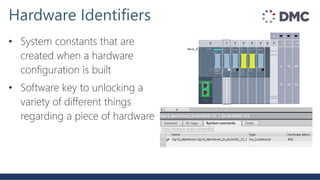

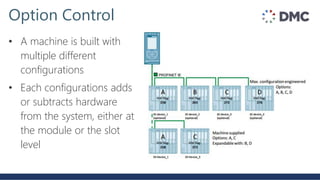

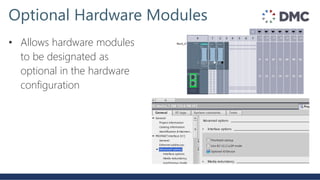

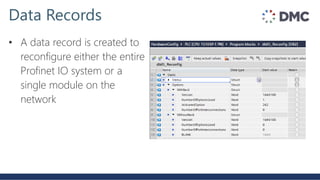

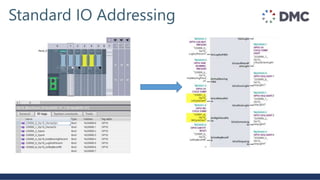

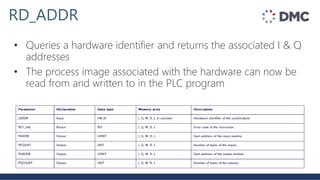

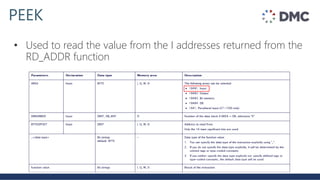

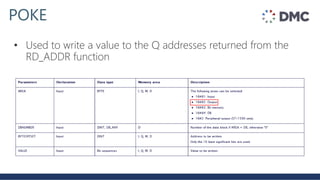

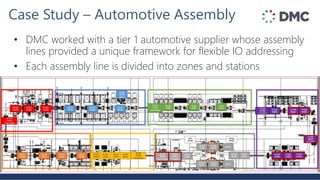

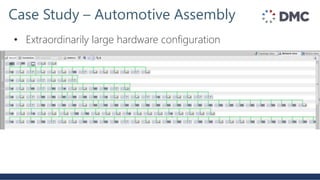

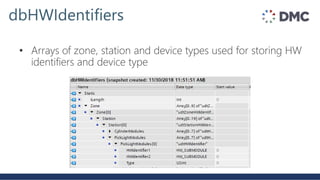

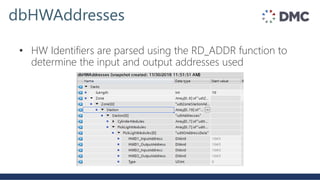

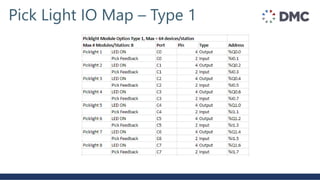

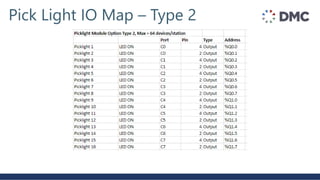

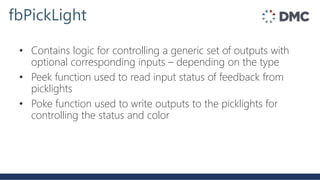

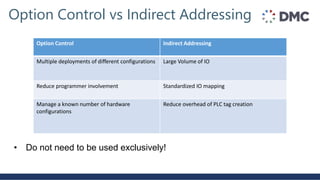

The document discusses the concepts of flexibility and standardization in I/O addressing and option handling, highlighting the challenges of managing diverse hardware configurations and large volumes of I/O. It presents dynamic I/O addressing and option control as solutions to simplify programming and improve efficiency, illustrated by a case study in an automotive assembly context. The insights emphasize the benefits of indirect addressing and standardized wiring schemes to enhance system manageability and reduce programming errors.