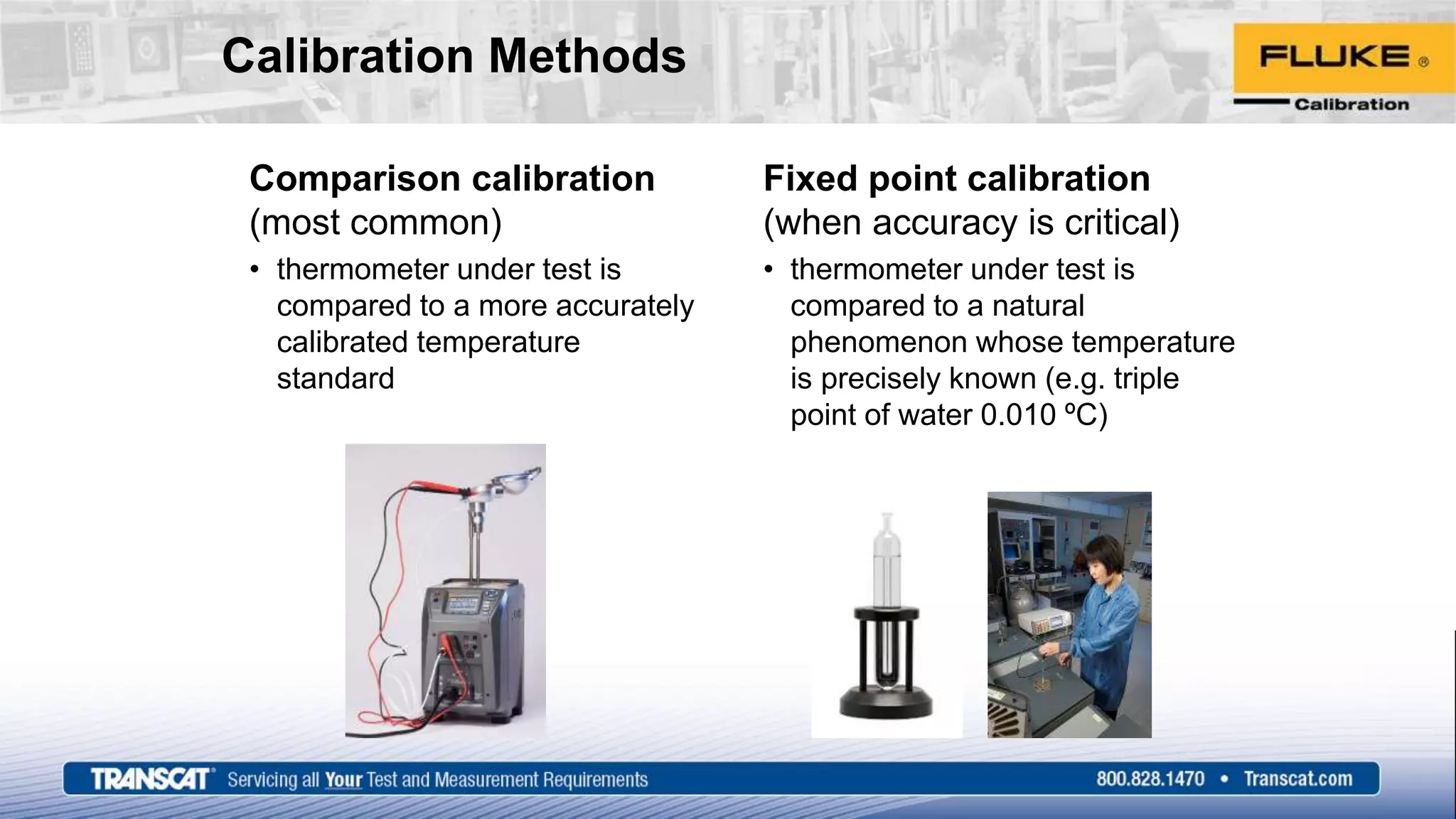

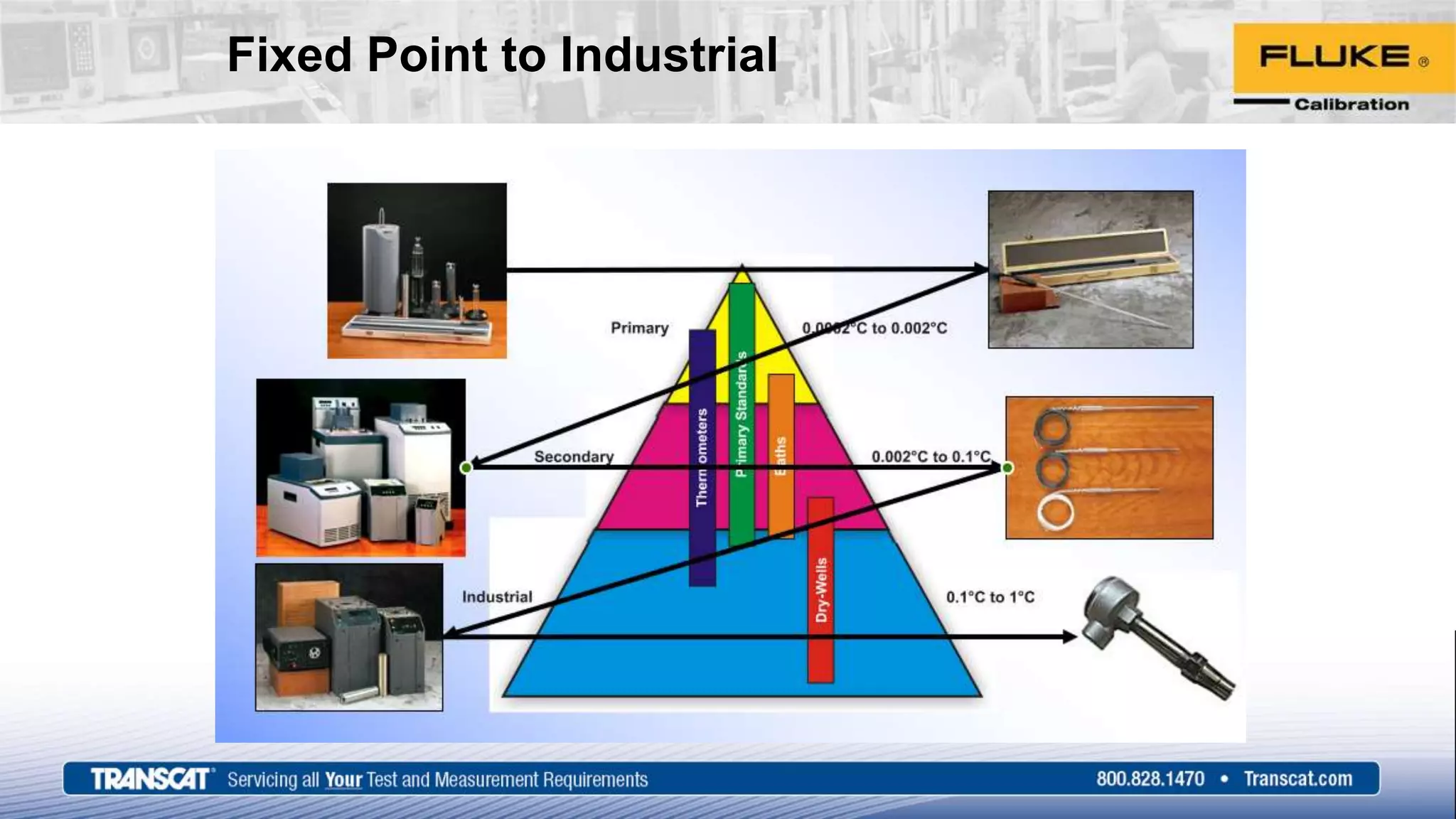

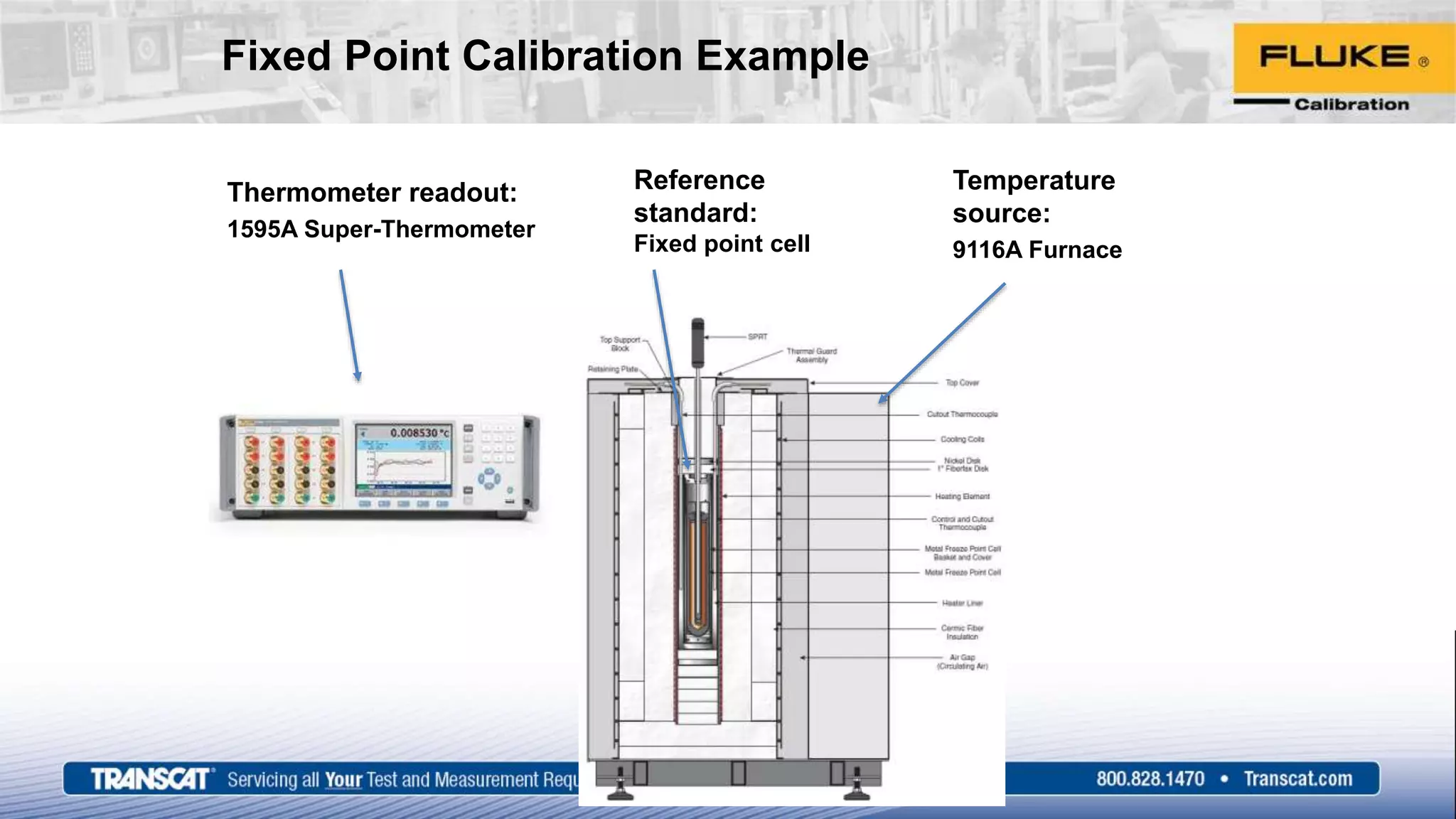

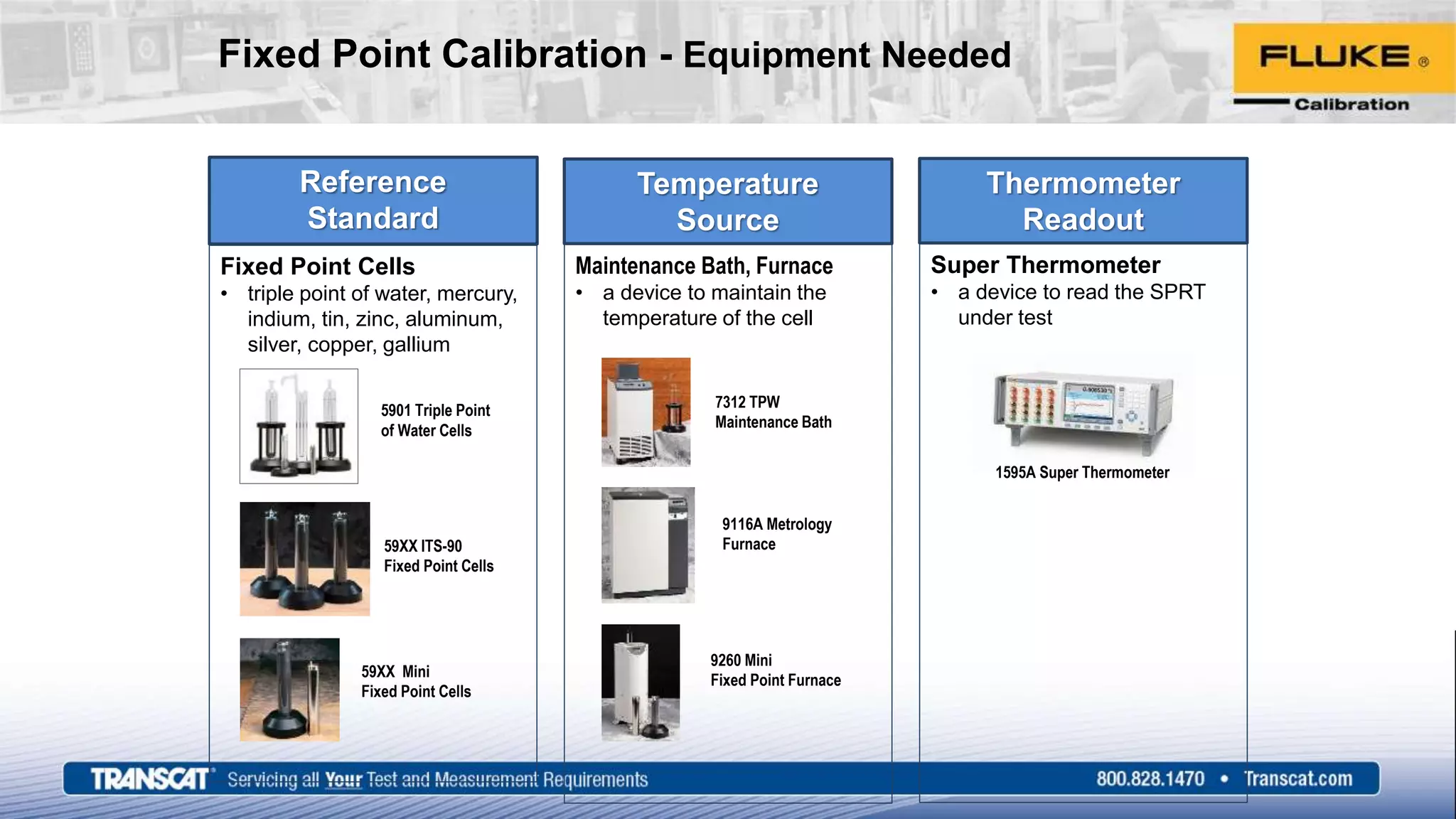

