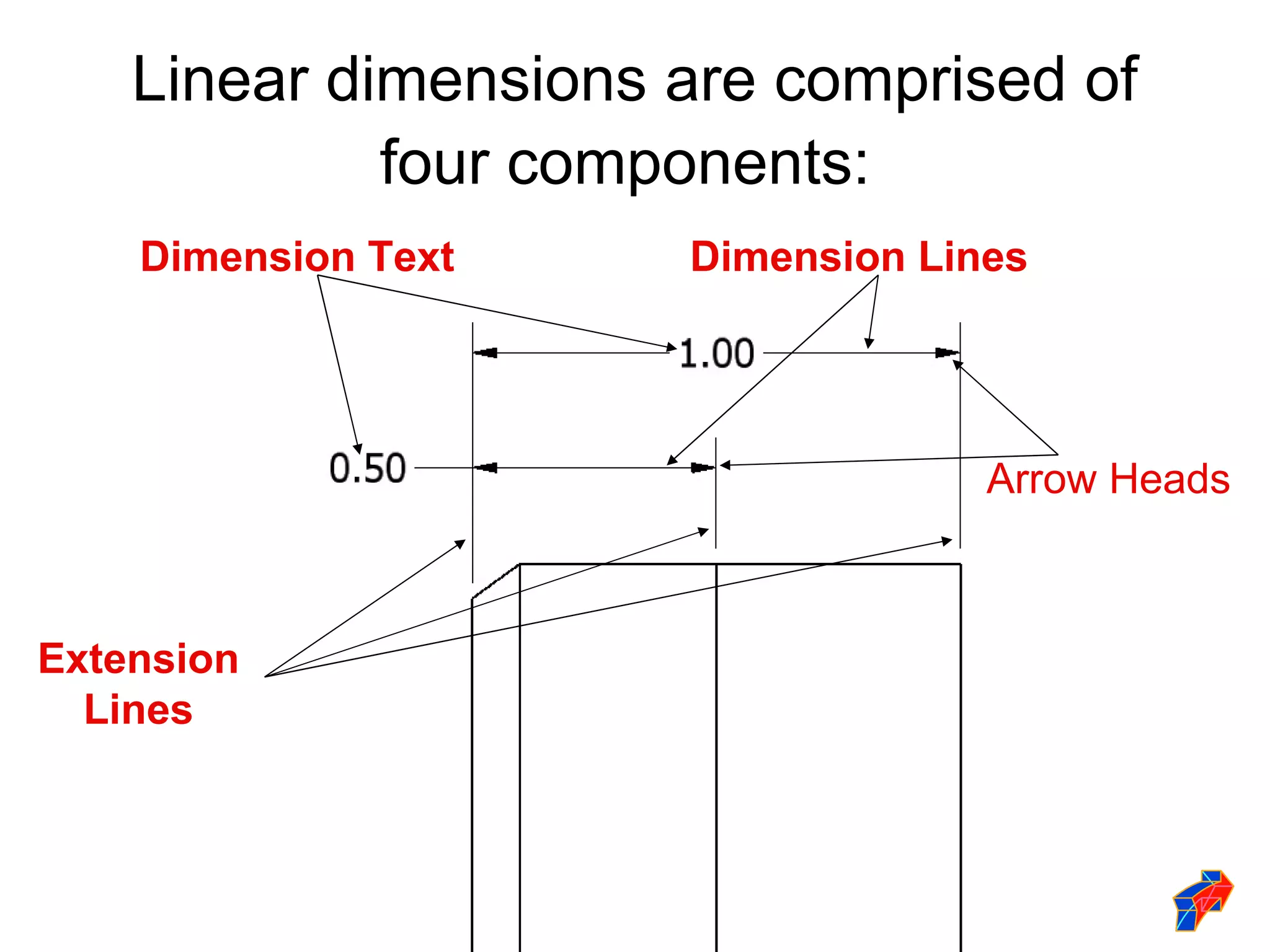

