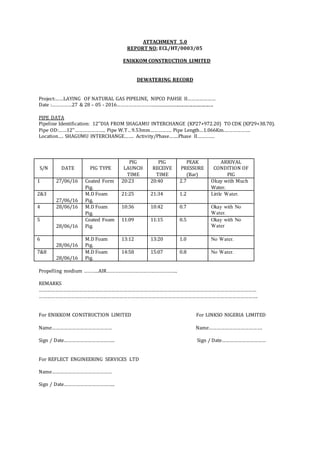

This hydro-test report summarizes the pressure testing of a 4" diameter and 158m long gas pipeline. Key details include:

- Water will be used to fill, flush, and pressure test the pipeline at 147 bar, which is 150% of the design pressure of 98 bar.

- Calculations are provided to determine the volume of water needed, expected back pressures, and pump requirements. Factors like elevation changes, pipe dimensions, and friction losses are accounted for.

- Test equipment will be calibrated and certified. Instruments will monitor and record pressure and temperature during the test.

- The pipeline will be isolated and prepared, then filled and pressure tested. Any leaks will be repaired before re-

![The pump required for the operation must be rated to 1.25 times the expected backpressure. Therefore the

expected discharge pressure for the pump is approximately.

1.25 * 10.19 bar ≈ 12.74 bar

The discharge pressure rating for the pump recommended for this operation must be able to discharge at

a pressure capacity well above 12.74 bars.

The pig speed in a normal pigging operation should be within 0.5 – 1m/s if we assume a maximum pig speed

of 1m/s for this operation the equivalent flow rate would be = 8997/1 = 8997 s =2.5h

Flow rate = 649.481/2.5 = 4.32m3 /mins = 4.32*6.289= 27.01 BPM (1m3 = 6.289 Barrel)

Compressed Air Design

The pig speed should be between 2 – 8km for normal pig runs and 2 -4km/h for gauging plate runs while

using compressed air as a medium to propel the pig,

By assuming an average pig speed of 4km/h the air flow required

= (649.48 / 8,997) * 4,000 = 289 m3/h = V1

The required driving pressure when the pipeline is full of water must

Total Driving pressure required ≈ 12.74 bar = P1

Total Back pressure = 10.5 = P2

Using equation = P1*V1 = P2*V2

V2 = ( P1*V1 ) / P2 = ( 12.74 X 289 ) / 10.5

V2 = 350.65 m3/h

@ 1 m3 = 35.315 CFM

Compressed air requirement = 350 x 35.315 = 12,383ft3/h = 207 CFM

To give allowance for error in calculation 1.25 time the required air will be used = 259CFM

Therefore, a 650 CFM @ 15 Bar compressor should be adequate for the project. To achieve an 8km/hr pigging

speed a second compressor would be added while a third would be on standby for in case of breakdown.

The pig delivery time at average speed of 4-8km/hr ≈ less dawn 2 – 4 hours

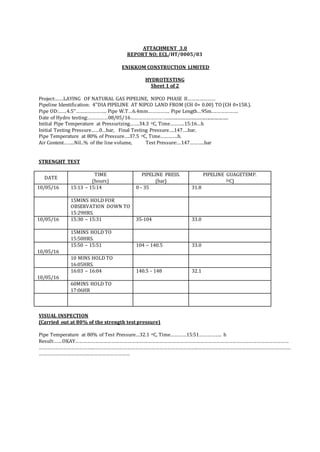

1. HYDROSTATIC TEST PUMP DESIGN

The pressurizing pump required should be suitable to pressurize the test section at approximately 1 bar per

minute. The volume required to inject to give 1bar pressure can be estimated using the theoretical equation

for volume change ∆V per Pressure change ∆P for pipeline with liquid under pressures at constant

temperature, disregarding effects of air absorption or free air in the line. The Pressure-volume relationship

considering elastic strain in the pipe and Compressibility of the water is calculated thus

∆𝑉 = (

𝐷

𝐸 ∗ 𝑡

∗ ( 1 − 𝛾2) +

1

𝐵

) ∗ ∆𝑃 ∗ 𝑉

DV/DP = V * [(D/ (E * t) (1 – v²) + C]

Where,

dV = incremental volume in the same units as V

dP = incremental pressure, bar = 1

V = volume of the segment 1 = 649.481m3

V = volume of segment 2 = 200.75m3

V = Volume of the Segment 2 = 200.75m3](https://image.slidesharecdn.com/9220ad6e-2906-47a0-a50a-9b051f8f9a93-160624171217/85/Hydrotest-REPORT-FOR-4-158m-Line-8-320.jpg)

![D = Outside diameter (m), = 0.314m

E = Elastic modulus of steel pipe (psi) = 2.07 x 10*6

t = Wall Thickness of pipe (m)= 0.0095m

v = passion’s ratio steel pipe = 0.3

C = Bulk compressibility factor of liquid, per psi (the reciprocal of the bulk modulus)=

46.7 x 10*-6 bar

DV/DP = V * [(D/ (E * t) (1 – v²) + C]

DV/1 = 649.481 [0.314 / (2.07x10*6) x 0.0095) (1-0.09) + 46.7 x 10*-6]

= 649.481 [0.314/(14697)(0.91) +46.7x10*-6]

= 649.481 [0.314/13374.27)

DV = 0.02m3/min

The test pump required for this project should be capable of pumping at approximately 0.3m3 per minute at

the required test pressure.

Theoretically pressurizing the system from zero to test pressure should be directly proportional to inject

volume as calculated above, due to the pipeline profile air entrapment is expected, careful estimation of the

air entrapment would be carried out and fillingprocess would be done with high sealing pig to reduce air

entrapment in the test system.

Pipe Drying

Most of the data uses for this estimate are theoretical but in the final analysis allowance would be given for

practical field situation.

The air dew point inside the pipeline is assumed to be the same as pipe wall temperature at 15degree C

therefore, the moisture content of the air estimated on I-X graph = Xm = 12.8 g/m3.

Dry air system temperature at Outlet (-30 degrees Centigrade dew point) Xout = 0.33 g/m3

The system flow rate Vr is design for 1180 m3/h (expected compressed air capacity equivalent to what air

dryer can handle @ required departing pressure of 0.5 – 1bar pigging pressure)

N.B – The capacity can be adjusted on the field depending on field criteria and client interest)

The moisture removal capacity of the dry air system Vm =

Vm = Vr (Xm-Xout) /1000

Vm = 1180 (12.8-0.33)/1000 = 14.72 kg/h

The expected remaining water in the pipeline after successful dewatering, assuming a water film of 0.1 mm.

Remaining water = W= 3.14/4(D12-D22)*L*1000

W = 3.14/4(0.3142- 0.2952)* 8.997*1000 = kg water

=0.00908 x 8997

= 82 kg of water

The total drying time for this project T:

T = W/Vm

T = 82 / 61.85 = 5.57 hours](https://image.slidesharecdn.com/9220ad6e-2906-47a0-a50a-9b051f8f9a93-160624171217/85/Hydrotest-REPORT-FOR-4-158m-Line-9-320.jpg)