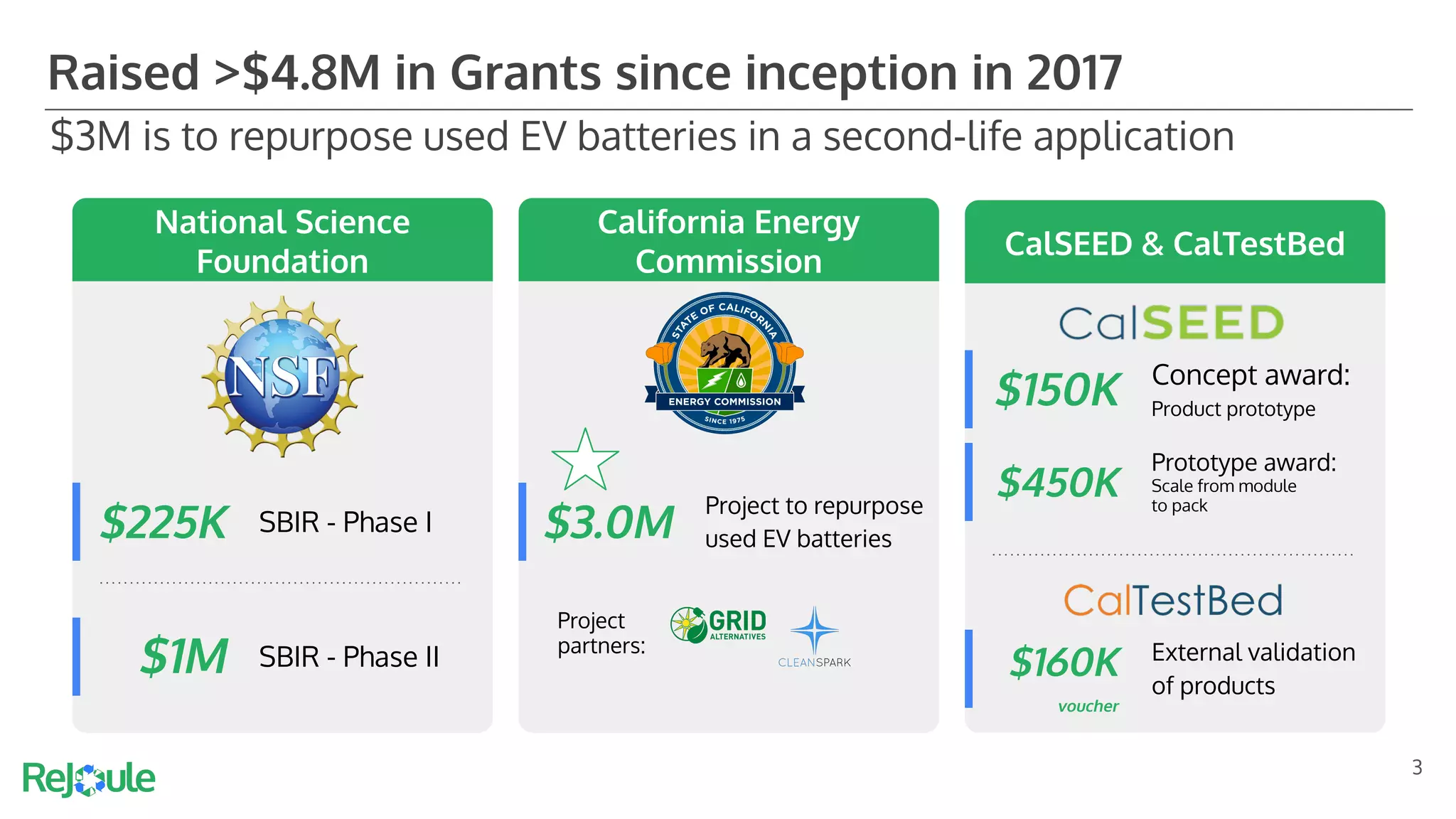

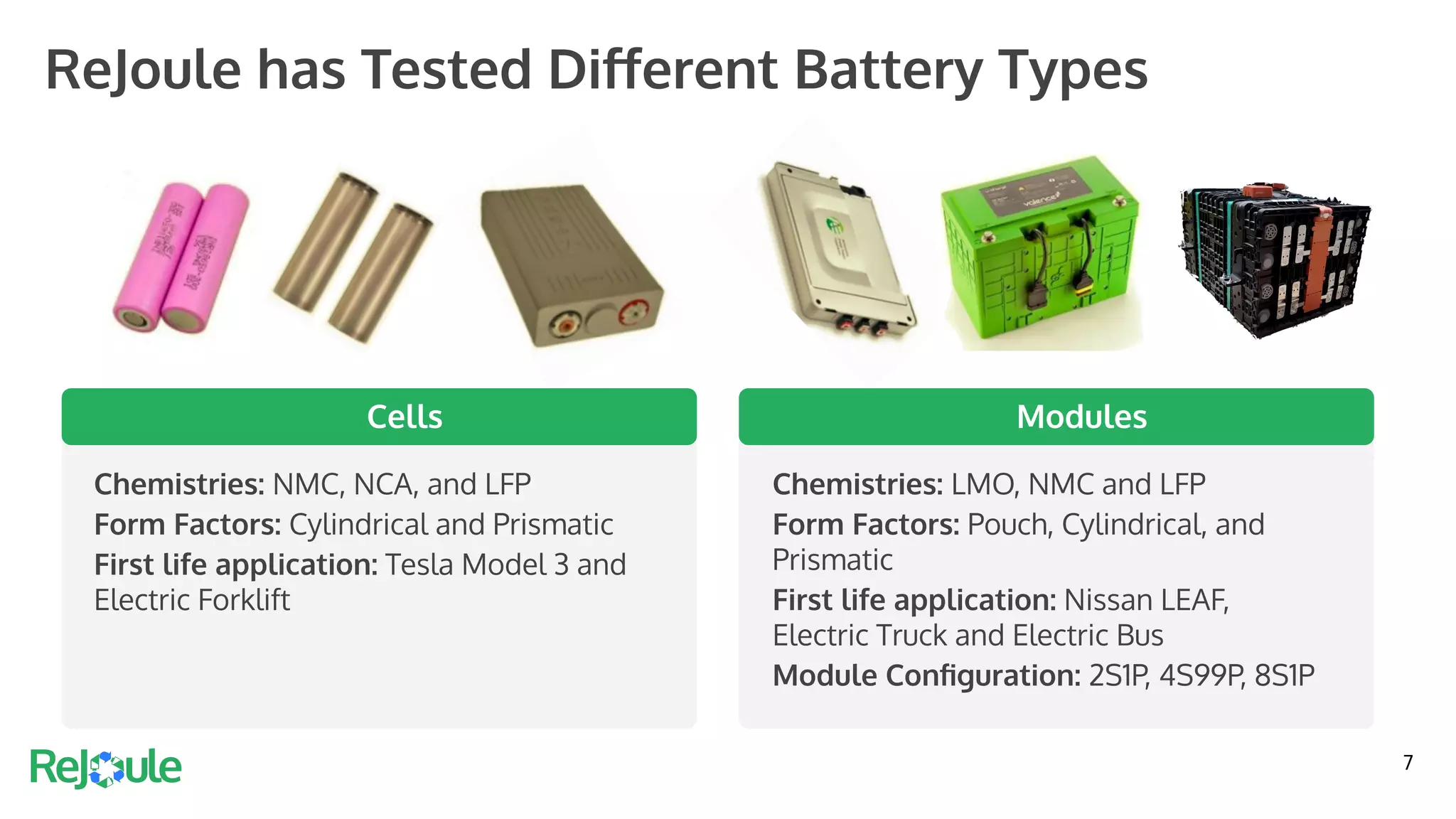

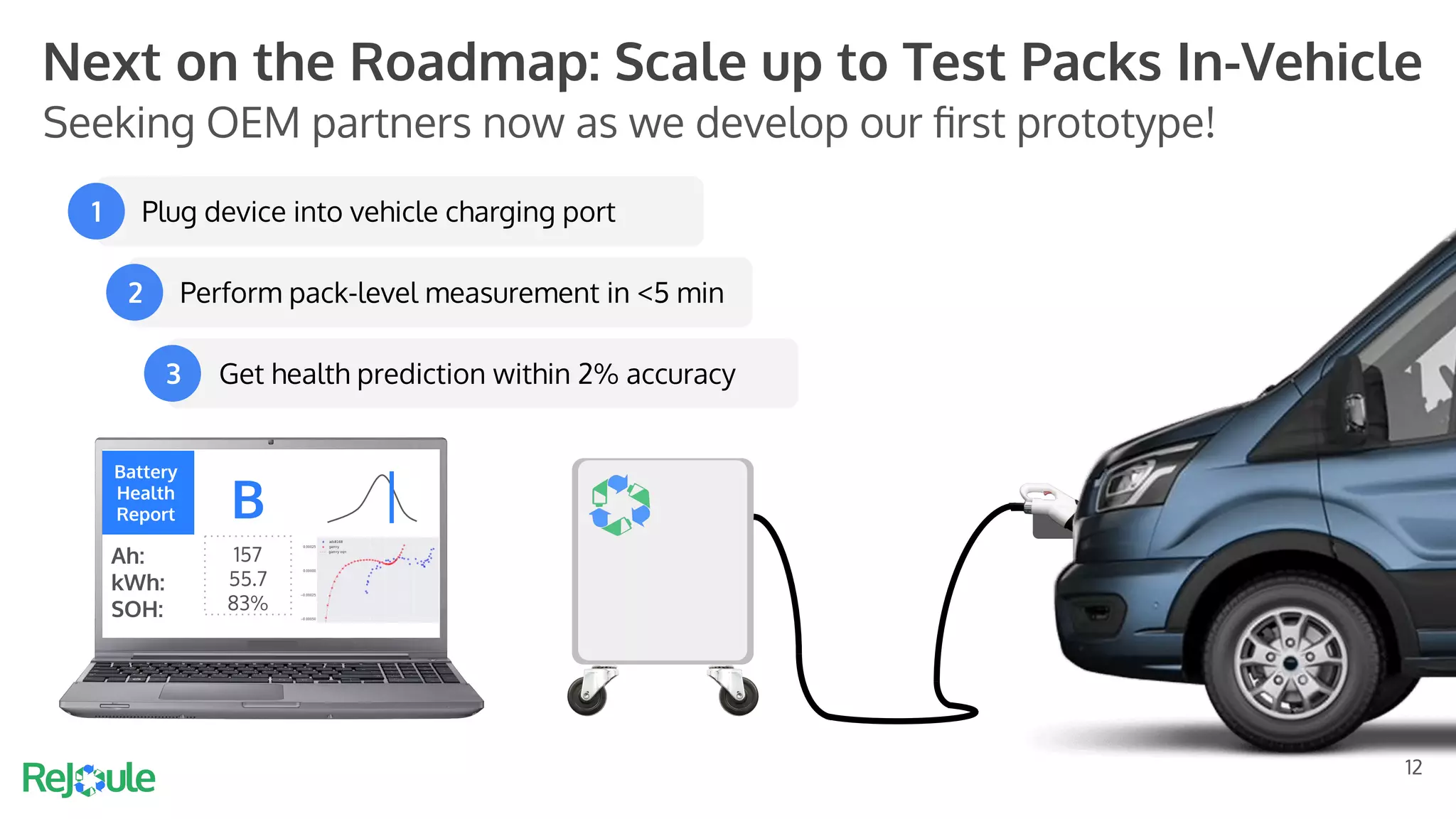

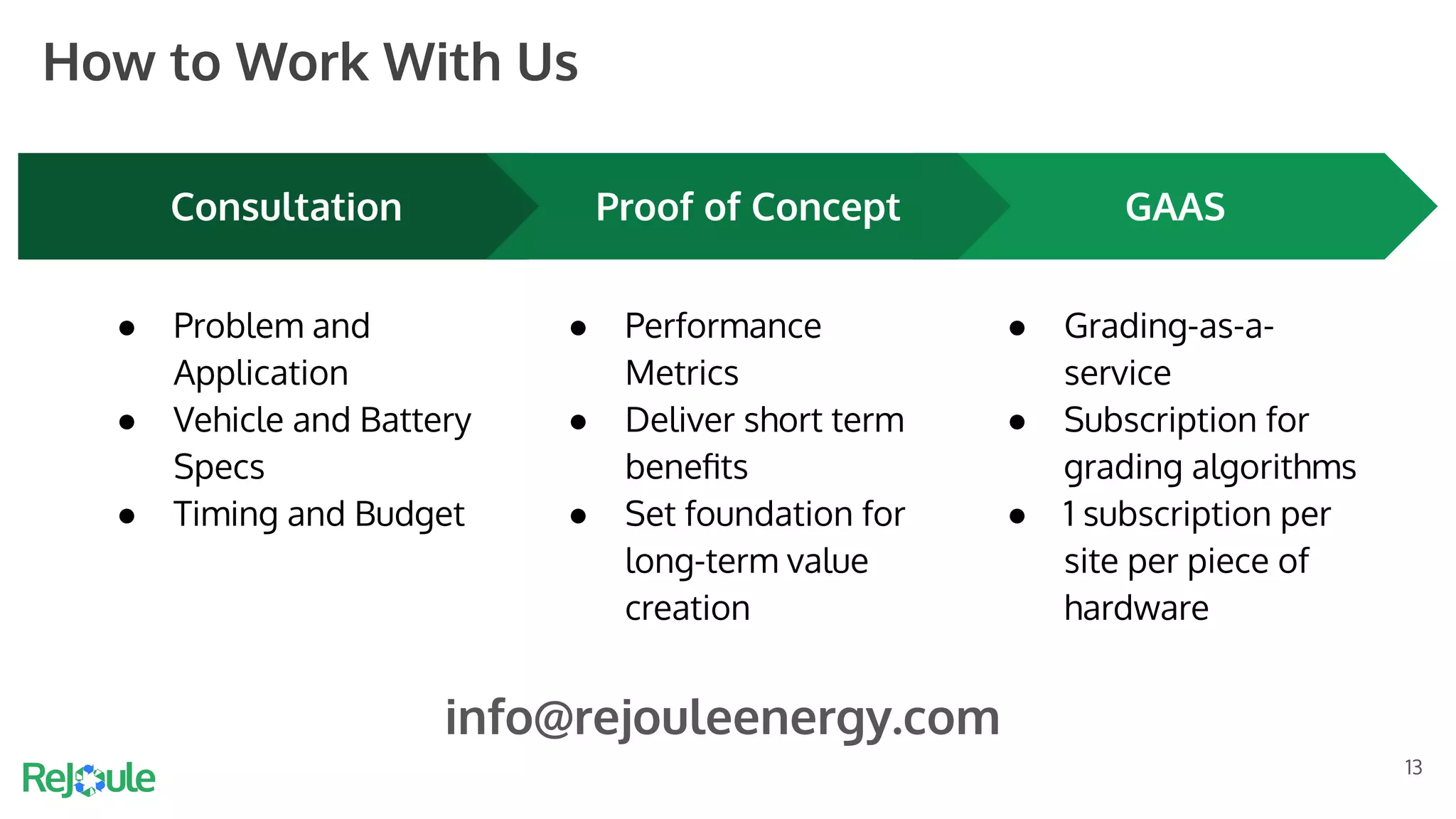

Rejoule Energy, based in Southern California, focuses on repurposing electric vehicle (EV) batteries through a fast and accurate battery grading tool utilizing electrochemical impedance spectroscopy. They have successfully secured over $4.8 million in grants for their innovative technology, which can assess battery health in less than five minutes, significantly faster than traditional methods. The company is looking to scale their testing capabilities and collaborate with OEM partners for future developments.