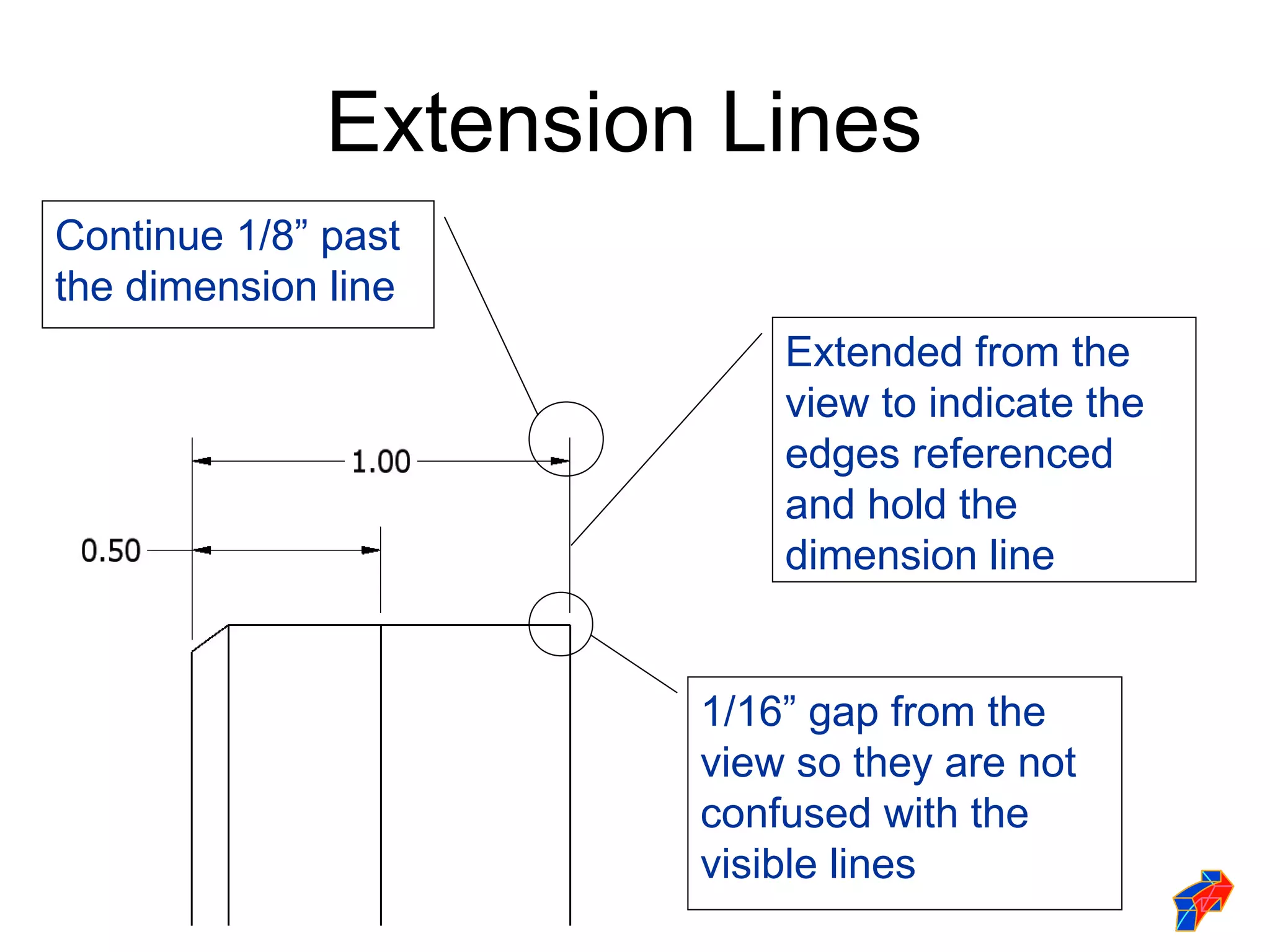

