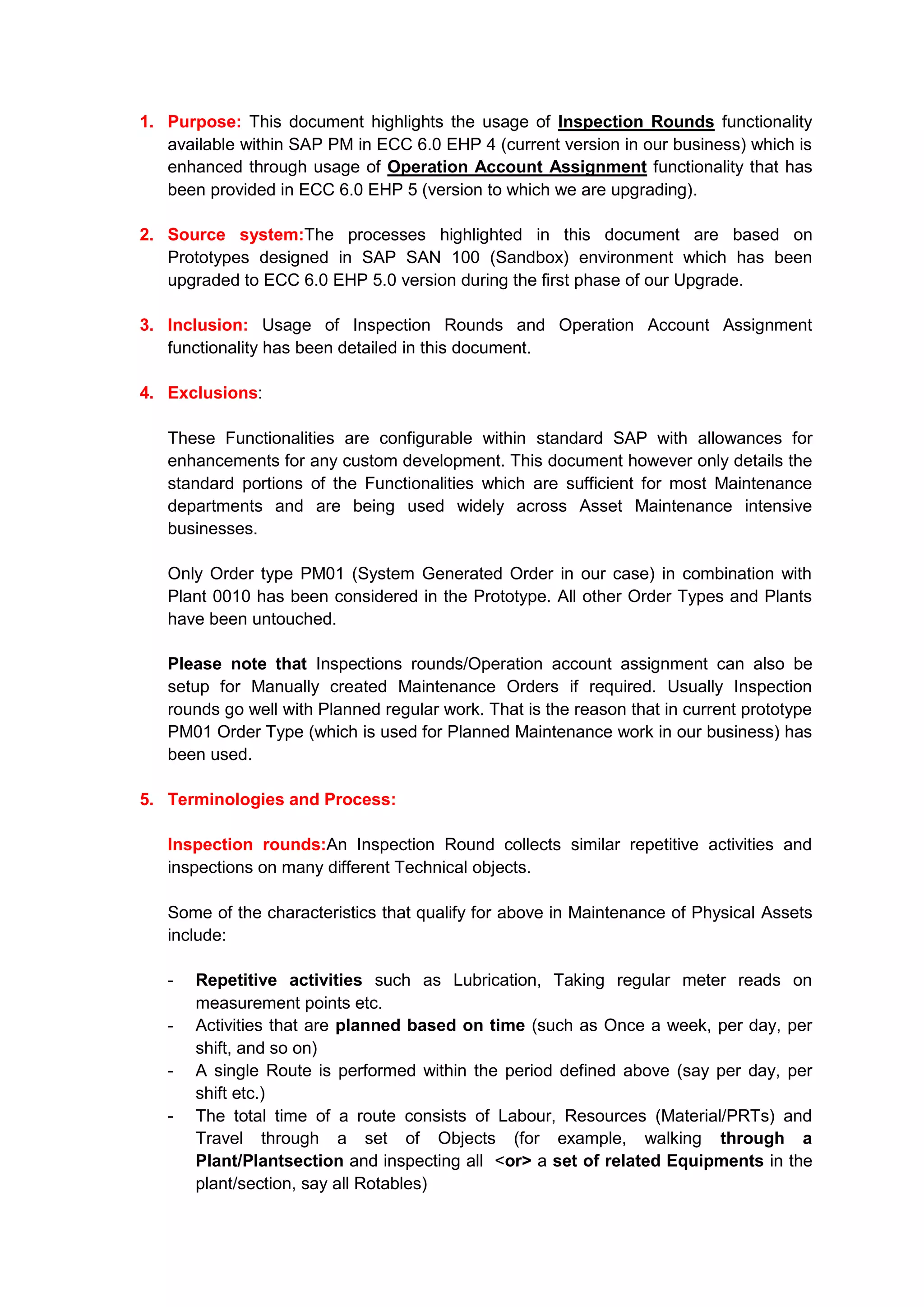

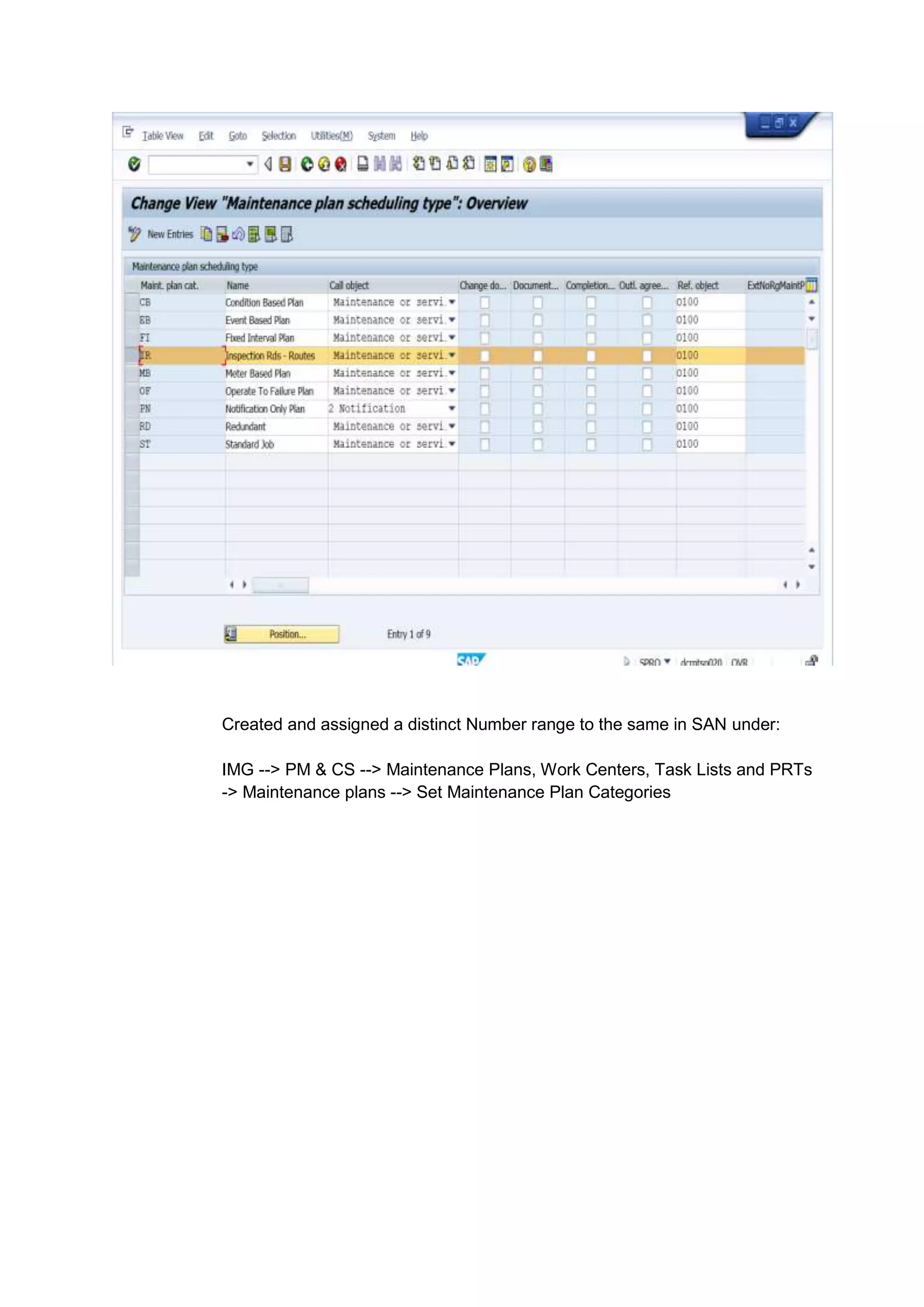

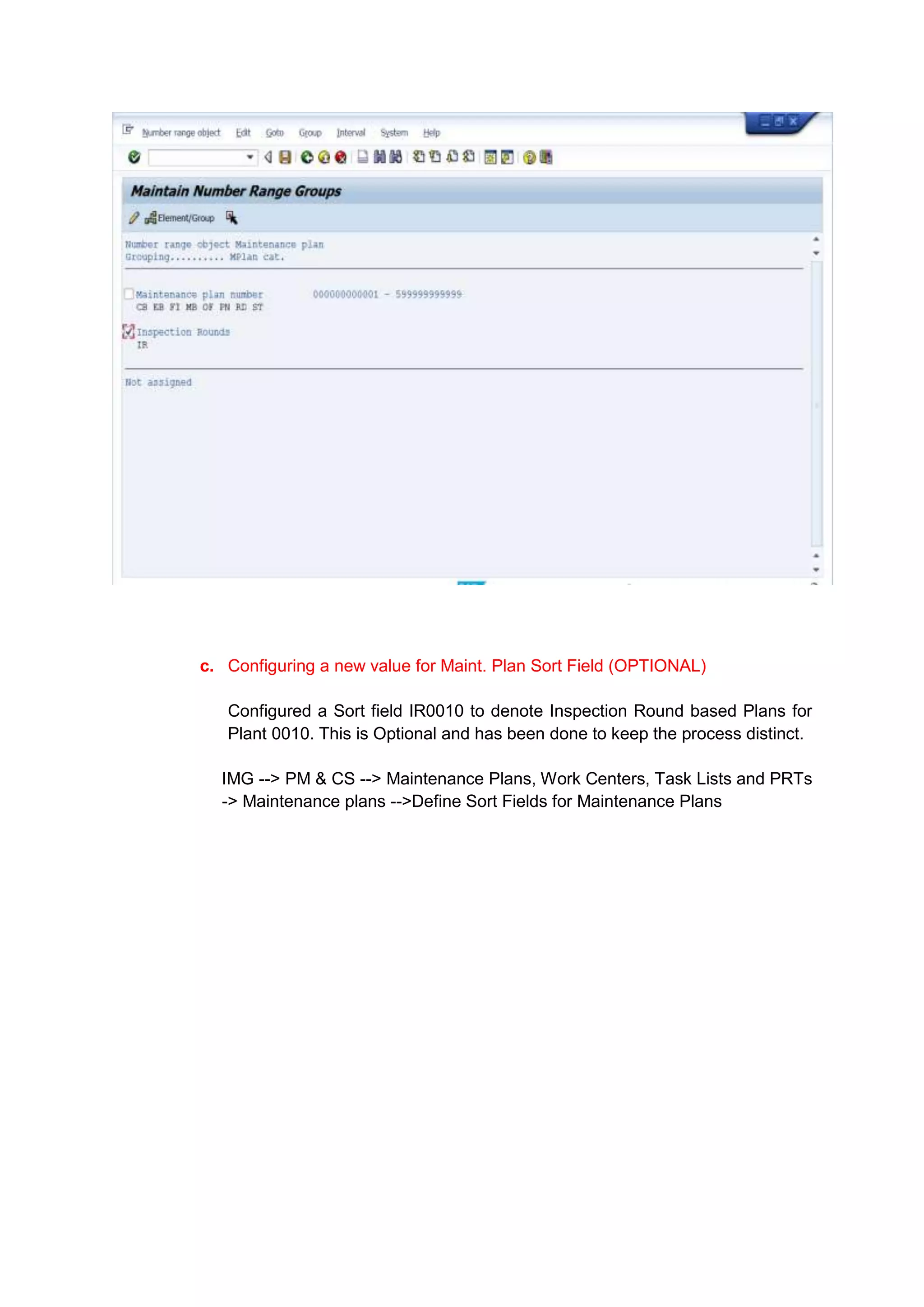

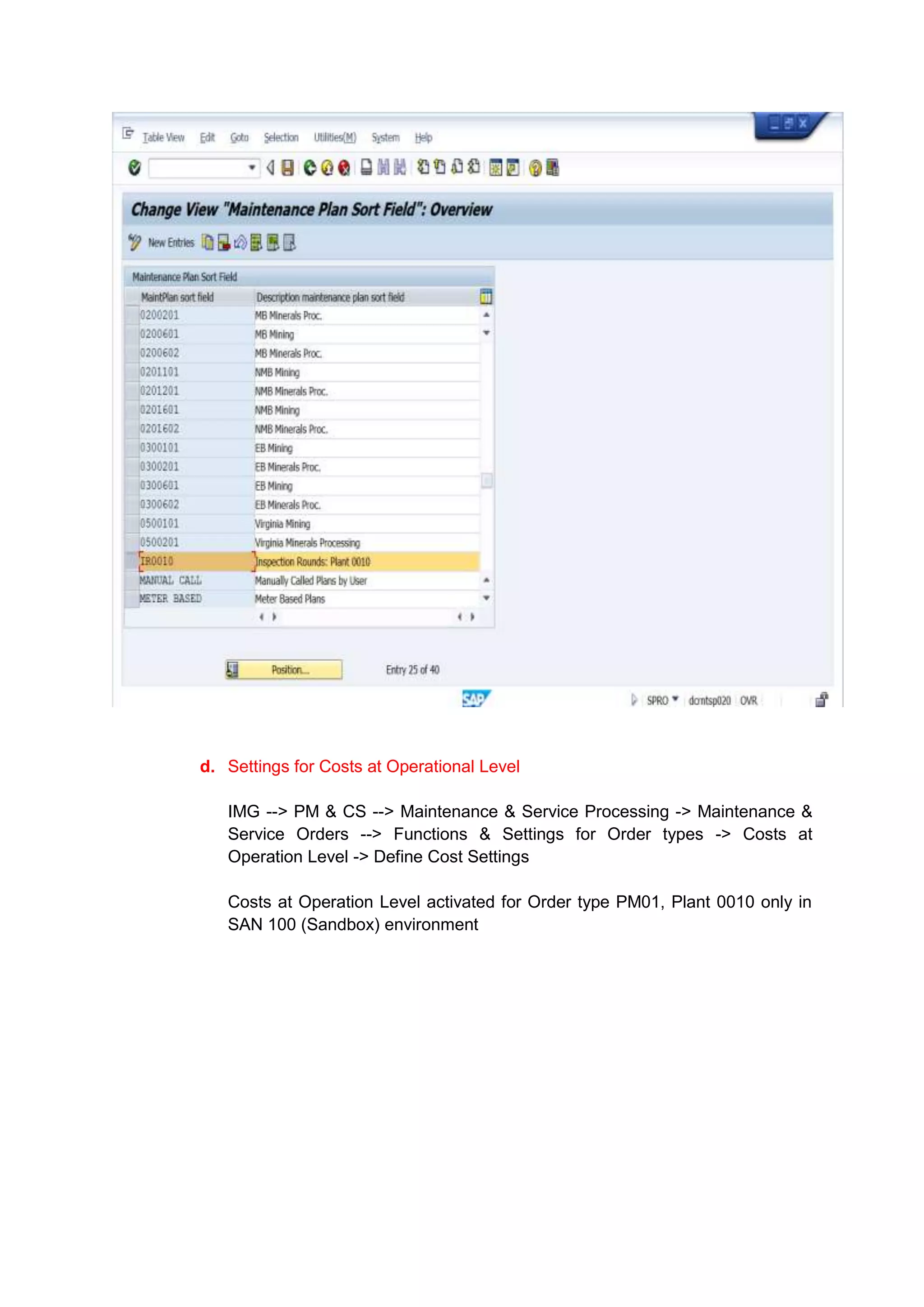

