Concrete Properties Guide

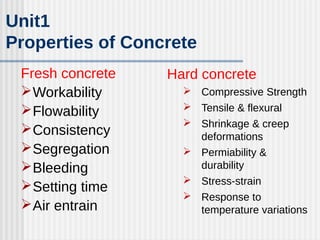

- 1. Unit1 Properties of Concrete Fresh concrete Workability Flowability Consistency Segregation Bleeding Setting time Air entrain Hard concrete Compressive Strength Tensile & flexural Shrinkage & creep deformations Permiability & durability Stress-strain Response to temperature variations

- 2. 1.Workablity As per IS 6461-1973(Part-7) workability of fresh concrete is defined as the ease & homogeneity with which concrete can be mixed, transported, placed in form work, compacted & finished. The workability is associated with the following four concepts: 1.Ease of flow (internal friction) 2.Prevention of segregation 3.Prevention of harshness 4.Prevention of bleeding Workable concrete have a uniform colour, the aggregates will be lubricated with sufficient paste, so that it can be easily poured into formwork. 2

- 3. Workability Vs Consistency Consistency:Amount of work required to be done in order to compact the concrete Stiff Normal Flowing Vee Bee Comp.Factor & slump Slump-flow Workability is ease and homogeneity with which concrete can work in different part. 3 Rheometer is instrument to use to measure viscosity & yield stress of concrete, which includes all above.

- 5. Factors Affecting Workability 1. W/C ratio-Amount of water content 2. Size & shape of aggregate 3. Grading & surface texture of aggregate 4. Quantity and characteristics of cementing materials 5. Quantity and characteristics of admixtures 6. Amount of entrained air 7. Mix proportion & ambient air temperature 8. Method and duration of transportation

- 6. 1. W/C ratio-Amount of water content-higher water content per cubic meter higher is the workability. lower water content means low slump. Hence water should be optimum for required slump. 2. Size & shape of aggregate- Bigger size aggregate –less surface area-less water for wetting aggregate-less paste require-reduce friction gives more workability. More fine aggregate-more surface area-more paste and water demand. rounded aggregate –less surface area-less void- required less paste-more workability. Angular, elongated results less void ratio-more paste-less workability-harsh concrete. Factors Affecting Workability

- 7. 3.Grading of aggregate & Surface texture - Rough surface texture-more surface area-more friction- less workability. Smooth surface particle-less internal friction-high workability. Well graded aggregate concrete gives less void ratio for given volume due to which more paste available-mix is cohesive and prevent segregation-less internal friction-high workability 4.Quantity & use of admixture- plasticizers & super plasticizers improves workability at low water content. pozzolana, air entraining agents improve workability. Dose of admixture depends on type of cement, temp. and site conditions. Factors Affecting Workability

- 8. Rounded particles – better workability Angular particles – poor workability

- 9. 5.Air entrained concrete-more workability 6.Temperature & environmental condition- Hot weather-more evaporation-reduce water content-low workability. Cold weather-Low temperature -frozen water reduces workability. 7.Transportation-Workability-slump-reduces as time increases. plasticizers control workability 8.Mix proportion-higher aggregate-cement ratio leaner is the concrete-in lean mix less paste quantity available for lubrication. Lower aggregate-cement ratio-rich cohesive mix-more quantity of paste available-better workability Factors Affecting Workability

- 10. Workability test on fresh concrete- Slump cone test Compaction factor test Vee-bee test Flow table test 10

- 11. 10 cm 20 cm 30 cm The slump cone is filled in 3 layers. Every layer is evenly rodded tamping rod of 16mm dia & 60 cm length about 25 times. Measure the slump by determining the vertical difference between the top of the mold and the displaced original center of the top surface of the specimen. 1.Slump cone test

- 12. Slump cone test-if the frustum just settle down called true slump 12

- 13. Slump cone test-most common test on site 13

- 14. Amount of Mixing Water Relationship between slump and water content is non-linear

- 15. % Loss of Slump Slump decreases with time •Hydration •Evaporation •Rate increases with increase in ambient Temp.