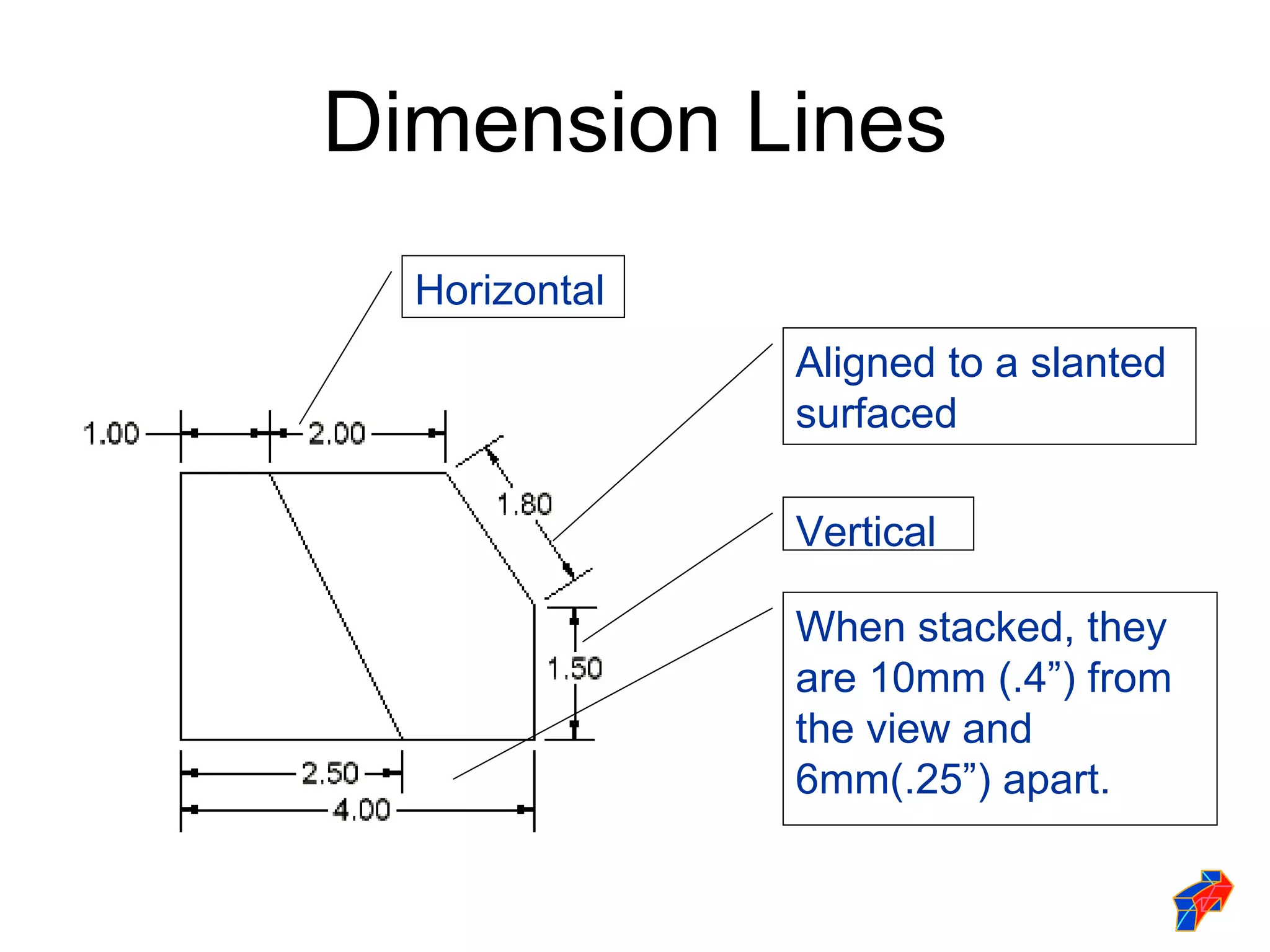

