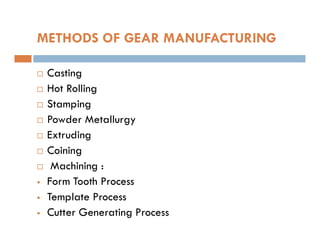

Methods of gear manufacturing

- 1. METHODS OF GEAR MANUFACTURING Casting Hot Rolling Stamping Powder Metallurgy Powder Metallurgy Extruding Coining Machining : Form Tooth Process Template Process Cutter Generating Process

- 2. Gear manufacturing by CASTING Gears are CAST in sand moulds, parmanent moulds, shell moulds, plastic mould dies, and lost–wax moulds. The characteristics of Gears produced by CASING The characteristics of Gears produced by CASING are same as those of other products made by these processes. Sand casting is particularly used for making heavy Gears of Cast Iron and Steel.

- 3. Gears manufacturing by Hot Rolling Gears are made by forcing a ‘Master Gear’ into a Hot Blank and the two are then rolled together until the teeth of the Master have penetrated far enough to ‘form’ a complete Gear. to ‘form’ a complete Gear. The Teeth are then Machined. Hot rolling is little used in present, but can be used as a method of Gear manufacturing in future.

- 4. Gear manufacturing by STAMPING Stamped Gears are made from sheet metals. Materials upto 3 mm thickness are practically used for this process. The Gears manufactured by ‘stamping process’ The Gears manufactured by ‘stamping process’ may be Shaved to improve the accuracy and finish. Gears manufactured by ‘Stamping’ are used in watches, clocks, toys and house – hold gadgets.

- 5. Gear manufacturing by POWDER METALLURGY In this process, a ‘Master Gear’ of ‘hard material’ is rolled against a ‘heated Gear-Blank’, thereby forming the teeth on the Hot Blank. Bakelite and other plastic materials are the most commonly used materials for manufacturing of Gears by this method.

- 6. Gear manufacturing by EXTRUDING In this process, the brass or aluminium bar is extended through several block dies with the final die having the shape of the desired tooth elements and thus the material can finally be EXTRUDED to obtain gear form on its surfaces, and the extruded bar is then hack- on its surfaces, and the extruded bar is then hack- sawed. At present only the Spur Gear is manufactured by this process. As the material is displaced by pressure, the outside surface of the material is quite hard and smooth.

- 7. Gear manufacturing by COINING Gears are coined from ‘blanks’ in a hydraulic press or forging hammer. Gears manufactured by this process require a light Gears manufactured by this process require a light machining.

- 8. Gear manufacturing by MACHINING Gears are machined from the blanks usually by a roughing and a finishing operation. Gear Machining Process: In Milling machine Gear Machining Process: Formed Tooth Process Templete Process Generating Process In Milling machine In Broaching machine In Shaper (Pinon and Rack) Shaving HOB Cutter process Rotary cutter process Reciprocating process

- 9. Gear manufacturing by : FORMED TOOTH PROCESS FORMED TOOTH PROCESS : The theory of FORMED TOOTH process is based upon forming the cutter tooth according to the shape of the tooth space to be removed. In Milling machine In Broaching machine In Shaper (Pinon and Rack type) tooth according to the shape of the tooth space to be removed. Theoretically, there should be different shaped cutter for each size of gear of given pitch, as there is a slight change in the curvature of the Involute. However, one cutter can be used for several gears having different number of teeth without much sacrifice in their operating action. Commercially, each pitch cutter is made in slightly varying shapes to compensate for this change. The forming operation can be performed in three ways i.e. MILLING, BROACHING and SHAPPING.

- 10. Gear manufacturing by : MILLING Gear manufacturing by MILLING The formed milling operations are usually employed for cutting Spur Gear, but these can be employed for cutting every type of gear by using a Universal Indexing mechanism. The cutter is mounted on the spindle in both horizontal and vertical The cutter is mounted on the spindle in both horizontal and vertical milling machines and rotates while the work is mounted on the table and reciprocated under the cutter. Once the cutter finishes tooth profile, the work is indexed to the next position, and again the tooth profile is finished and so on. Gear MILLING process is employed for course pitch gears, racks of all pitches, segment gears, worms and toothed parts as sprockets and ratchets.

