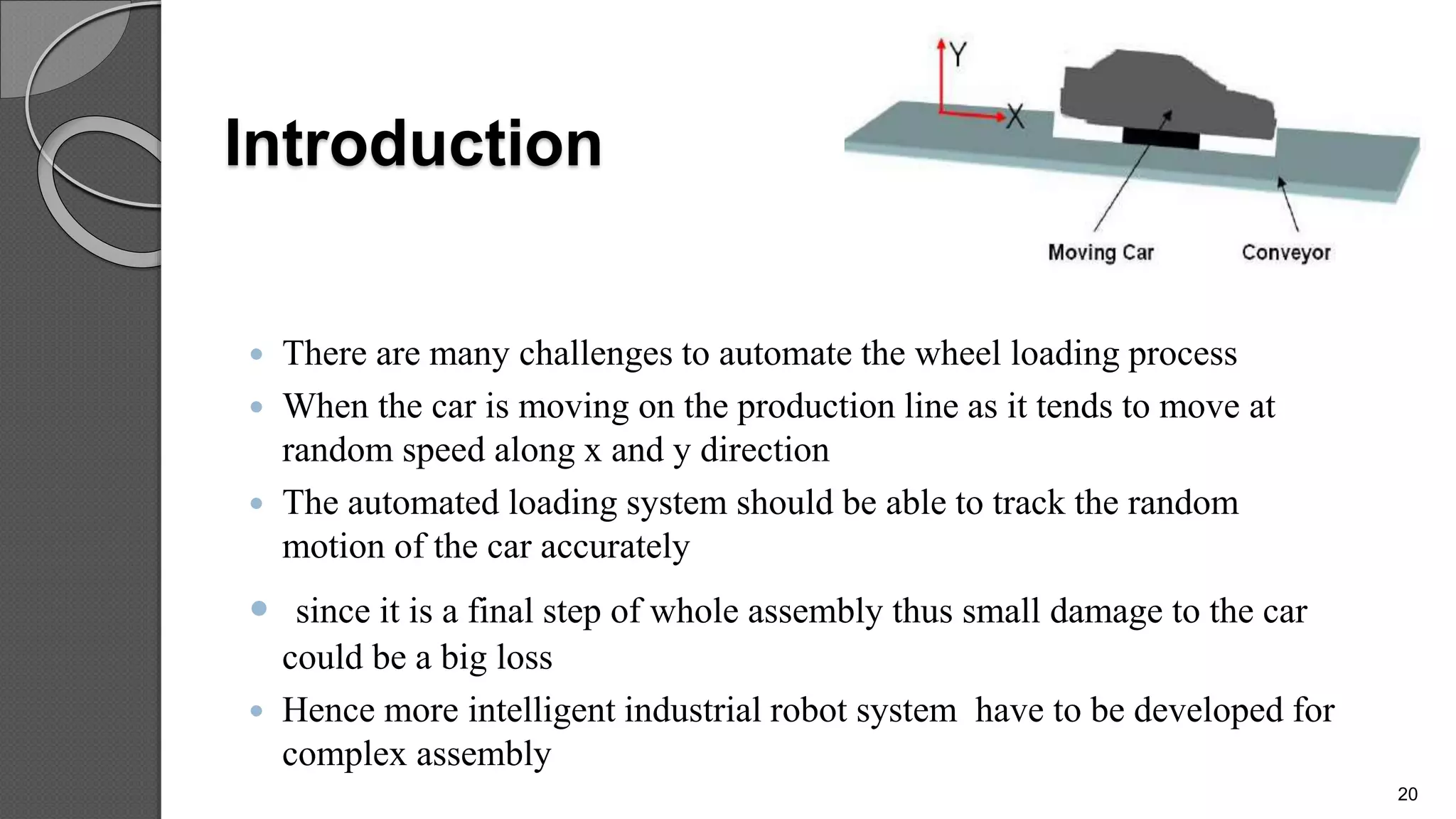

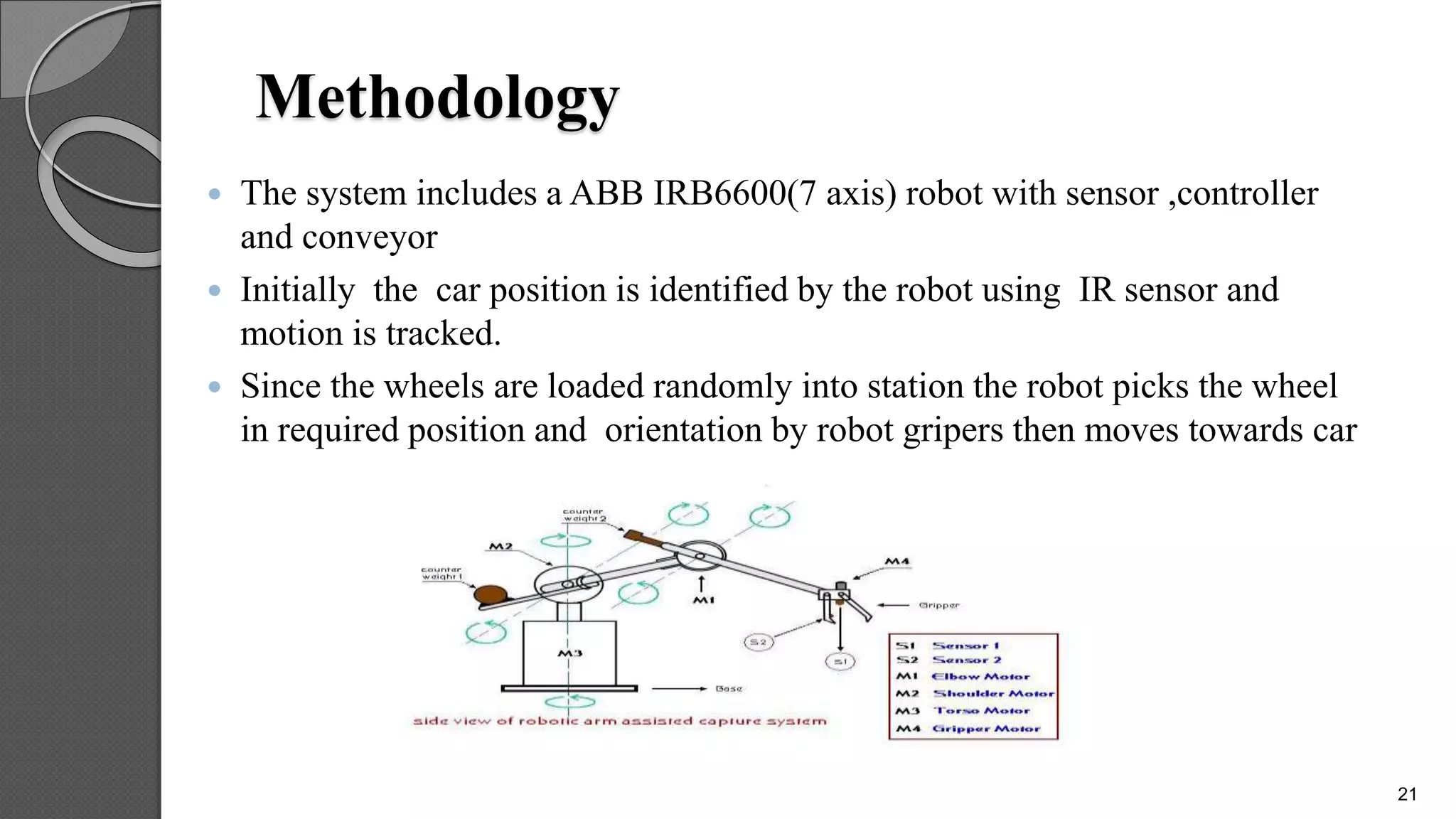

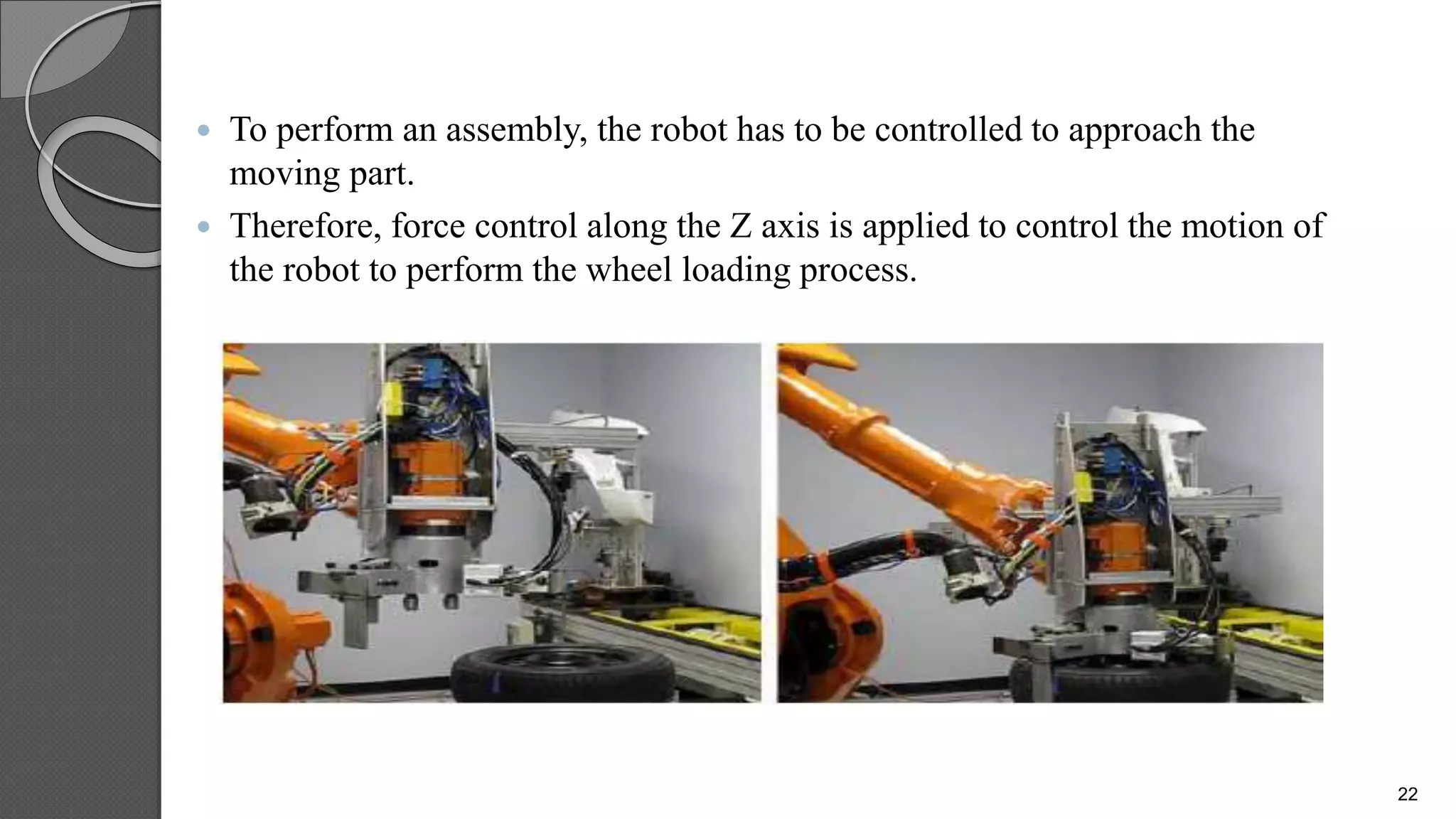

