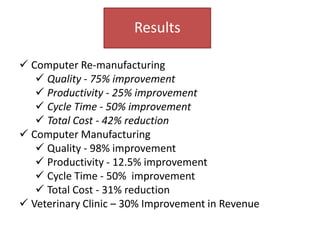

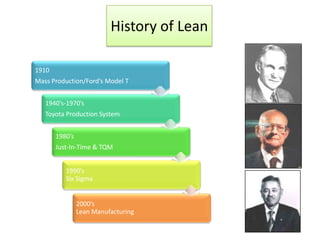

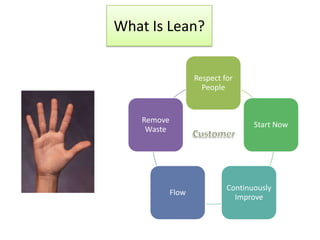

The document discusses the history and principles of lean culture, emphasizing the importance of respect for people and continuous improvement across various waste reduction strategies. It contrasts traditional lean practices focused on production with customer service-oriented approaches while providing guidelines for effective leadership and organizational change. Through engagement and leadership participation, organizations can experience significant improvements in quality, productivity, and overall performance.

![(615) 852-LEAN [5326]

www.TheLeanWayConsulting.com

The Seven Wastes

Transportation Inventory Motion Wait time Over Processing Over Production Defects

Movement between Buffers Poor work Materials Excessive testing Material Shortages Internal

buildings/sites design Shortages

Excess WIP & Install Un-level Demand Rework

Premium RIP Ergonomic Un-level Demand

freight Design Reconfiguration Build to stock Supplier

Supplier Startup

Distribution inventories for Travel time Double handling Economic Lot Sizes Final Test

Network long lead time Vendor

Tool & Predictability Material Batching Inspection

Plant Layout Stock Material variability/over

access Scheduling design

Conflicts

Operations, Overhead, Materials, Suppliers](https://image.slidesharecdn.com/leancultureintroduction-12719657127246-phpapp01/85/Lean-Culture-Introduction-10-320.jpg)

![(615) 852-LEAN [5326]

www.TheLeanWayConsulting.com

Traditional Lean enterprise

Emphasis on production Emphasis on customer service

Make product to forecast Makes to actual customer demand

‘Push’ production system ‘Pull’ production system

Machine utilization Employee utilization

Reduce cost and increase efficiency Reduce waste and add value

Leadership by executive command Leadership by vision and broad participation

Specialized employees Multi-functional employees

Penalize mistakes Educate

Blame people Identify and solve process failure

Reactive Proactive

Inspect in Quality Built in Quality

Complexity Simplicity

Functional Management Structure Manage by Value Stream

How does your company rate as a Lean Rating Scale: 1 2 3 4 5

Enterprise?](https://image.slidesharecdn.com/leancultureintroduction-12719657127246-phpapp01/85/Lean-Culture-Introduction-14-320.jpg)