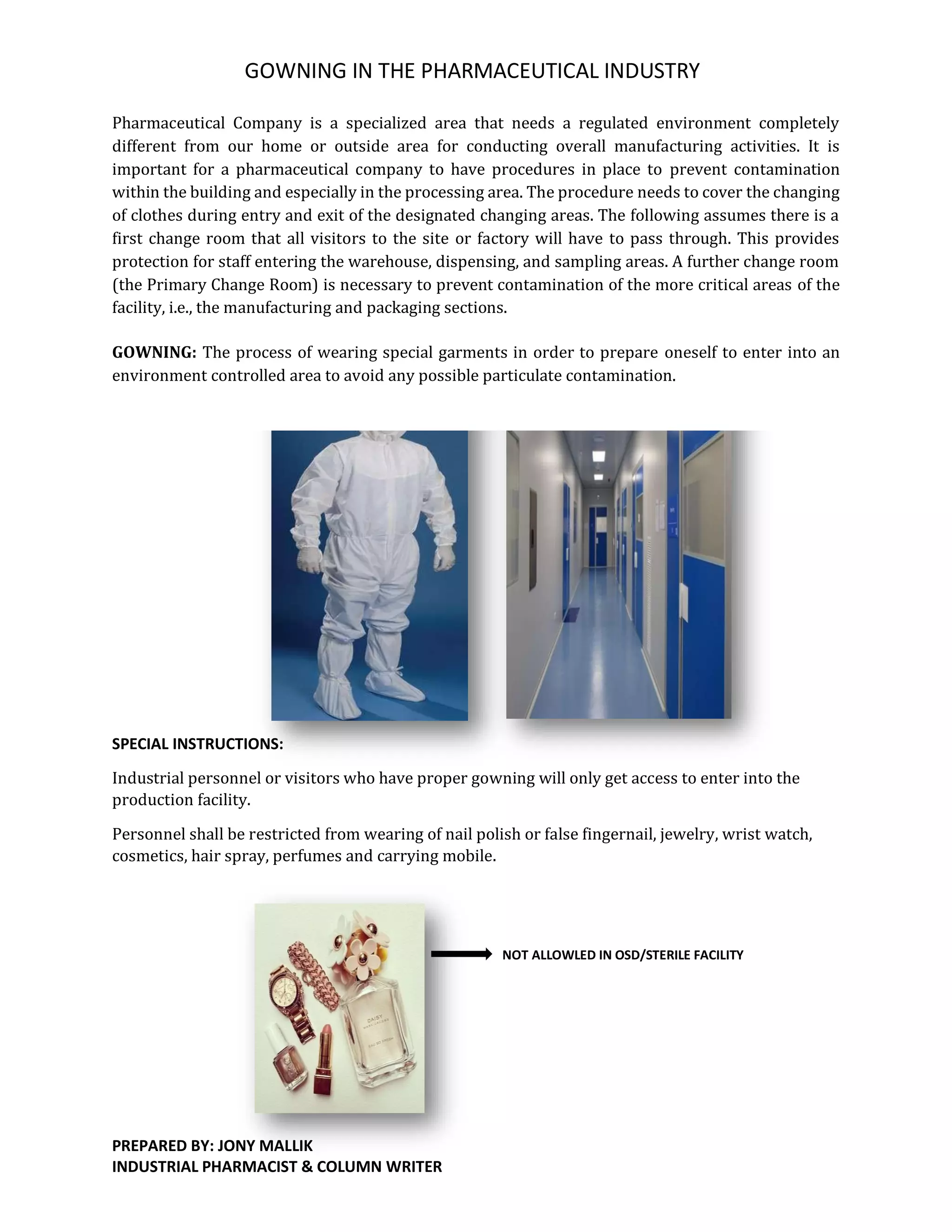

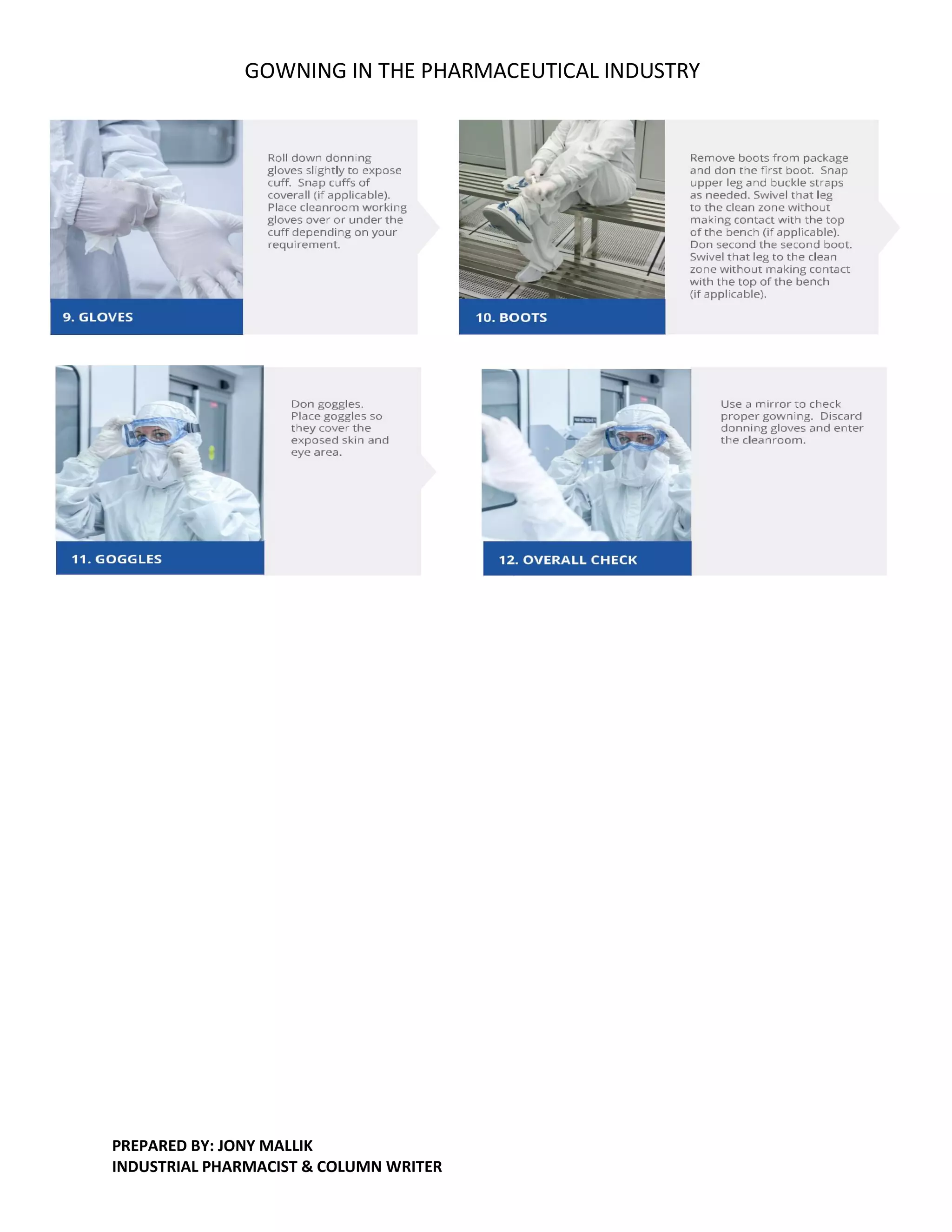

Gowning procedures in the pharmaceutical industry are important to prevent contamination. Special garments must be worn to enter controlled manufacturing areas. There are multiple change rooms with increasing restrictions. The first change room provides basic protective clothing for warehouse and sampling areas. The primary change room has a stricter protocol for manufacturing areas, including lint-free attire, shoe covers, and hand washing. Uniform colors are assigned by department to identify personnel. Strict hygiene practices are required both at home and at the facility for anyone entering production zones.