04 ingestive-cleaning-es9-62-rev-l-pdf

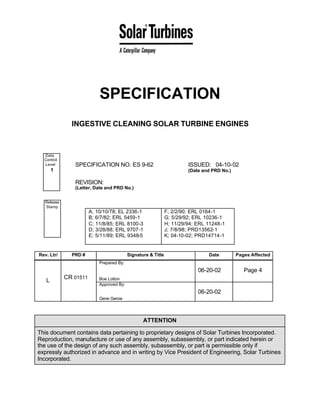

- 1. Data Control Level 1 Release Stamp SPECIFICATION INGESTIVE CLEANING SOLAR TURBINE ENGINES SPECIFICATION NO. ES 9-62 ISSUED: 04-10-02 (Date and PRD No.) REVISION: (Letter, Date and PRD No.) A; 10/10/78; EL 2336-1 B; 6/7/82; ERL 5459-1 C; 11/8/85; ERL 8100-3 D; 3/28/88; ERL 9707-1 E; 5/11/89; ERL 9348-5 F; 2/2/90; ERL 0164-1 G; 5/29/92; ERL 10236-1 H; 11/29/94; ERL 11248-1 J; 7/8/98; PRD13562-1 K; 04-10-02; PRD14714-1 Rev. Ltr/ PRD # Signature & Title Date Pages Affected Prepared By: Boe Lotton 06-20-02 Page 4 L CR 01511 Approved By: Gene Gerow 06-20-02 ATTENTION This document contains data pertaining to proprietary designs of Solar Turbines Incorporated. Reproduction, manufacture or use of any assembly, subassembly, or part indicated herein or the use of the design of any such assembly, subassembly, or part is permissible only if expressly authorized in advance and in writing by Vice President of Engineering, Solar Turbines Incorporated.

- 2. Specification No. ES 9-62 ii CONTENTS Paragraph Page 1.0 SCOPE 1 1.1 Purpose 1 1.2 Cleaning Procedures 1 1.3 Cleaning Solutions 1 2.0 DEFINITIONS 1 3.0 APPLICABLE DOCUMENTS 2 3.1 Specifications 2 4.0 GENERAL REQUIREMENTS 2 4.1 On-Crank Vs. On-Line Cleaning 2 4.2 Intervals Between Engine Cleaning 2 4.3 Cleaning Procedures 3 4.4 Cleaning Equipment 4 4.5 Ambient Temperature During Engine Cleaning 4 4.6 Engine Temperature During Engine Cleaning 4.7 Recuperated Cycle Applications 4 4.8 Flow Requirements 5 5.0 CLEANING PRODUCT 6 5.1 Water 6 5.2 Cleaning Product Composition [& Mix Ratios] 6 5.3 Emulsified Kerosene/Water Solutions 8 5.4 Abrasive Cleaners 8 TABLES Table Page 1 On-Crank Requirements for Water/Freeze Point Depressant Mix, Volume Ratio 4 InCold Ambient Temperatures 2 On-Crank Cleaning Solution and Rinse Water Flow Requirements 5 3 On-Line Cleaning Solution and Rinse Water Flow Requirements 5 4 Requirements for Water Used in Ingestive Cleaning of Solar Engines 6 5 Requirements for Cleaning Product Used in Ingestive Cleaning of Solar Engines 7 6 Solar Cleaning Solutions for On-Line and On-Crank Cleaning 7

- 3. Specification No. ES 9-62 1 1.0 SCOPE 1.1 PURPOSE - This specification establishes technical requirements for removing contamination in the compressor air path of Solar turbine engines by ingestive cleaning. 1.2 CLEANING PROCEDURES - The requirements defined herein serve as a basis for establishing proper cleaning procedures such that surface contamination in the compressor air path can be removed without damage to the engine. Details of the cleaning methods, cleaning instructions and suitable equipment for each engine model are not a part of this document as they are provided in the Operation and Maintenance Instruction (OMI) manual and in Solar's Service Bulletins. 1.3 CLEANING PRODUCTS - This specification provides the standards for product acceptance to ensure that the cleaning product(s) used are not harmful to the materials of construction. 2.0 DEFINITIONS 2.1 FREEZE POINT DEPRESSANT– Material used to depress the freezing point of the cleaning product. 2.2 CLEANING EQUIPMENT - Accessory equipment used to properly introduce a cleaning product (not solid cleaners) into the air inlet. 2.3 CLEANING MODE - The mode of operation of the engine (on-crank or on-line) while cleaning is performed. 2.4 CLEANING PRODUCT – A chemical solution that is introduced into the air inlet for the purpose of ingestive cleaning of the engine. 2.5 CLEANING SOLUTION – A detergent and/or solvent material that is mixed with water to produce the cleaning product. 2.6 CLEANING SYSTEM - An appropriate combination of cleaning product, cleaning procedure and cleaning equipment to be used for a particular engine model. 2.7 DETERGENT – Cleaning solution that liberates contamination by surface interaction (surfactant). 2.8 INGESTIVE CLEANING - Engine compressor cleaning where cleaning product is introduced through the air inlet. 2.9 ON-CRANK - Engine operation at maximum speed obtainable on starter alone with fuel and ignition deactivated. 2.10 ON-LINE - Engine fired and operating at any power level ranging from idle (no load) to full rated power and load. 2.11 SOLVENT – Cleaning solution that dissolves contamination through reaction at molecular bonds.