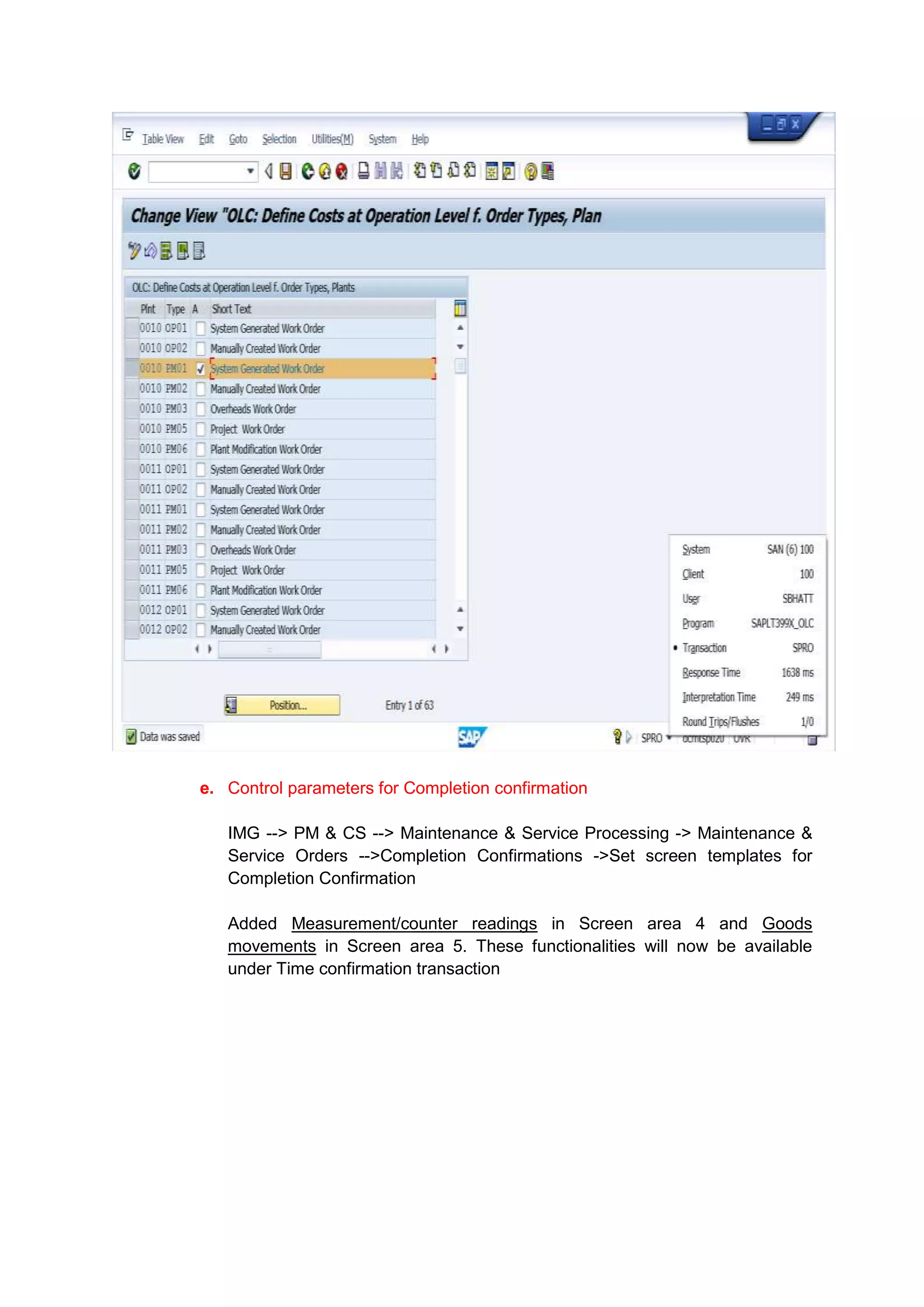

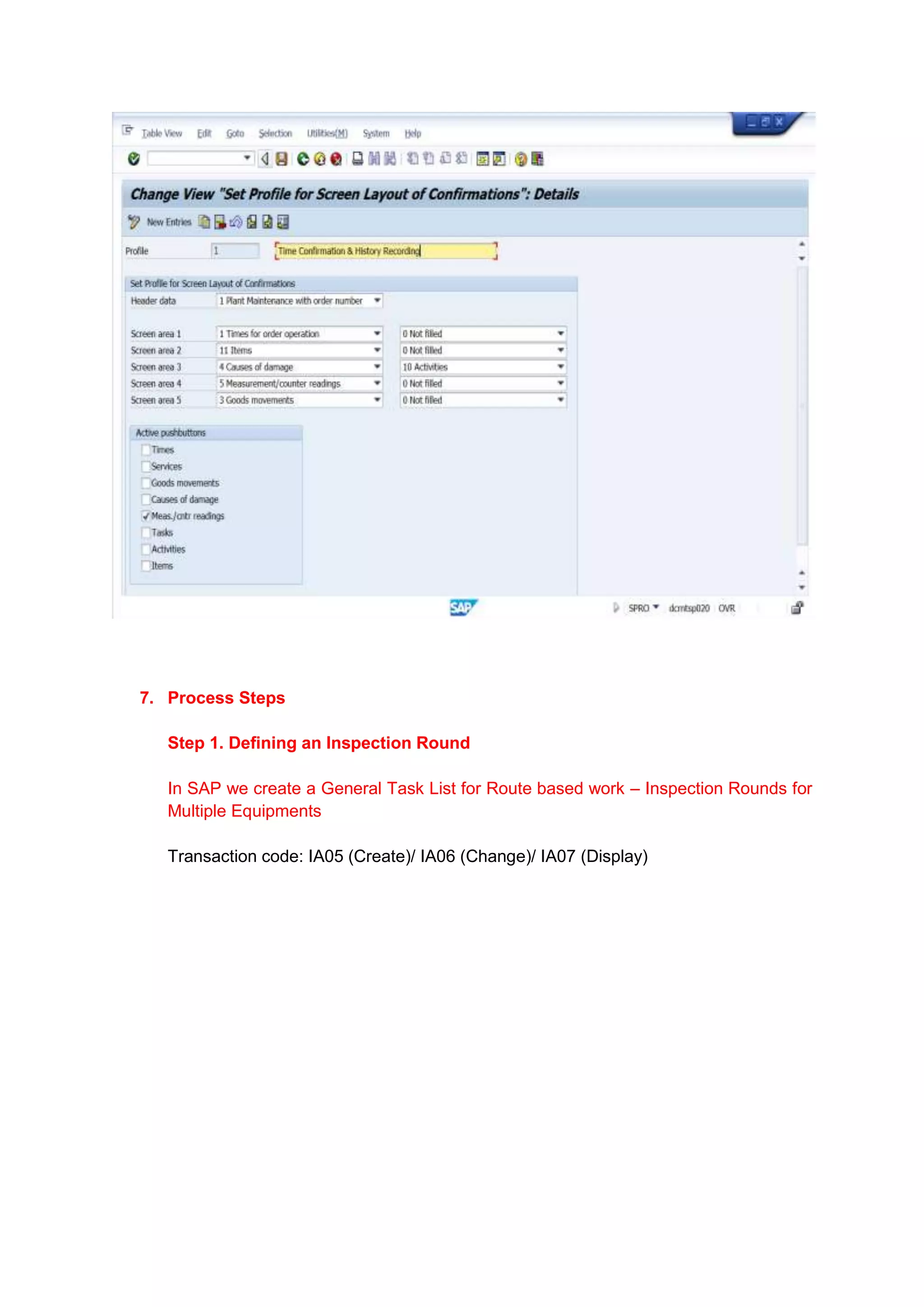

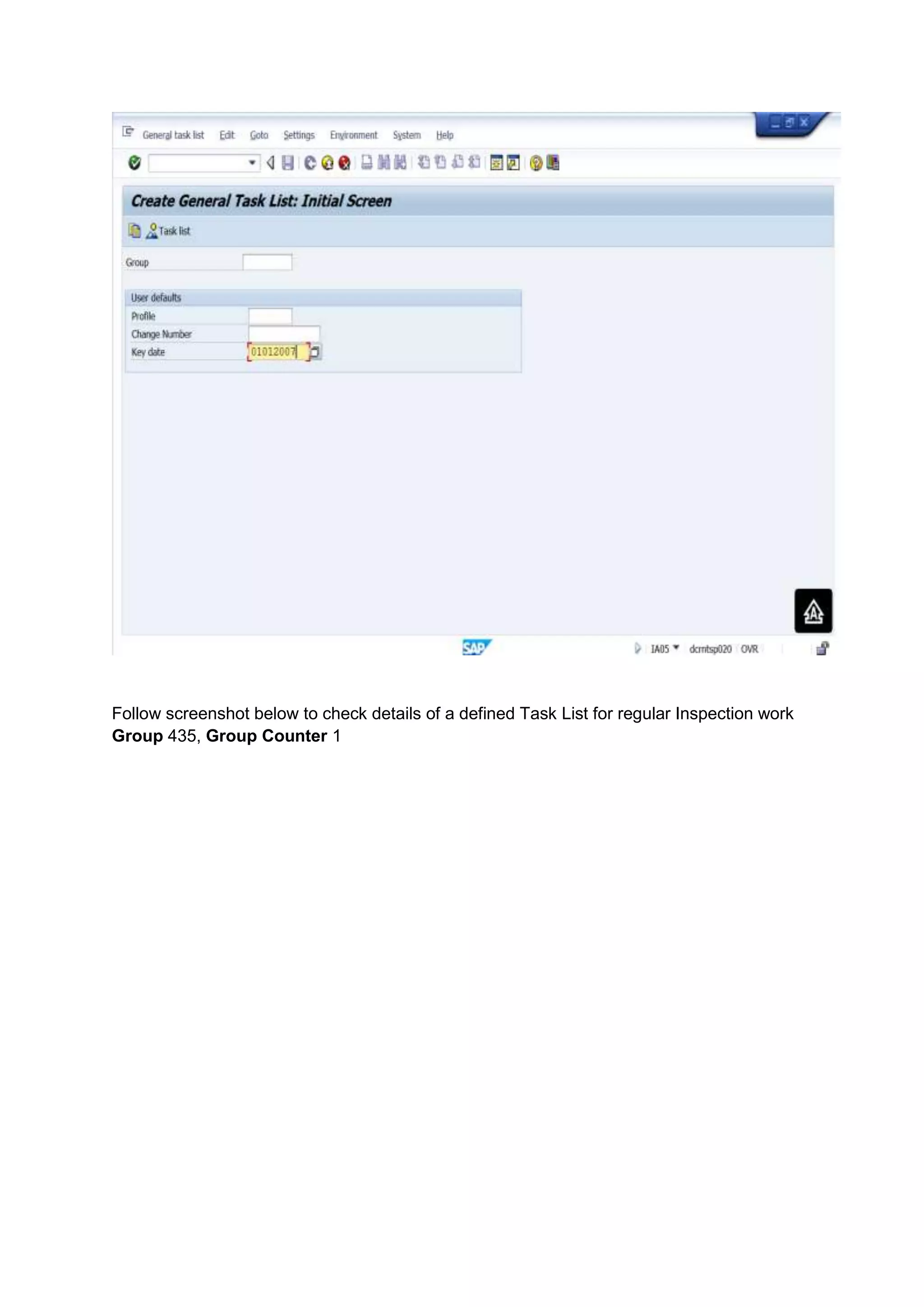

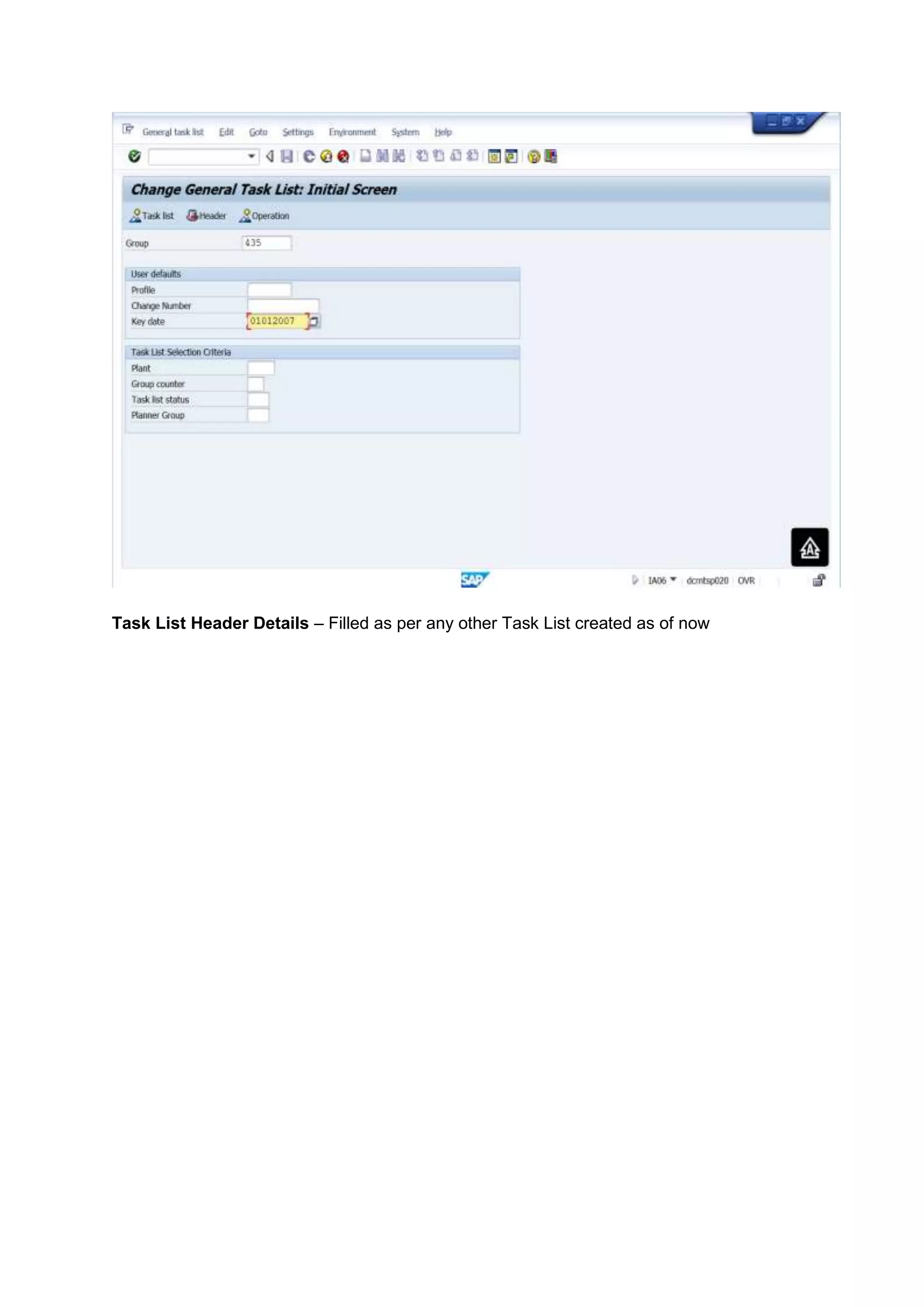

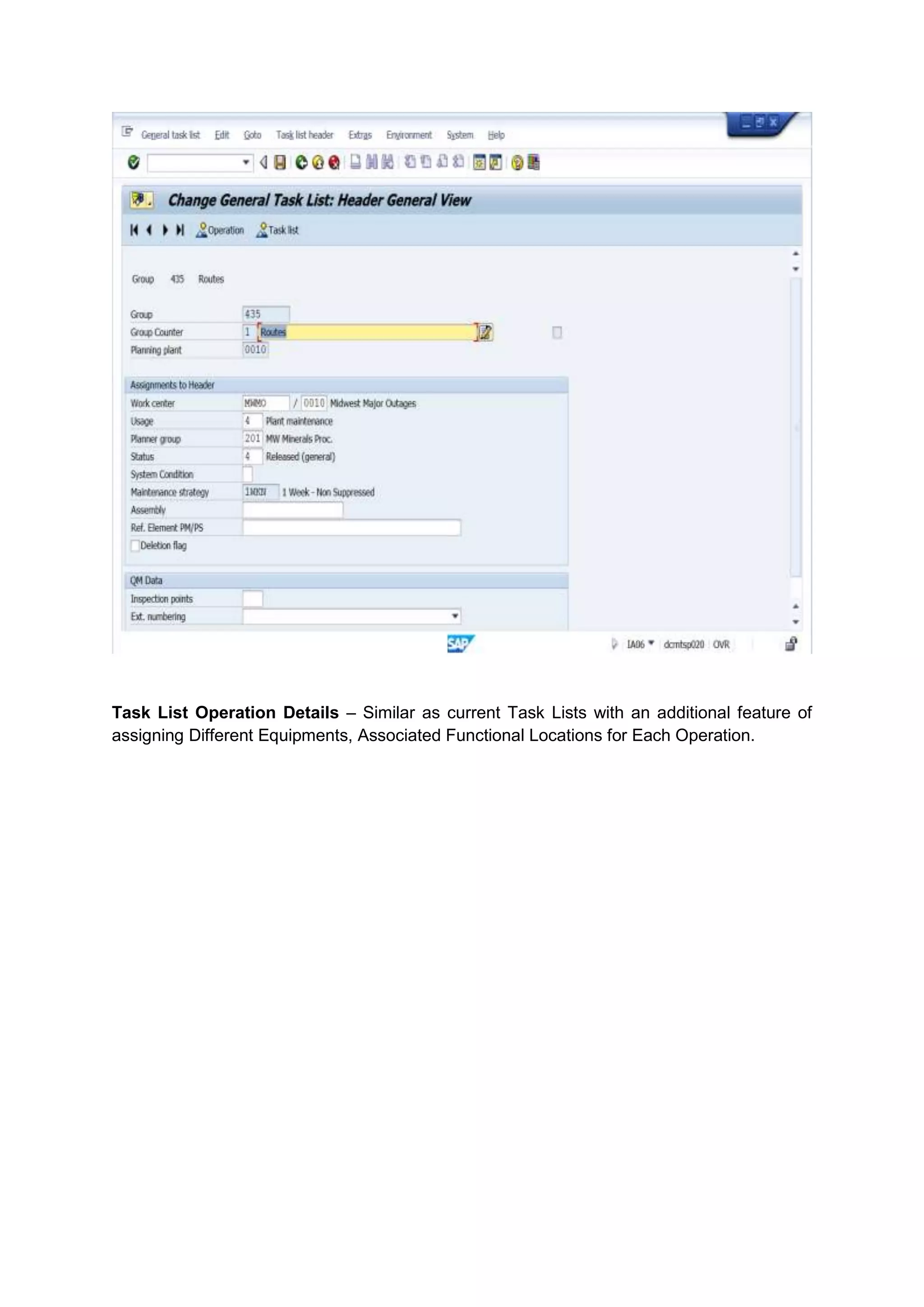

