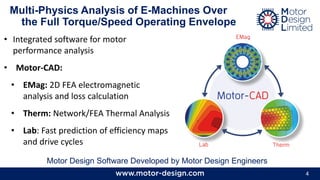

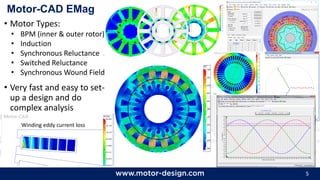

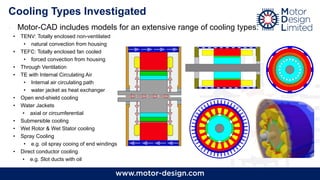

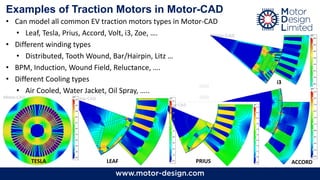

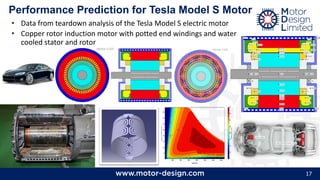

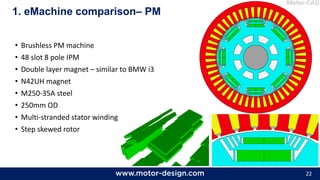

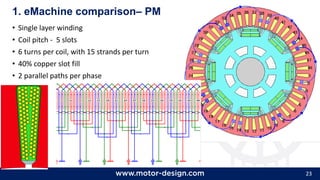

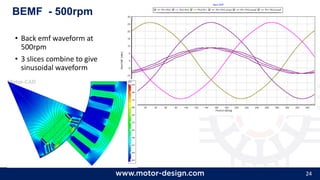

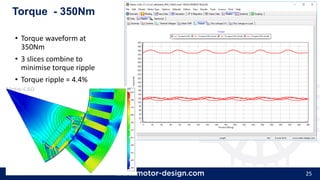

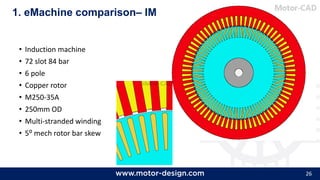

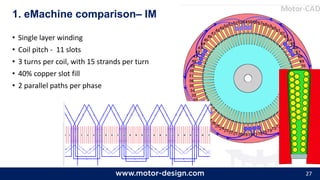

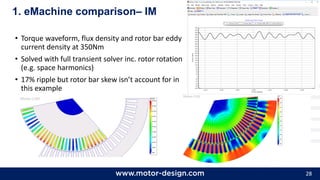

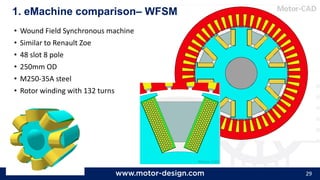

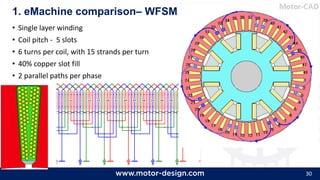

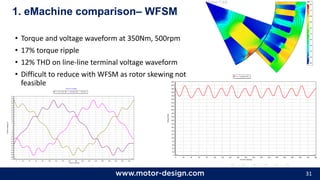

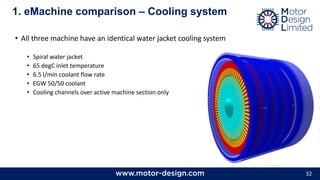

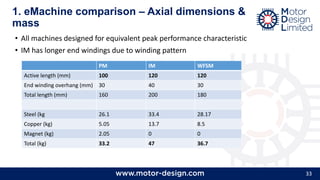

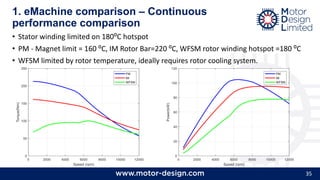

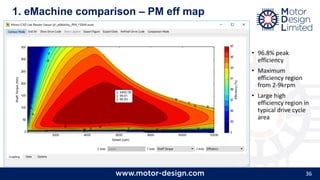

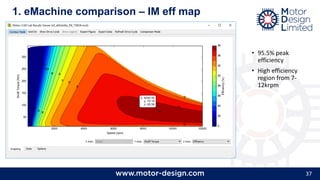

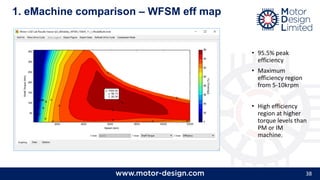

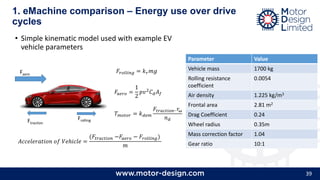

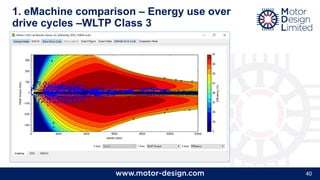

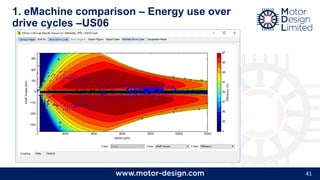

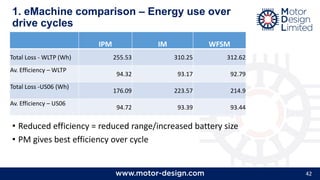

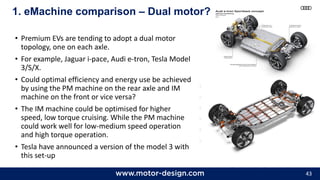