- 4. Specification No. ES 9-62 2 3.0 APPLICABLE DOCUMENTS 3.1 SPECIFICATIONS - The following documents of the latest issue in effect on the release date of this specification form a part of this specification to the extent specified herein. Solar ES 9-98 Fuel, Air and Water (or Steam) for Solar Gas Turbine Engines Military MIL-D-16791 Detergents, General Purpose (Liquid, Nonionaic) MIL-F-16884 Fuel Oil, Diesel, Marine MIL-E-9500 Ethylene Glycol, Technical American Society for Testing Materials ASTM D482 Standard Test Method for Ash from Petroleum Products ASTM D512 Chloride Ion in Water and Waste Water, Test for ASTM D770 Standard Specification for Isopropyl Alcohol ASTM D857 Standard Test Methods for Aluminum in Water ASTM D858 Standard Test Methods for Manganese in Water ASTM D1068 Standard Test Methods for Iron in Water ASTM D1293 pH of Water, Test for ASTM D1428 Sodium and Potassium in Water and Water-Formed Deposits by Flame Photometry, Tests for ASTM D1688 Standard Test Methods for Copper in Water ASTM D1888 Particulate and Dissolved Matter, Solids, or Residue in Water ASTM D2699 Standard Specification for Kerosene 4.0 GENERAL REQUIREMENTS 4.1 ON-CRANK VERSUS ON-LINE CLEANING - In general, on-crank cleaning tends to be more effective to remove deposits in the compressor air path. On-line cleaning may be performed in between on-crank cleaning cycles to extend time between on-crank cleaning and to minimize further deposition on to cleaned airfoils. Because the engine is firing during on-line cleaning, the cleaning liquid (either water or cleaning solution) ingested must meet the more stringent requirements defined in this specification to minimize introduction of corrosive/fouling contaminants. 4.2 INTERVALS BETWEEN ENGINE CLEANING – Appropriate intervals for both on-crank and on-line cleaning should be determined by recording and trending engine performance

- 5. Specification No. ES 9-62 3 degradation. Cost of the maintenance outage versus that of continued operation with compromised performance. must also be considered. However, one should not delay cleaning so long that contamination becomes impossible to remove completely by on-crank cleaning. On- crank cleaning is recommended at maximum intervals of every 4,000 hours operation, and before full load power degrades more than 5%. For two shaft turbines operating at full load on T5 topping this typically corresponds to a 2.5% drop in Pcd. For two shaft turbines operating at full load on Ngp topping, degree of compressor fouling is more difficult to quantify. As the compressor fouls, T5 will increase with little change in power or Pcd until T5 topping is achieved. On-line cleaning intervals should be determined by observing the effectiveness in restoring performance. On-line cleaning is best suited to remove the initial buildup of contamination from already clean airfoils. If the airfoils become significantly fouled between on-line cleaning intervals, cleaning will be less effective. Initial on-line cleaning interval should be at most 48 hours of operation. Performance should then be evaluated to determine effect of each cleaning operation, and overall rate of performance degradation. After completing an on-crank cleaning, on-line cleaning interval can be increased to 72 hours of operation. If no significant difference in on-line cleaning effectivenes is observed, the interval may be increased again by 24 hours. Typically, the maximum interval for an effective on-line cleaning program is no more than 96 hours of operation. Recommended minimum intervals between cleaning operations to avoid excessive ingress of cleaning product into the oil system are: On-Crank Cleaning - at least 96 operating hours between each on-crank cleaning cycle On-Line Cleaning - at least 24 operating hours between each on-line cleaning cycle 4.3 CLEANING PROCEDURES - Detailed cleaning procedures are described in the Operation and Maintenance Instruction (OMI) manual provided with each package. An outline of typical procedures are provided here: On-Crank: • Shut down turbine normally • Cool until turbine case temperature at compressor to diffuser flange is less than 66C (150F) • Open air inlet access covers • Open air inlet drain port • Disconnect and isolate Pcd, buffer air and air sensing lines at connection points to compressor or diffuser • Disconnect combustor, torch and exhaust drain lines • Prepare cleaning product and cleaning equipment • Crank turbine on the starter motor and allow speed to stabilize • Apply cleaning product • Stop turbine and allow cleaning product to soak for a period of 20 minutes • Crank turbine on the starter motor and allow speed to stabilize • Apply rinse water • Verify that rinse water exiting from drains is clean, indicating that compressor cleaning was effective and repeat cleaning operation as necessary • Continue crank for 5-10 minutes after rinse water is consumed • Stop turbine • Inspect inlet housing and compressor inlet to verify cleanliness • Reassemble and reconnect all components and lines • Restart turbine and operate for at least one hour to evaporate remaining rinse water