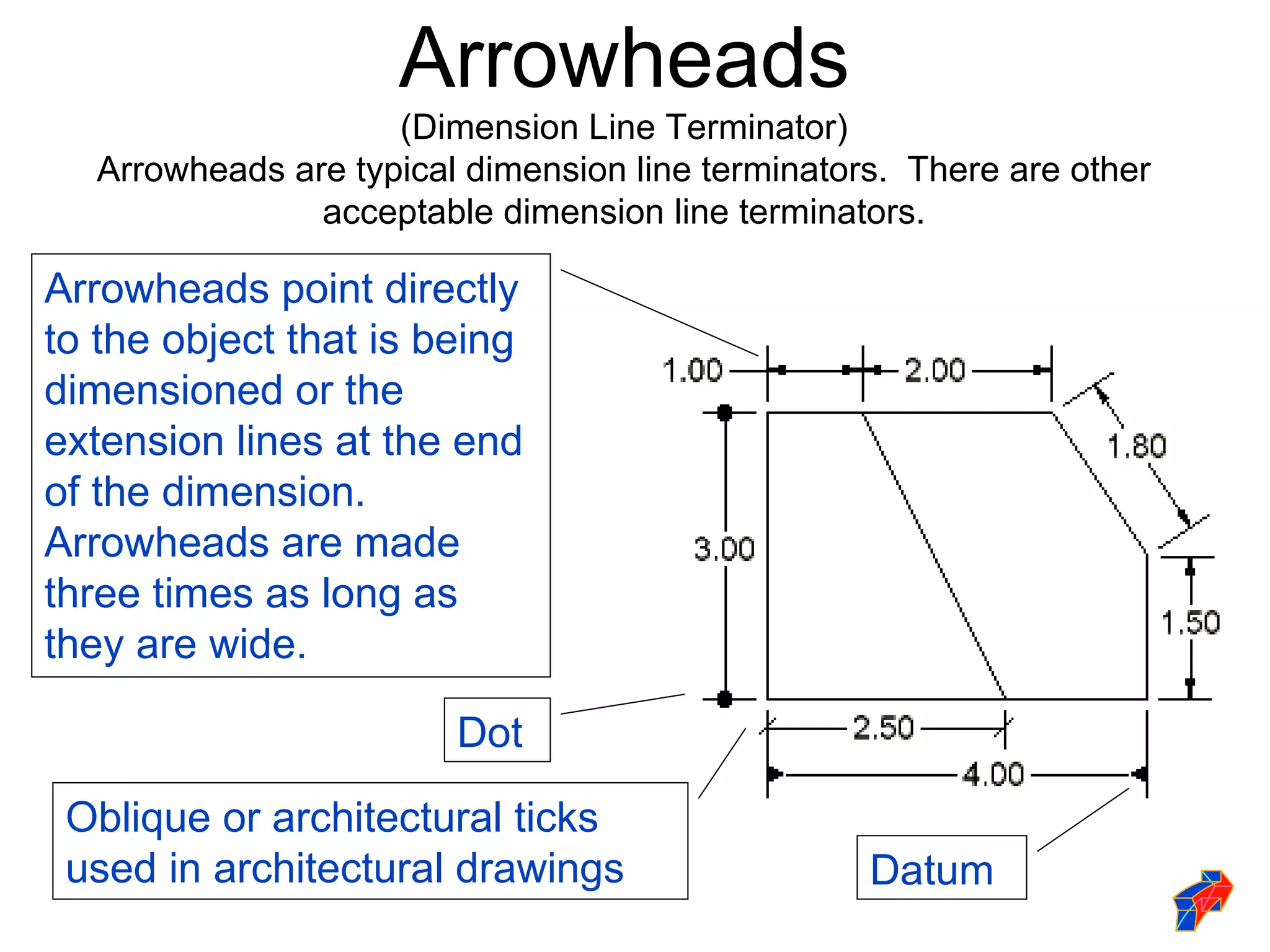

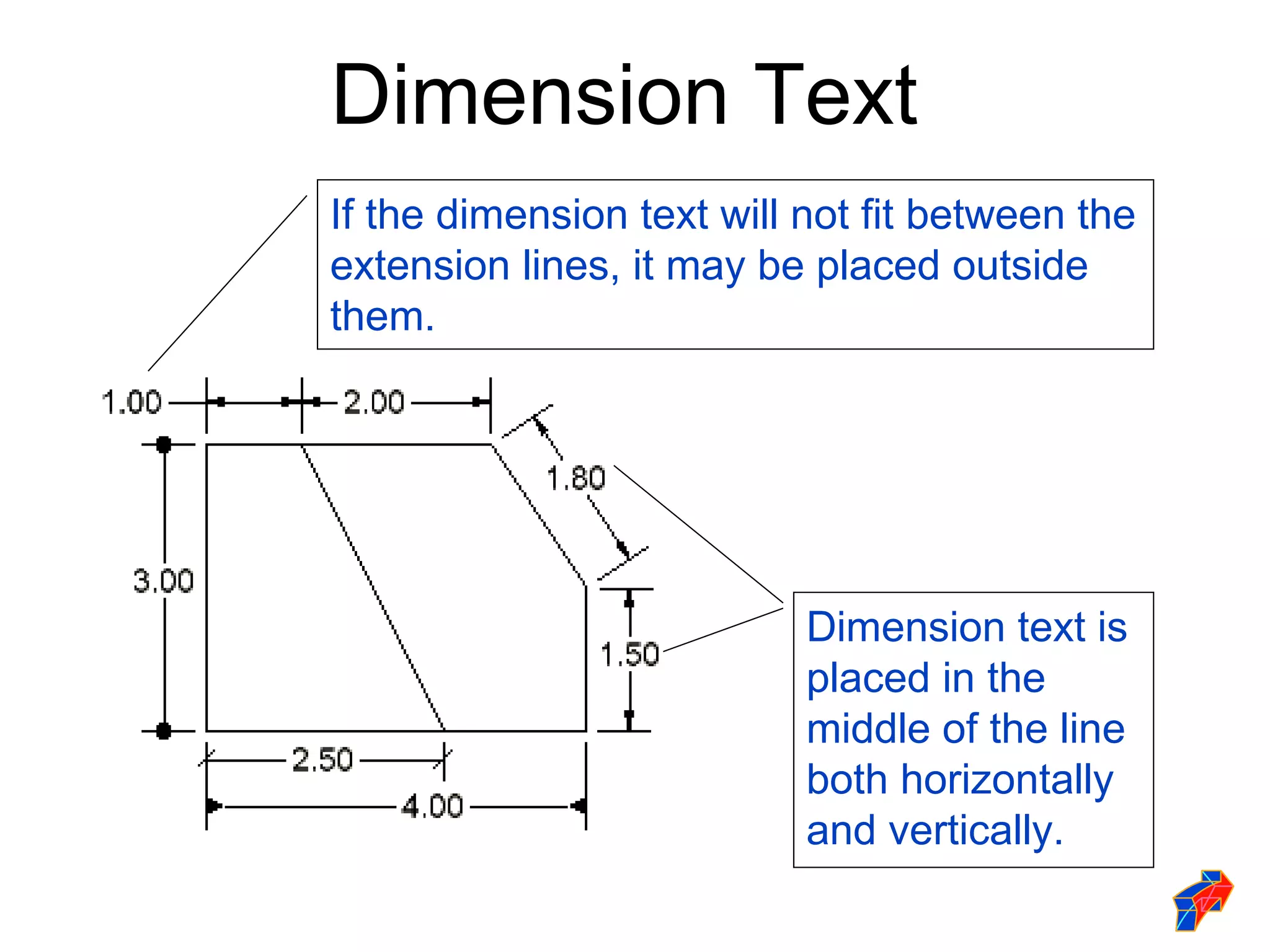