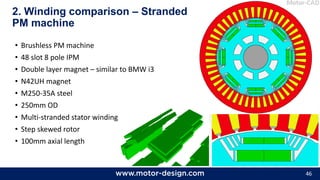

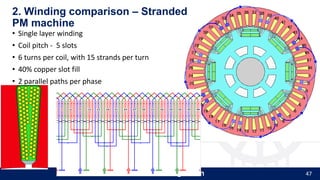

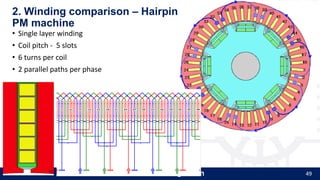

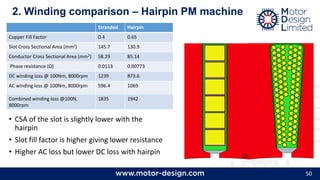

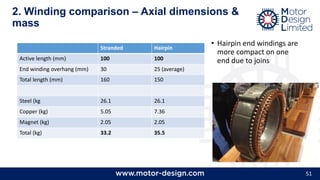

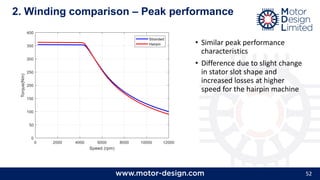

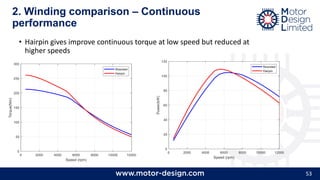

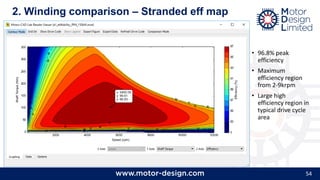

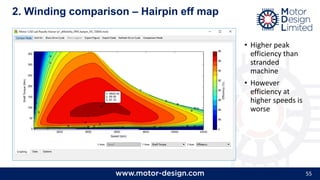

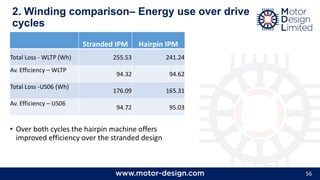

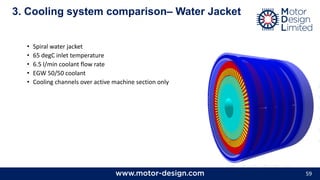

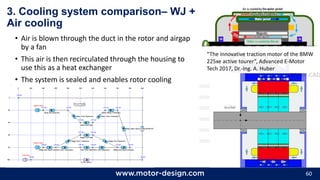

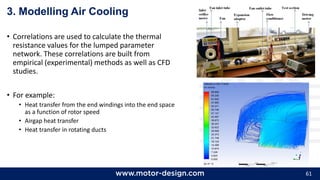

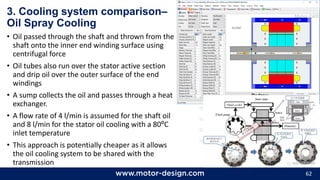

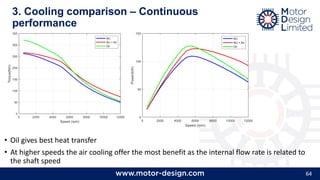

The document discusses trade-off analysis for electric vehicle traction motors using Motor Design Ltd's Motor-CAD software. It compares performance parameters of permanent magnet, induction, and wound field synchronous motor types for a battery electric vehicle application. It also compares hairpin vs stranded stator windings for a permanent magnet machine and different cooling methods like water jacket, internal air, and oil spray cooling.