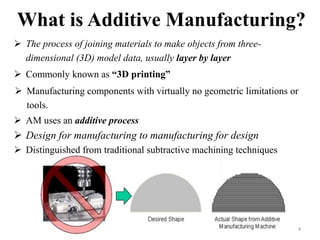

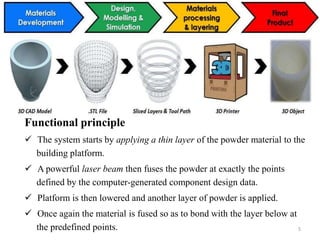

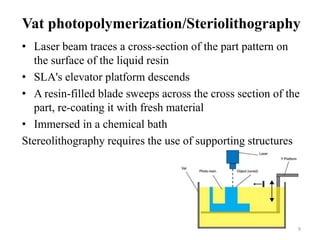

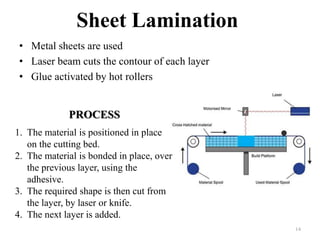

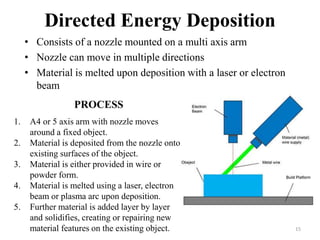

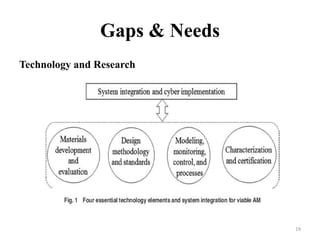

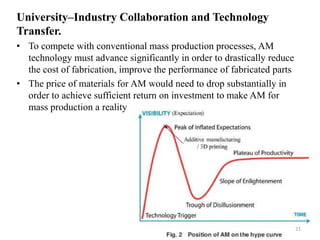

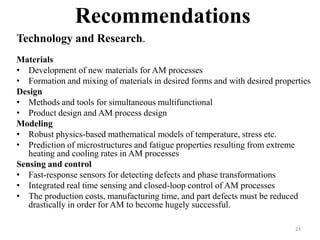

Additive manufacturing, also known as 3D printing, involves building 3D objects layer by layer from digital models. The document discusses the current state and future potential of 7 additive manufacturing processes, including stereolithography, material jetting, binder jetting, material extrusion, powder bed fusion, sheet lamination, and directed energy deposition. It also identifies gaps in technology, materials, design, modeling, and education/training that must be addressed for additive manufacturing to become more widely used for mass production. Recommendations include increased collaboration between universities and industry to advance the technology and reduce costs.