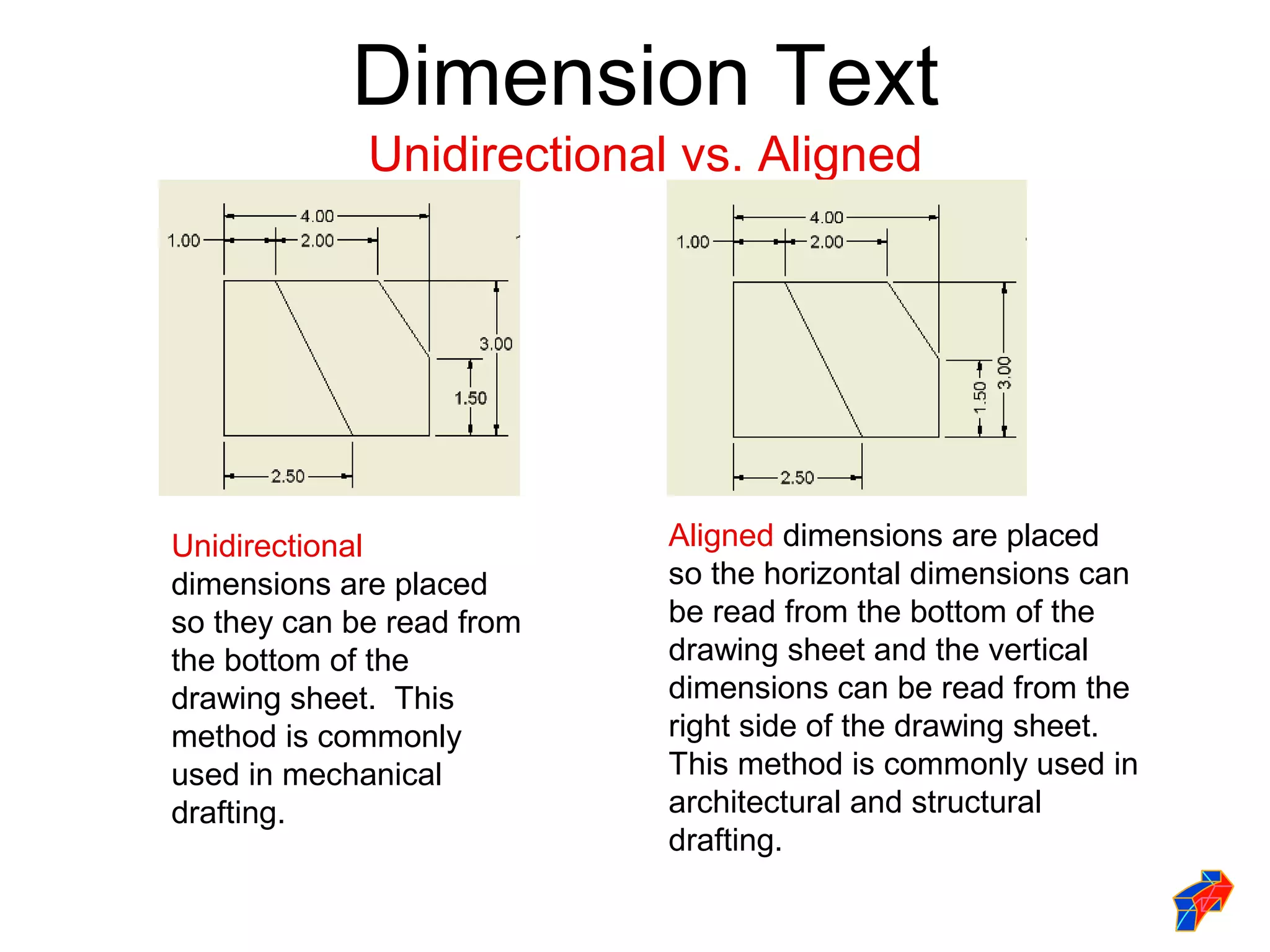