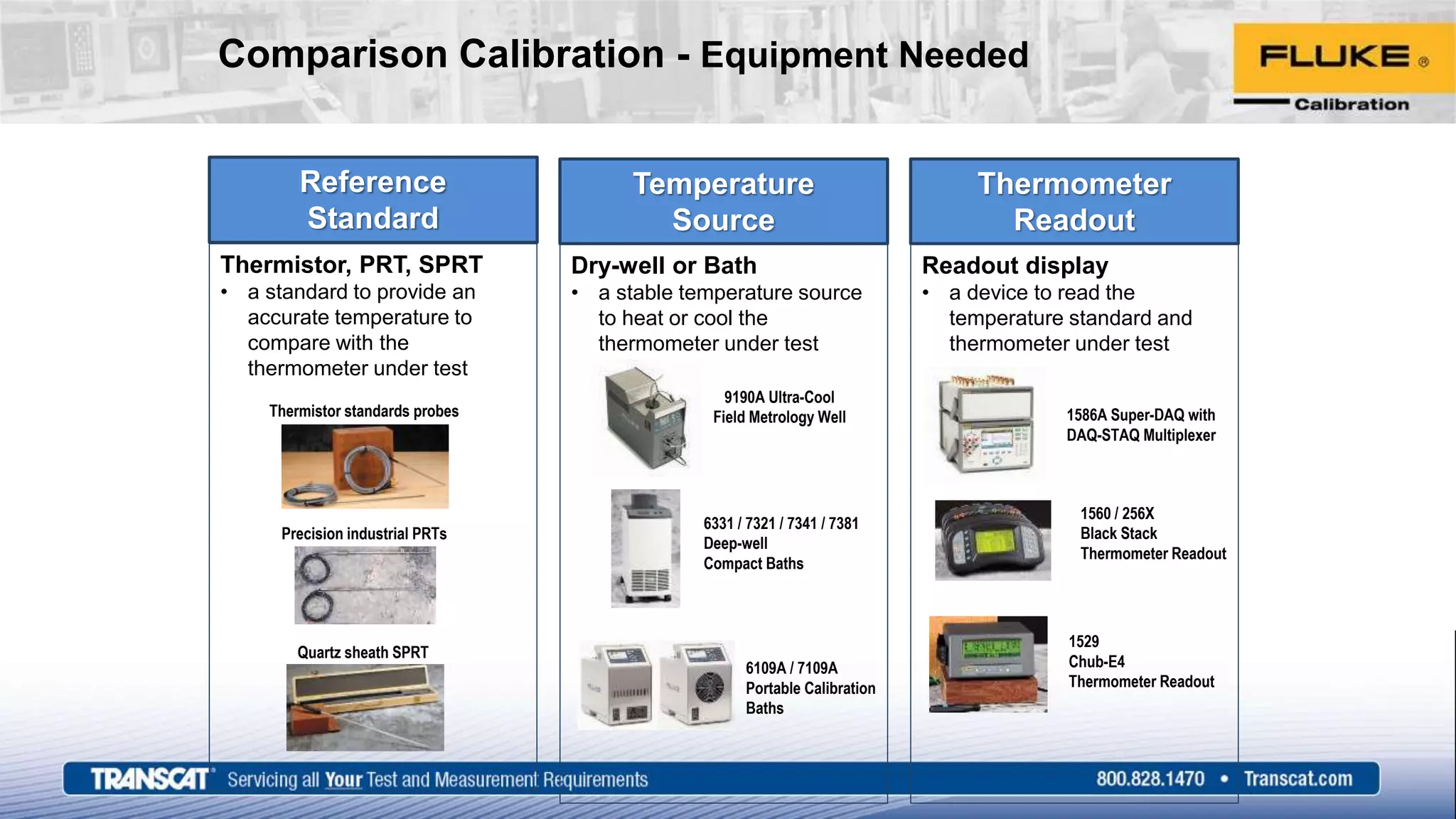

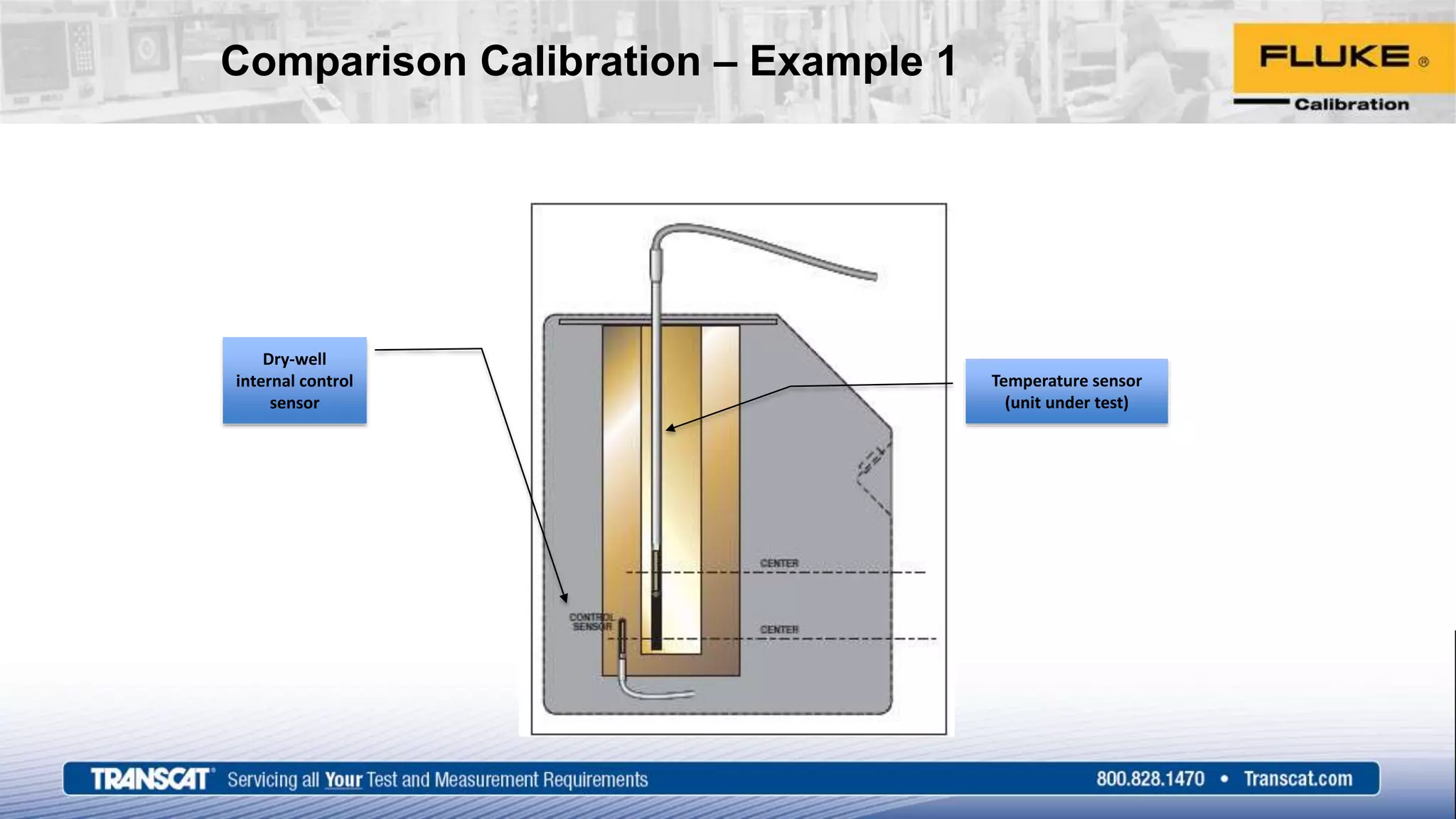

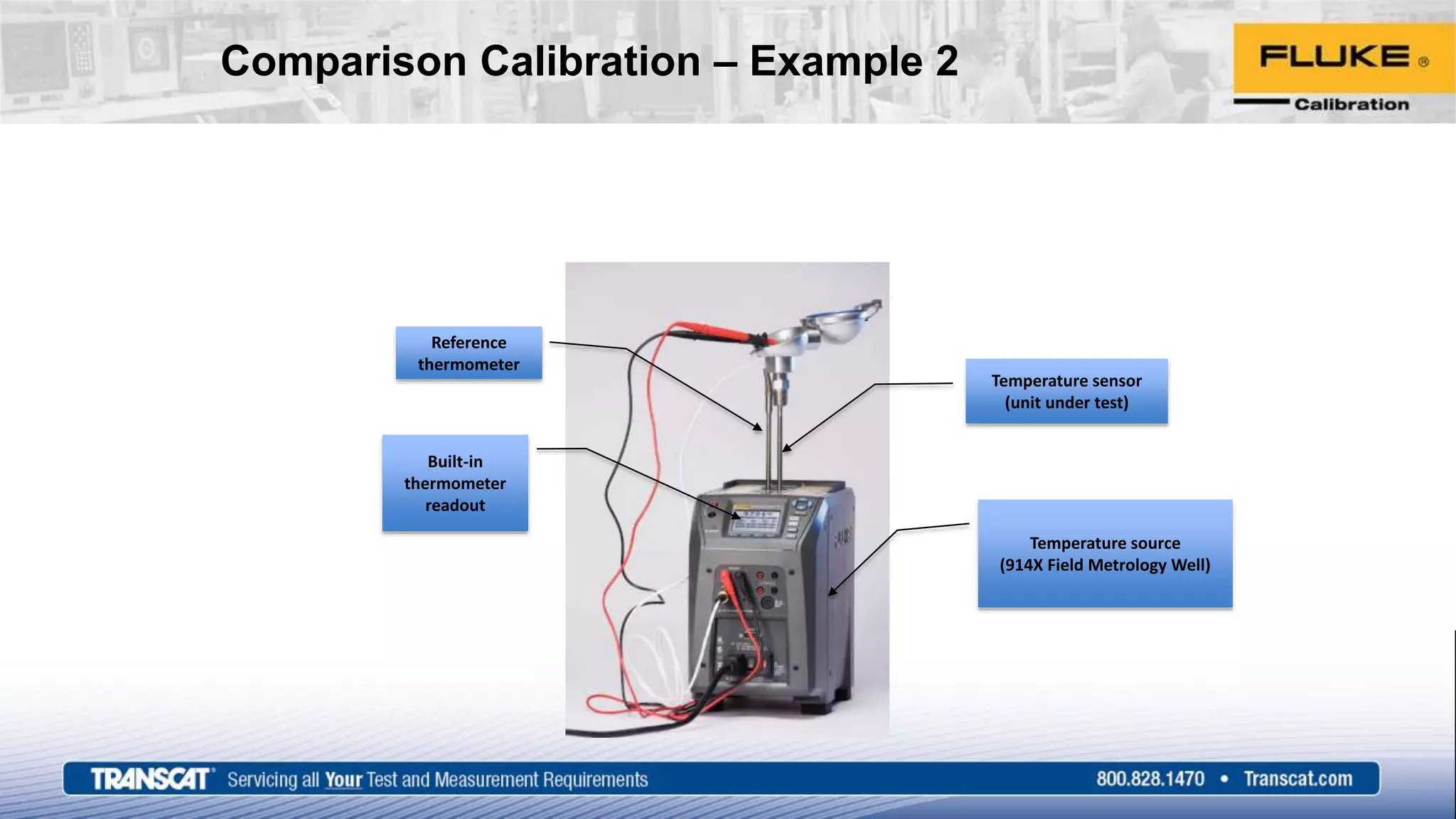

