27 Hydrostatic Pressure Testing inside buildings Risk Assessment Templates.docx

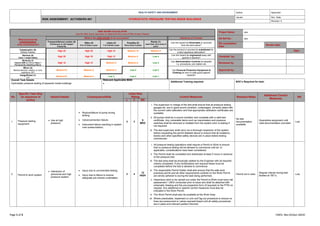

- 1. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 HYDROSTATIC PRESSURE TESTING INSIDE BUILDINGS Issued: Rev. Date: Revision: 0 Page 1 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 1 Pressure testing equipment Use at high pressure; Rupture/failure of pump during testing; Valve/connection failure; Instrument failure resulting in system over-pressurization; 3 3 9 MED i. The supervisor in charge of the test shall ensure that all pressure testing gauges etc. are in good sound condition, undamaged, correctly dated with the current valid calibration and that appropriate calibration certificates are available; ii. All pumps shall be in sound condition and complete with a valid test certificate. Any vulnerable items such as manometers and pressure switches shall be removed or isolated from the system prior to testing if not required; iii. The test supervisor shall carry out a thorough inspection of the system before requesting the permit detailed above to ensure that all isolations, blanks and other specified safety devices are in place before testing commences; No test documentation available Quarantine equipment until valid documentation provided Low 2 Permit to work system Interaction of personnel and high pressure system; Injury due to uncontrolled testing; Injury due to failure to ensure adequate pre-checks undertaken; 3 4 12 HIGH i. All pressure testing operations shall require a Permit to Work to ensure that no pressure testing will be allowed to commence until all, or applicable, considerations have been considered; ii. The Permit shall be completed and distributed at least 2 hours in advance of the pressure test. iii. The test area shall be physically walked by the Engineer with all required checks completed. If any rectifications are required these must be completed before the test is allowed to commence. iv. The responsible Permit Holder shall also ensure that the safe work practices permit and all other requirements outlined on the Work Permit are strictly adhered to during the task being performed. v. Hazardous work to be carried out under the Permit to Work must have risk assessment / JSEA conducted prior to issue and shall be attached with schematic drawing and the pre-inspection form (if required) to the PTW on request. Any additional or specific control measures must also be indicated in the Work Permit. vi. The Work Permit shall also be available at the Work Area; vii. Where practicable, implement a Lock out/Tag out procedure to ensure no lines are pressurized or valves opened/closed until all safety procedures are in place and relevant parties informed. Permit not in area Regular checks during test. Briefed at TBT’s; Low Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Hydrostatic pressure testing of pipework inside buildings Relevant Applicable MAS: Additional Training required: NOC’s Required for task: RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1

- 2. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 HYDROSTATIC PRESSURE TESTING INSIDE BUILDINGS Issued: Rev. Date: Revision: 0 Page 2 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR 3 Establishing exclusion zones Personnel in area Unauthorized access to test area; Workers struck by flying materials; Worker struck by High pressure water release; 3 4 12 HIGH i. The establishment of an exclusion zone(s), (this zone shall be dependent on the positioning, pressure, test zone and personnel in adjacent area) from the pressure source, around the test area shall be undertaken; ii. Simple barrier tape is not an adequate control of any area where personnel are present and shall only be used on doorways etc., if a sentry is to be present at all times to control access; iii. If practicable, the area may be securely closed off using plywood, handrail or similar to prevent unauthorized access. The board/rails shall be securely fixed with suitable signage attached; iv. Any doors shall, if practicable, be locked with keys retained by the permit holder; v. In areas where other contractors are working or other exposed areas, the use of sentries shall be considered to prevent access, however this shall be determined by the locality and nature of the test. The sentries shall be instructed as to emergency contact details etc. and shall remain in position for the duration of the test; vi. All flange and valve connections, blank ends or clip connections etc. shall be zoned off as a matter of general good practice; vii. All drain or vent points must be fitted with a blanking plug. Any other areas shall be secured as applicable; viii. Under no circumstances will any persons be allowed within safety barriers during pressure testing. Unable to secure area during normal working hours Test undertaken out of normal work shift timings, weekends etc. Low 4 Signage to test area Personnel in area Unauthorized access to test area; Inadequate signage to test area; 3 4 12 HIGH i. The exclusion zone shall be clearly marked with suitable signage, including ‘Warning – Pressure Test’, and emergency contact details; ii. Signs will be of adequate size and in languages as applicable (minimum English and Arabic) and shall include the test date; iii. Simple paper signs are not to be used, as these can blow away or torn off. Signs shall be fixed onto hard backing and secured to handrails etc.; iv. On completion of the test all signage shall be removed to prevent confusion. Workers not understanding signage Communicated at Induction Low 5 Pressure testing High pressure to pipework; Uncontrolled Stored Energy release; Rupture/failure in Pipe lines during testing; Valve/connection failure; Instrument failure resulting in system over-pressurization; End caps/plugs ejecting under high pressure; Weld/seal/fitting failure, flying objects; High pressure water/air injection. 3 4 12 HIGH i. The initial pressurizing of a system has the potentially highest risk of failure and sudden release of pressure, possibly resulting in serious injury; ii. High pressure testing on systems shall be reached in clearly defined and controlled stages; iii. If required as part of the design, on completion of each stage and after a period of stabilization an inspection of the test area shall be completed by the responsible person and his team, checking for leaks etc.; iv. All pressure test details shall be recorded throughout the entire test schedule; v. The personnel carrying out the test must be provided with a safe place from which the progress of the test can be observed and controlled; Low 6 Emergency procedures High pressure to pipework; Emergency procedures not briefed to task workers; Poor response in the event of an emergency; 3 4 12 HIGH Emergency procedures shall be developed for the pressure test, to be specific to the area/zone. These shall include: i. Emergency Contact details; ii. Persons responsible for shutting down the system; iii. Actions to be taken in an emergency, escape routes; iv. Means of communication between parties; v. First aid response; Low

- 3. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 HYDROSTATIC PRESSURE TESTING INSIDE BUILDINGS Issued: Rev. Date: Revision: 0 Page 3 of 3 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR L C RR These will communicated to all personnel involved in the tests. 7 Re-testing in the event of failure Re-testing with high pressure Injury due to uncontrolled testing; Worker injury due to working on pressurized system; Injury due to failure to ensure adequate pre-checks undertaken; 3 4 12 HIGH i. If on pressurization any leaks are found in the system, the system shall be depressurized and leaks repaired as required. ii. Under no circumstances will personnel work on any pressurized systems unless the leaking section can be successfully isolated by valves and can be depressurized safely; iii. A valve lock out/tag out system shall be adopted in these circumstances on the closed valves to prevent unauthorized opening; iv. No unauthorized personnel will be allowed in any test area until depressurization is complete. Only when leaks have been repaired and control checks undertaken will the system be re-pressurized following the same procedure as previous; v. After full pressure has been achieved another inspection is to be completed; vi. If the leak was due to a weld failure or a fixing/valve failure then the causation must be determined and other welds/fixings/valves with possible similar defects investigated before a retest is undertaken; Low