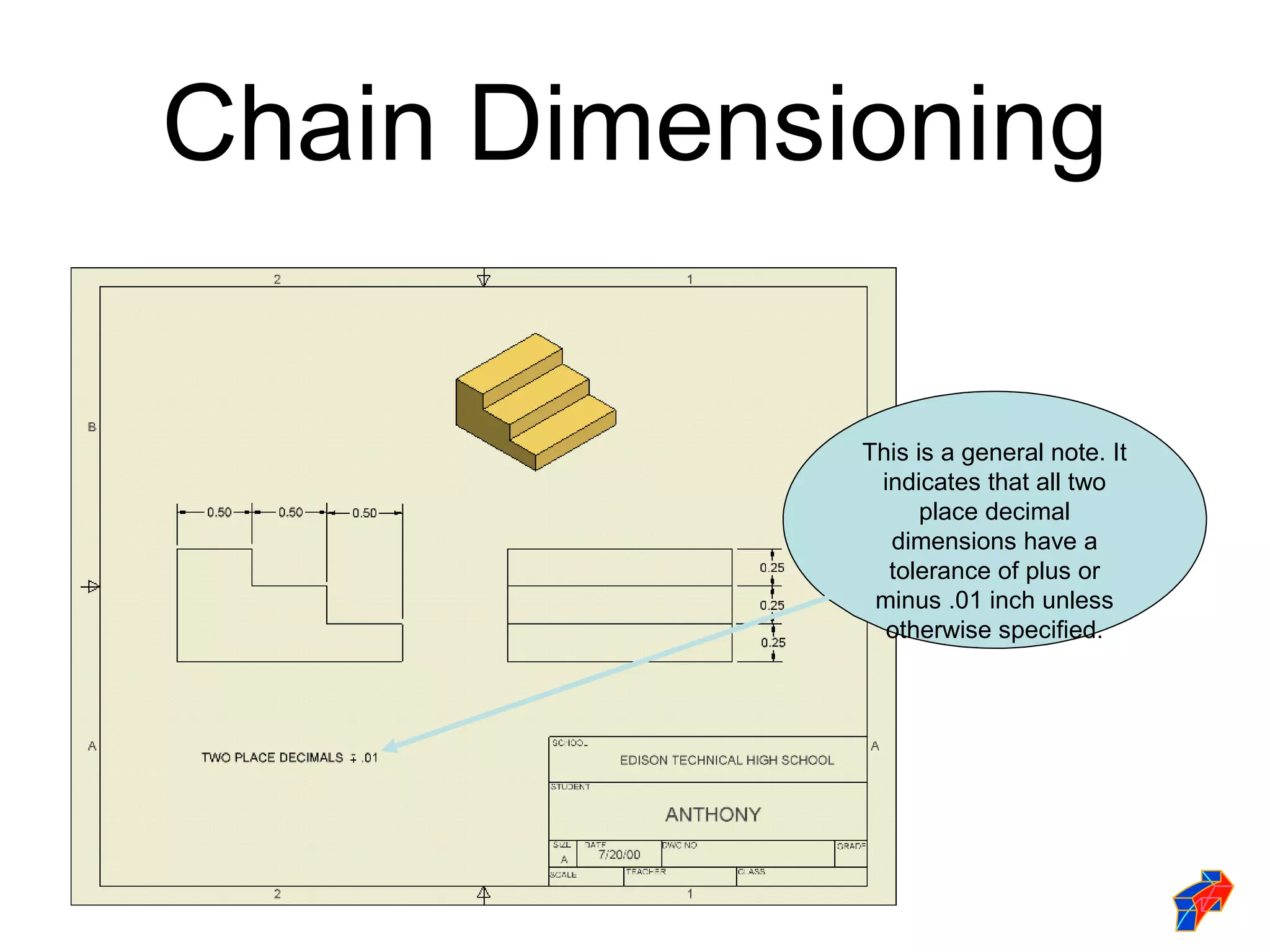

