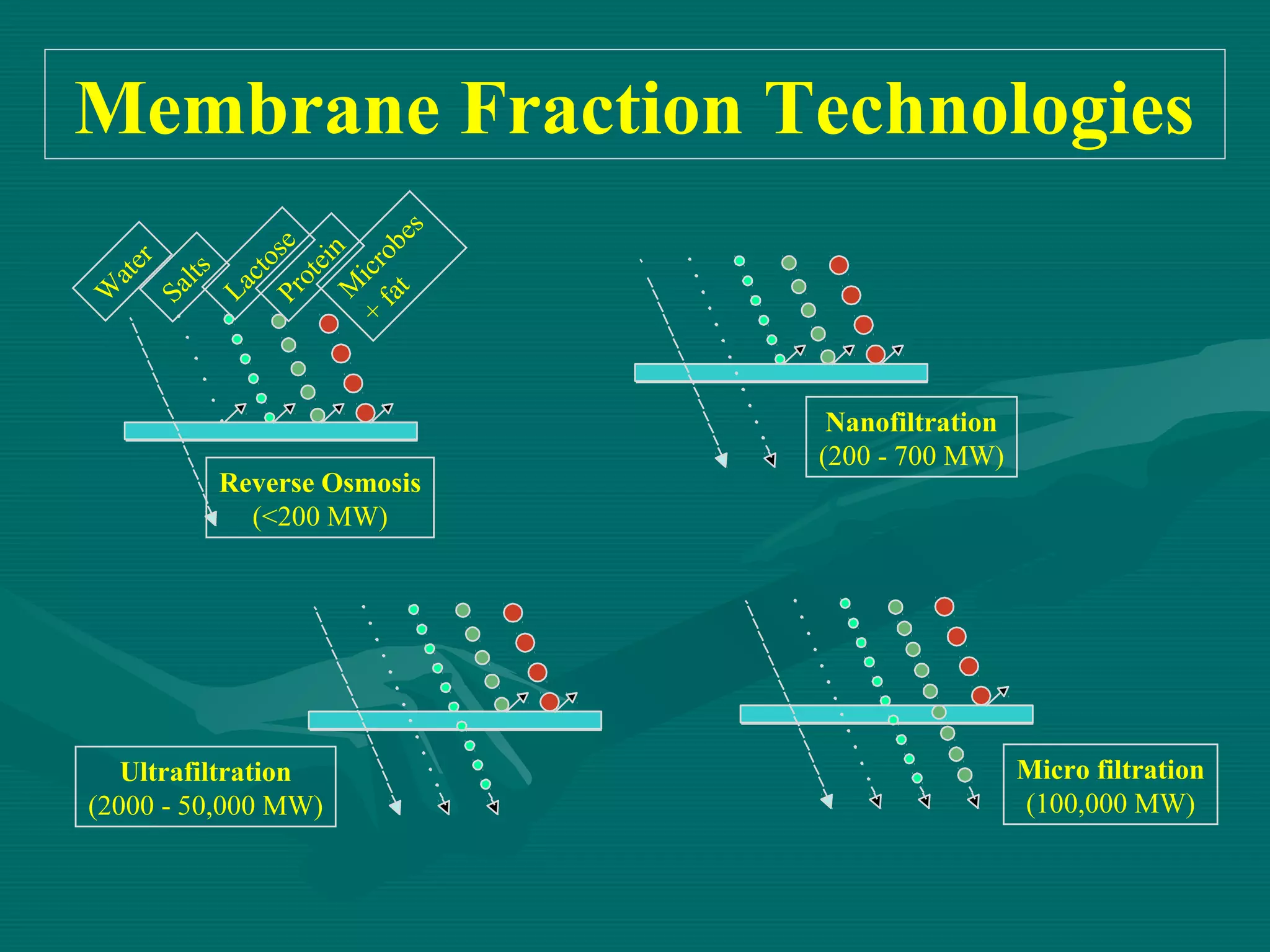

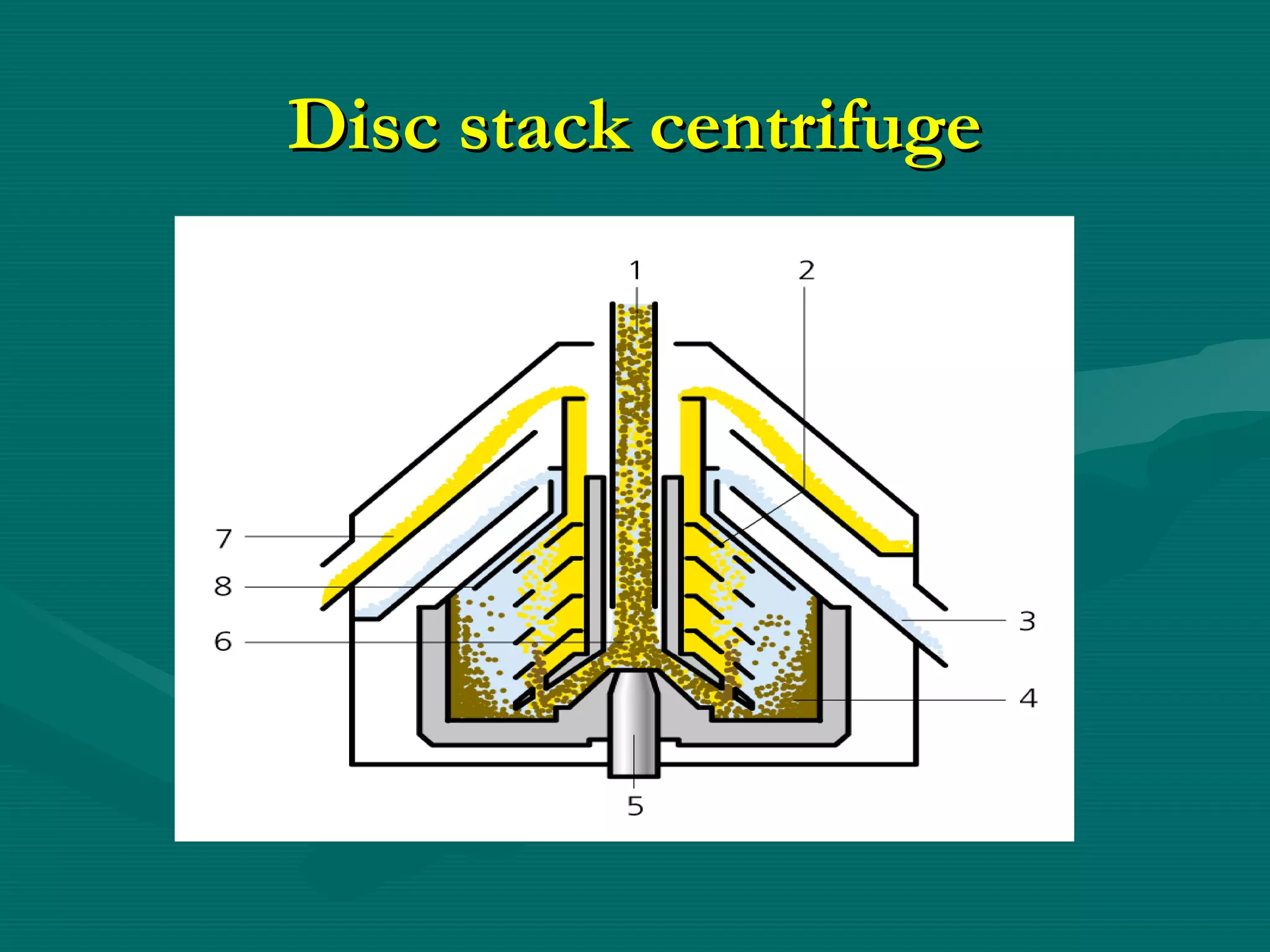

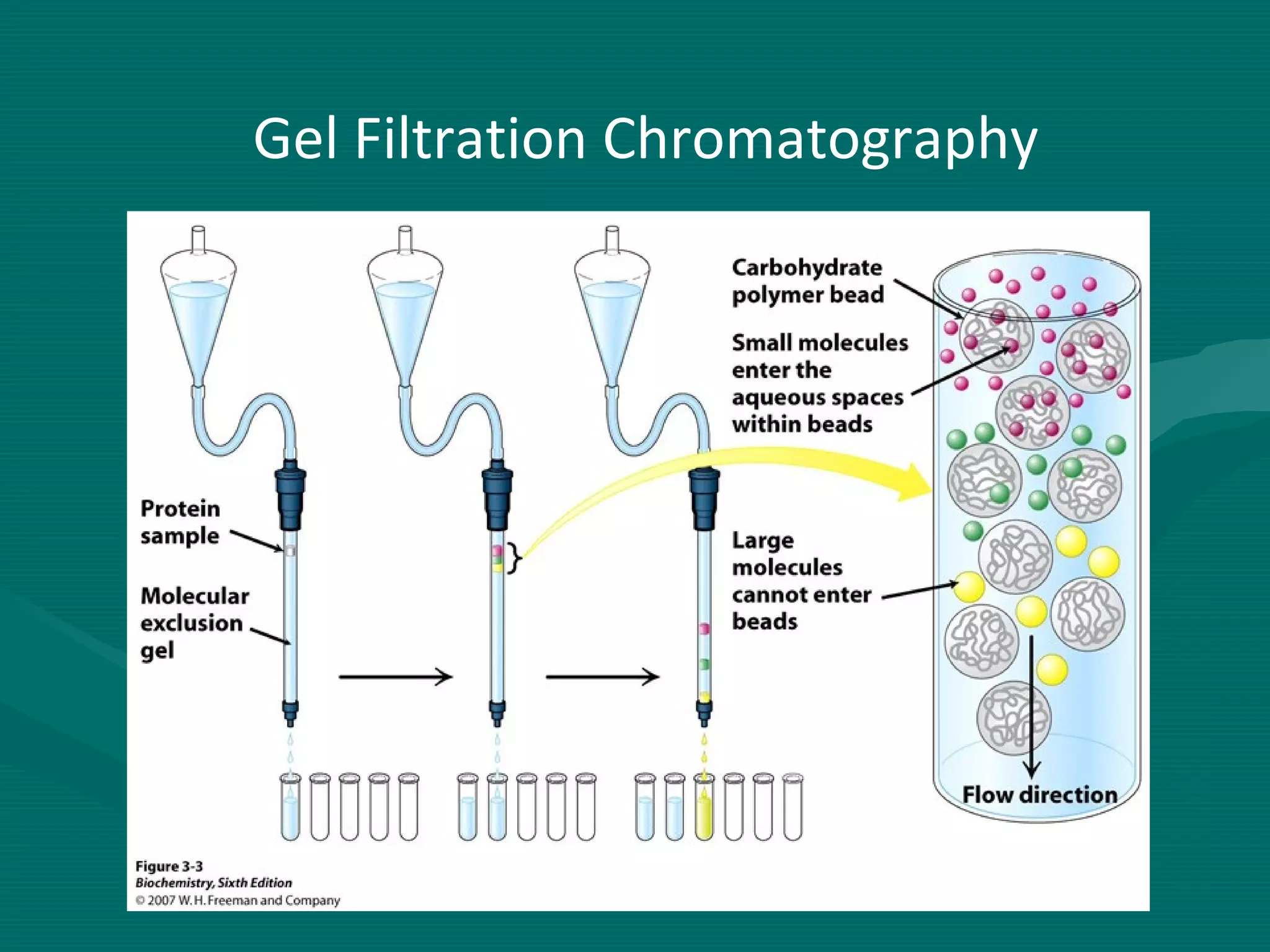

