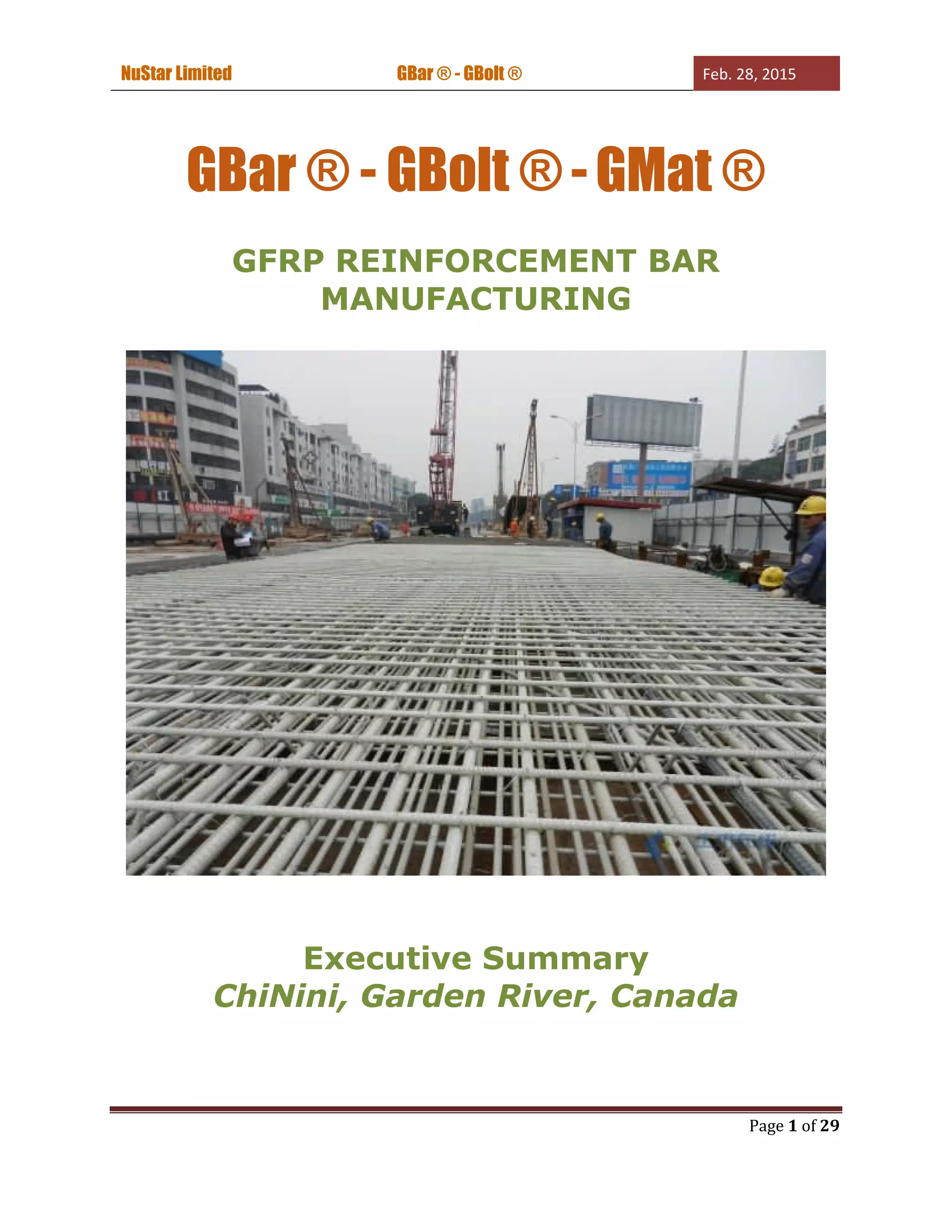

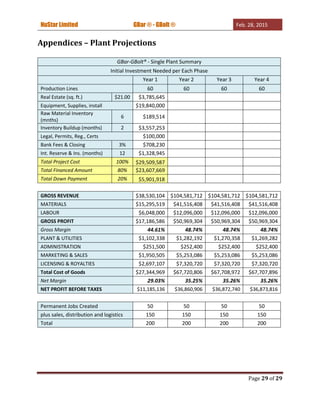

This document provides an executive summary and details of NuStar Limited's GBar, GBolt, and GMat glass fiber reinforced polymer (GFRP) rebar manufacturing process. GFRP rebar offers benefits over steel rebar such as corrosion resistance, higher tensile strength, lower weight, and a projected service life over 100 years. NuStar plans to use pultrusion, an established manufacturing method, to produce the GFRP rebar in various diameters and shapes at competitive linear foot prices. Facility requirements, management plans, and production projections are also outlined.