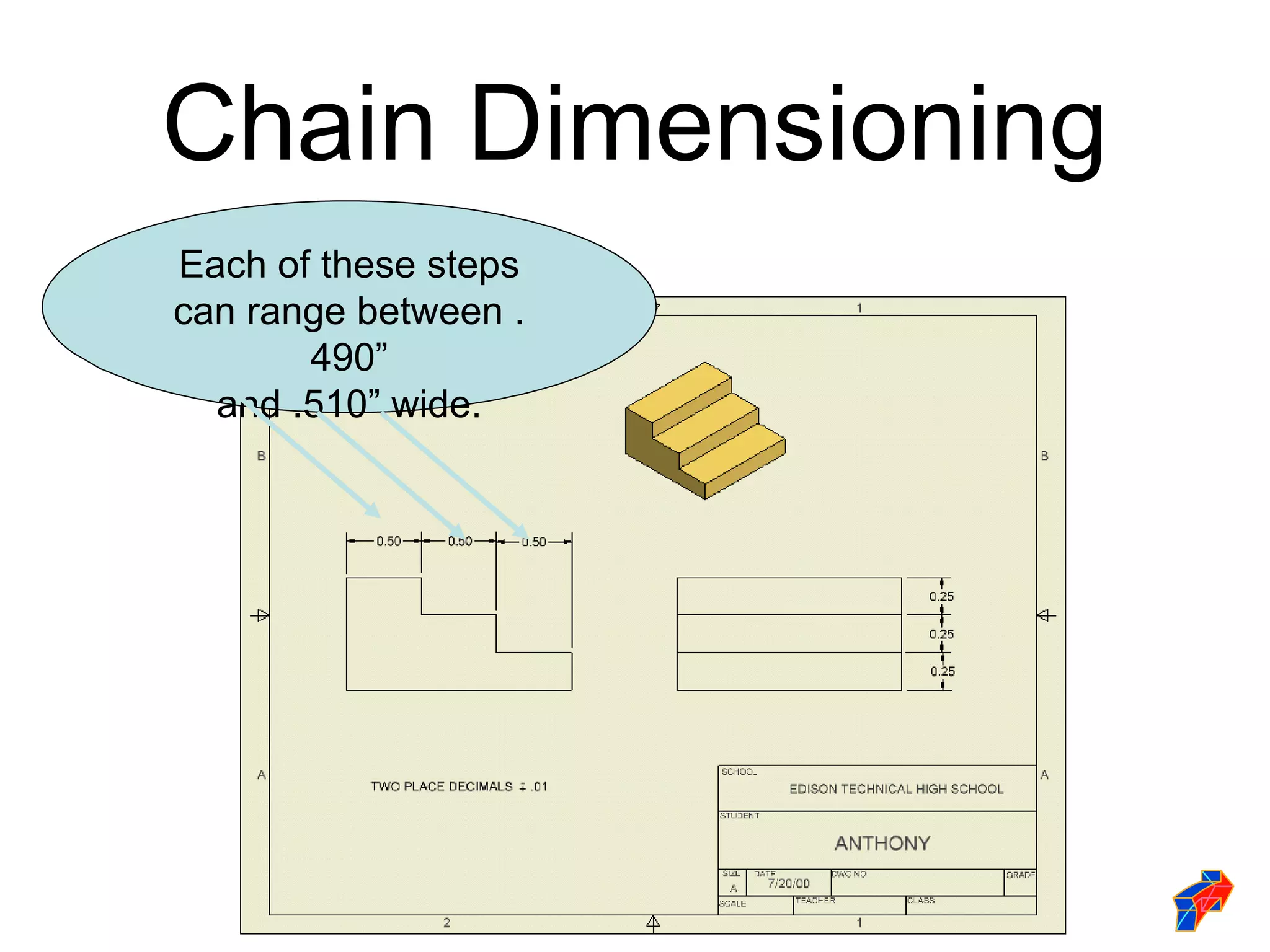

