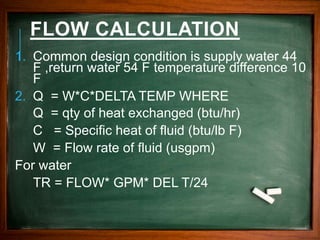

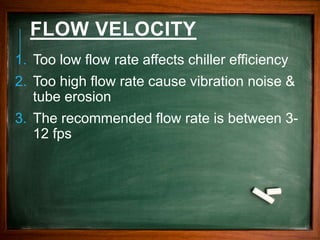

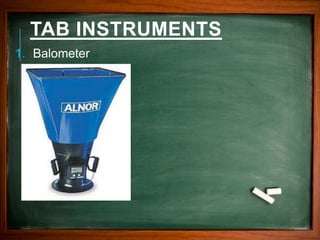

The document discusses the key components and operation of chilled water systems. It describes the main components as chillers, cooling towers, pumps, piping and air handling units. It then covers topics such as chiller types, flow calculations, recommended flow velocities, chiller efficiency ratings, expansion tanks, piping basics including materials and valves used, and testing and balancing (TAB) of the system.