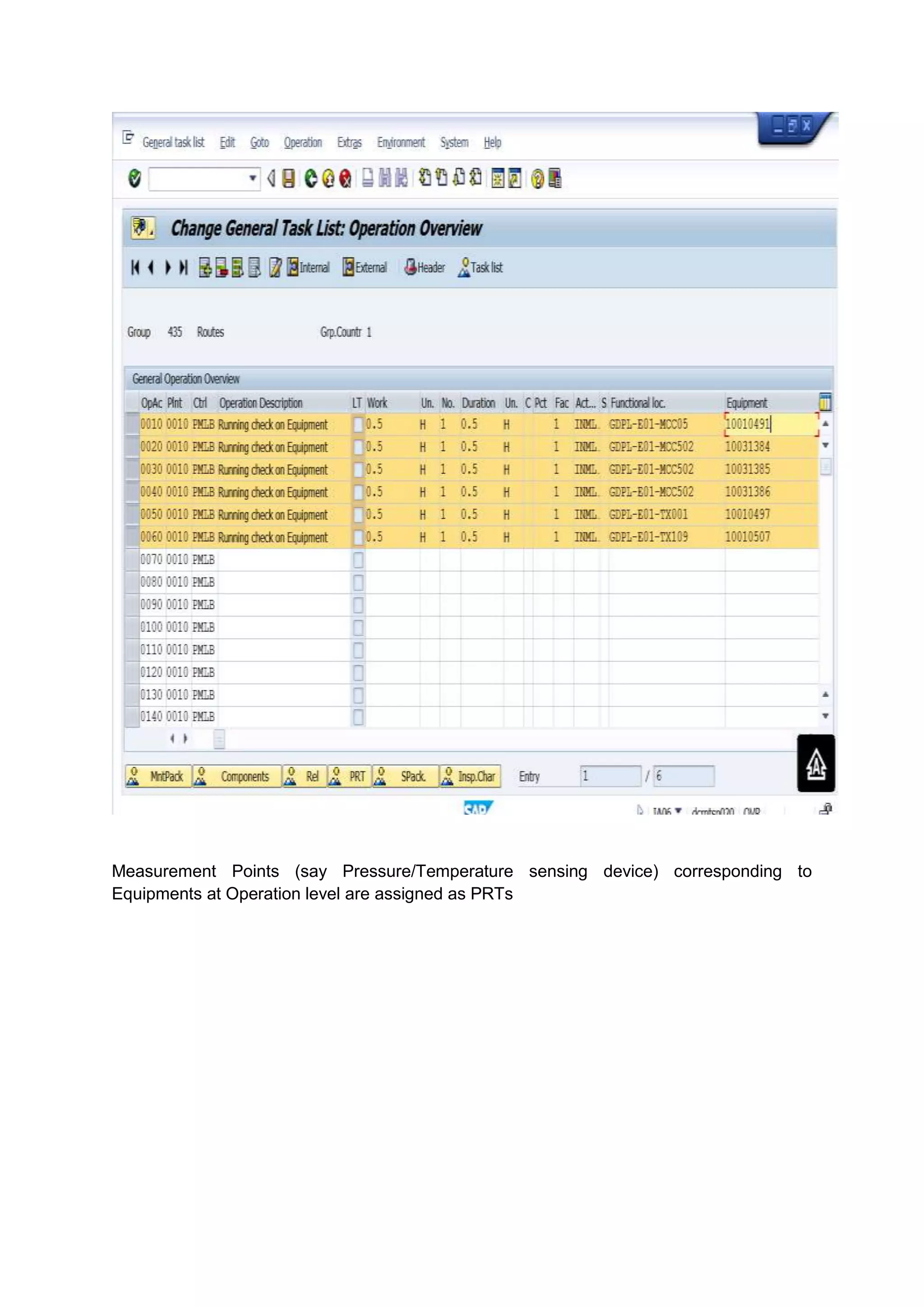

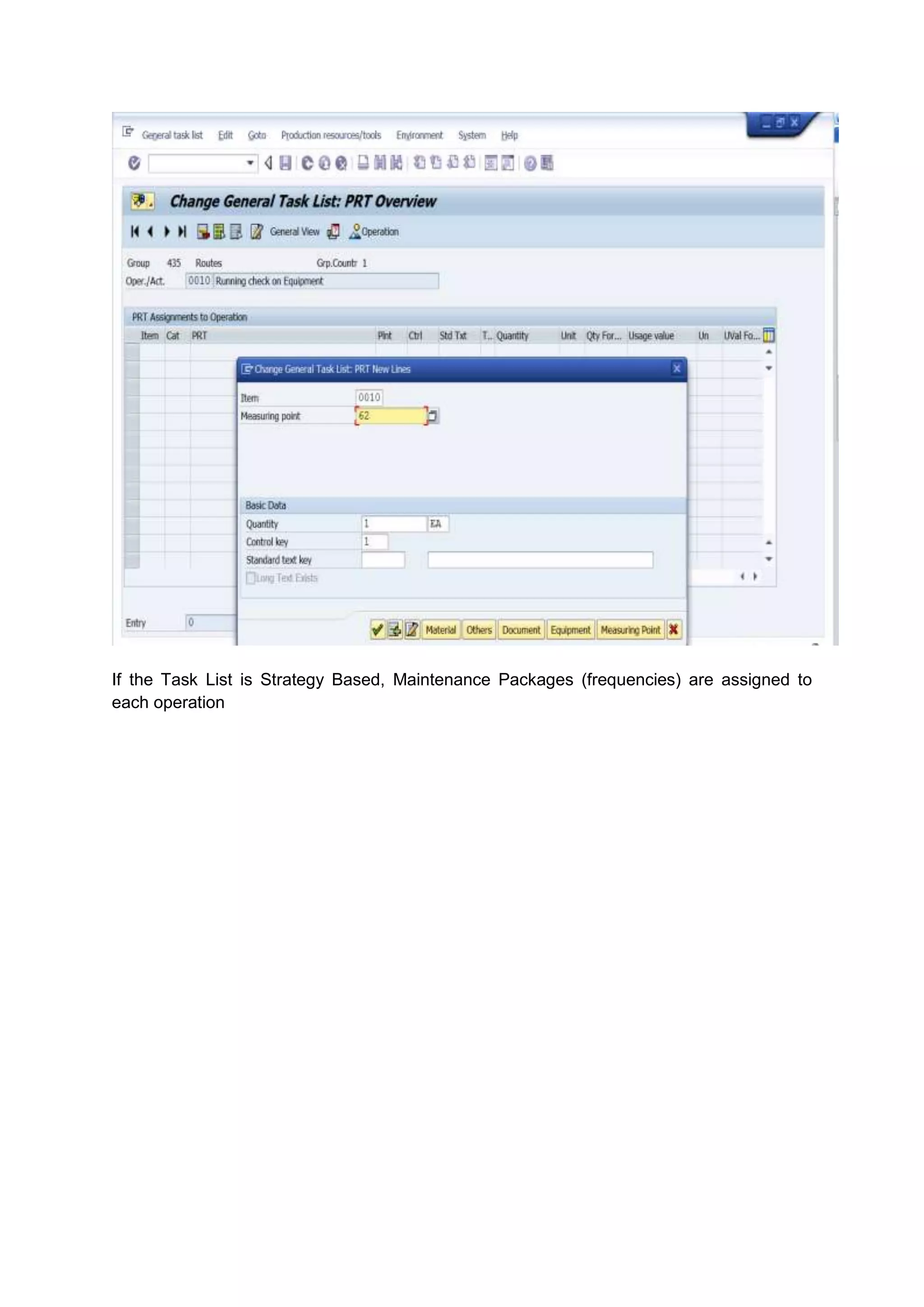

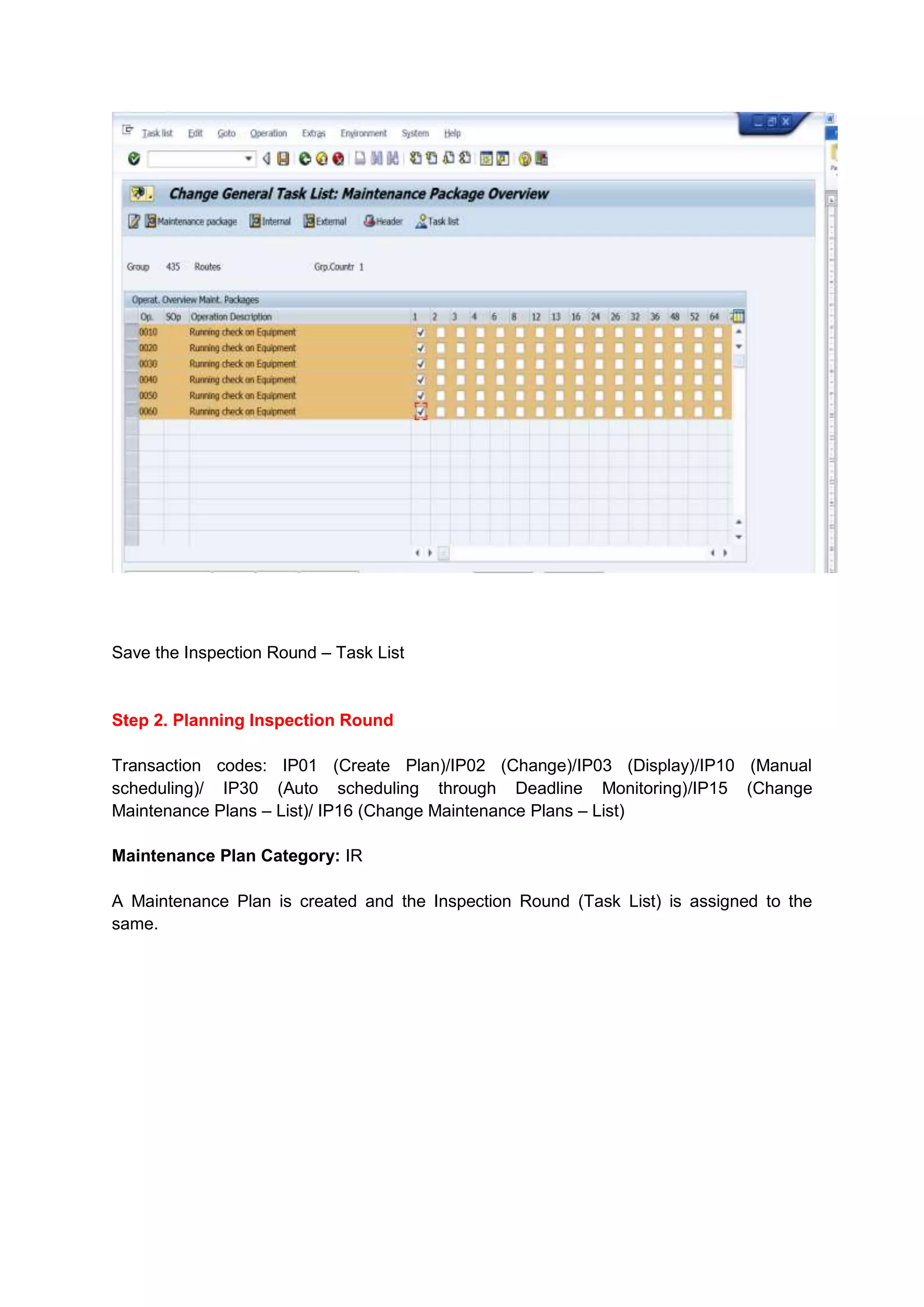

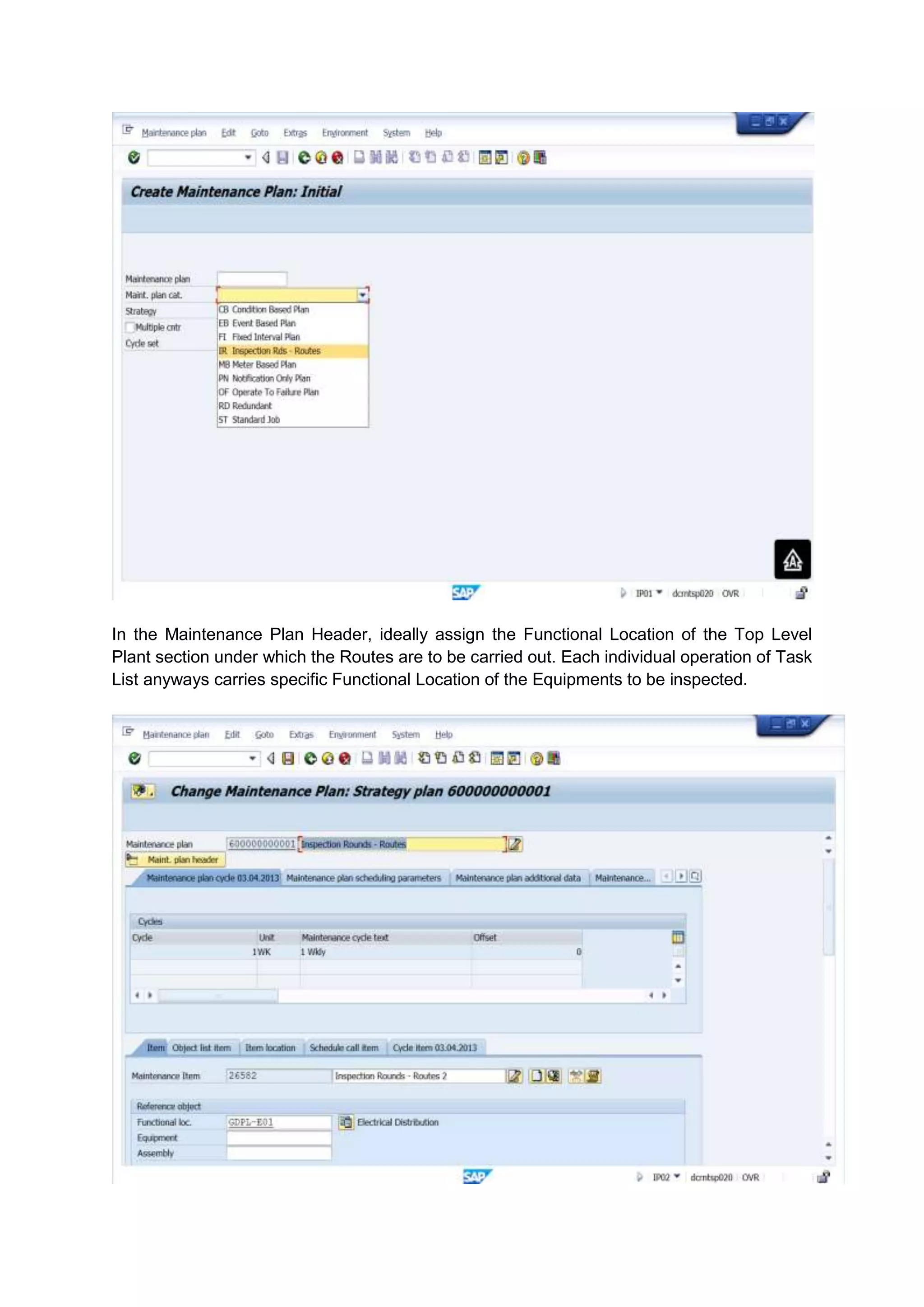

