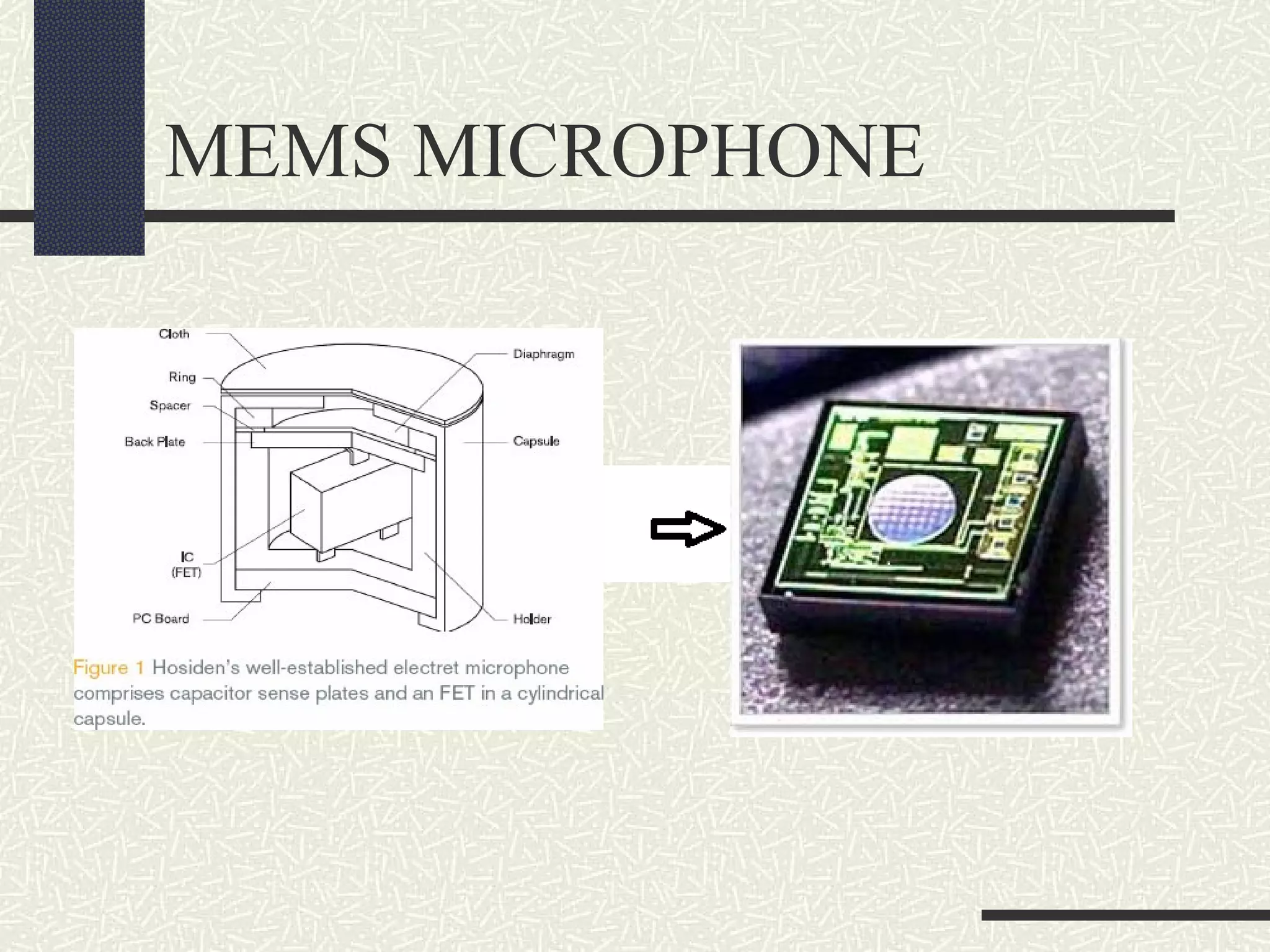

MEMS microphones are microphones built using microelectromechanical systems technology, integrating the microphone components onto a single chip using CMOS technology. There are two main types - analog MEMS microphones that output an analog voltage signal, and digital MEMS microphones that output a digital pulse density modulation signal. MEMS microphones use a flexible diaphragm that vibrates in response to sound waves, causing a change in capacitance between the diaphragm and a back plate. This change in capacitance results in a change in voltage that forms the microphone output signal. MEMS microphones offer advantages over traditional microphones like greater reliability, smaller size, and integrated analog-to-digital conversion.

![Transducer Physics

The heart of the MEMS microphone is the variable

capacitor formed by a fixed back plate and a flexible

membrane.

Sound pressure deflects the membrane, causing a

change in capacitance. This change in capacitance

causes a change in voltage according to:

C=Q/V

C = Capacitance [Farads]

Q = Charge [Coulumbs]

V = Voltage [Volts]](https://image.slidesharecdn.com/memsmicrophone-140115054535-phpapp01/75/Mems-microphone-12-2048.jpg)