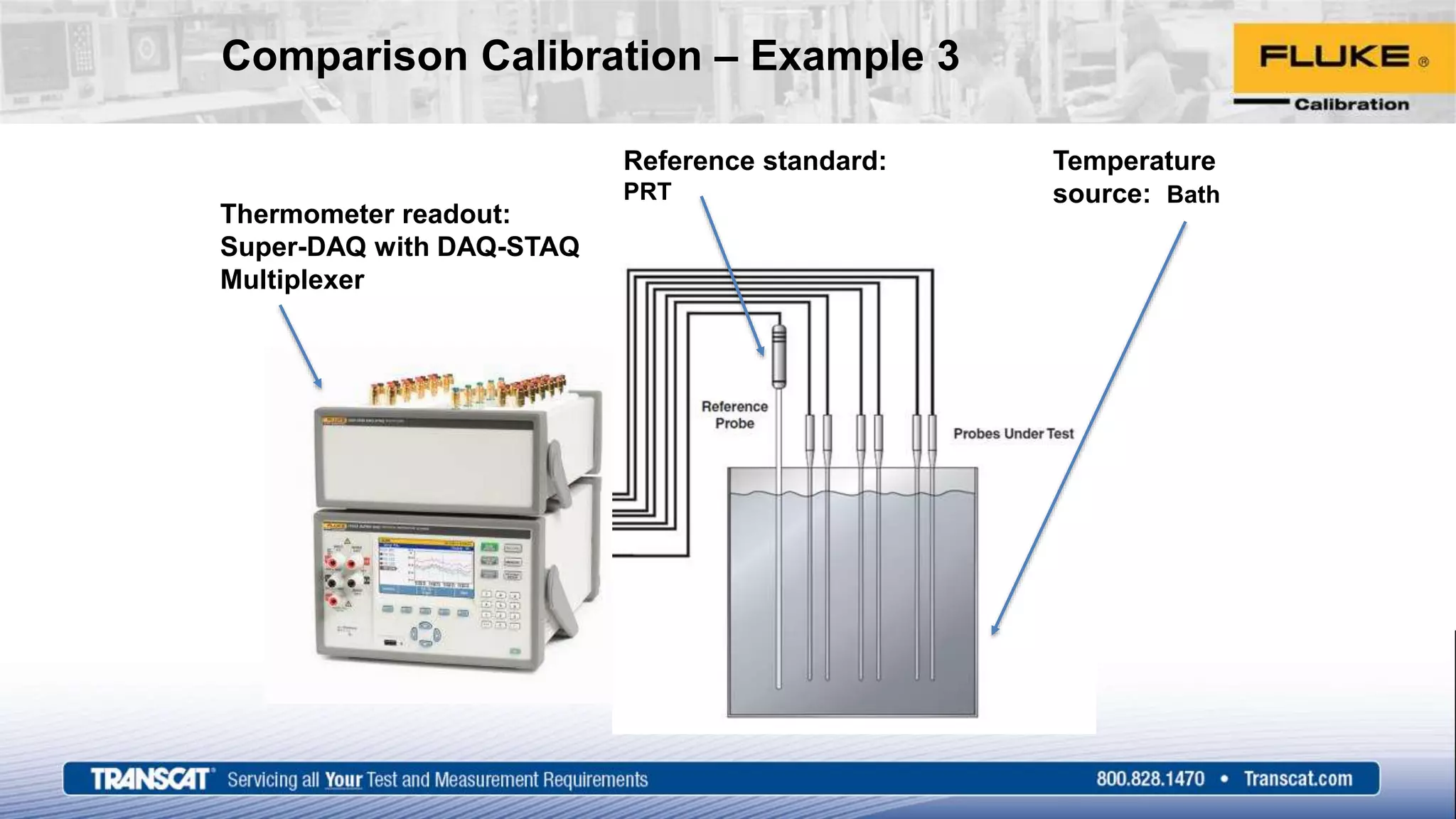

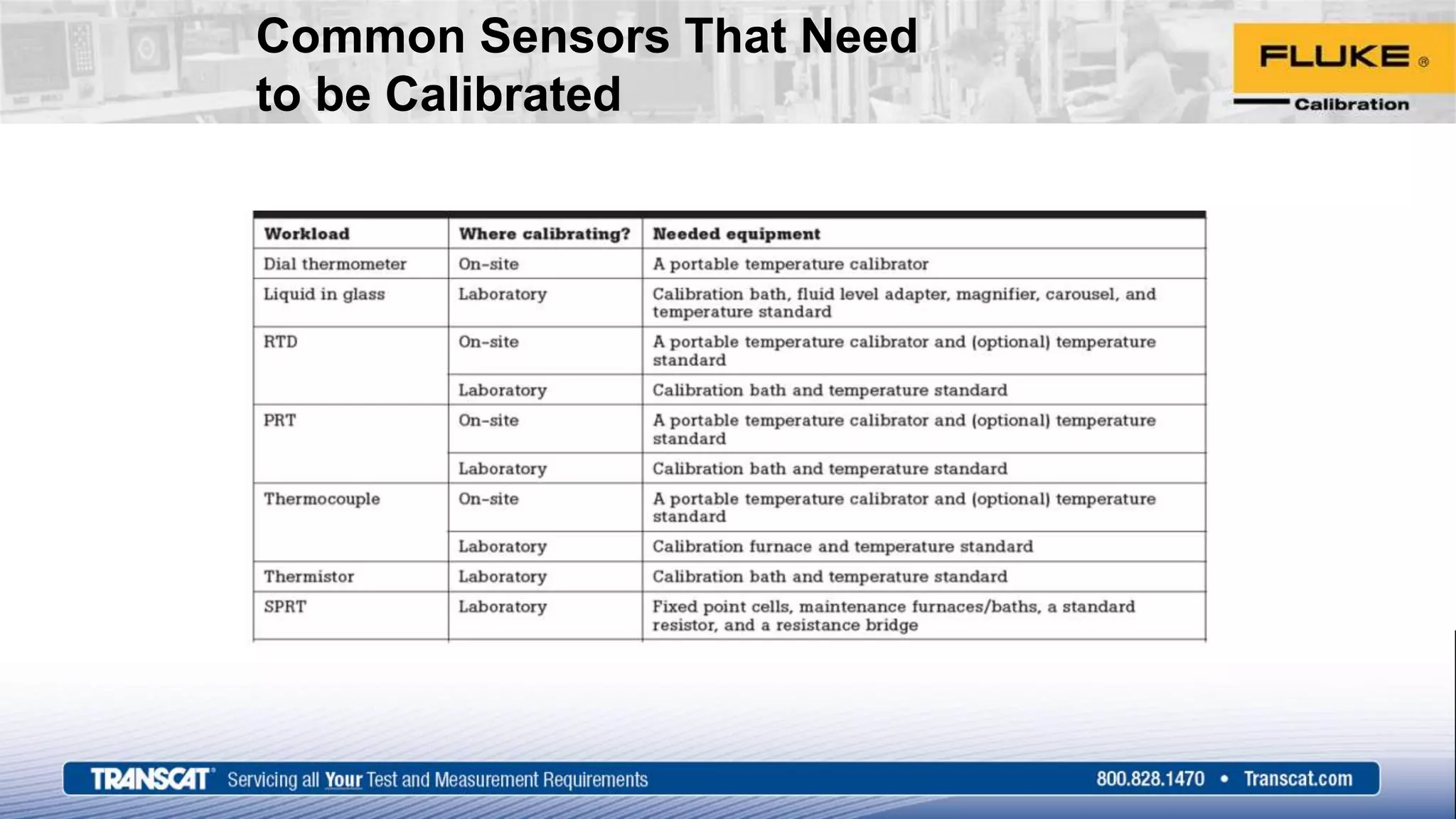

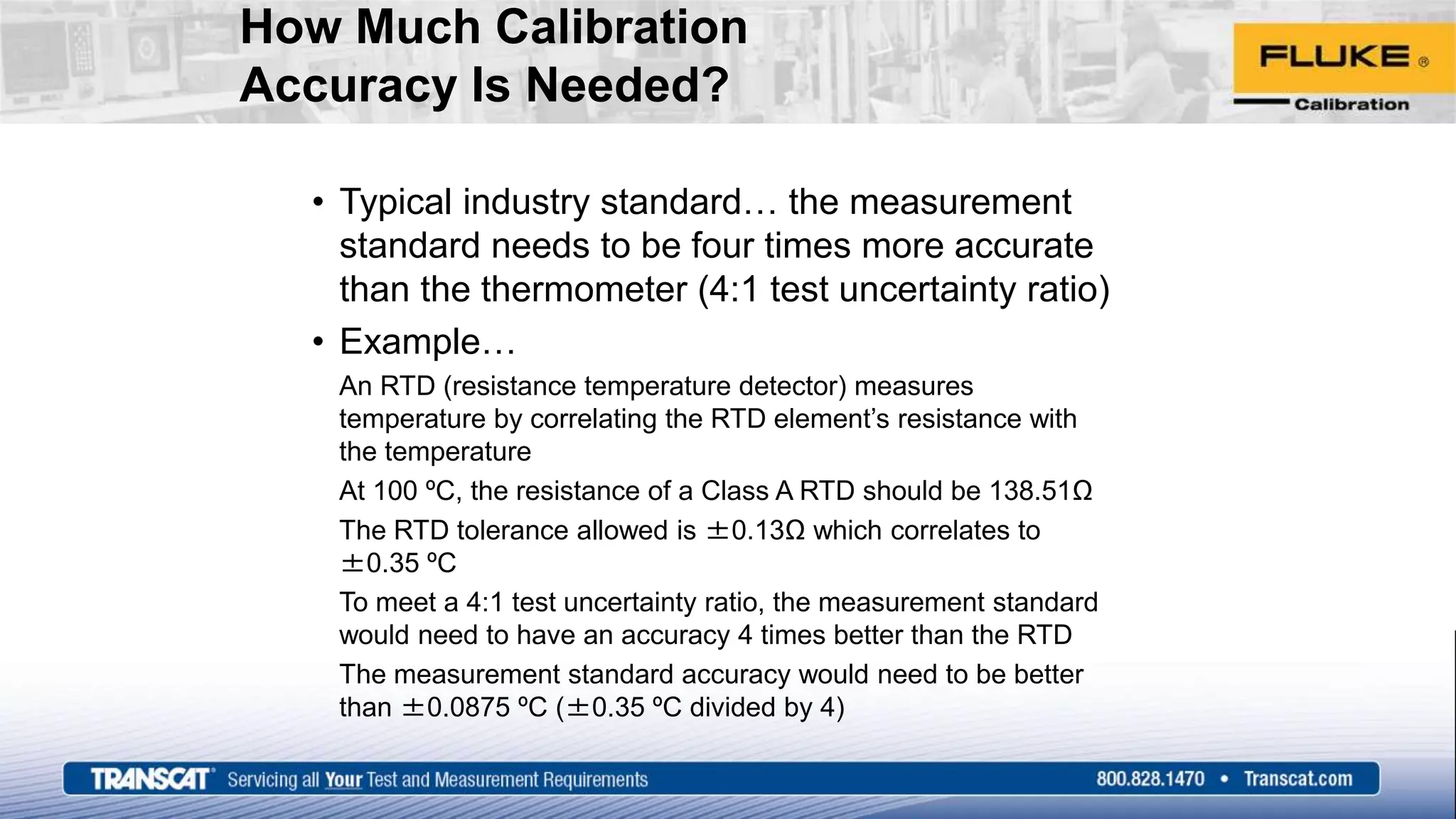

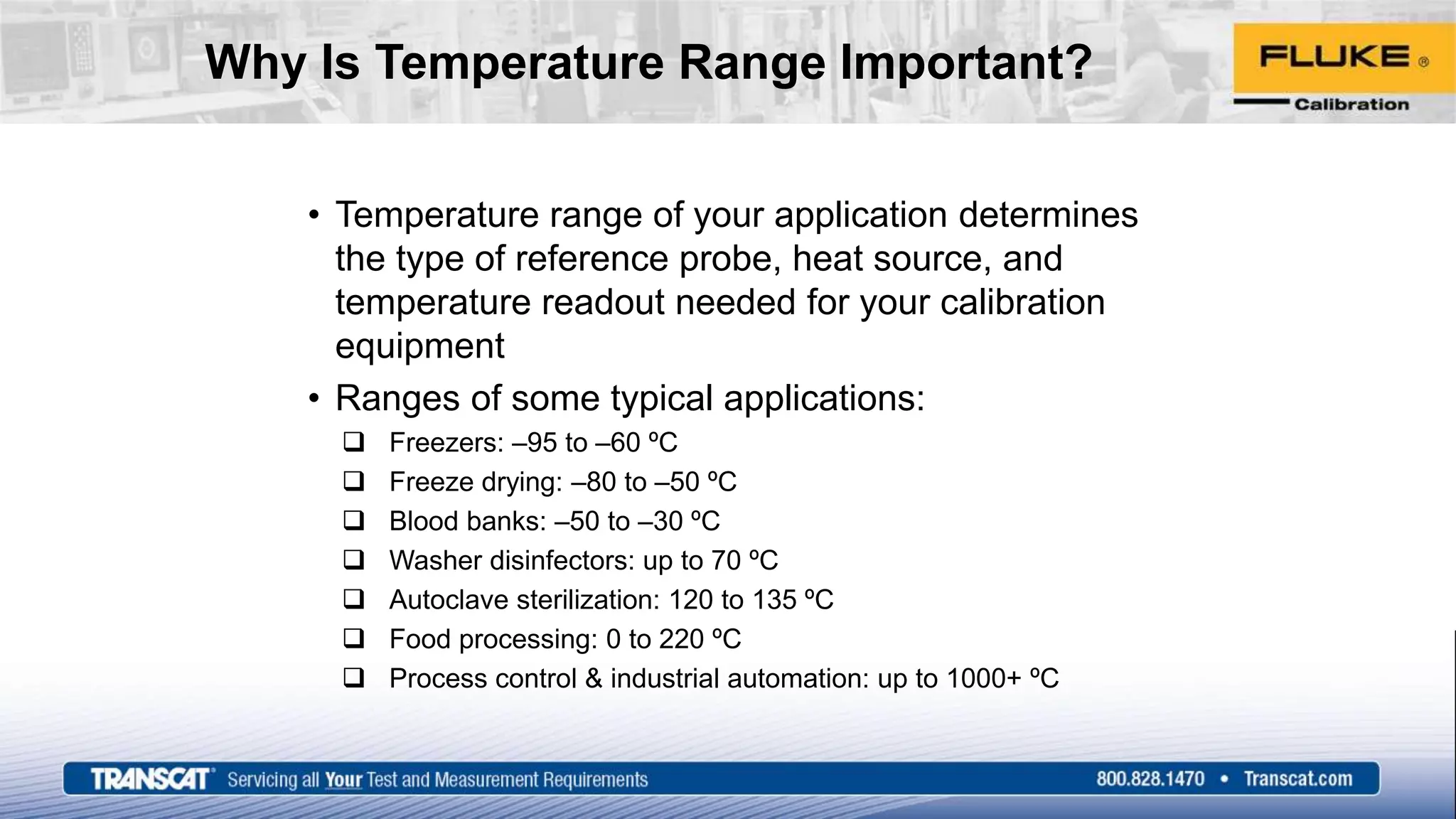

