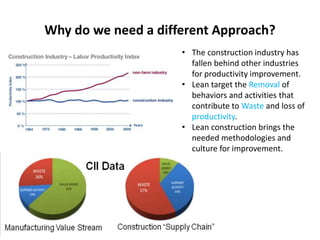

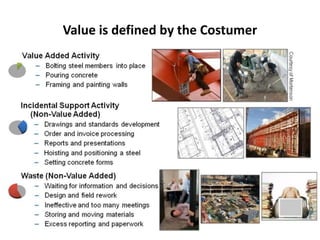

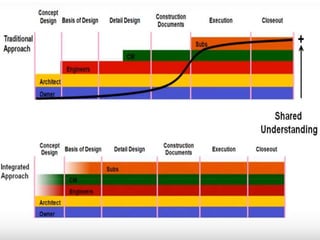

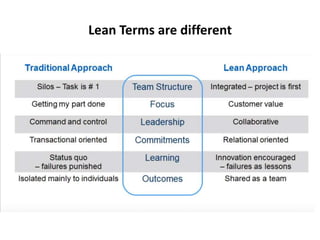

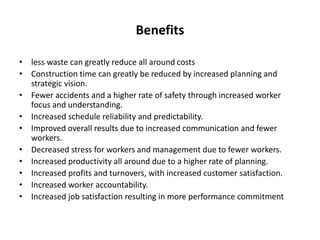

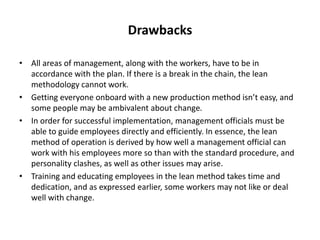

The document discusses lean construction as a methodology focused on minimizing waste and maximizing value in project delivery, particularly in the construction industry which has lagged in productivity improvements. It outlines the seven types of waste, benefits such as reduced costs and increased safety, as well as drawbacks like the need for cohesive teamwork and potential morale issues during implementation. It emphasizes the importance of effective management and communication with stakeholders to successfully adopt lean practices.