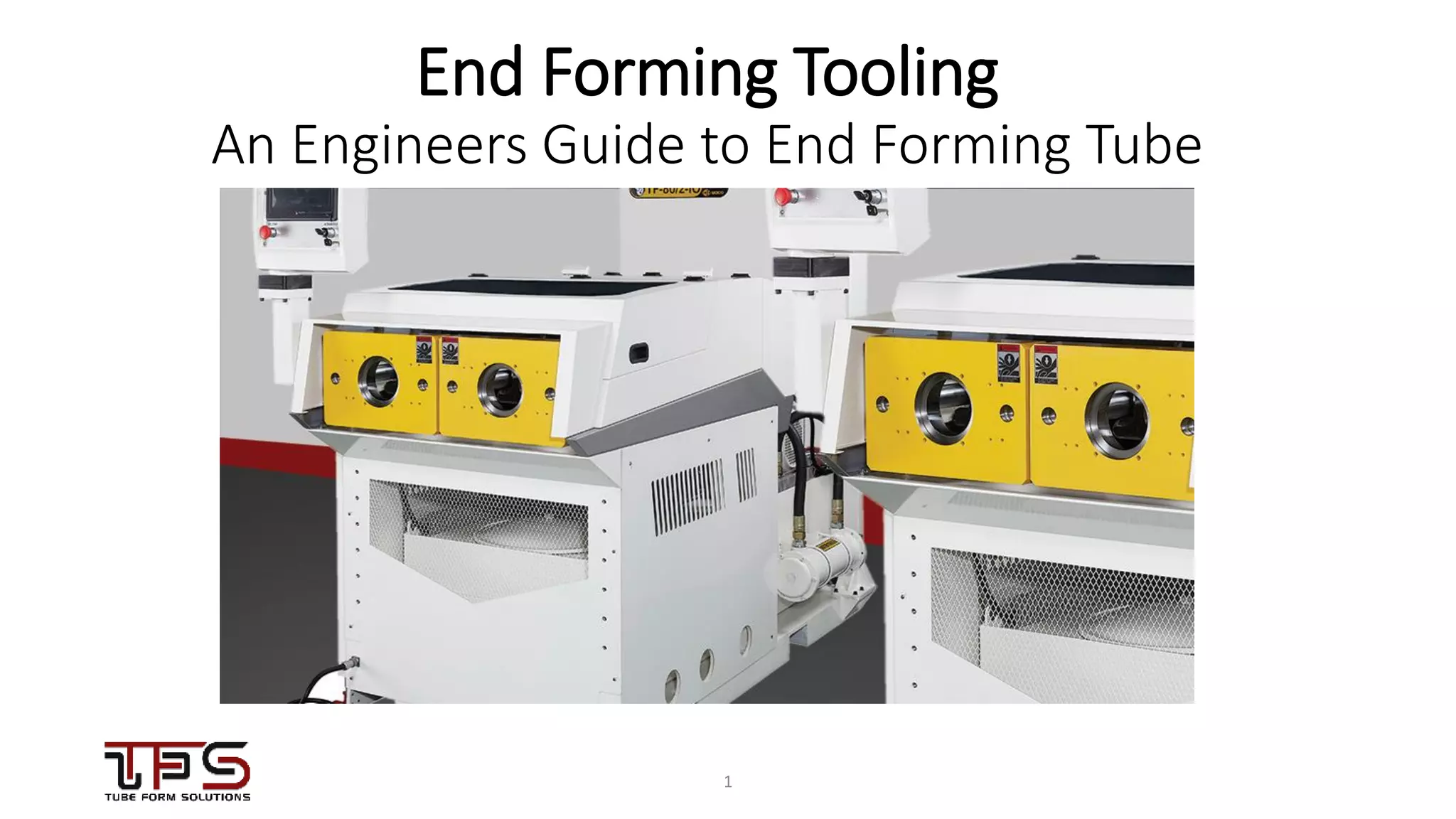

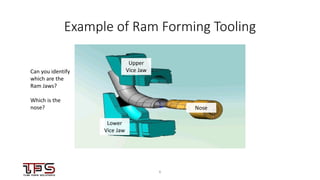

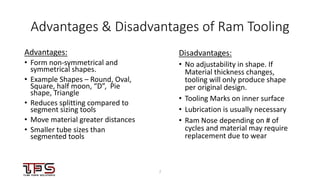

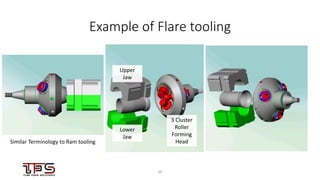

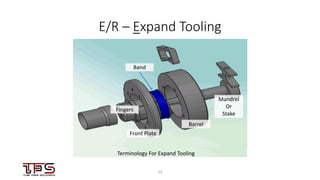

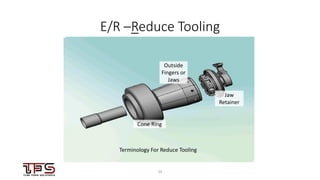

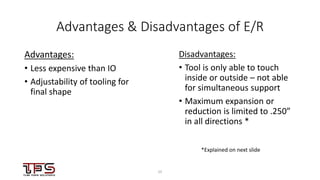

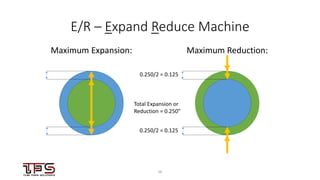

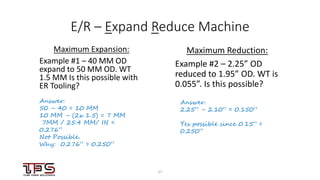

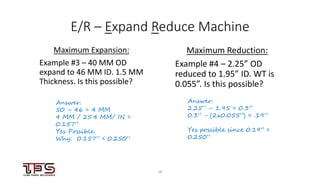

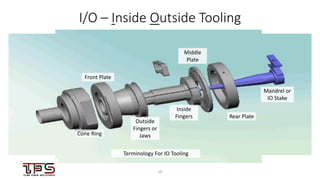

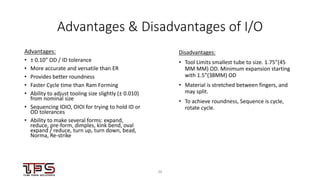

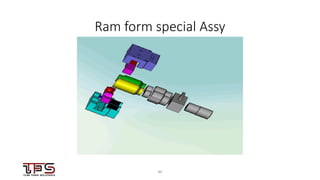

The document provides a comprehensive guide to end forming tooling, detailing various techniques, such as ram forming and expanding/reducing, used to change a tube's shape. It outlines the benefits and drawbacks of different tooling methods, along with machine specifications and examples of applications. The document emphasizes the importance of understanding material properties and desired final shapes to select appropriate tools and processes.