- 6. Specification No. ES 9-62 4 On-Line: • Verify that unit is operating normally with steady load and speed • Prepare cleaning product and cleaning equipment • Apply cleaning product • Apply rinse water • Isolate cleaning equipment 4.4 CLEANING EQUIPMENT - Use of cleaning equipment designed specifically for each turbine model is important to ensure that adequate and uniform atomization occurs at the compressor inlet. This is particularly important for on-line cleaning to avoid overloading of airfoils that can result from non-uniform distribution or excessively large liquid droplets. Use of inappropriate equipment may result in compressor damage. Cleaning product is introduced to the turbine inlet through manifolds and nozzles mounted directly to the turbine inlet duct, with separate systems for either on-crank or on-line cleaning. Cleaning product can also be introduced manually using a hand held sprayer wand, but only for on-crank cleaning procedure. With either application method, cleaning product volume and flow rates must comply with the requirements defined in Section 4.8 of this specification. 4.5 AMBIENT TEMPERATURE DURING ENGINE CLEANING – On-line engine cleaning is permitted only at ambient temperatures above 4°C (39°F). On-crank engine cleaning is permitted only at ambient temperatures above -20°C (-4°F). When the ambient temperature is between -20°C (-4°F) and 4°C (39°F), a mixture of water and freeze point depressant must be used for on-crank cleaning. The ratio of the water/freeze point depressant mix depends upon the type of freeze point depressant used, and recommended ratios are listed in Table 1. In order to be effective, the solution must be well mixed immediately prior to use. Table 1. On-Crank Requirements for Water/Freeze Point Depressant Mix Volume Ratio in Cold Ambient Temperatures Ambient Temperature Freeze Point Depressant Volume Ratio Freeze Point Depressant : Water -20°C(-4°F) to 4°C(39°F) Methanol 2 : 3 -20°C(-4°F) to 4°C(39°F) Mono-ethylene Glycol 2 : 3 -10°C(14°F) to 4°C(39°F) Isopropyl Alcohol 1 : 1 4.6 ENGINE TEMPERATURE DURING ENGINE CLEANING - Prior to on-crank cleaning, the engine casing surface temperature, measured at the compressor to diffuser flange shall not exceed 65°C (150°F). 4.7 RECUPERATED CYCLE APPLICATIONS - Water and/or cleaning solutions are not permitted in recuperators except for Harrison and GEA models. For all other recuperator models, on-crank cleaning must be performed at a reduced crank speed of 800 - 900rpm to avoid depositing cleaning refuse in the recuperator. On-line cleaning is not permitted for any recuperated units.