- 11. Gear manufacturing by MILLING Gear manufacturing by MILLING

- 12. Gear manufacturing by MILLING All types of Gears i.e. Spur, Helical, Worm, Bevel etc can be cut. It can be employed both for roughing and finishing operations, and fine surface finish can be obtained. Cutter No. No. of Teeth 1 135 teeth to a rack 2 55 to 134 ADVANTAGES OF MILLING IN MANUFACTURING GEAR operations, and fine surface finish can be obtained. The initial cost of the cutters is low compared to other types of Gears. It can be used to machine almost any tooth form and usually confined to producing replacement gears or small lot production, roughing and finishing coarse pitch gears and finish milling fine pitch gears having special tooth forms. It is necessary to have a tool with a special profile for milling each gear with a different number and module as shown in the table. 2 55 to 134 teeth 3 35 to 54 teeth 4 26 to 34 teeth 5 21 to 25 teeth 6 17 to 20 teeth 7 14 to 16 teeth 8 12 to 13 teeth

- 13. Gear manufacturing by BROACHING Gear manufacturing by BROACHING The formed tooth principle can be utilized in a Broaching Machine by making the broach tool, conforming to the Tooth space. In this process, full form finished gears are produced in one pass by circular broach having inward facing teeth. The broaching tool consists of a series of full – form finishing rings The broaching tool consists of a series of full – form finishing rings at the end of a series of generating ring. It is important that adequate chip space be provided and provision be made of staggered chip breakers on successive broach teeth. This process has limited application, because of high initial cost of tooling and is only used where mass production technique is to be applied. It is usually used to produce only for Internal Spur and Helical Gears, though broaching process can be used for external gears also.

- 14. Gear manufacturing by MACHINING SHEAR CUTTING OF GEARS It utilizes a cutter made from tool blades so shaped that the gap between these blades forms the desired gear teeth shape. It is an operation very similar to Broaching. It cuts all teeth of external Spur forms simultaneously at a high rate of It cuts all teeth of external Spur forms simultaneously at a high rate of production. It is possible to form-cut involute Spur Gear teeth with practically any required tooth modification. Even unsymmetical or unequally spaced spur-tooth forms can be cut. The cutting tools are easily removed for sharpening and are sharpened all at one time on a surface grinder. The process of Shear Cutting of Gears is limited to only coarse-pitch gears having spur teeth.

- 15. Gear manufacturing by TEMPLATE PROCESS Gear manufacturing by TEMPLETE PROCESS In this process, the form of the tooth is controlled by a template which guides and reciprocates. The tool is similar to a side cutting tool and is given a reciprocating motion in the process of cutting. The machine used is called Gear Planner. The machine used is called Gear Planner. The frame of Gear Planner carries the reciprocating tool and is guided at one end by a roller acting against the ‘template’, while the other end is pivoted at a fixed point. Three sets of templete are used, one for roughing cut, and one for finishing each side of tooth space. The ‘Gear blank’ is held stationary during the process and is moved only when indexed.

- 16. Gear manufacturing by GENERATING PROCESS Gear manufacturing by In cutting Gears by using ‘generating’ type of machine, the gear teeth are formed as a result of certain relative motions between ‘Gear blank’ and ‘cutter’, instead of simply reproducing the shape of a formed cutter. A generating process is capable of enabling a cutter of a given pitch to cut Gears having different numbers of teeth to the correct shape. Gears having different numbers of teeth to the correct shape. ‘Gear cutter Generating’ process is based on the face that any two involute gears of same pitch will mesh together. Hence, if one ‘Gear’ is made to act as a ‘Cutter’ and is given a reciprocating motion, as in shaper, it will be capable of cutting of cutting into the Gear blank and Generating conjugate teeth forms. GEAR GENERATING principle is applied in three ways: 1. With PLANNING PROCESS using INVOLUTE RACK CUTTER 2. With HOB CUTTERS 3. In GEAR SHAPPERS in which both reciprocating as well as rotating cutting principle are applied.

- 17. GEAR PLANING In GEAR PLANNING process, the cutter consists of true Involute rack which ‘reciprocates’ across the ‘face of the blank’ and the ‘blank’ ‘rotates’ in the correct relationship to the longitudinal movement of the cutter as if both roll together as ‘ rack and pinion’. Initially the cutter is fed into full tooth depth with ‘cutter’ reciprocating and ‘blank’ stationary. ‘blank’ stationary. ‘Involute shape’ is generated as the ‘blank’ rotates and involute ‘rack cutter’ feeds longitudinally. After completion of one or two teeth, the blank and cutter ‘stop feeding’ and the cutter is withdrawn and indexed back to its starting position. Cutter is again 'fed back to depth’ and the cycle is repeated. Number of teeth is controlled by the machine gearing, and pitch and pressure angle by the rack cutter. This method is used for the generation of ‘external spur gears’, being ideally suited for cutting large, double helical gears.