- 16. 2.Compacting factor apparatus-slump cone test will not give good results in case of stiff or harsh concrete then this test suit. Wt. of partially compacted concrete Compaction factor= Wt. of fully compacted concrete 16 Compaction factor test not suitable for low workability (compacted by vibrations)concrete or low slump concrete. As per IS compaction factor for low slump concrete should be between- 0.75 to 0.8

- 17. Degree of workability Slump in mm Compaction factor Placing conditions Very low 0-25 0.78 Blinding concrete, shallow sections, pavement pavers- vibrated by power machines Low 25-50 0.85 Mass concrete, light reinforcement section, slab, beam, canal lining, strip footings Medium 50-100 0.92 Manually compacted flat slab, normal RCC & heavily reinforced sections with vibrations High 100-150 0.96 Congested reinforcement, pumped concree, tremie placing, Trench filling, in situ piling

- 18. •This lab test is a extension of slump cone test •Perform slump test in cylinder first. •Turn glass plate, start vibrator and stop watch. •Record the time required when concrete has fully acquired cylindrical shape. •That time is known as vee-bee degree. Method is suitable for low slump (stiff)concrete. 3.Vee-Bee consistometer Test

- 19. 19 Degree of workability w.r.t. Vee-Bee Seconds S.NO. Time in seconds Degree of workability 1. 2. 3. 4. 5. 20-40 10-20 7-10 3-7 1-3 Very low Low Medium High Very High

- 20. 4.Workability by flow table 20 •Method is suitable for high slump concrete(Self Compacting Concrete). •Cone size-17,25cm dia & 12cm ht.

- 21. Segregation can be defined as the separation of the constituent material of fresh concrete, resulting in a non-uniform mix. Sp.Gr. Size Cement 3-3.15 5-90 m C.Agg. 2.4-2.8 4.75-40 mm F.Agg. 2.4-2.8 <4.75 mm SEGREGATION The primary causes of segregation are differences in specific gravity and size of constituents of concrete. Moreover, improper mixing, improper placing and improper consolidation also lead to segregation.

- 22. Honeycombing

- 23. Segregation occurs in 3 forms- 1.The coarse aggregate settles down in the matrix 2.The matrix paste separates from the coarse aggregate 3.Water (slurry)separates out from other ingredients. SEGREGATION

- 24. Causes of Segregation: 1. Wrong proportion or bad proportion mix- insufficient paste available 2. Insufficient mixing with excess water 3. Dropping of concrete more than 1m,in case of columns 4. Badly designed mixer and continuous vibrations for long time. 5. Transportation by conveyor belt, wheel borrow at long distance 6. Discharge of concrete at dense reinforcements SEGREGATION

- 25. Factors affecting segregation: 1. Larger maximum particle size (25mm) and proportion of the larger particles. 2. High specific gravity of coarse aggregate. 3. Decrease in the amount of fine particles. 4. Particle shape and texture. 5. Water/cement ratio. SEGREGATION

- 26. Bleeding is the form of segregation in which water comes up to the top of concrete or tendency of water to rise to the surface of freshly placed concrete. It is also called as water gain , form of segregation Bleedıng

- 27. 27 Causes of bleeding. (i) presence of excess water. (ii) Deficiency of fine aggregate. (iii) Too much finishing. Bleedıng Prevention of bleeding. bleeding can be prevented by: 1. Controlling the water- content ratio 2. Proper proportioning and uniform mixing. 3. Providing finer grading of fine aggregates. 4. Using finely ground cement. 5. Controlling compaction. 6. The air-entraining agents should be used to prevent bleeding. Bleeding is not harmful when rate of evaporation is high.

- 28. The tendency of concrete to bleeding depends largely on properties of cement. It is decreased by: Increasing the rate of hydration (C3S, C3A and alkalies) Adding pozzolans Reducing water content Proper uniform mixing Bleedıng

- 29. Properties of Hardened Concrete Compressive Strength Tensile & flexural Shrinkage & creep deformations Permiability & durability Stress-strain Response to temperature variations 29

- 30. Following are important factors which affect strength: 1. Water -cement ratio, Abram’s law 2. Gel -space ratio 3. Aggregate cement ratio 4. Aggregate size, grading 5. Age of concrete 6. Degree of hydration & consolidation, Temperature 7. Specimen parameters ; loading parameters Factors affecting strength of Concrete

- 31. Factors Affecting Strength of Concrete: Water -cement ratio, Abram’s law 1. W/C is defined as ratio of weight of water added at the time of mixing to the weight of concrete mix. 2. W/C ratio affect strength of concrete directly. 3. Strength of concrete depends upon strength of paste. strength of paste increases with increase in cement & decreases with water & air contents.

- 32. Factors Affecting Strength of Concrete: Water -cement ratio, Abram’s law But by proper compaction of concrete pores can be reduced & strength can be improves. It can be seen that lower w/c ratio could be used when concrete is vibrated to achieve high strength, comparatively higher w/c ratio required when concrete is hand compacted. The graph shows hyperbolic shape which is difficult to interpolate.

