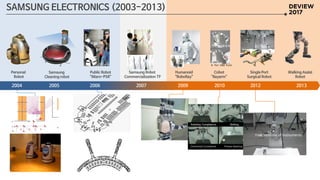

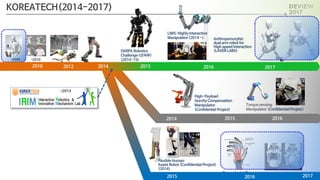

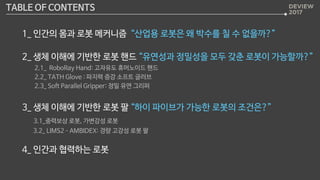

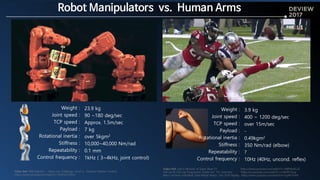

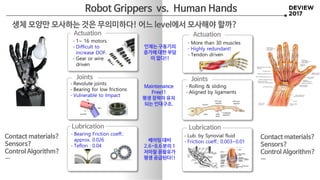

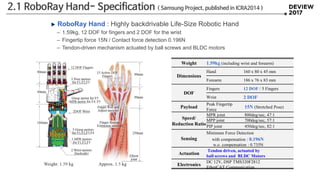

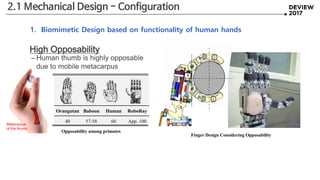

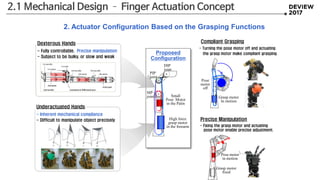

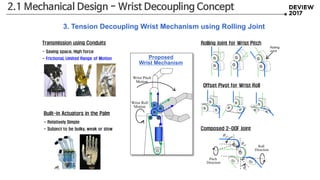

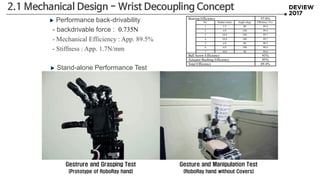

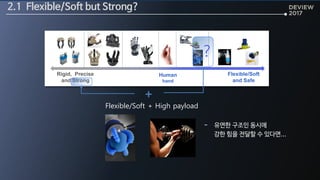

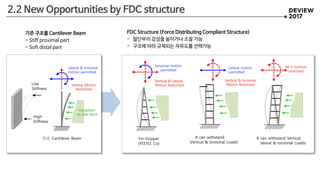

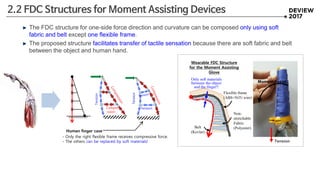

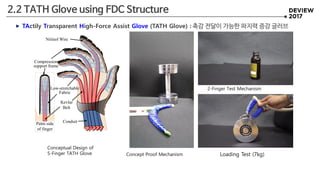

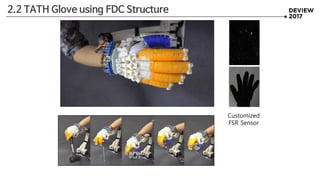

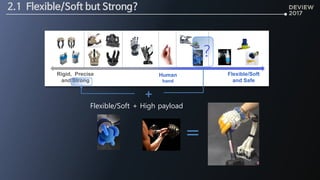

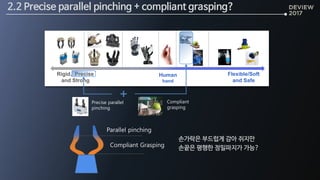

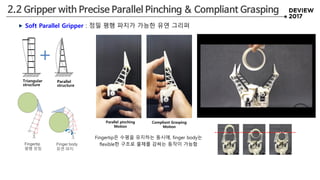

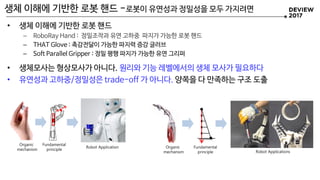

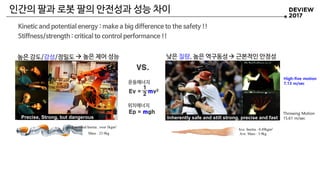

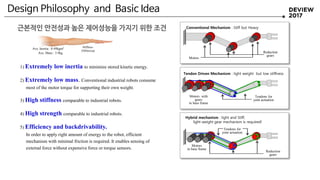

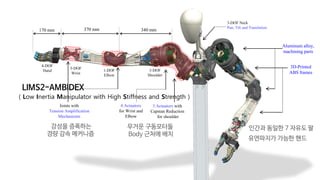

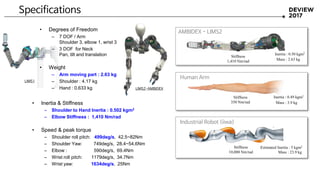

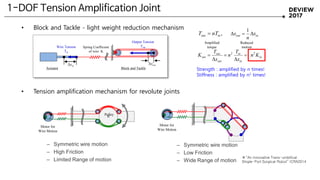

Yong Jae Kim is a professor at KoreaTech who researches wearable, surgical, humanoid and mobile robots. His research interests include mechanism design and control of flexible robots. He has worked at Samsung Electronics and MIT. Some of his projects include a high-DOF robotic hand called RoboRay Hand, a power-assist glove called TATH Glove, and a soft parallel gripper. He aims to design robots with both flexibility and precision, like the human hand. He proposes using tendon-driven and compliant mechanisms inspired by biology to achieve this goal.