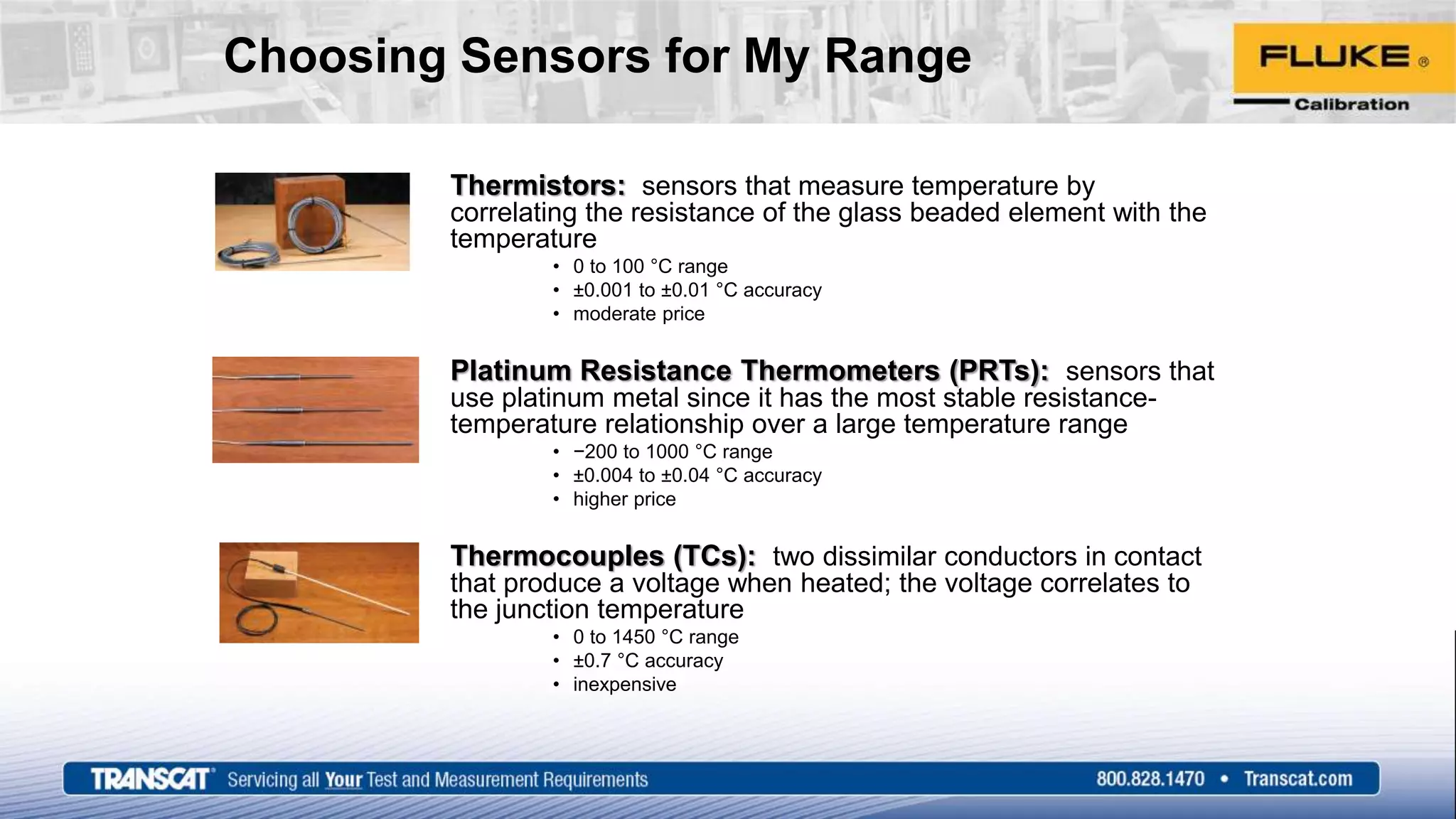

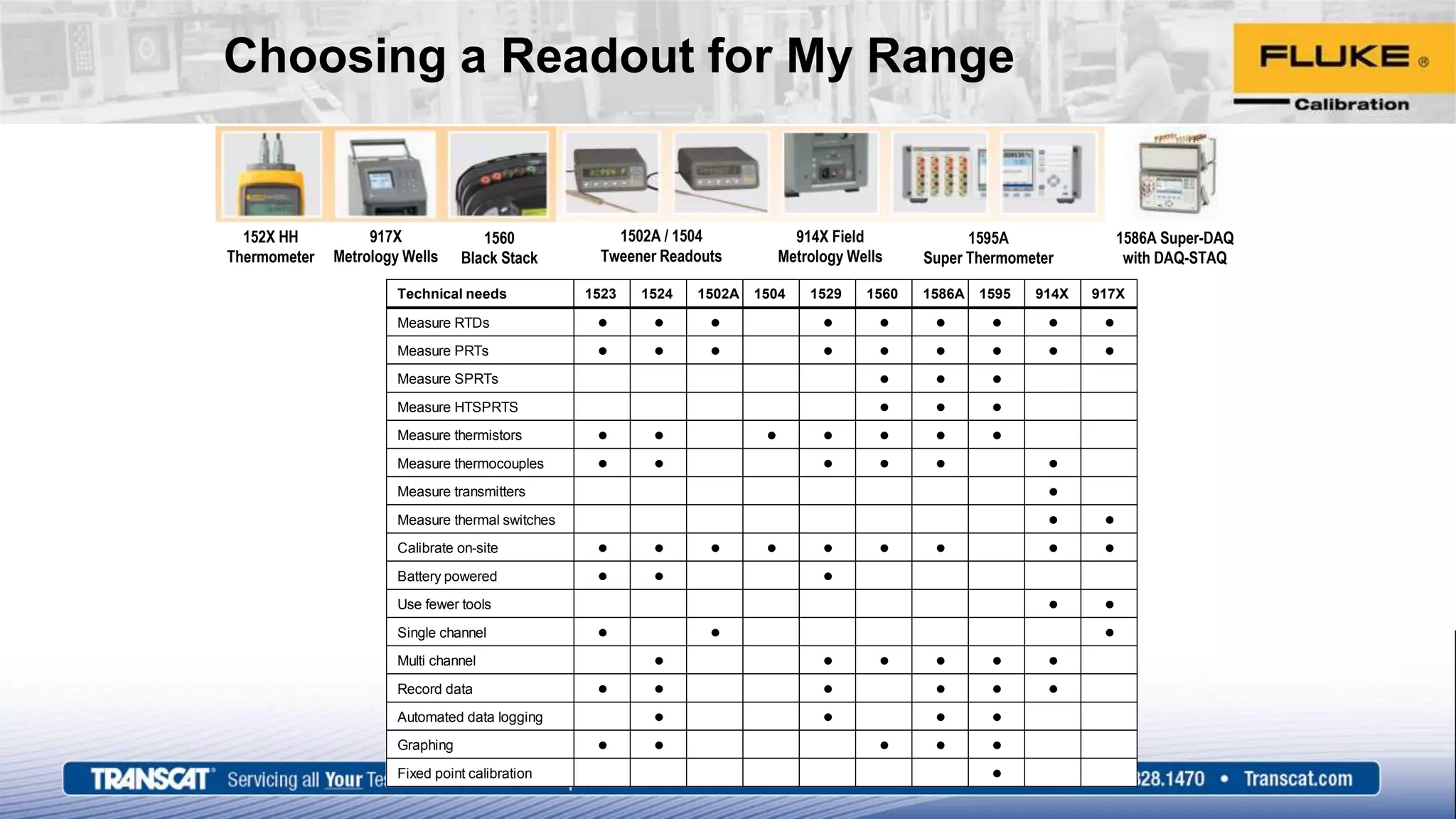

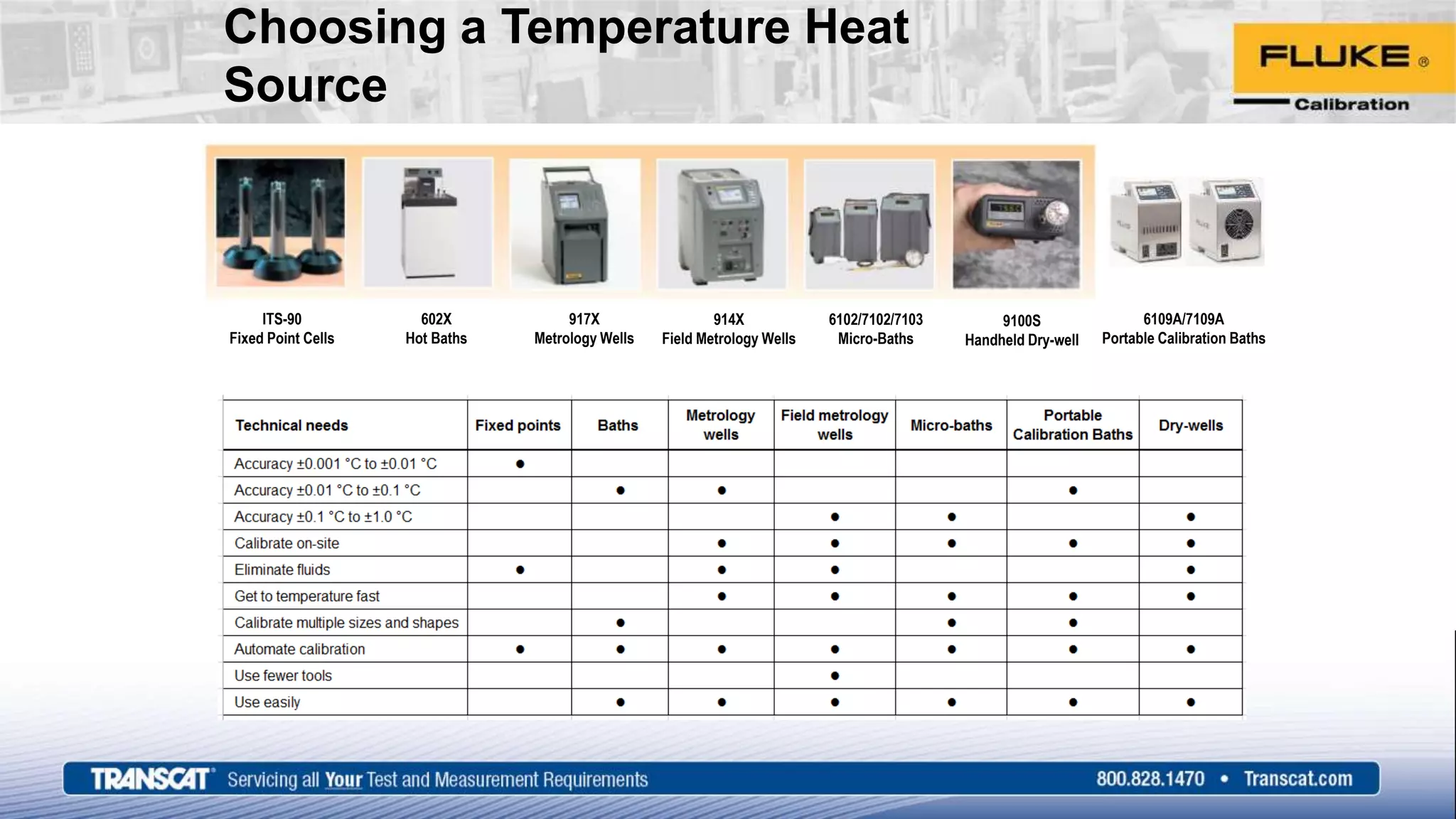

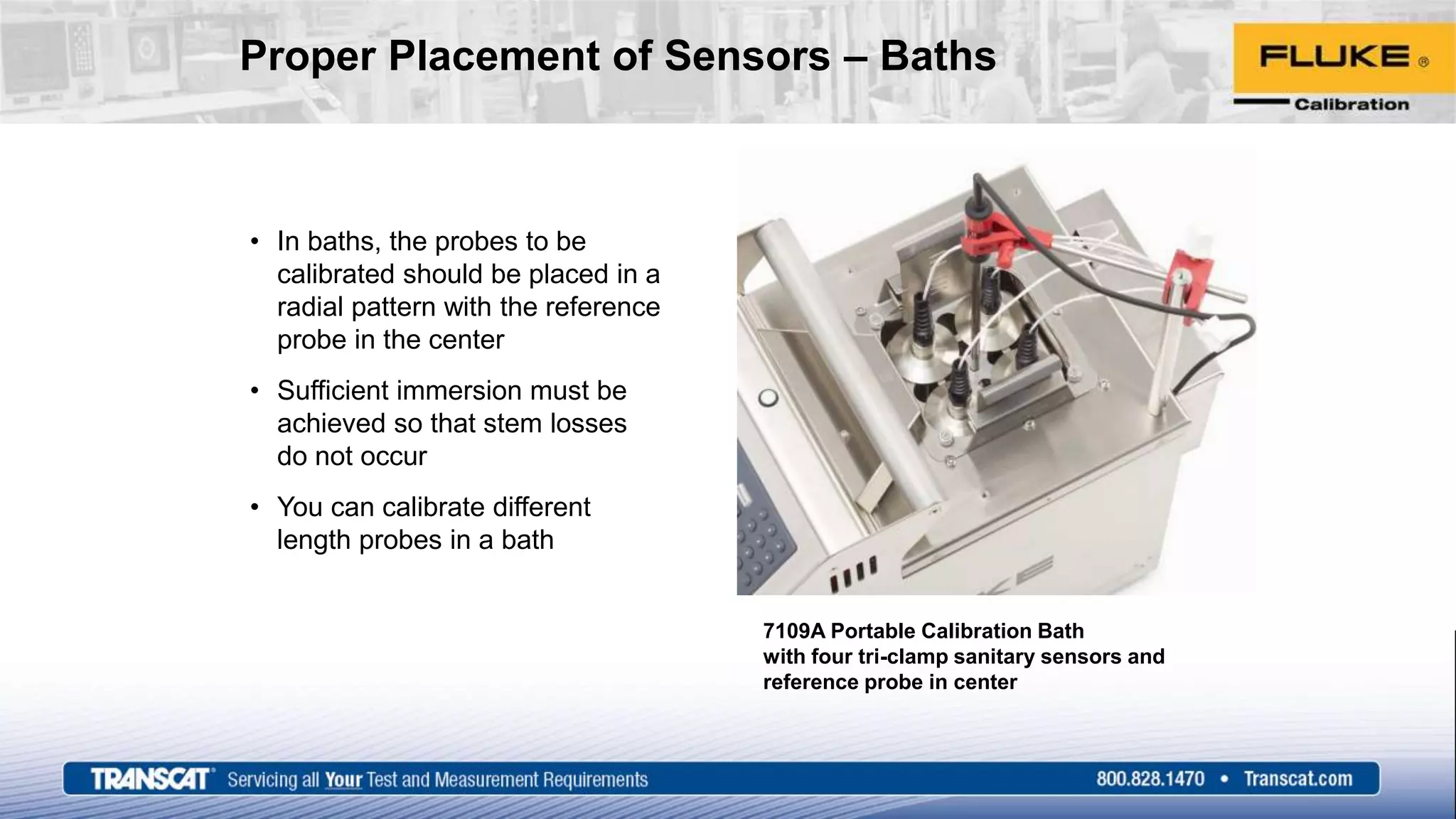

