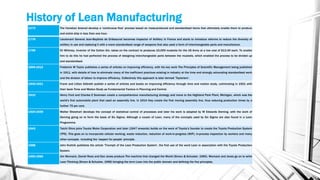

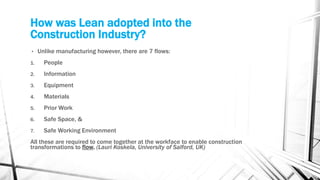

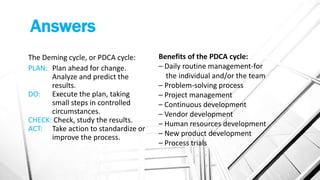

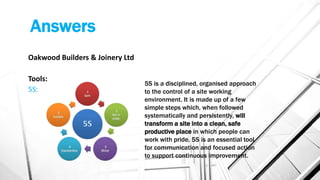

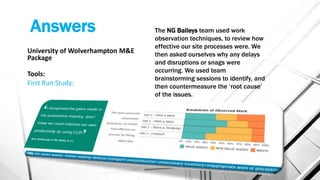

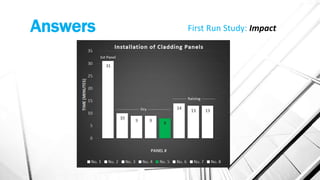

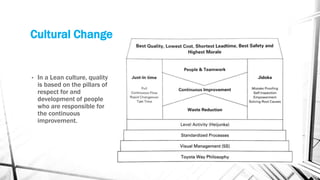

The document outlines the history and principles of lean thinking in construction, tracing its origins back to early standardized manufacturing processes and highlighting key developments in lean methodology over centuries. It emphasizes the importance of cultural change for successful lean implementation, reflecting on Toyota's principles and the need for a supportive management system. Furthermore, it discusses specific lean tools applicable to construction, such as the PDCA cycle and 5S, while noting that many attempts to adopt lean fail without a strong cultural foundation.