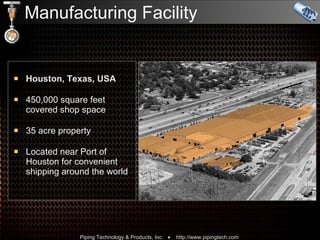

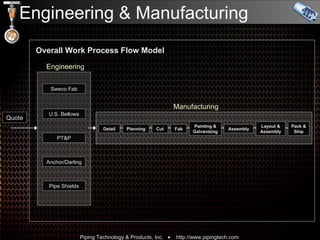

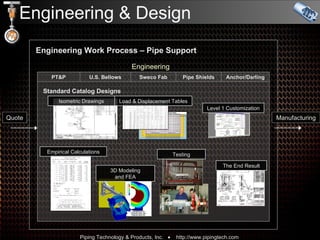

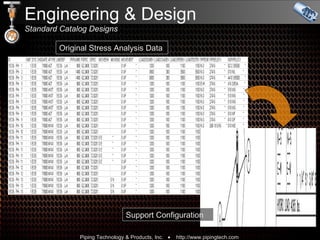

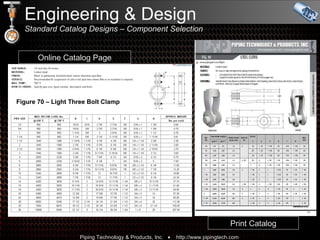

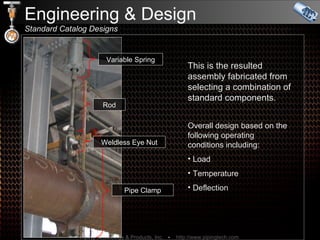

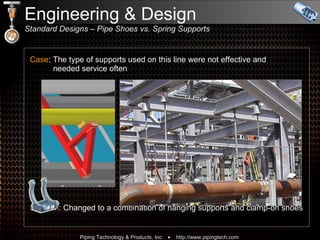

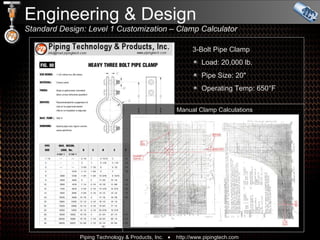

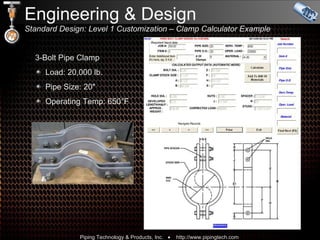

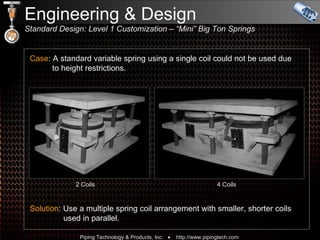

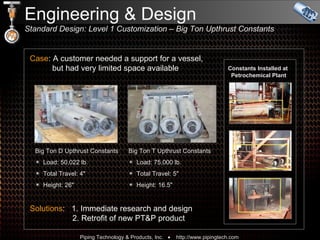

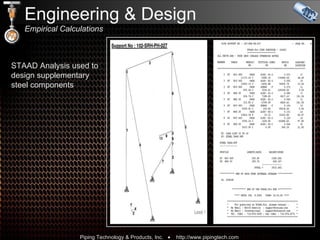

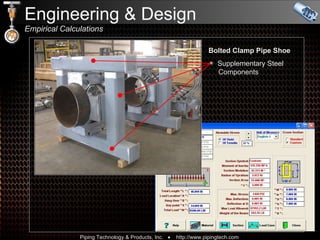

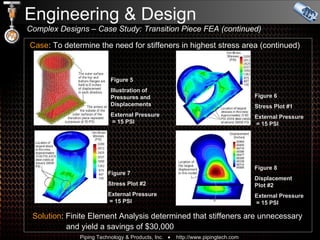

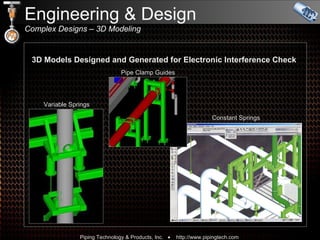

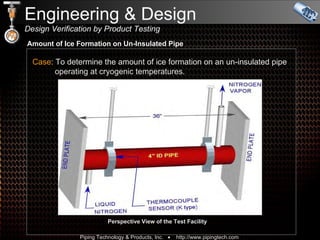

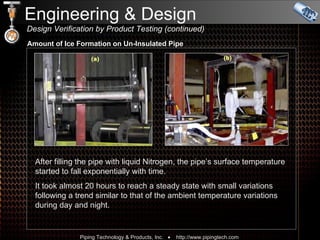

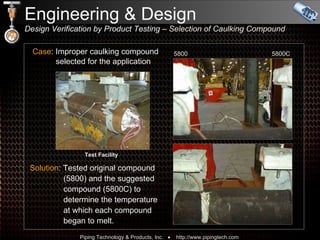

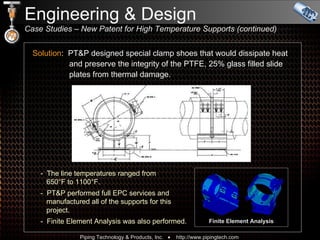

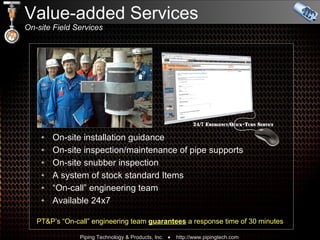

The document outlines a webinar hosted by Piping Technology & Products, Inc., focused on pipe support engineering and design, featuring presenter Jerry Godina. It highlights the company's offerings, including engineered pipe supports, and details on their manufacturing capabilities, technical resources, and various engineering services. Attendees can earn PDH credits and access additional resources such as online quotes and technical webinars.

![PIPING TECHNOLOGY & PRODUCTS, INC. Pipe Support Engineering & Design Webinar Attention Attendees : to listen to the audio portion, check that your speakers or headset are on and turned up OR dial the number and use the access code listed in your confirmation email. Attention P.E.’s : this Webinar is worth 1 PDH credit for TX P.E.’s (send request to [email_address] )](https://image.slidesharecdn.com/engineering-design10-6-2011-111006075835-phpapp01/85/Engineering-Design-of-Pipe-Supports-1-320.jpg)

![Thank You for Joining PT&P’s Engineering & Design Webinar Please send any additional questions or inquiries to [email_address] Useful Links: Online Quote: www.pipingtech.com/quote Online Catalog: www.pipingtech.com/catalog Technical Webinars: www.pipingtech.com/ webinar Blog: www.pipesupportsblog.com](https://image.slidesharecdn.com/engineering-design10-6-2011-111006075835-phpapp01/85/Engineering-Design-of-Pipe-Supports-37-320.jpg)