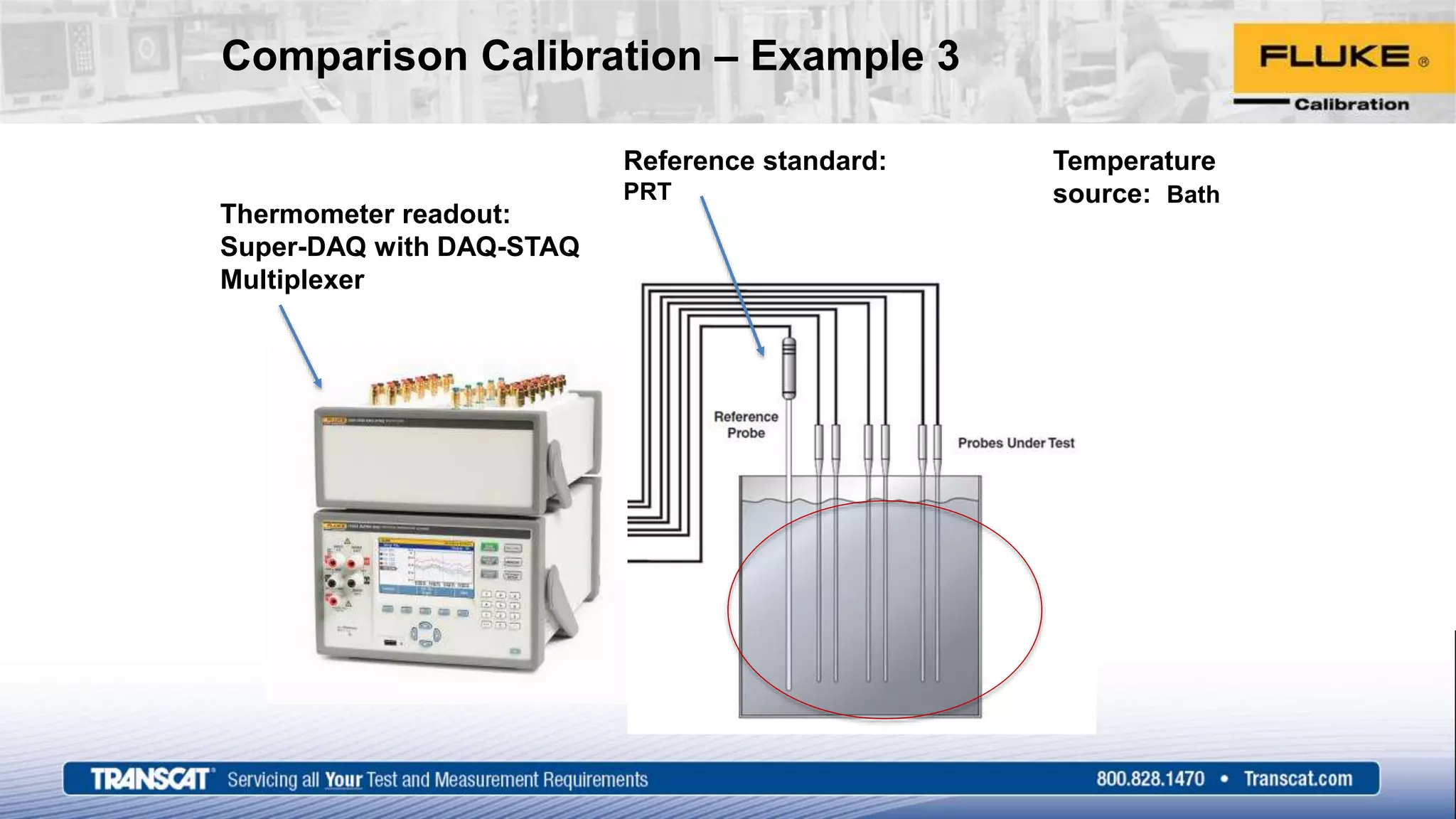

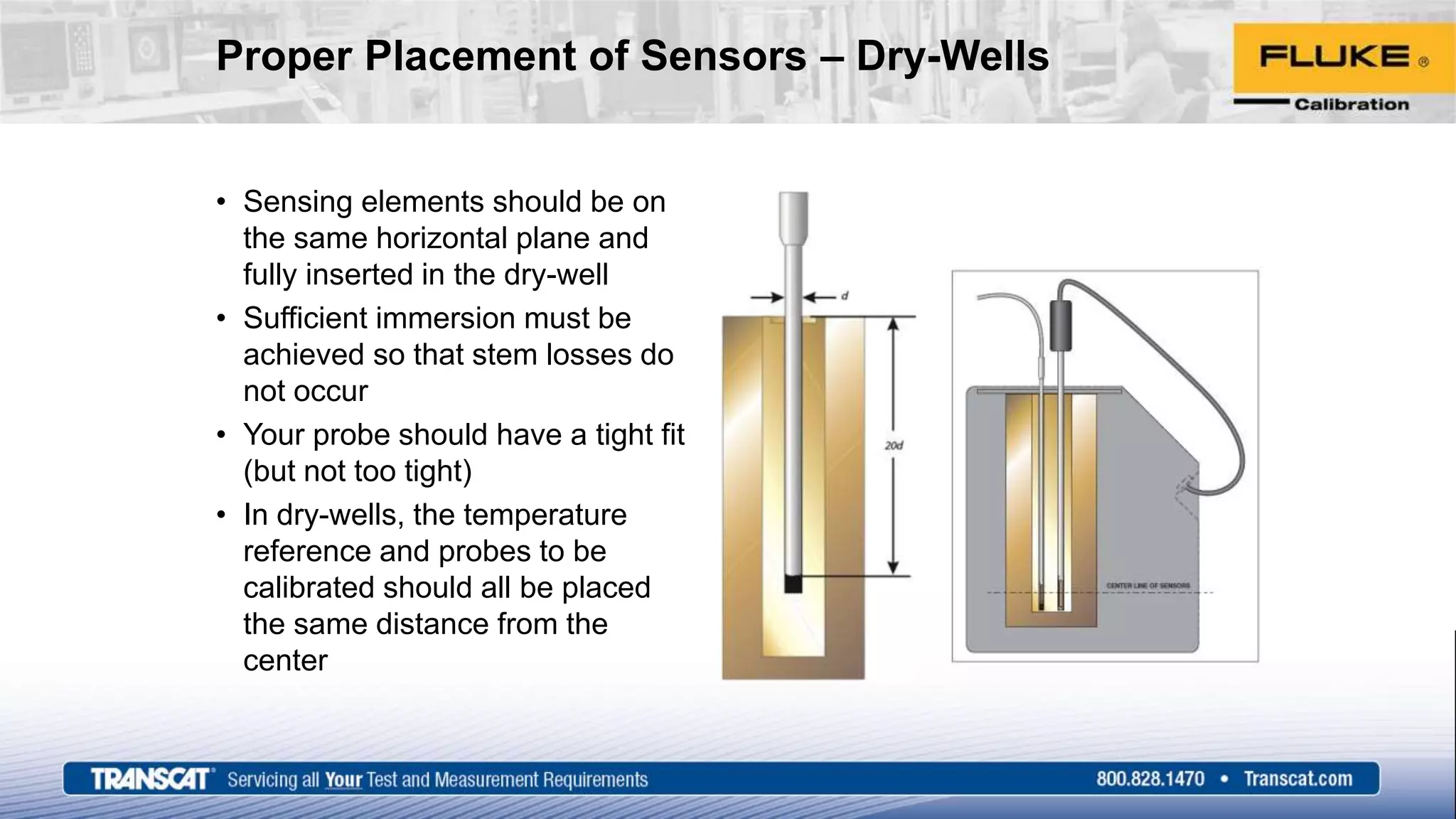

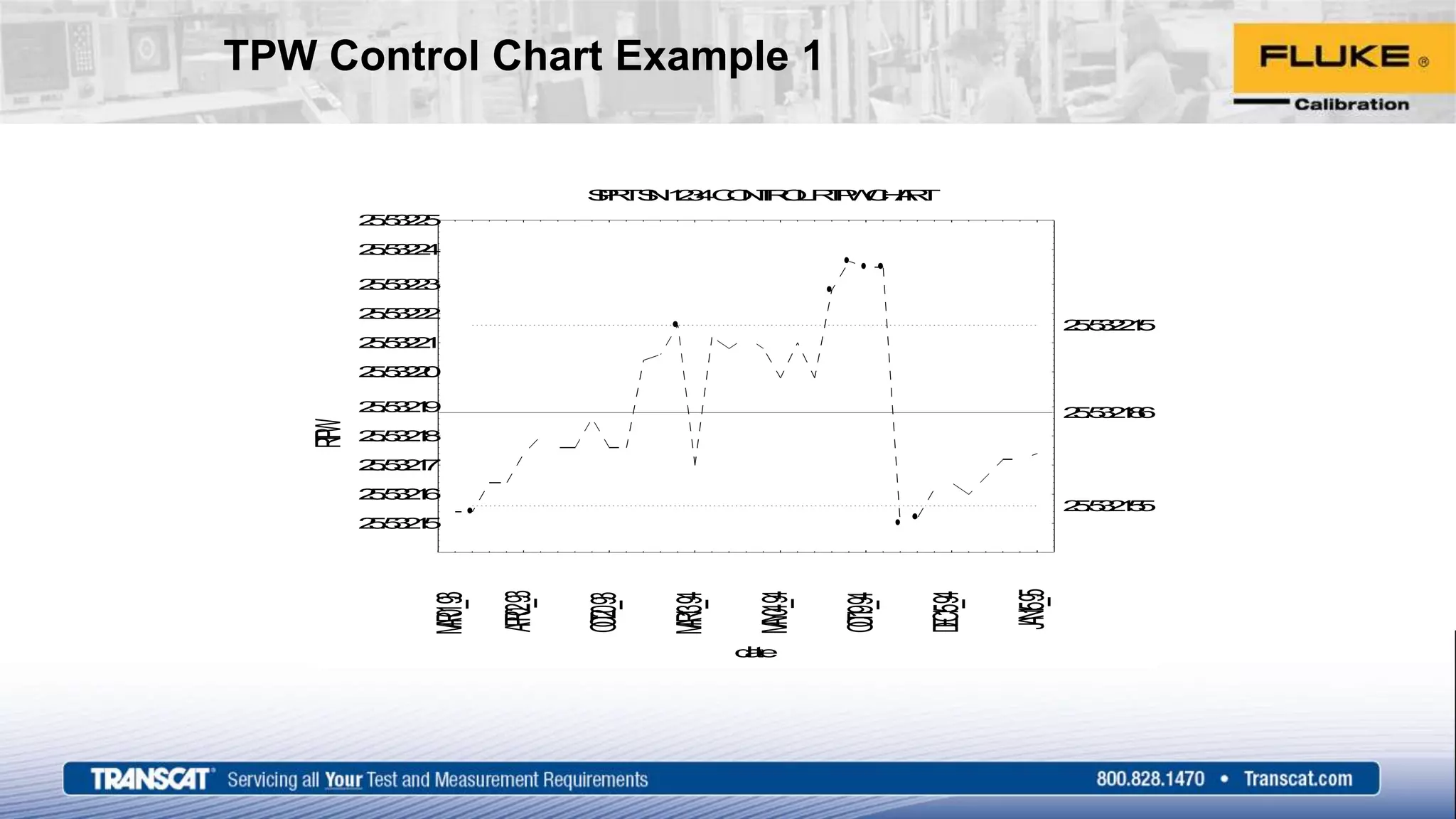

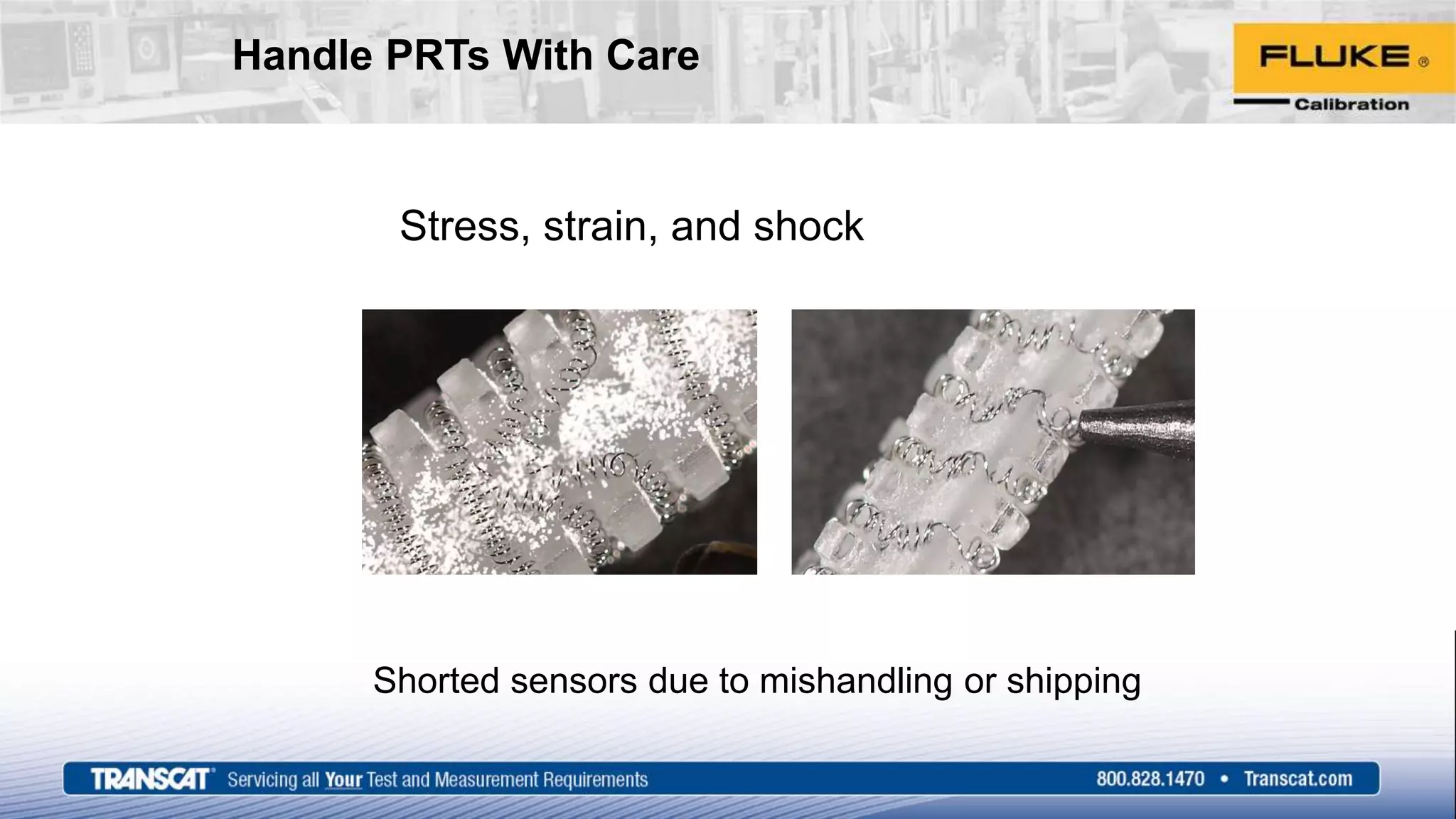

This document provides an overview of temperature measurement and calibration. It discusses calibration methods like comparison calibration and fixed point calibration. Key factors for choosing temperature measurement equipment are discussed, such as sensor type, temperature range, and required accuracy. Proper placement of sensors in baths and dry wells is also covered. The importance of maintaining calibration standards and training users is emphasized.