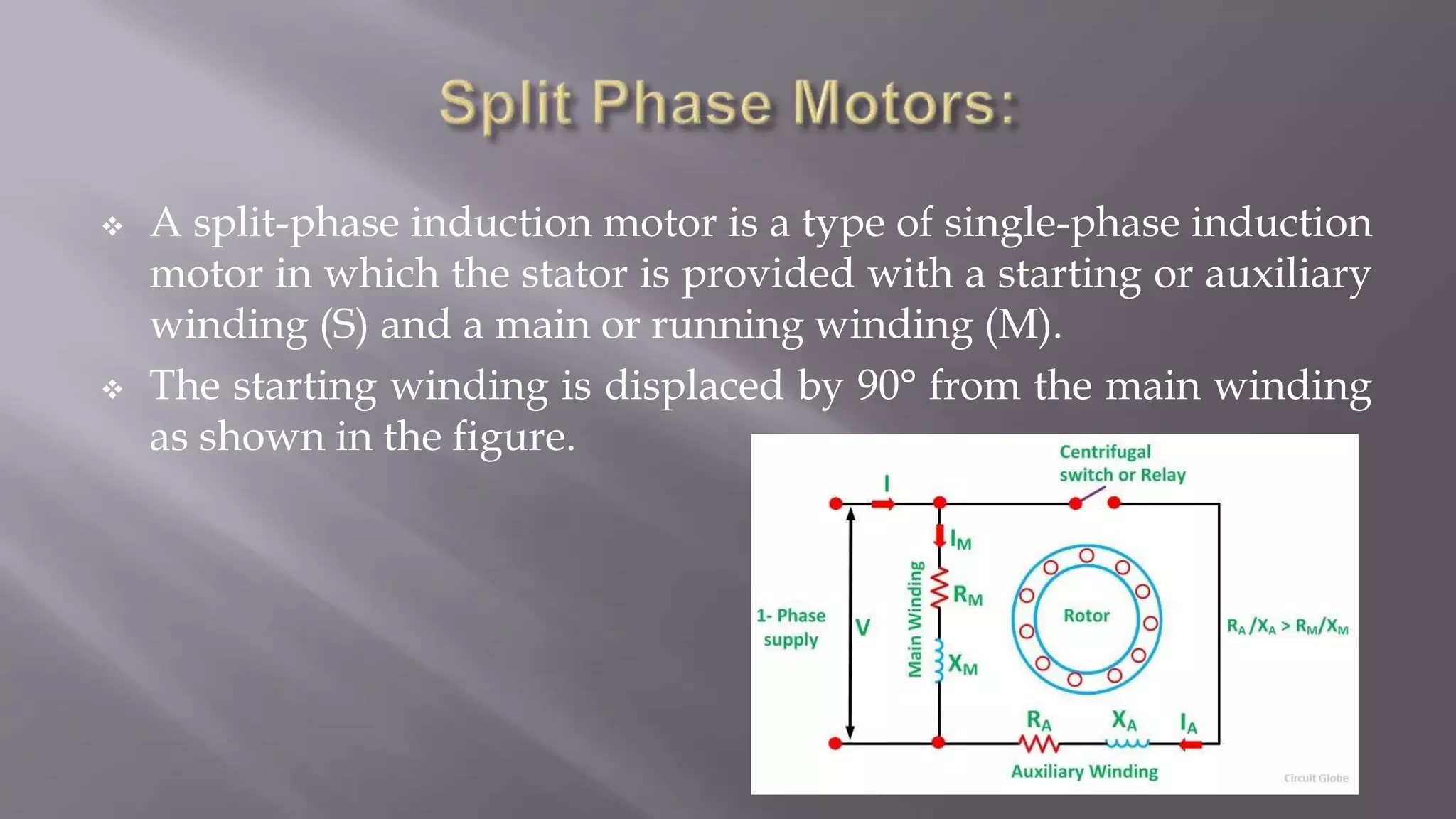

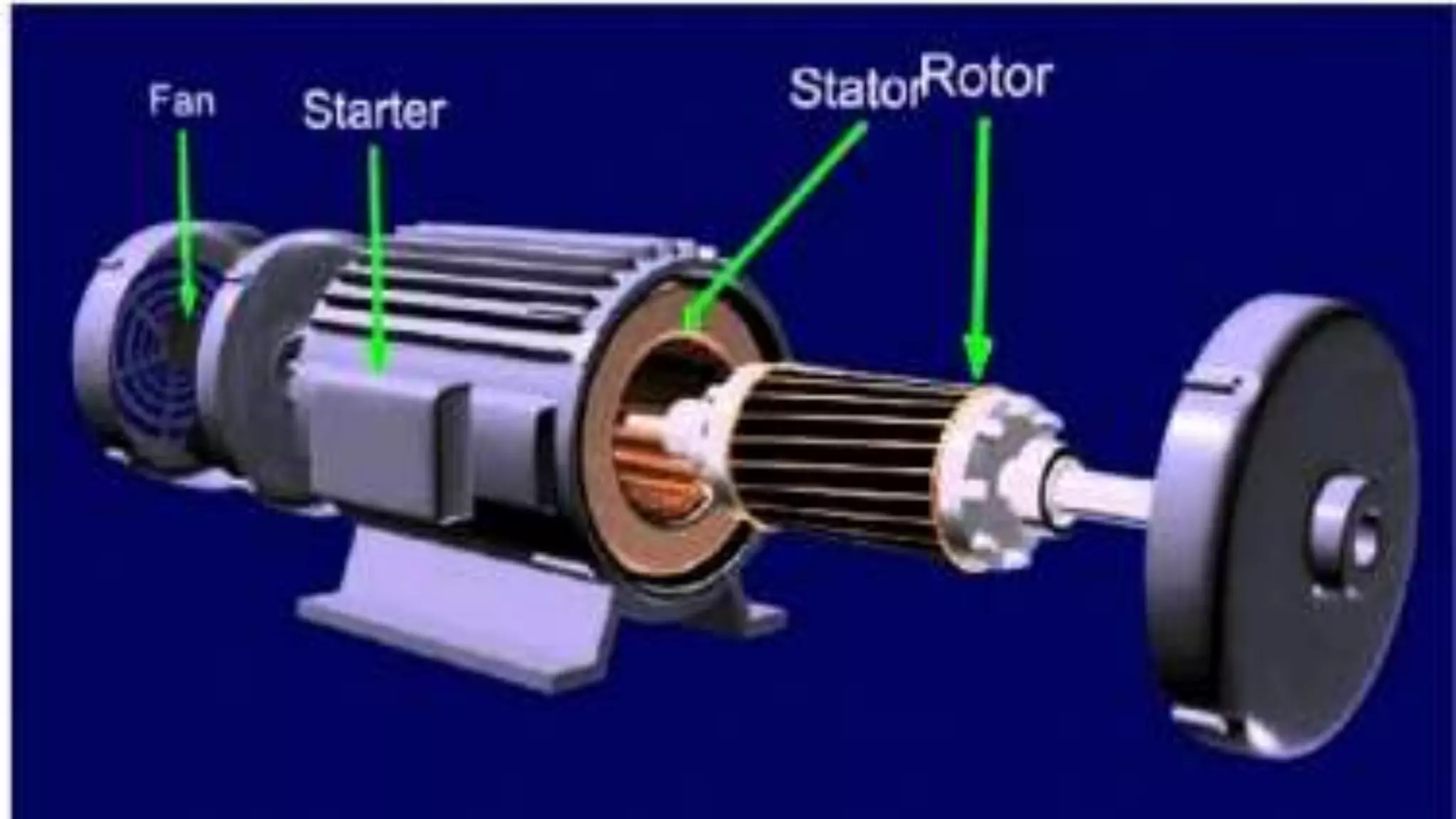

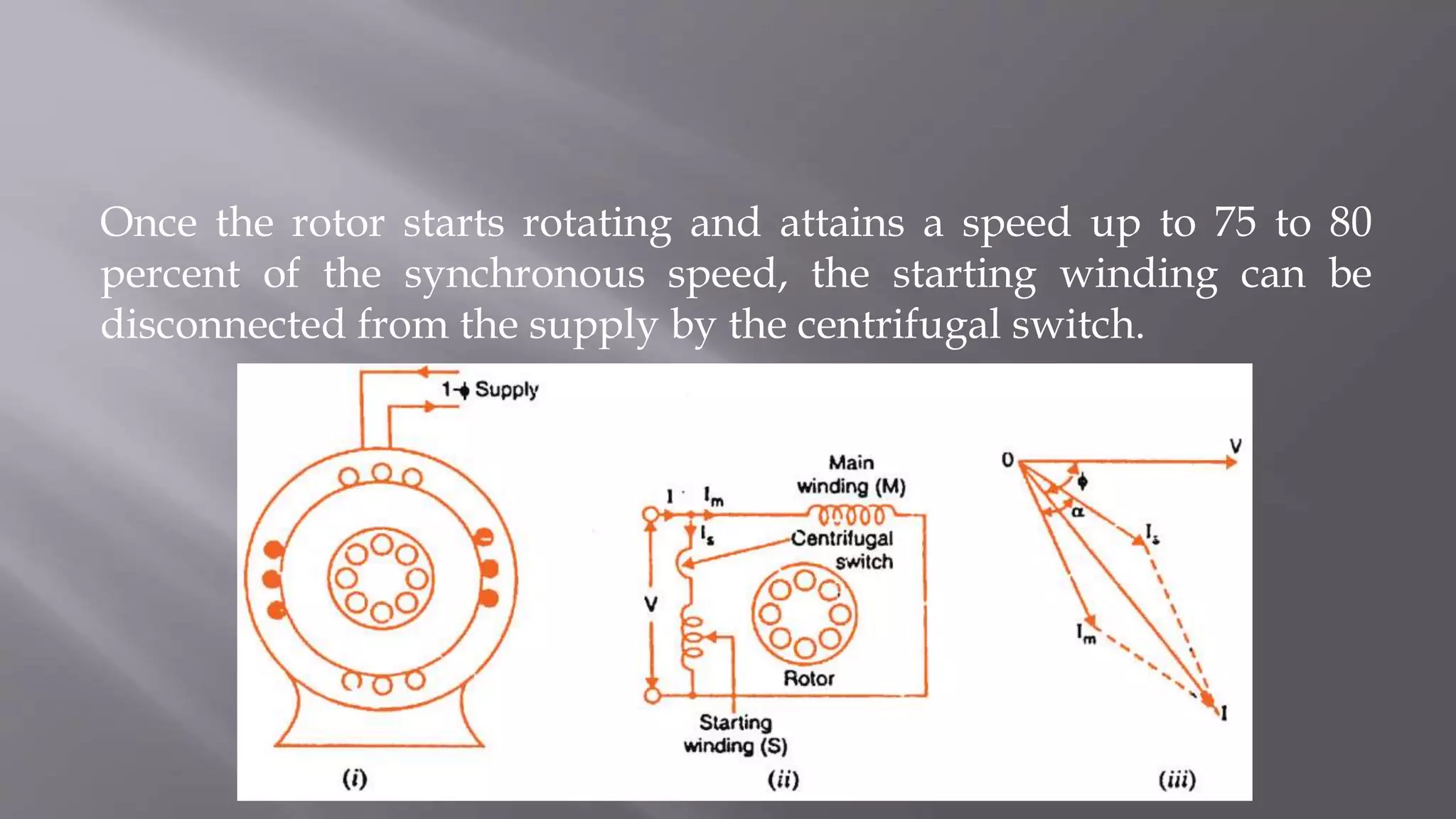

A split-phase induction motor presentation was given by four group members. It has a stator with a main winding and auxiliary winding displaced by 90 degrees to produce a rotating magnetic field for starting. It relies on the different resistance and inductance of the windings. Once up to 75-80% of synchronous speed, the centrifugal switch disconnects the auxiliary winding. Split-phase motors are used in appliances due to their low cost but have lower efficiency than three-phase motors.