- 7. Specification No. ES 9-62 5 4.8 FLOW REQUIREMENTS - Tables 2 and 3 list the total volume of fluid and flow rate required for on-crank and on-line cleaning for each model turbine. Table 2. On-Crank Cleaning Solution and Rinse Water Flow Requirements Product Family On-Crank Cleaning Product Volume On-Crank Rinse Water Volume On-Crank Flow Rate [FOR CLEANING OR RINSE] Titan 130 75.7 – 94.6 liters (20-25 Gallons) 94.6 – 189.3 liters (25-50 Gallons) 17 to 20.8 liter/min (4.5 to 5.5 gpm) Mars 90/100 56.8 – 75.7 liters (15-20 Gallons) 75.7 – 151.4 liters (20-40 Gallons) 11.4 to 15.1 liter/min (4 to 5 gpm) Taurus 70 56.8 – 75.7 liters (15-20 Gallons) 75.7 – 151.4 liters (20-40 Gallons) 7.5 to 11.3 liter/min (4 to 5 gpm) Taurus 60 45.4 – 64.3 liters (12-17 Gallons) 64.4 – 128.7 liters (17-34 Gallons) 9.1 to 12.9 liter/min (2.4 to 3.4 gpm) Centaur 40/50 45.4 – 64.3 liters (12-17 Gallons) 64.4 – 128.7 liters (17-34 Gallons) 9.1 to 12.9 liter/min (2.4 to 3.4 gpm) Saturn 10/20 30.3 – 37.9 liters (8-10 Gallons) 37.9 – 75.7 liters (10-20 Gallons) 5.7 to 9.5 liter/min (1.5 to 2.5 gpm) Mercury 50 56.8 – 75.7 liters (15-20 Gallons) 75.7 – 94.6 liters (20-25 Gallons) 6.8 to 7.6 liter/min (1.8 to 2.0 gpm) Table 3. On-Line Cleaning Solution and Rinse Water Flow Requirements Product Family On-Line Cleaning Product Volume On-Line Rinse Water Volume On-Line Flow Rate [FOR CLEANING OR RINSE] Titan 130 75.7 – 94.6 liters (20-25 Gallons) 94.6 – 189.3 liters (25-50 Gallons) 11.4 to 13.6 liter/min (3 to 3.6 gpm) Mars 90/100 56.8 – 75.7 liters (15-20 Gallons) 75.7 – 151.4 liters (20-40 Gallons) 8.3 to 10.6 liter/min (2.2 to 2.8 gpm) Taurus 70 56.8 – 75.7 liters (15-20 Gallons) 75.7 – 151.4 liters (20-40 Gallons) 5.3 to 7.6 liter/min (1.4 to 2 gpm) Taurus 60 45.4 – 64.3 liters (12-17 Gallons) 64.4 – 128.7 liters (17-34 Gallons) 2.3 to 4.5 liter/min (0.6 to 1.2 gpm) Centaur 40/50 45.4 – 64.3 liters (12-17 Gallons) 64.4 – 128.7 liters (17-34 Gallons) 2.3 to 4.5 liter/min (0.6 to 1.2 gpm) Saturn 10/20 30.3 – 37.9 liters (8-10 Gallons) 37.9 – 75.7 liters (10-20 Gallons) 1.5 to 3.8 liter/min (0.4 to 1 gpm) Mercury 50 N/A N/A N/A

- 8. Specification No. ES 9-62 6 5.0 CLEANING PRODUCT 5.1 WATER - Water to be used for ingestive cleaning (or rinsing) of any Solar turbine engine shall comply with the requirements set forth in Table 4. Table 4. Requirements for Water Used in Ingestive Cleaning of Solar Engines Test Method Max. Limits for On-Crank Cleaning Max. Limits for On-Line Cleaning Sodium + Potassium ASTM D1428 105 ppmw 1.9 ppmw Fluorine 100 ppmw 1.9 ppmw Chlorine ASTM D512 100 ppmw 40 ppmw Lead ASTM D3559 2 ppmw 0.70 ppmw Vanadium ASTM D3373 2 ppmw 0.35 ppmw Iron, Tin, Silicon, Aluminum, Copper, Manganese, Phosphorus ASTM D857, D858, D1068, D1688 10 ppmw 3.8 ppmw Calcium + Magnesium ASTM D3605, D511 100 ppmw 3.8 ppmw Total Dissolved Solids ASTM D1888 350 ppmw 5 ppmw PH ASTM D 1293 6 - 9 6 - 9 5.2 CLEANING PRODUCT COMPOSITION AND PHYSICAL PROPERTIES – Composition and physical properties of cleaning products must comply with the limits defined in Table 5. Failure to comply with these limits can cause corrosive attack and/or other harmful effects resulting in rapid engine deterioration. When the cleaning product consists of a mixture of cleaning solution concentrate and water, the limits in Table 5 apply to the resulting cleaning product. Solar offers various cleaning solutions that that when properly mixed as a cleaning product, comply with both on-crank and on-line requirements of Table 5. These are available through the Solar Service Parts support network and part numbers are listed in Table 6. Three different types of cleaning solutions are available, each in either concentrate or ready mixed solutions: 5.2.1 Solar Gas Turbine Cleaner No. 1 – Petroleum solvent based solution is the most effective type for cleaning oil and Carbon based fouling. However, local environmental regulations may require special treatment of the waste from on-crank cleaning. Disposal is not typically a consideration for on-line cleaning because the cleaning product is combusted completely in the turbine. 5.2.2 Solar Gas Turbine Cleaner No. 2 - This biodegradable type of solution is formulated with natural solvents and detergents and is generally less effective than pretroleum based solution. Warming solution to approximately 30°C (86°F) and allowing longer soak time can improve effectiveness.