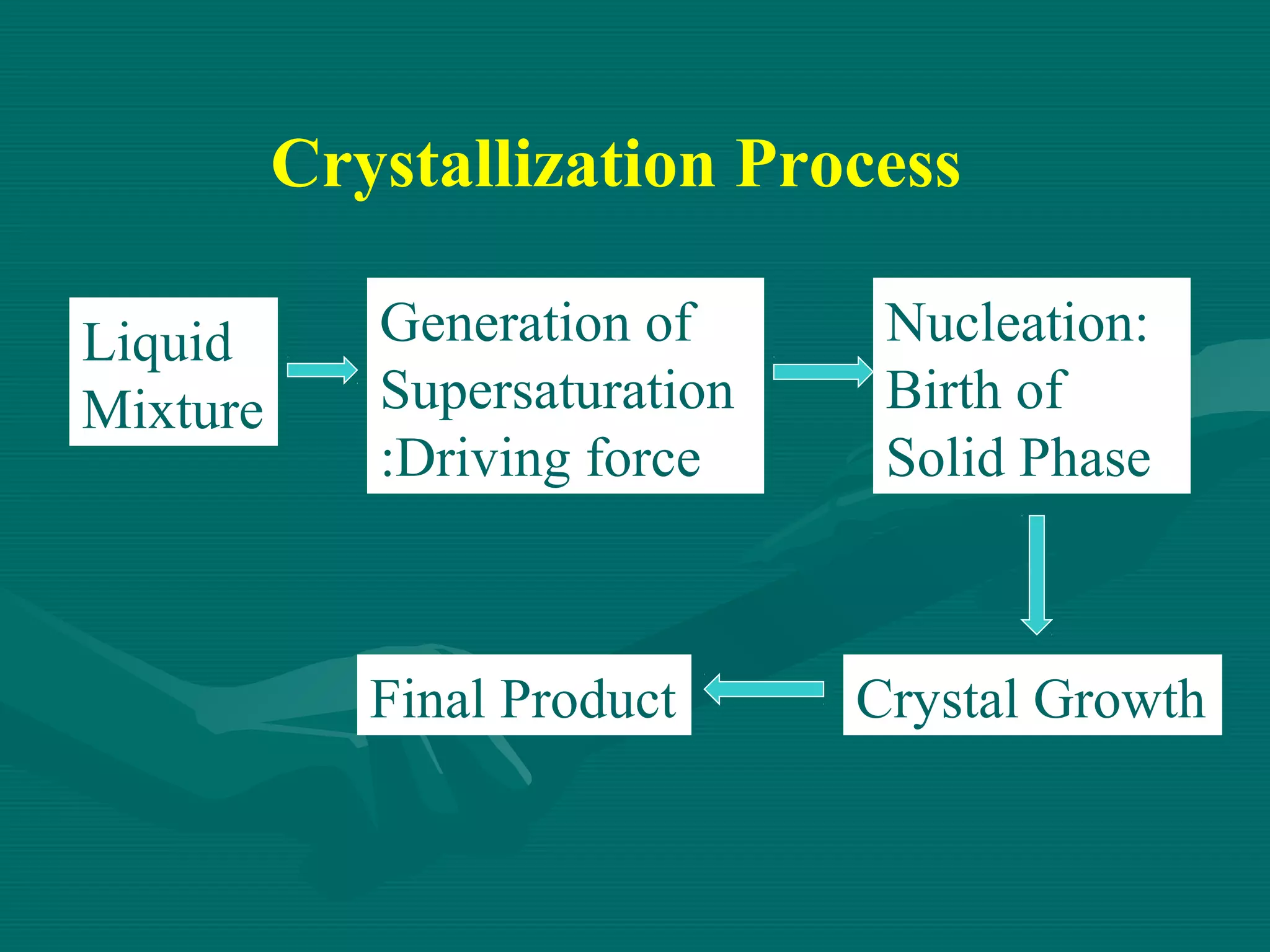

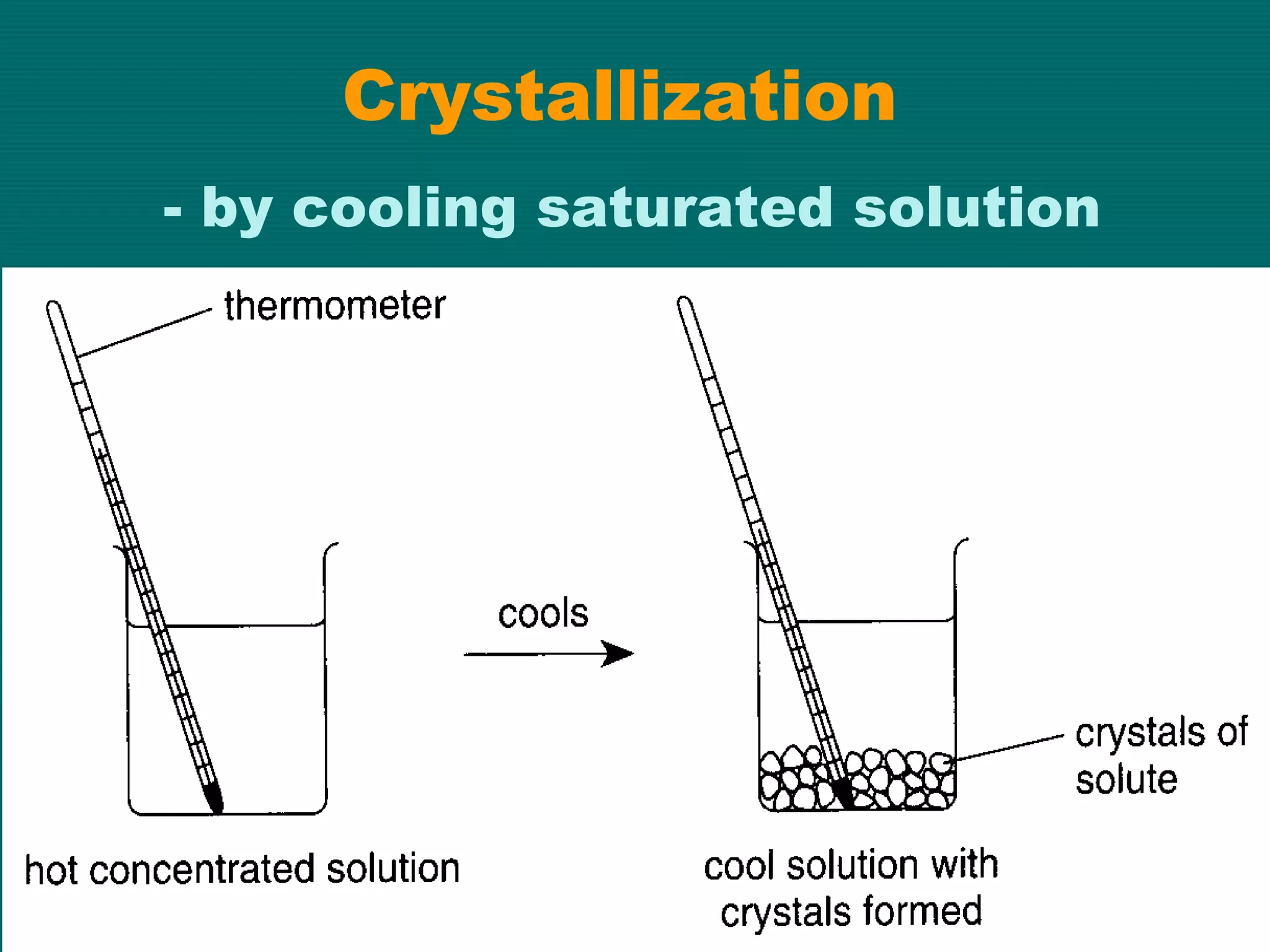

Downstream processing involves treating culture broth post-fermentation to concentrate and purify products, which includes cell disruption, separation, and purification methods. Techniques such as centrifugation, filtration, and various chromatography forms are employed to recover and refine products. Final processing steps, known as product polishing, ensure the product is stable and transportable through methods like crystallization and drying.