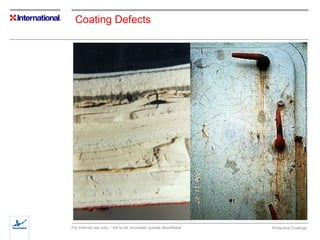

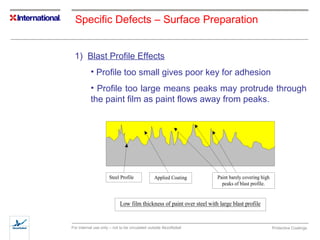

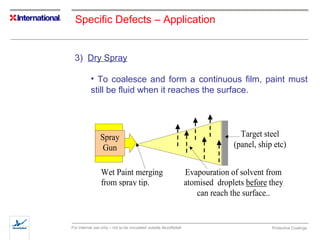

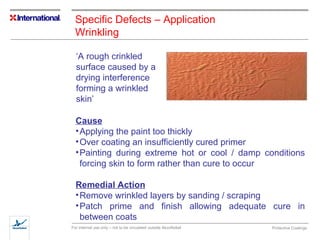

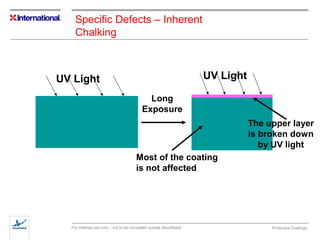

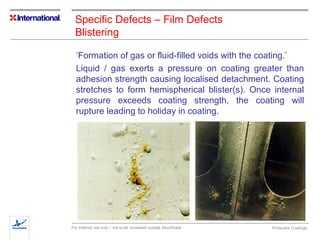

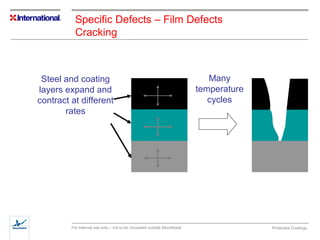

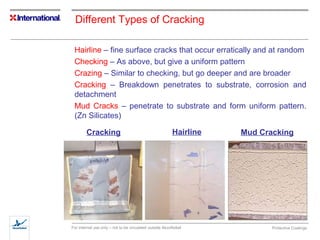

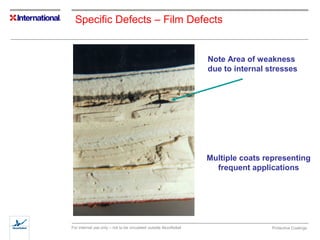

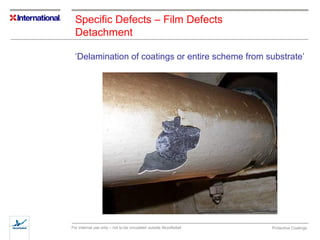

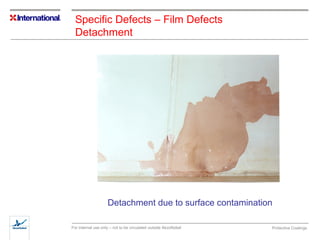

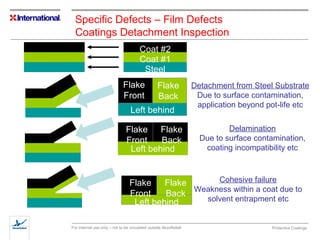

The document defines and categorizes various coating defects that can occur, including those related to surface preparation, application, and the coating film itself. It describes 13 common defects - blistering, bubbling, checking, cracking, corrosion, edge/corner failure, peeling/flaking/delaminating - and discusses their causes. The document is intended for internal use by AkzoNobel Protective Coatings to understand and address coating defects.