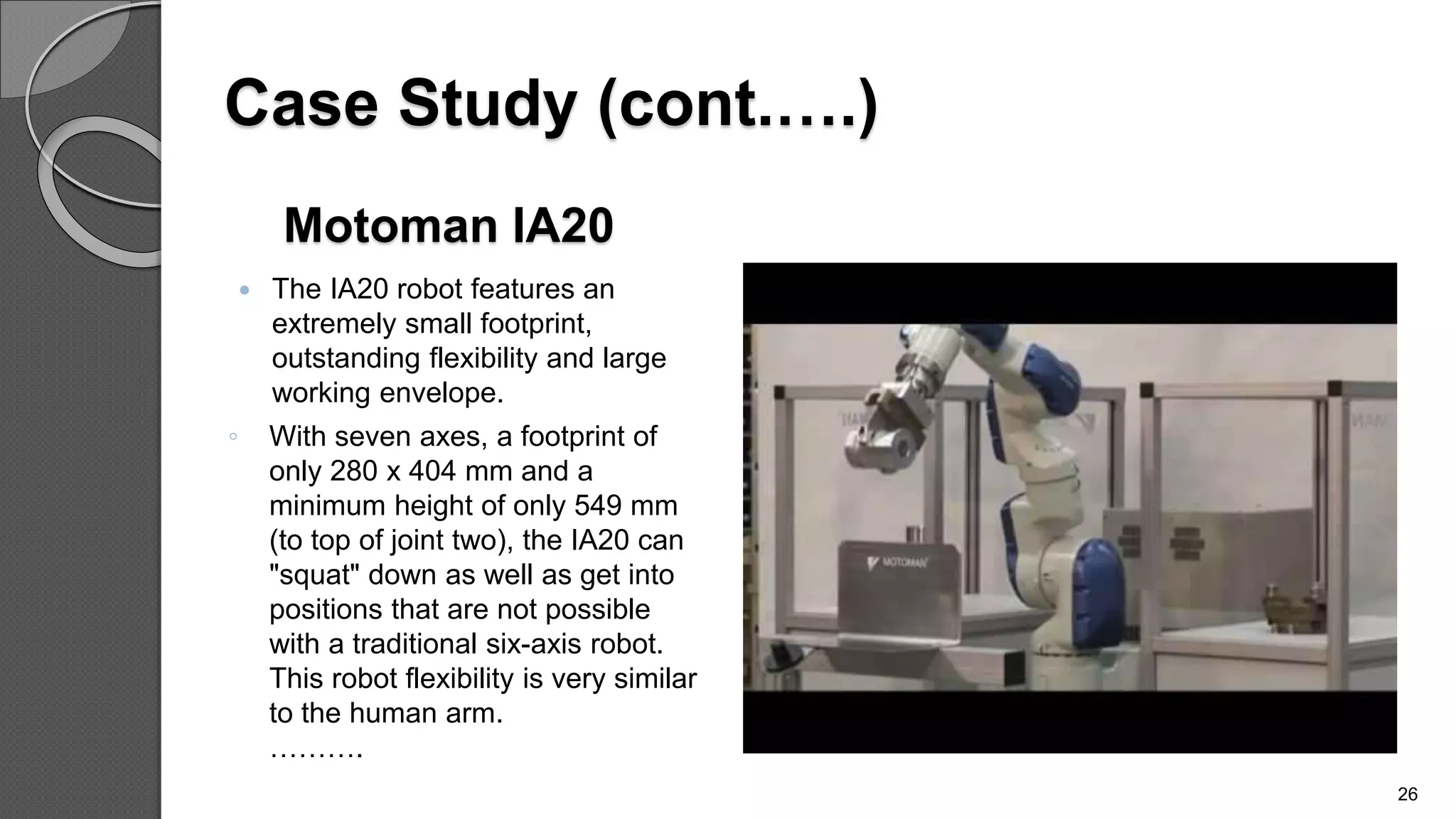

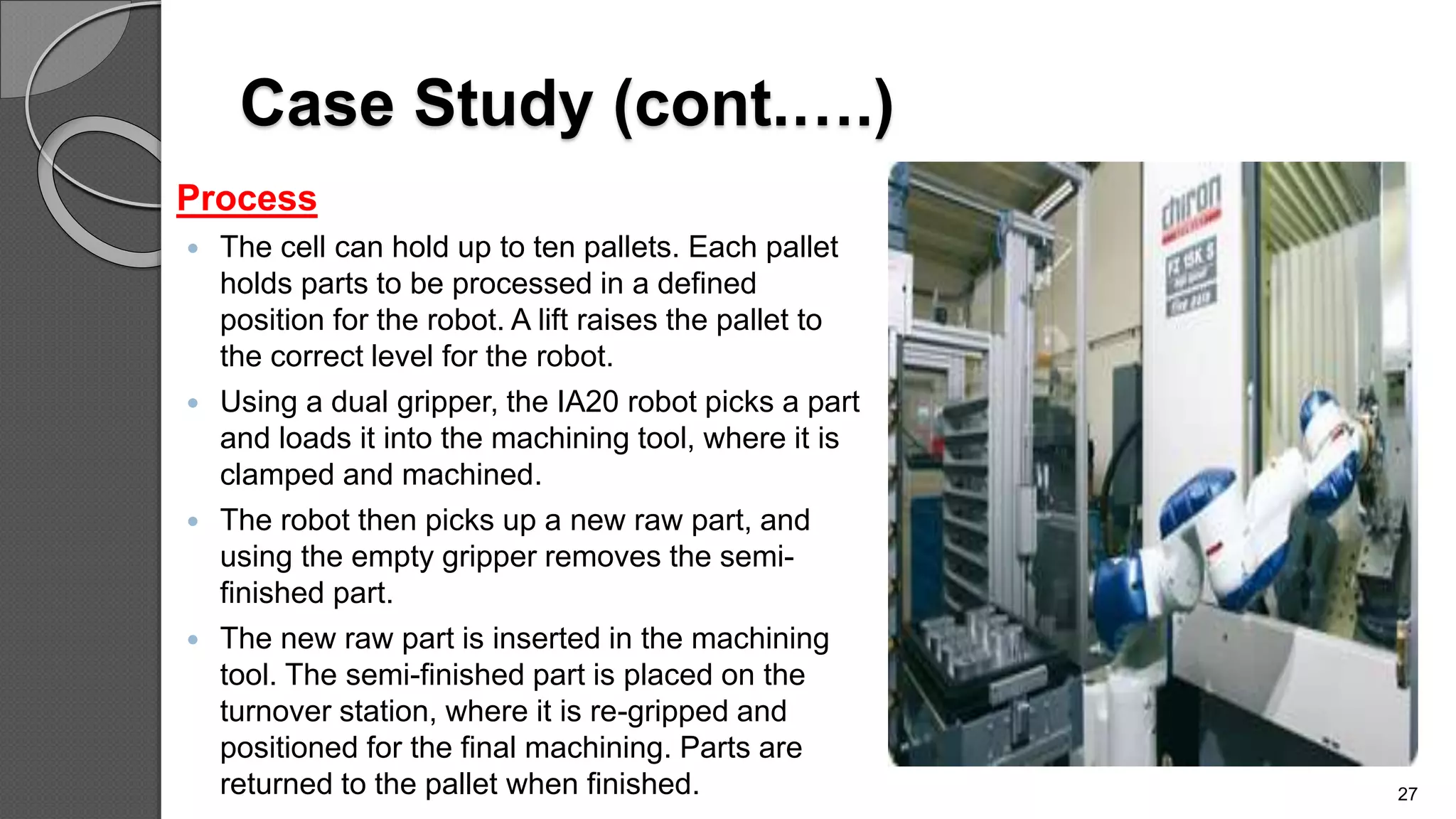

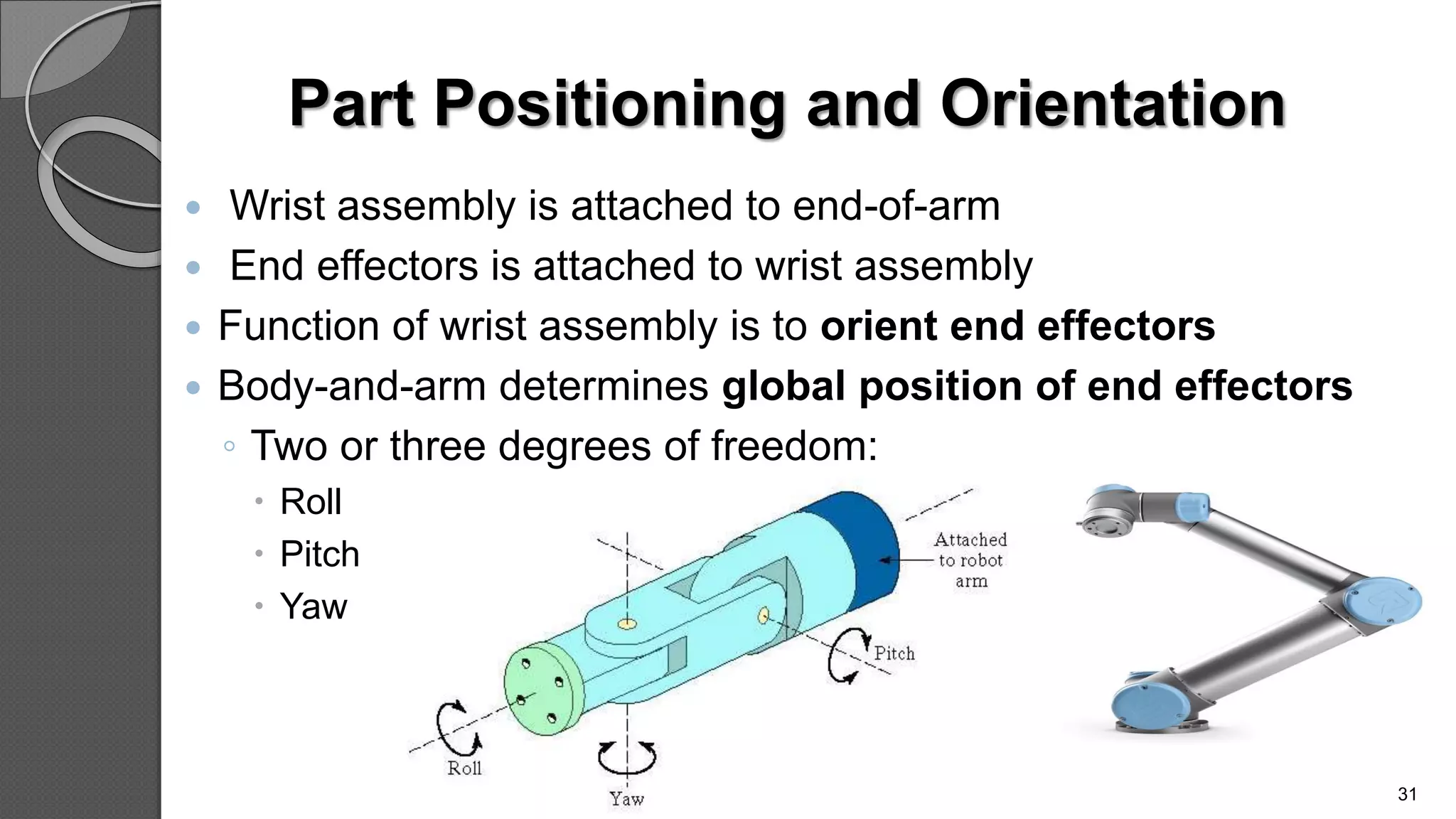

