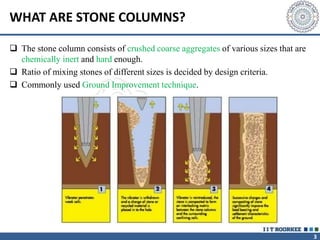

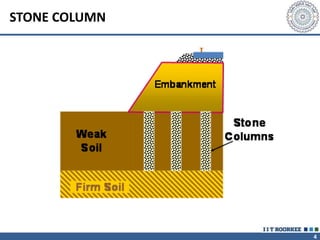

The document compares pile foundations and stone column treated ground, highlighting that stone columns offer a more economical and effective ground improvement technique for low-rise and medium loaded structures. It details the installation methods, principles, advantages, and limitations of stone columns, emphasizing their ability to improve soil characteristics. The study concludes that stone columns are an advantageous option in suitable scenarios, while also noting the need for further data on pile foundations.

![11

BEARING CAPACITY OF IMPROVED GROUND

• Assumptions:

- Vertical deformation of the top of stone column and soil is

same

=> total foundation pressure shared b/w column and soil in proportion to

their relative stiffness.

where A= total area of unit cell for each stone column

(assuming triangular pattern)

S= spacing of stone solumns

qsafe= [(A-As)qs + Psafe]/A

where qs = safe allowable bearing capacity of untreated ground

Psafe = safe allowable bearing capacity of stone column

As = cross sectional area of stone column

A = 0.868 S2](https://image.slidesharecdn.com/comparitive-study-of-pile-foundations-with-foundations-on-stone-column-treated-ground-170704090313/85/Comparitive-study-of-pile-foundations-with-foundations-on-stone-column-treated-ground-11-320.jpg)