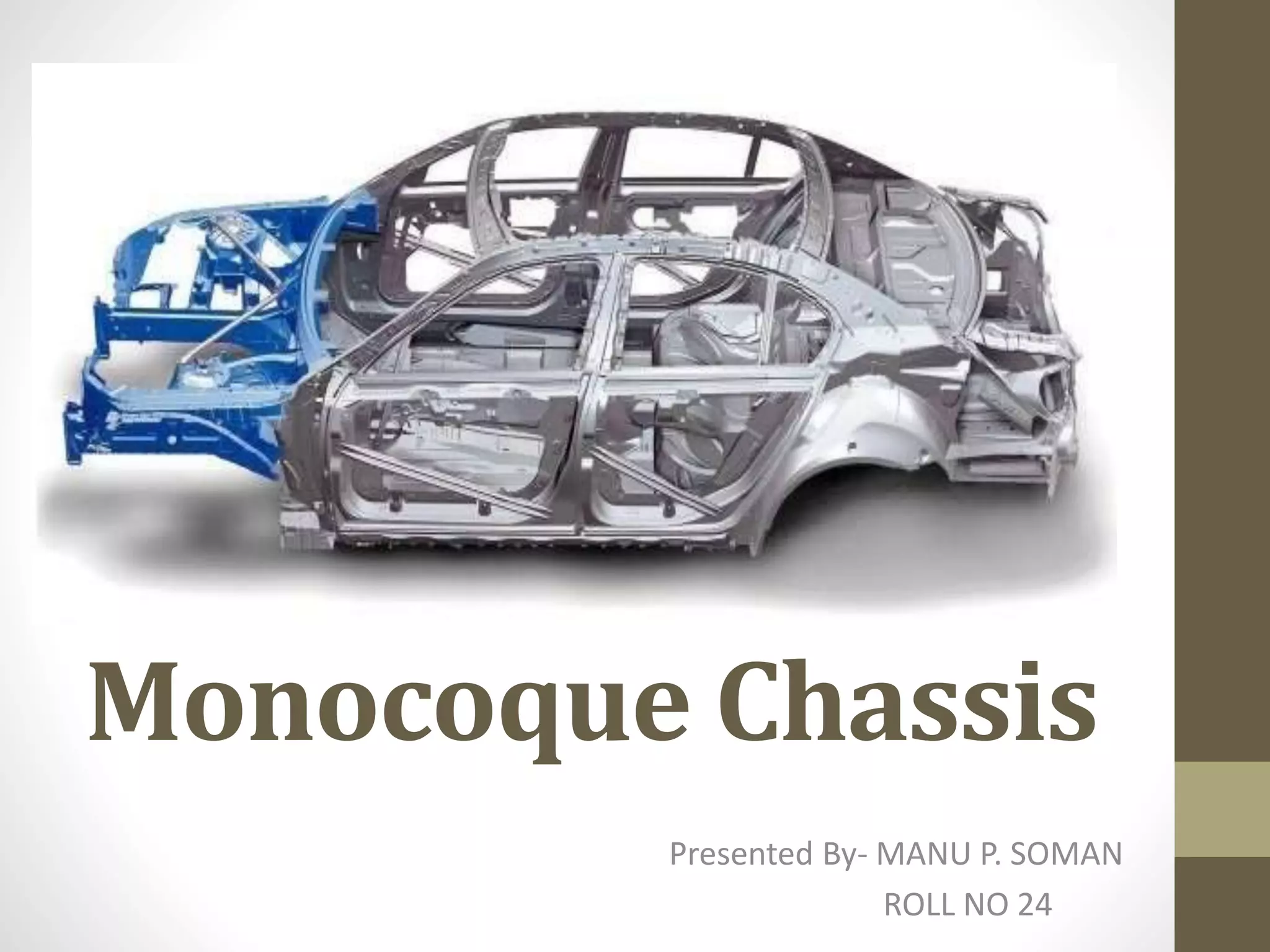

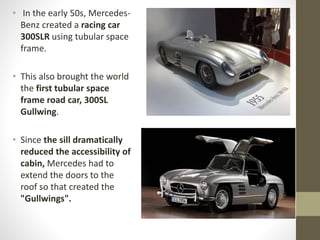

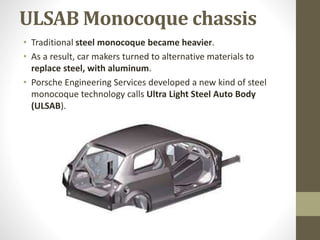

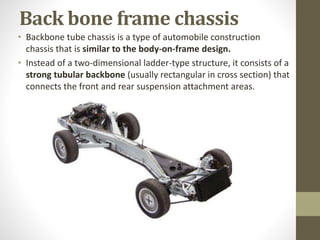

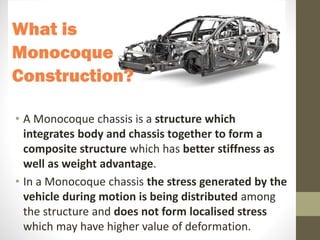

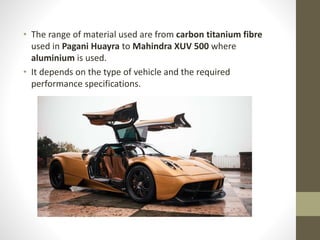

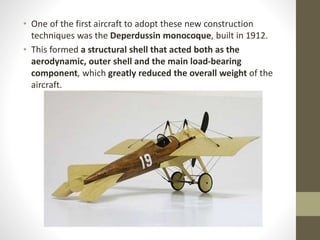

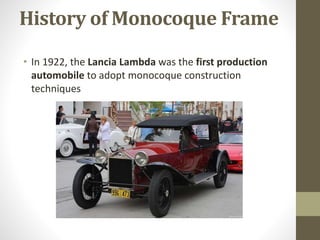

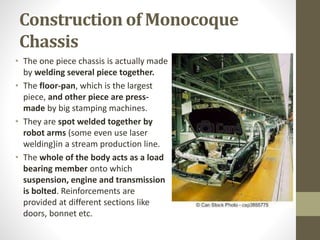

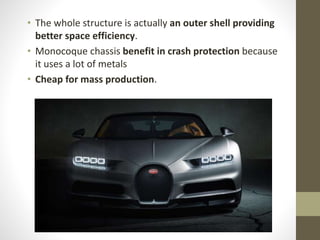

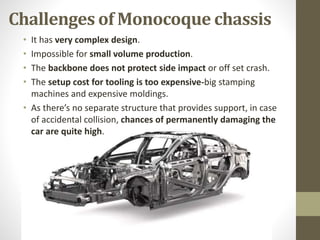

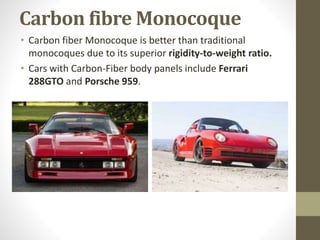

The document provides an overview of various types of chassis, including ladder frame, tubular space frame, aluminum space frame, and monocoque chassis. It discusses the evolution and advantages of monocoque design, highlighting its lightweight properties and structural efficiency while also noting challenges like complex designs and tooling costs. Historical context is given, tracing the origins of monocoque construction from aerospace to its application in automobiles.