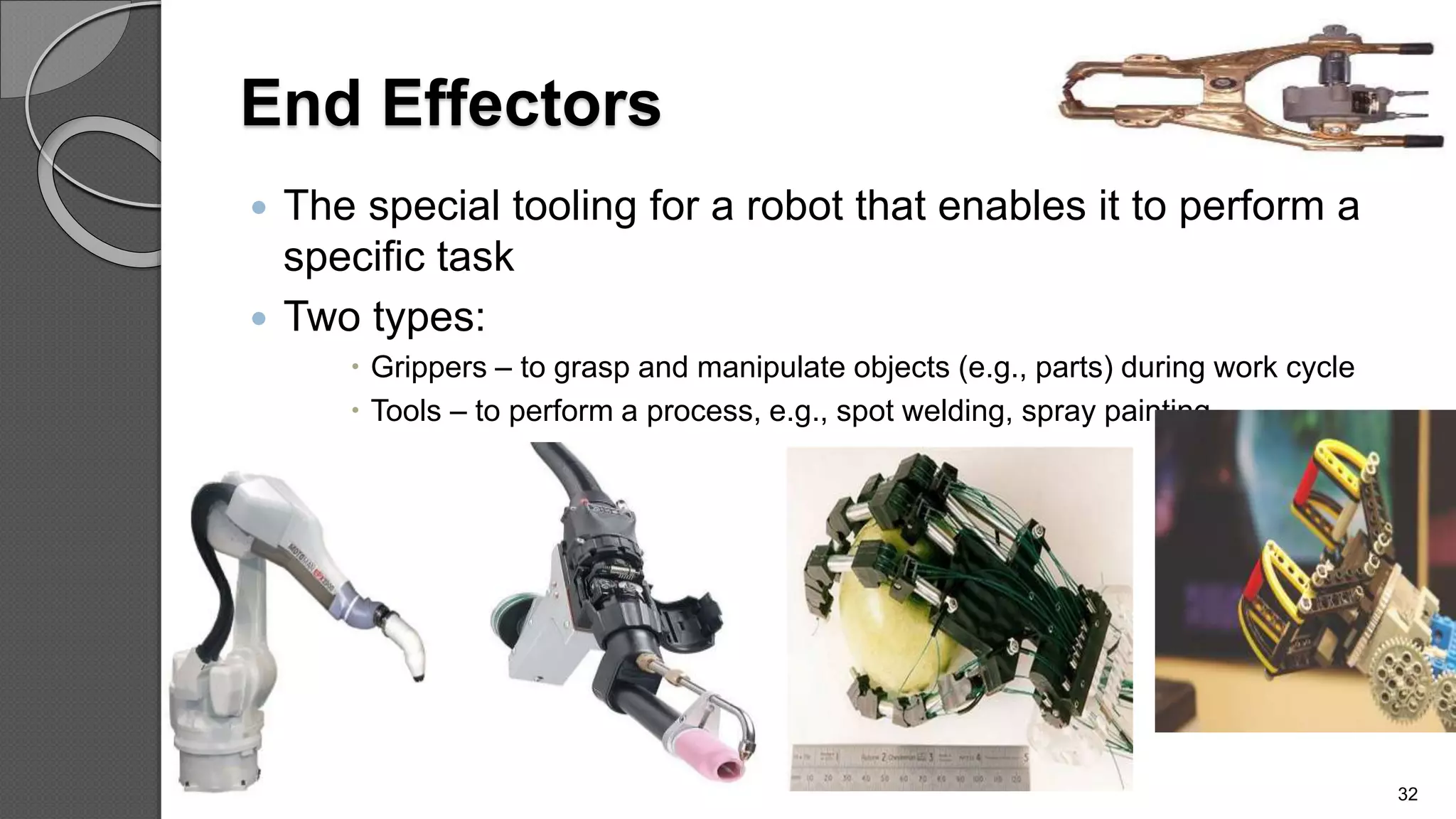

The document discusses the role and importance of material handling robots in industrial applications, highlighting their ability to automate tedious tasks, enhance production efficiency, and improve safety for workers. It reviews various types of robots, their applications in part transfer, packaging, and palletizing, along with case studies demonstrating their effectiveness in real-world settings. Moreover, it emphasizes technological advancements, such as improved end-of-arm tooling and vision systems, that enhance the capabilities and appeal of robotic automation in manufacturing.