- 9. Specification No. ES 9-62 7 Table 5. Requirements for Cleaning Product Used in Ingestive Cleaning of Solar Engines Test Method Max. Limits for On-Crank Solutions Max. Limits for On-Line Solutions Sodium + Potassium ASTM D1428 105 ppmw 1.9 ppmw Fluorine 100 ppmw 1.9 ppmw Chlorine ASTM D512 100 ppmw 40 ppmw Lead ASTM D3559 2 ppmw 0.70 ppmw Vanadium ASTM D3373 2 ppmw 0.35 ppmw Iron, Tin, Silicon, Aluminum, Copper, Manganese, Phosphorus ASTM D857, D858, D1068, D1688 10 ppmw 3.8 ppmw Calcium + Magnesium ASTM D3605 ASTM D511 100 ppmw 3.8 ppmw Ash ASTM D482 0.25 wt. % 0.01 wt. % Flash Point ASTM D93 >140o F >140o F PH ASTM D 1293 6 - 9 6 - 9 Table 6. Solar Cleaning Solutions for On-Line and On-Crank Cleaning SOLAR PRODUCT NAME SOLAR P/N Maximum Strength Volume Ratio (Water:Cleaning Solution) P/N 701690C2 (6.5 gal)Solar Gas Turbine Cleaner No. 1 (Petroleum Solvent Based) Concentrate P/N 701691C2 (55 gal) 4:1 P/N 701696C2 (6.5 gal)Solar Gas Turbine Cleaner No. 1 (Petroleum Solvent Based) Ready-To-Use P/N 701697C2 (55 gal) Full Strength P/N 701688C2 (6.5 gal)Solar Gas Turbine Cleaner No. 2 (Natural Solvent Water Based) Concentrate P/N 701689C2 (55 gal) 4:1 P/N 701694C2 (6.5 gal)Solar Gas Turbine Cleaner No. 2 (Natural Solvent Water Based) Ready-To-Use P/N 701695C2 (55 gal) Full Strength P/N 1011634 (6.5 gal)Solar Gas Turbine Cleaner No. 3 (Non-Solvent Water Based) Concentrate P/N 1011635 (55 gal) 4:1 P/N 1011636 (6.5 gal)Solar Gas Turbine Cleaner No. 3 (Non-Solvent Water Based) Ready-To-Use P/N 1011637 (55 gal) Full Strength

- 10. Specification No. ES 9-62 8 5.2.3 Solar Gas Turbine Cleaner No. 3 – This biodegradable type of solution is formulated with natural detergents and is generally less effective than solutions containing solvents. Warming solution to approximately 30°C (86°F) and allowing longer soak time can improve effectiveness. 5.3 EMULSIFIED KEROSENE/WATER SOLUTIONS - An emulsified mixture of kerosene and water or diesel fuel and water may be used for on-crank cleaning only. This mixture is formulated by mixing diesel fuel per MIL-F-16884 and water per Table 3 with an emulsifier per MIL-D-16791 (Type II) such that a homogenous, sprayable solution is formed. The mixing ratio shall be according to that recommended by the emulsifier manufacturer, but limited such that the combined diesel/kerosene and emulsifier content does not exceed 10% by volume of the final mixture. 5.4 ABRASIVE CLEANING – Abrasive cleaners, such as Carboblast, walnut shells, pecan shells or rice, are not recommended for use in Solar’s gas turbines. Use of abrasive cleaners can cause plugging of cooling air passages in nozzles and blades, resulting in loss of cooling air and thermal degradation of the component. Abrasive cleaners may also have a detrimental effect on compressor coating.