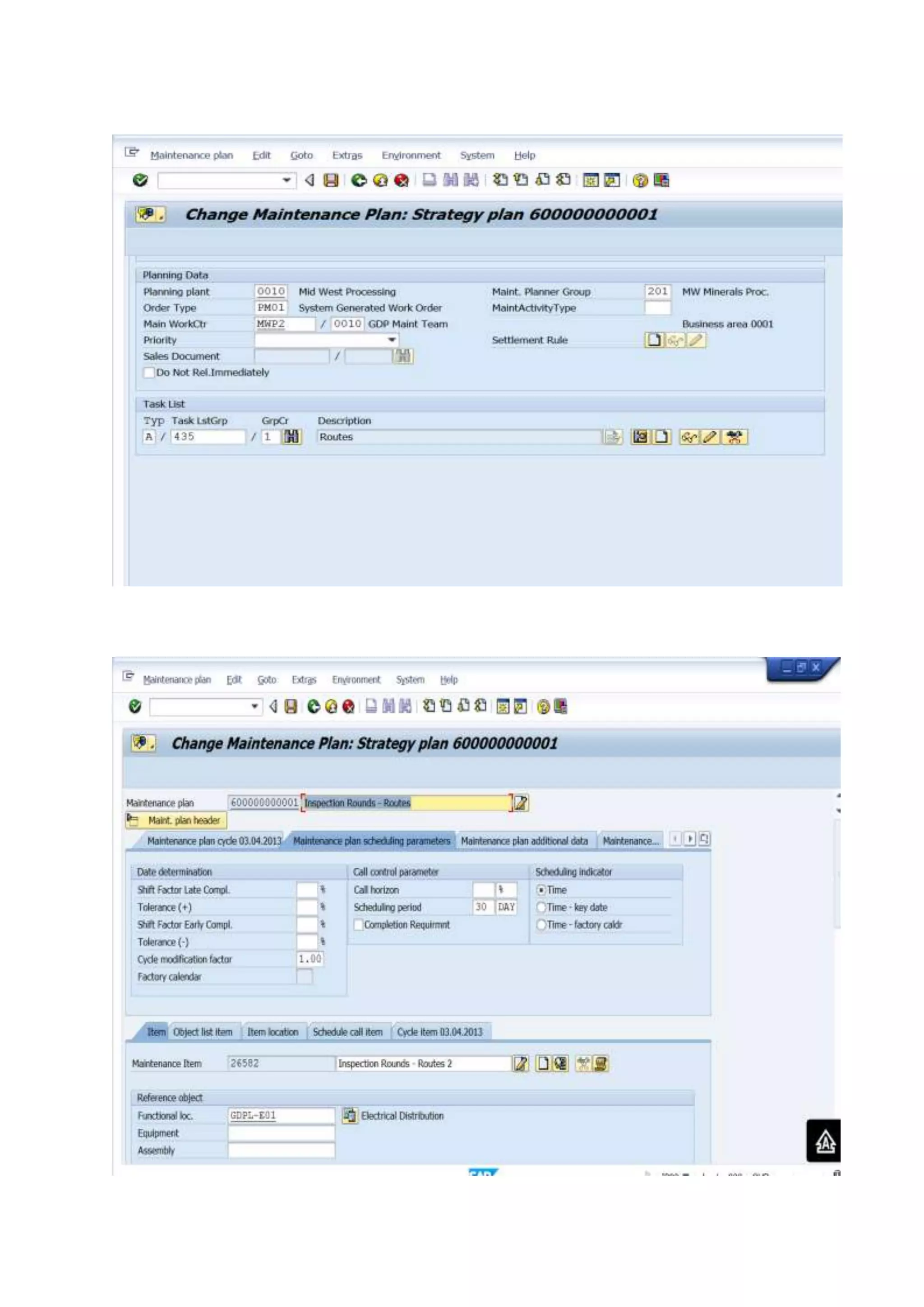

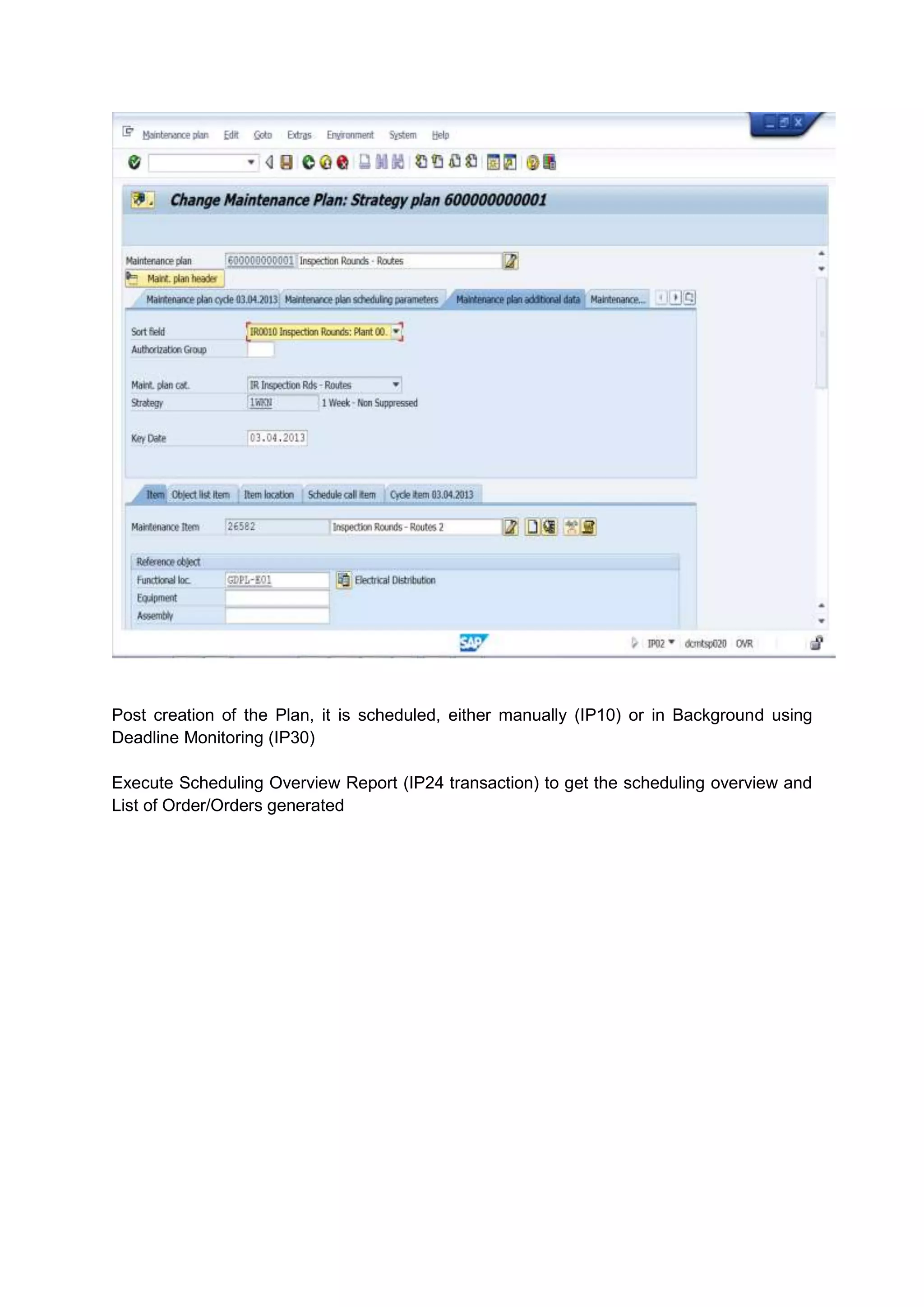

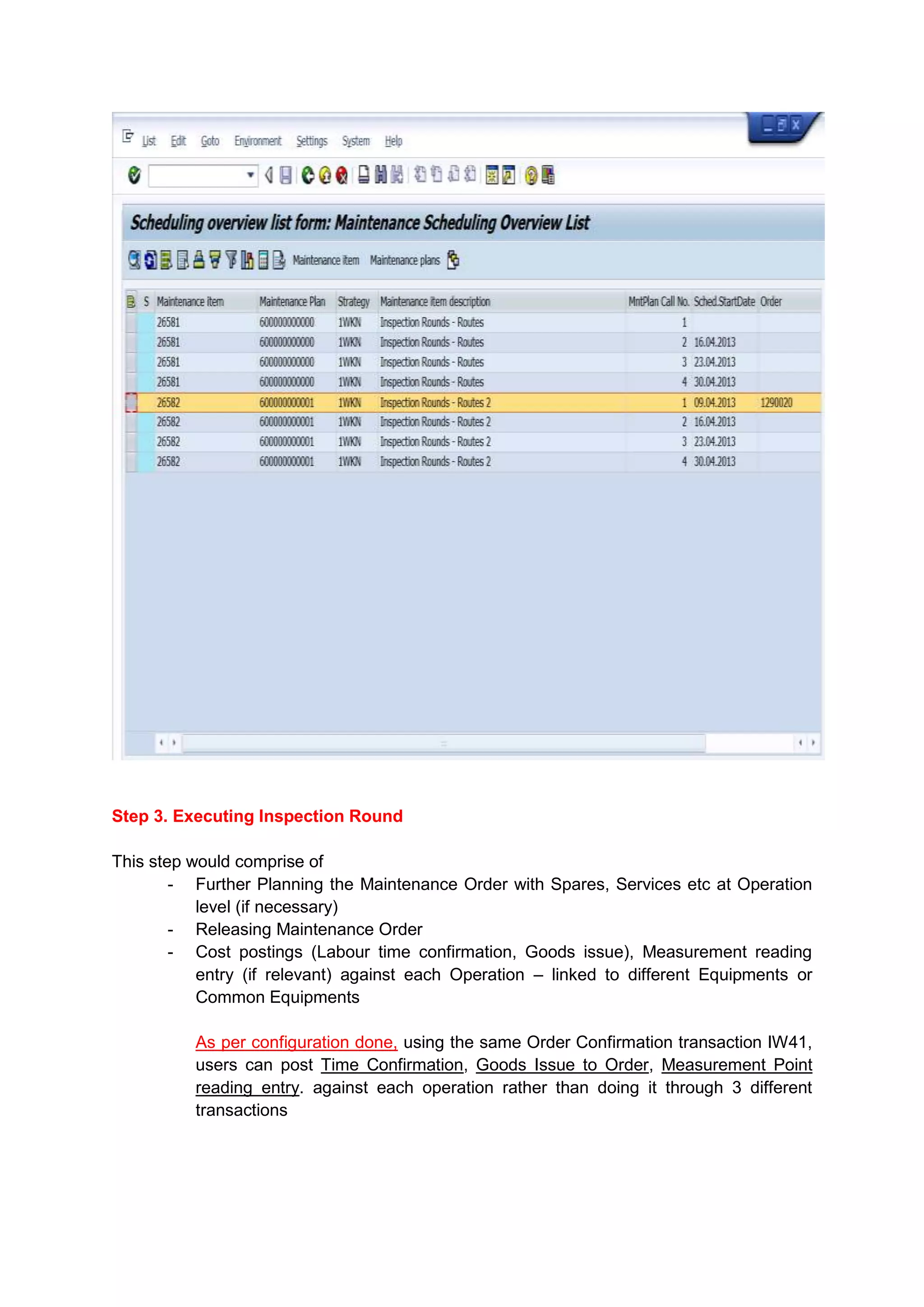

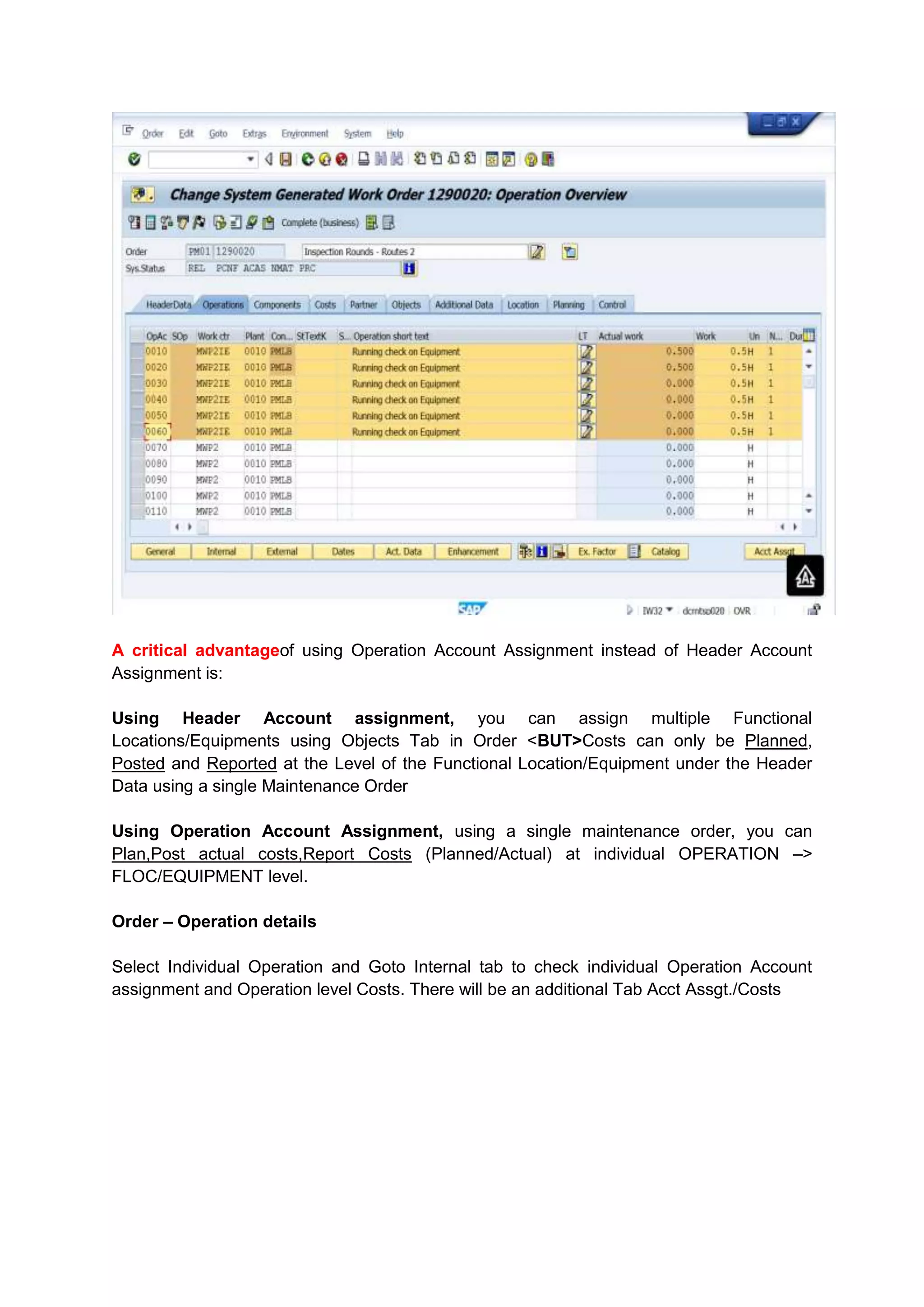

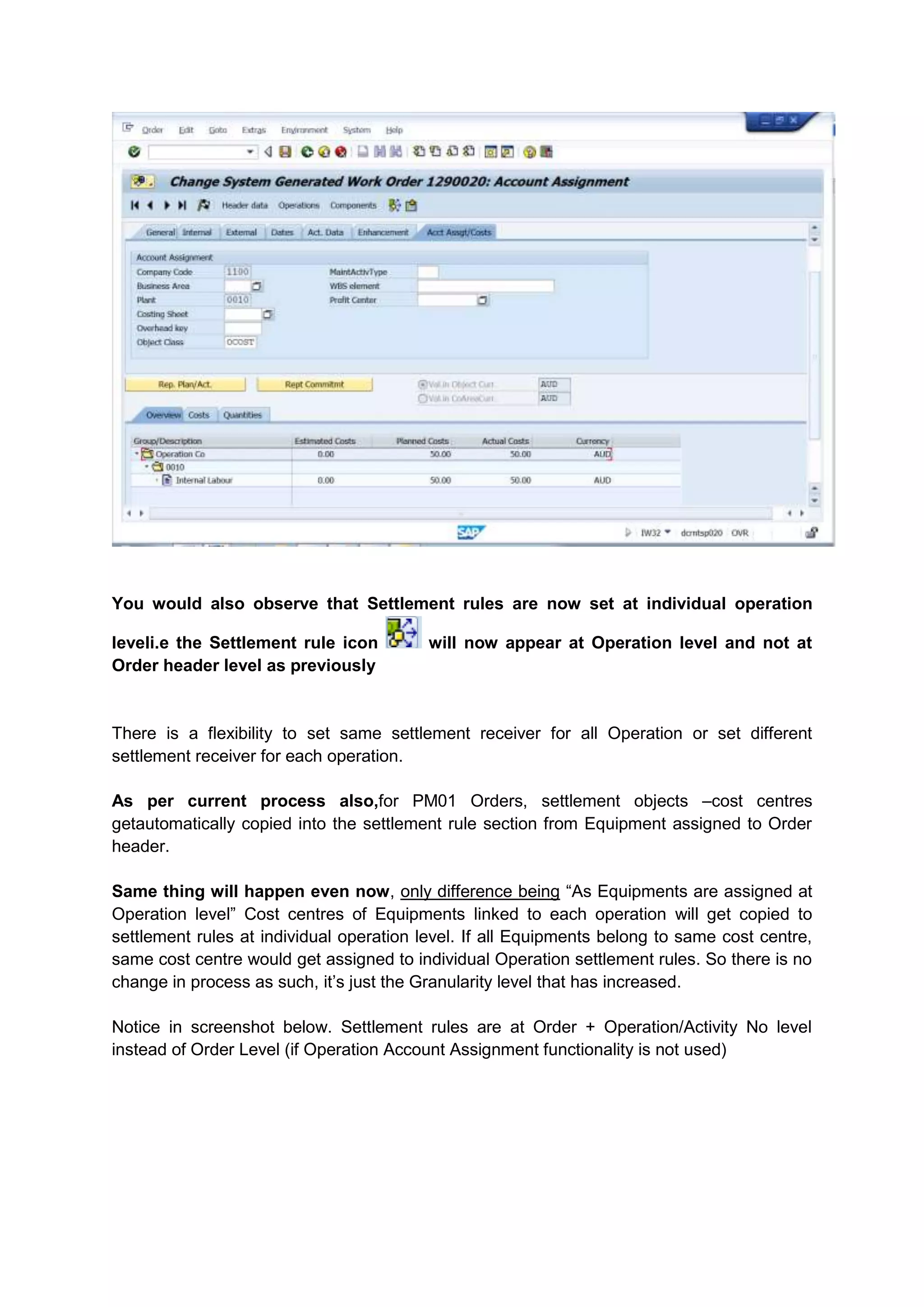

