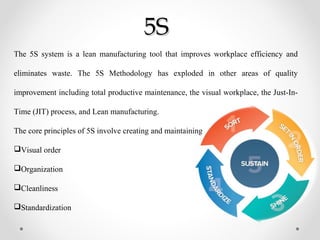

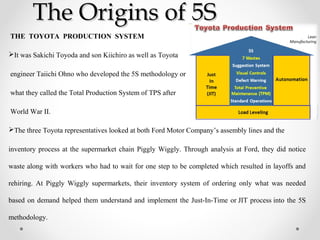

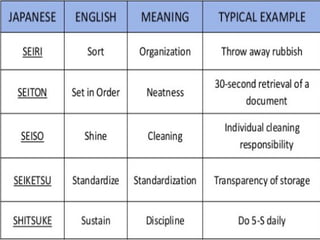

The 5S system is a lean manufacturing tool focused on improving workplace efficiency and eliminating waste through visual order, organization, cleanliness, and standardization. Originating from the Toyota Production System, it was developed by key figures like Sakichi Toyoda and Taiichi Ohno, drawing insights from both Ford's assembly lines and the Piggly Wiggly inventory model. The methodology has gained global popularity, particularly after the publication of influential texts that detail its implementation and benefits.