- 33. Factors Affecting Strength of Concrete: Gel-space ratio The strength of concrete at any w/c ratio depends upon hydration of cement & air content in case of air entrain concrete. Therefore instead of relating w/c ratio, the strength can be related to the solid product of hydration of cement & space available to form these product-Gel Space Ratio. It is better approach as it take into account- 1.Degree of hydration 2.Chemical & physical properties of cement 3.Temperature at which hydration takes place. 4.Air entrain in case of air entrain concrete 5.Effect of w/c ratio 33

- 34. Factors Affecting Strength of Concrete: Gel-space ratio As water/cement ratio increases- gel / space ratio decreases ● As gel/space ratio decreases concrete porosity increases ● As concrete porosity increases its strength decreases. ● If we focus on gel/space ratio and it increases -concrete porosity decreases and concrete gives better strength. ● Strength obtained by W/C ratio is depend on age whereas strength obtained by Gel- space ratio is independent of age. 34

- 35. Factors Affecting Strength of Concrete: Gel-space ratio Gel- space ratio is the ratio of the volume of hydrated cement paste to the sum of volumes of the hydrated cement paste and the capillary pores. Volume of gel Gel space ratio=------------------------------- Space available (vol. of hydrated cement gel+vol. of capillary pores) 35

- 36. Factors Affecting Strength of Concrete: Gel-space ratio Powers & Brownyard established relationship between strength & gel- space ratio. Power experiment found the relationship 240 x³ where x is the gel-space ratio & 240 is the inherent strength of the gel in Mpa. Gel-space ratio can be calculate at any age & any fraction of hydration of cement. As gel space ratio increases strength increases. 36

- 37. Factors Affecting Strength of Concrete: Aggregate-cement ratio Aggregate cement ratio is a secondary factor which affect strength. A large amount/quantity of aggregate absorb more quantity of water & reduce w/c ratio. Thus it affects the strength indirectly. For economy consideration ,aggregate-cement ratio should be high but as higher the aggregate-cement ratio will reduces strength. 37

- 38. Factors Affecting Strength of Concrete: Size of Aggregates Larger the size of aggregate lesser the surface area available for development of gel bonds which is responsible for lower strength of concrete. Larger size aggregate causes more heterogeneity in concrete which will prevent uniform distribution of load under stressed. Large size aggregate, due to internal bleeding, resulting weaker transition zone and micro cracks are developed. 38 The influence of maximum size of aggregate on compressive strength of concrete

- 39. Factors Affecting Strength of Concrete: Size of Aggregates High strength concrete effected by large size aggregates & use of lower size aggregate give high strength. In lean mixes large size aggregates give highest strength. 39 Influence of maximum size of aggregate on 28 day compressive strength of concrete of different richness

- 40. Factors Affecting Strength of Concrete: Age of concrete Concrete develops strength with age due to continued hydration. Initially rate of gain of strength is fast which reduces as time increases. As per IS456-2000 –there is gain of strength beyond 28 days. The quantum of increase depends upon grade, type of cement, curing, environmental conditions. The design based on 28 days strength. 40 Gain of strength with time Vs different W/C ratio

- 41. Factors Affecting Strength of Concrete: Age of concrete Maturity of concrete/strength gain also depends on temperature. Maturity= (time +temperature) Ʃ Hydration of concrete is continue up to -11°C.Hence it is datum temp. Concrete cured at 18°C for 28days consider as fully maturated. Plowman give the constants (A,B)to calculate maturity in eq. Comp. strength=A+B log 10 (Maturity/1000) 41

- 42. 42 Factors Affecting Strength of Concrete: Age of concrete Concrete develops strength due to 4 Bouge compounds.C3S & C2S plays major part. Fineness of particles plays also role- 5-7 micron- contribute in first 1- 2 days strength 20-25 micron- contribute in first 7 days strength More than 30 micron- contribute in first 28 days strength

- 43. Rise in temp. speed up rate of hydration resulting strength in early ages. But higher temp. during placing & setting will effect poor physical structure, more porous, less strength. 43 Factors Affecting Strength of Concrete: Temperature

- 44. Maturity concept Since the degree of cement hydration depends on both time and temperature, the strength of concrete may be evaluated from the concept of maturity, which is expressed as a function of the time and the temperature of curing. It is assumed that batches of the same concrete mixtures of same maturity will attain the same strength regardless of the time-temperature combinations leading to that maturity. Maturity = ∑ (time x temperature) 44

