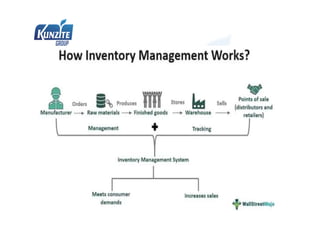

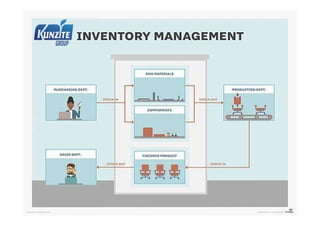

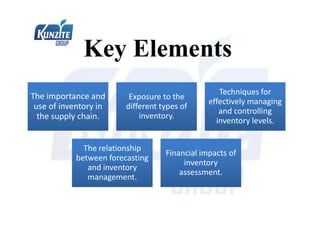

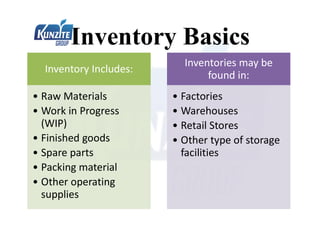

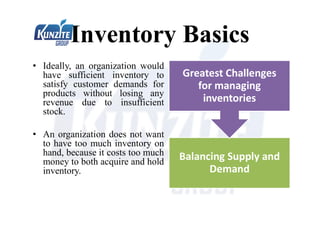

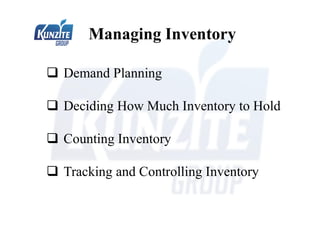

Inventory management refers to the process of ordering, storing, using, and selling a company's inventory, including raw materials, components, and finished products. It aims to have the right amount of inventory to meet customer needs without overinvesting, and involves demand planning, determining optimal inventory levels, inventory tracking and control, and periodic counting.