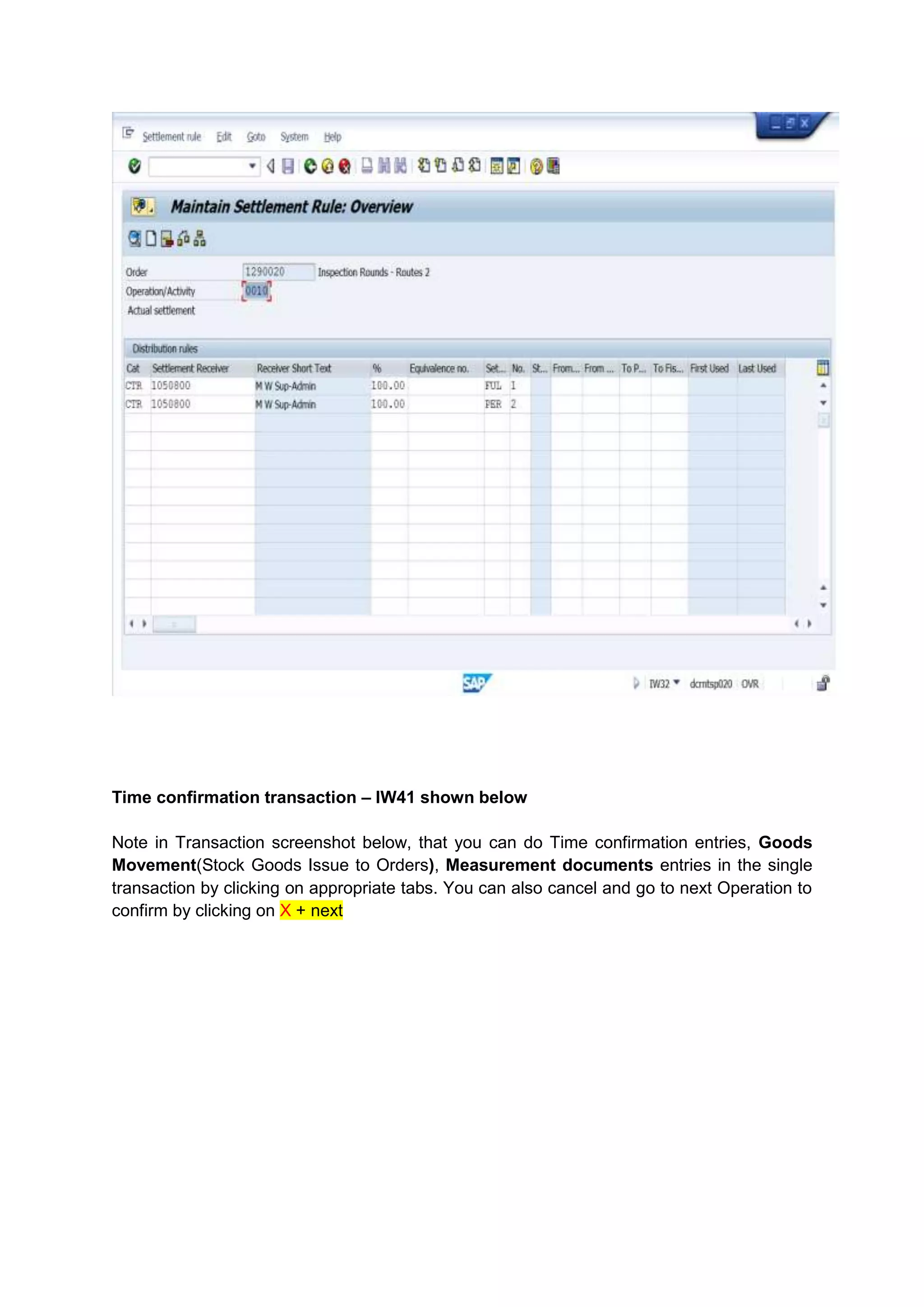

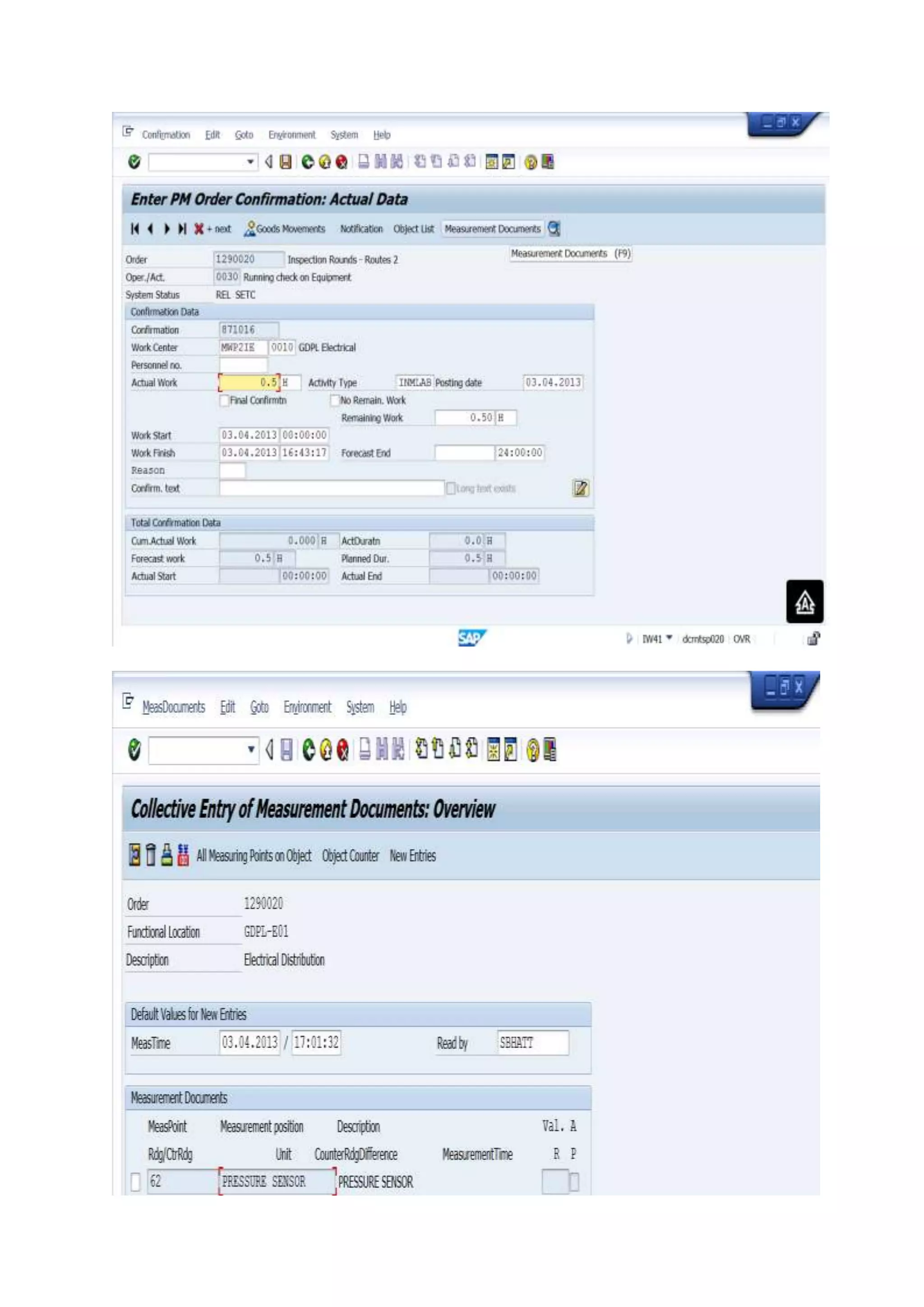

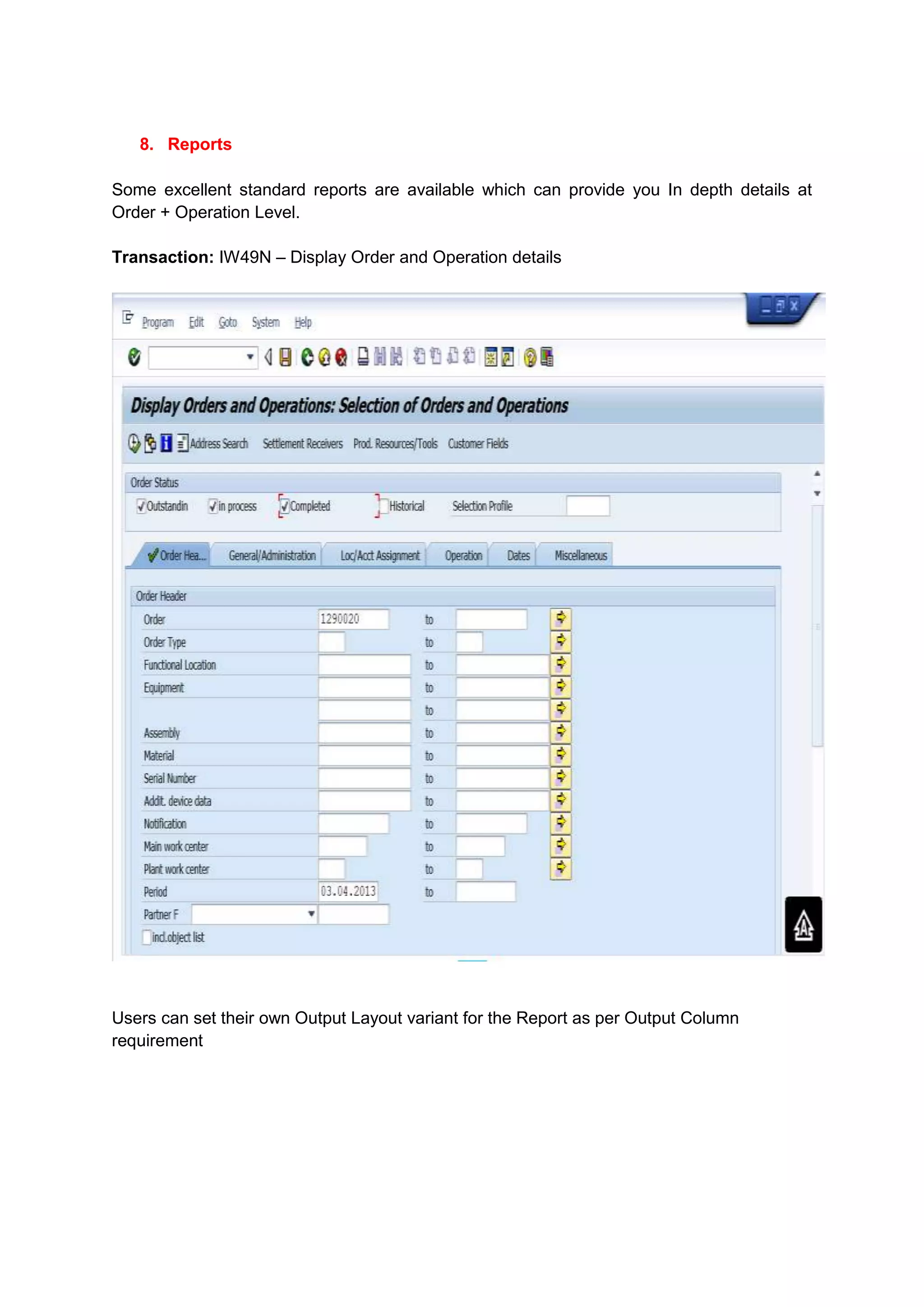

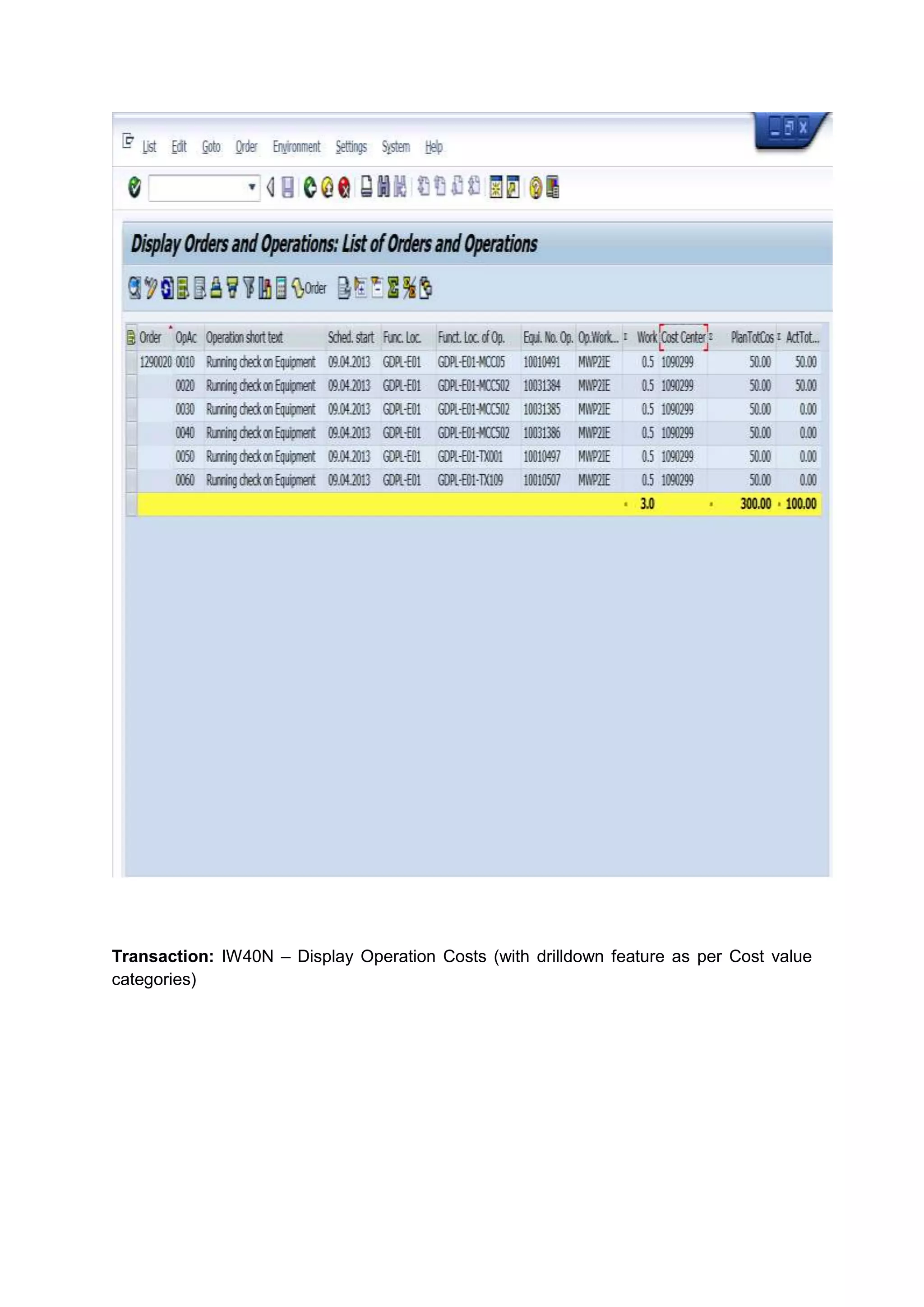