- 45. Maturity concept Datum temperature for calculating maturity of concrete is -11ºC The rate of strength development at early ages is related to the rate of hydration of cement. Heat generated from the hydration reaction will be recorded as a temperature rise in the concrete. The main advantage of the maturity method is that it uses the actual temperature profile of the concrete in the structure to estimate its in-place strength. The maturity concept is governed by the underlying assumption that concrete samples of a given mixture will have the same strength when they have the same maturity index. For example, concrete cured at a temperature of 50°F (10°C) for 7 days may have the same maturity index as concrete cured at 80°F (27°C) for 3 days and therefore would have similar strengths. 45

- 46. 46 Maturity test

- 47. 8) To increase resistance to chemical attack, corrosion of steel 9) To reduce segregation and improve pump ability, finish. 10) To increase bonding between steel & concrete 11) To produce colour concrete 12) To increase bonding between old & new concrete 13) To reduced cost of concrete 47 Functions of Admixtures In concrete

- 48. Classification of Admixtures • Mineral Admixture- A)Natural pozzolana- Clay & shale Opalinc cherts Diatomaceous earth Volcanic tuffs & Pumicites B)Artificial pozzolana- Fly ash Blast furnace slag Silica Fumes Rice husk ash Metakaoline surkhi • Chemical Admixture Plasticizers Super plasticizers Accelerators Retarders Air entraining agents Grouting Waterproofing agents Corrosion resisting Bonding agents Colouring admixtures 48

- 49. Mineral Admixtures and Properties

- 50. Fly Ash: How it work in concrete? 50

- 51. Advantages of fly ash 1) To reduce heat of hydration & thus reduce thermal cracks & improve soundness of concrete. 2) To improve workability & pump ability 3) It convert released lime from hydration of OPC into additional cementations material-contribute strength improvement. 4) Due to reaction between fly ash & liberated lime improves permeability (pore refinement) 5) To reduce requirement of cement for same strength & reduce cost of concrete. 6) Concrete using fly ash is generally show reduced segregation and bleeding

- 52. Silica Fume Properties 1. It is also referred as “microsilica”. It is an artificial pozzolanic admixture.It is a by-product during the manufacture of silicon or Ferro silicon alloy. 2. Spherical shape. Extremely fine ( particle size < 1 micron) 3. 100 times smaller than avg. cement particles. 4. Specific surface area 20000 m2/kg. Silica fume, is a highly active pozzolan and has cement properties because of fine nature. 5. Water demand increase, workability reduce. Concrete with micro silica causes produce more heat of hydration & initial plastic shrinkage. 6. Reduce bleeding & no segregation. 7. With silica fume concrete become resistant to corrosion, increase in strength & durability, control permeability. 52

- 53. Plasticizers-(water reducers) Plasticizes is an admixtures used in concrete to improve workability by reducing water content. They gives- 1. Better workability without increasing water 2. Which gives easy placement of concrete in poor locations without vibrations. 3. True shutter finish for highly reinforced member. 4. Reduction in cement content Typical water reducers reduce the water content by approximately 5% to 15%.

- 54. Plasticizers-(water reducers) 54 Cement particles are deflocculated & dispersed. When they deflocculated water trapped in flocs get released.

- 55. Super plasticizers :(High-Range Water Reducers HRWR) • These admixtures are added to concrete for production of flowing, self levelling, self compacting and for production of high strength, high performance concrete. • They reduce water content upto 30% • Dosage -1 to 2% by weight of cement • workable concrete that can be placed with little or no vibration or compaction while still free of excessive bleeding or segregation.

- 57. Retarding Admixtures 1. Retarder is an admixture that slows down the chemical process of hydration(rate of hydration) 2. Concrete remain in plastic & workable for long time. We can place it without structural discontinuities. 3. They use to overcome the accelerating effect of high temperature ,high humidity on concrete in hot weather. ex. grouting oil wells. 4. Retarders do not decrease the initial temperature of concrete. 5. They delay initial setting by forming a thin coating on the cement particles & slow down their reaction with water .

- 58. Accelerating Admixtures They added to concrete to accelerate or increase the rate of early strength development in concrete and shorten the setting time- 1.For earlier removal of formwork 2.Reduce period of curing 3.Structure can be place in service in advance 4.Compensate retarding effect of low temperature during cold weather concreting-add calcium chloride. 5.In emergency repair work- highway, bridge 6.Plugging leakage

- 59. Air-Entraining Admixtures Increased resistance to freezing and thawing. Improvement in workability. Reduction in strength. Reduces the tendencies of segregation. Reduces the bleeding and laitance. Decreases the permeability. Increases the resistance to chemical attack. Permits reduction in sand content. Improves place ability, and early finishing. Reduces the cement content, cost, and heat of hydration. Reduces the unit weight. Permits reduction in water content. Reduces the modulus of elasticity.