- 18. GEAR PLANING

- 19. GEAR PLANING

- 20. GEAR HOBBING Hobbing is a process of generating a Gear by means of a ‘rotating cutter’ called a HOB. It is a continuous indexing process in which both the cutting tool and workpiece rotate in a constant relationship, while the HOB is being fed into the WORK. A HOB resembles a ‘Worm’, with gashes made parallel to its axis to provide cutting edges. For Involute gears, the hob has essentially straight sides at a given pressure angle. For Involute gears, the hob has essentially straight sides at a given pressure angle. The faces of the Hob teeth are relieved radially to form clearance behind the cutting edge. The Hob is fed into the Gear blank to the proper depth and the two are rotated together as if in ‘mesh’. The ‘teeth of Hob’ cut into the ‘workpiece’ in successive order and each in a slightly different position. Each Hob tooth cuts its own profile depending on the shape of the cutter. One rotation of ‘cutter’ completes the cutting upto certain depth upto which the HOB is fed.

- 21. GEAR CUTTERS : HOBS HOBS

- 22. GEAR HOBBING The Gear cutting with a HOB involves three basic motions, all of them occurring at a time. The HOB and the BLANK have a rotating motion and the third one is the radial advancement for the HOB , thus causing the cutting and indexing simultaneously. HOB cutter may set with its teeth parallel to the axis of the ‘Gear Blank’ when HOB cutter may set with its teeth parallel to the axis of the ‘Gear Blank’ when Spur Gear is cut. If Helical Gear are to be cut, the axis of the HOB can be set at an angle to the helix.

- 24. GEAR HOBBING

- 25. GEAR HOBBING

- 26. Comparison of Gear HOBBING and Gear MILLING Gear Hobbing is faster than milling because several teeth are cut at a time and because of the continuous meshing process. Milling requires that the cutter and work disengage before indexing can occur. The milling machine can cut only one tooth at a time, while the Hob operates on several teeth at a time.

- 27. Characteristics, Merits and Limitations of HOBBING Any external tooth form which is uniformly spaced about the centre, so that all the teeth are identical, can be hobbed using suitable hob. One hob of a particular module can be used to cut teeth of all involute Spur and Helical Gears of any number of teeth of same module and pressure angle. It is thus a versatile process and can be used to cover a variety of work like Spur, Helical, Worm, Splines and a variety of special forms. Helical, Worm, Splines and a variety of special forms. Accuracy of Gears produced by Hobbing is dependent upon the accuracy of machine, hob , and the blank, care in mounting work and Hob, and rigidity of the tooling. The indexing is continuous and there is no intermittent motion to give rise to errors. There is no loss of time due to non-cutting on the return stroke. Finish is dependent on the amount of feed and upon the accuracy of Hob and rigidity of Tooling also. It can’t be used to cut bevel and internal geras and for Gears having adjacent shoulders larger than the root diameter of Gear and close enough to restrict the approach or runout of the Hob.

- 28. Gear manufacturing by SHAPING Gear manufacturing by SHAPING In Gear Shapers, the above Generating Principle is applied in the following way: The Cutter is hardened disc shaped and slightly dished at the bottom (ground with top rake and clearance) to facilitate cutting. The teeth have desired tooth profile and pressure angle. The cutter is reciprocated with the required cutting speed for stock removal along the The cutter is reciprocated with the required cutting speed for stock removal along the face of the workpiece, and is gradually fed radially to plunge if for correct ‘teeth depth’ by means of a Cam. A relieving mechanism enables the cutter to clear the work on noncutting or return stroke. The continuous generation motion is obtained by feeding ‘cutter’ to full depth and rotating the cutter and the workpiece slowly in the exact ratio of their respective number of teeth. The ‘cutter’ is considered as the ‘driving gear’ and the ‘workpiece’ as the ‘driven member’. The workpiece gear is fully generated when the cutter has plunged to correct depth (set previously) into the workpiece gear. The machine comes to rest automatically after the workpiece gear is fully cut.

- 29. Gear manufacturing by SHAPING In Gear manufacturing by SHAPING, the ‘generated ‘ surface, whether it is curved or straight, is produced by continuous motion of a point, a line or a surface. The direction in which the generating point travels determine the shape produced. The cutting point of the tool generates a circle when the work piece is rotated. Cutting action of a pinion type cutter

- 30. Gear manufacturing by SHAPING The peripheral feeding of the pinion type cutter takes place in relation to the workpiece, when the cutter has been feed to the full depth of the tooth by the in fed cam. Pinion type cutter The bulk material is removed by the tip and the fillet portion of the cutter. The involute portion of cutting tooth profile removes very little material during the fininshing stage , thus producing supirion fininsh on the cut gear. cutter Workpiece or GearBlank

- 31. Gear manufacturing by : SHAPING Features of Gear Shaping: Ideally suited for mass production and single piece production. Gear manufacturing by SHAPING single piece production. Gear SHAPING is a versatile process and can cut Gears, Cams, Splines and special shapes. Gear SHAPING has got automatic cycle os operation and centralized control. High rate of production cuts.

- 32. Comparison of GEAR PLANNING, GEAR HOBBING, GEAR SHAPPING Relative Motions of Tool and Work for gear PLANNING, HOBBING, SHAPPING