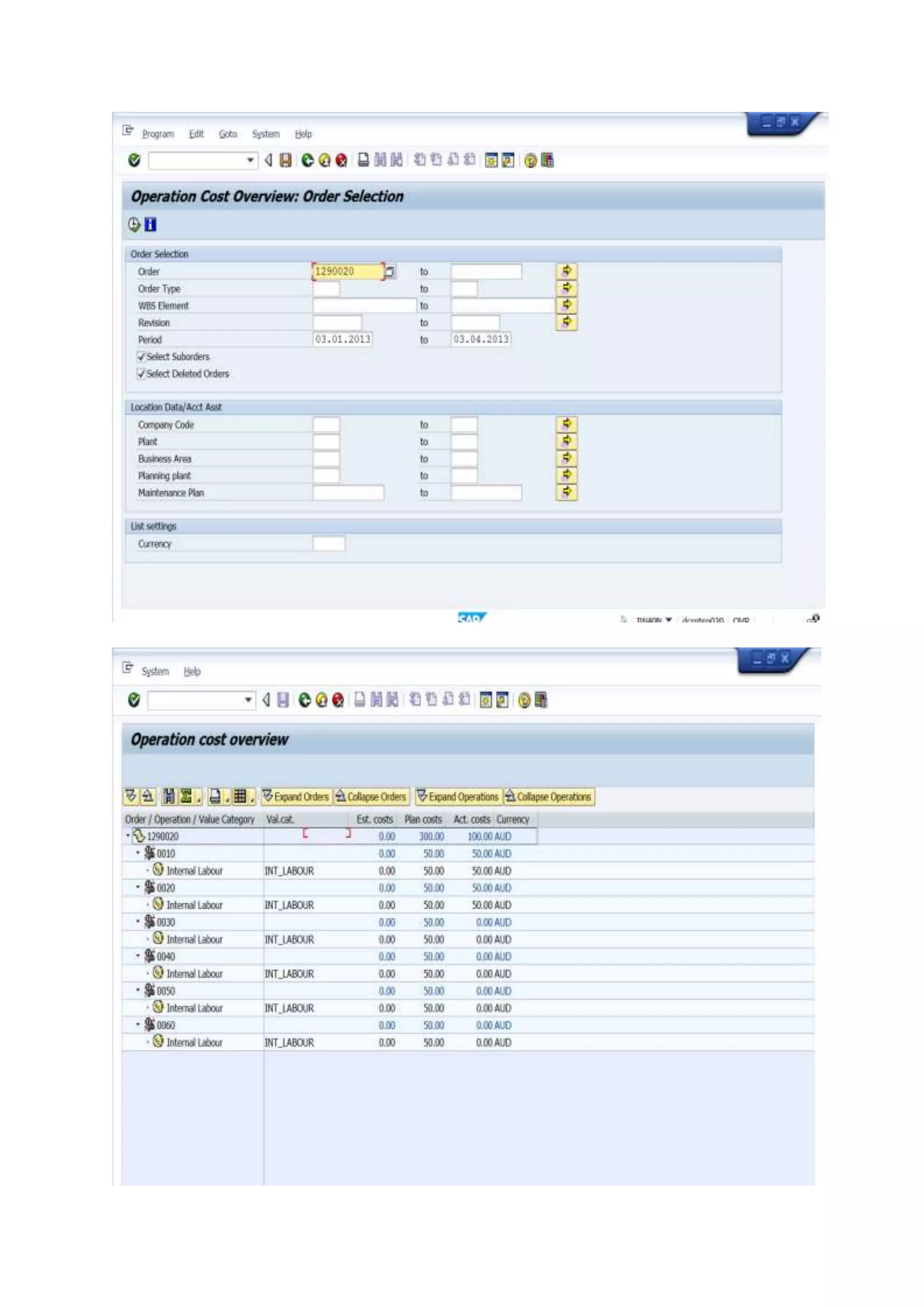

This document describes how to use inspection rounds and operation account assignment functionality in SAP PM. It provides instructions for defining an inspection round using a general task list, planning the inspection round by creating a maintenance plan and assigning the task list, and executing the inspection round by further planning any generated maintenance orders and recording time and costs at the operation level linked to different equipment references. Background prerequisites and configurations are also outlined.