- 60. Corrosion resistancing • The chlorides can cause corrosion of steel reinforcement in concrete. • Ferrous oxide and ferric oxide form on the surface of reinforcing steel in concrete. • Ferrous oxide reacts with chlorides to form complexes that move away from the steel to form rust. The chloride ions continue to attack the steel until the passivating oxide layer is destroyed.

- 61. Shrinkage-Reducing Admixtures • Shrinkage cracks, such as shown on this bridge deck, can be reduced with the use of good concreting practices and shrinkage reducing admixtures.

- 62. Coloring admixtures (Pigments) • Red and blue pigments were used to color this floor

- 63. What is Green Concrete? • A concrete that uses less energy in its production & produces less carbon dioxide than normal concrete is green concrete. • Green Concrete is taken to mean environment-friendly concrete. • Fly ash used for partial replacement of cement called as green concrete.

- 64. Green concrete

- 65. • The main ingredient in concrete is cement and it consists of Limestone (Calcium Carbonate CaCO3). • During manufacture of cement, its ingredients are heated to about 800 - 1000C. • During this process the Carbon Dioxide is driven off. • Approximately 1kg of cement releases about 900gms of Carbon Dioxide into the atmosphere. • Therefore, green concrete came into existence to reduce the emission of carbon dioxide. What is Green Concrete?

- 66. Materials for Green Concrete • Locally available: Construction materials, components, and systems found locally or regionally, saving energy and resources in transportation to the project site. • Salvaged, re-furnished, or re- manufactured: Includes saving a material from disposal and renovating, repairing, restoring, or generally improving the appearance, performance, quality, functionality, or value of a product. • Reusable or recyclable: Select materials that can be easily dismantled and reused or recycled at the end of their useful life.

- 67. Materials for Green concrete

- 68. Materials for Green concrete • Fly ash • Ground Granulated Blast-Furnace Slag (GGBS) • Silica Fume (SF) • Rice Husk Ash (RHA) • Silpozz(made from RHA) 2. Use of Recycled Material Concrete Debris • Post –Consumer Glass • Foundry Sand • Cupolas Slag • Wood Ash

- 69. How green concrete help in achieving the sustainable construction 1. Increased dependence on recycled materials: Effective use of recycle material ,industrial byproducts etc. can help in reducing the dependence on virgin material. 2. Effective use of supplementary cementitious material: Partial replacement of cement can be done by the byproducts of industrial processes, such as fly ash and slag as the production of Portland of cement is responsible for generation of CO2 and huge energy is consumed. 3. Improved mechanical properties: Proper use of recycle material can help in improving the mechanical properties. 4. Reuse of wash water: The recycling of wash water can be seen practice by the most of the construction industry and required by law in some countries.

- 70. IMP points in Mix Design • Optimizes void space between aggregates by optimizing particle proportions and packing of materials. This makes more effective use of the cement binder. Less W/C and W/B ratios. • Aggregates replace excess cement paste to give improved stability, less shrinkage and increase in strength & durability. • Less cement also generates less heat of hydration.

- 71. Example: Fly Ash concrete • Fly ash is the by-product during the operation of coal fired power plants. Its divided in coal ash & pond ash • Fly ash particles are round and fine, act as ball bearing in concrete mix provided lubricant effect. Which improve concrete workability & pumping ability. • By using 20% fly ash water demand reduces approx. 10% hence lower w/c ratio possible with high workability. • Replacement for cement, fly ash reduce the heat of hydration. • Increased durability & lower permeability. • Fly ash reacts with available lime & alkali in concrete, produces additional C-S-H gel • It improves latter age strength of concrete • Decrease in water content with production of additional

- 72. Advantages of Green concrete • High use of industrial waste about 20% , Green Concrete uses local and recycled materials in concrete. • Reduce CO2 emissions about 30%. • Reduce energy consumption during manufacturing process • User-friendly, no environmental pollution during production • Optimized mix designs mean easier handling, better consistency, workability and easier finishing • Low heat of hydration & reduction in shrinkage & creep. • Less maintenance & better compressive, flexural strength than traditional concrete

- 73. Limitations • Increase in reinforcement cost consumption • It has lesser split tension when it is compared to the conventional types of concrete. • Durability study is essential, as green concrete have comparatively less life in aggressive environment