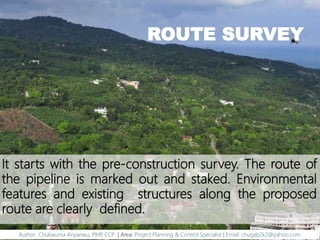

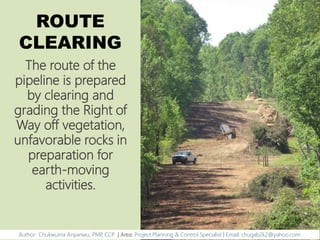

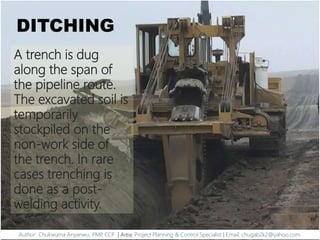

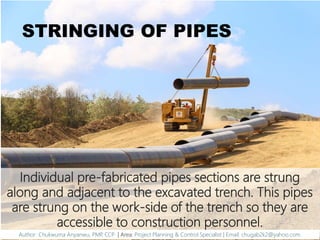

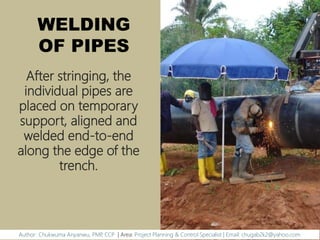

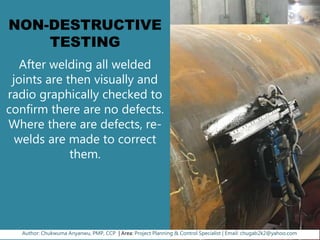

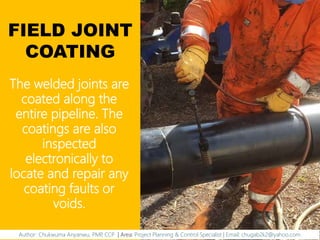

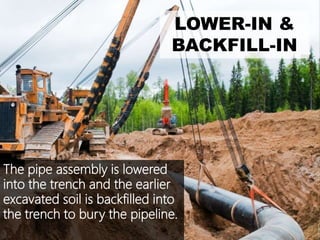

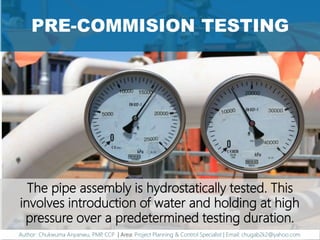

The document outlines the steps involved in the construction of an onshore gas pipeline, emphasizing a sequenced assembly line approach. Key stages include route survey, clearing, trenching, pipe stringing, welding, non-destructive testing, coating, lowering and backfilling, pre-commission testing, and site restoration. Each phase is carried out by specialized crews to ensure efficient project execution.