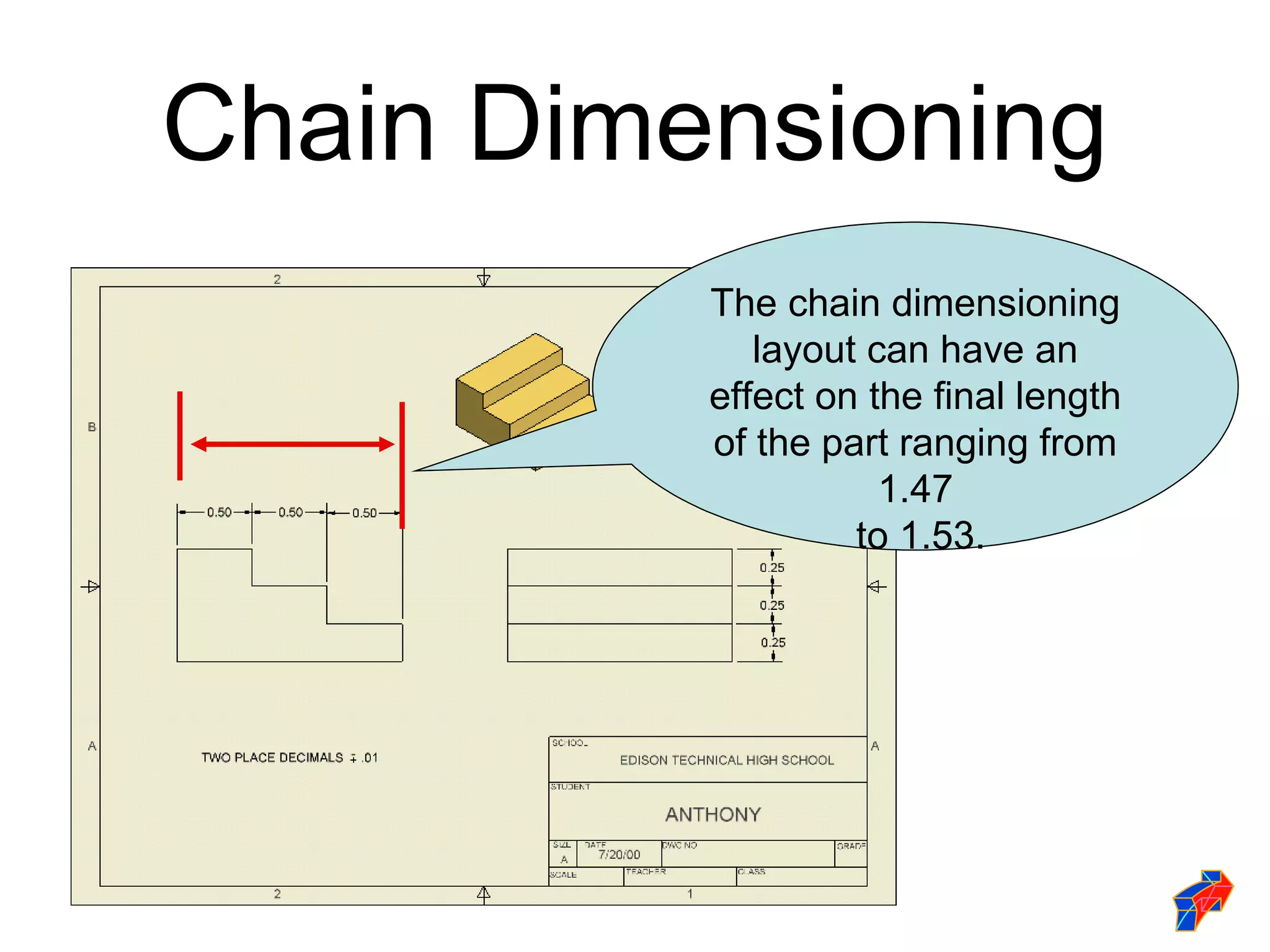

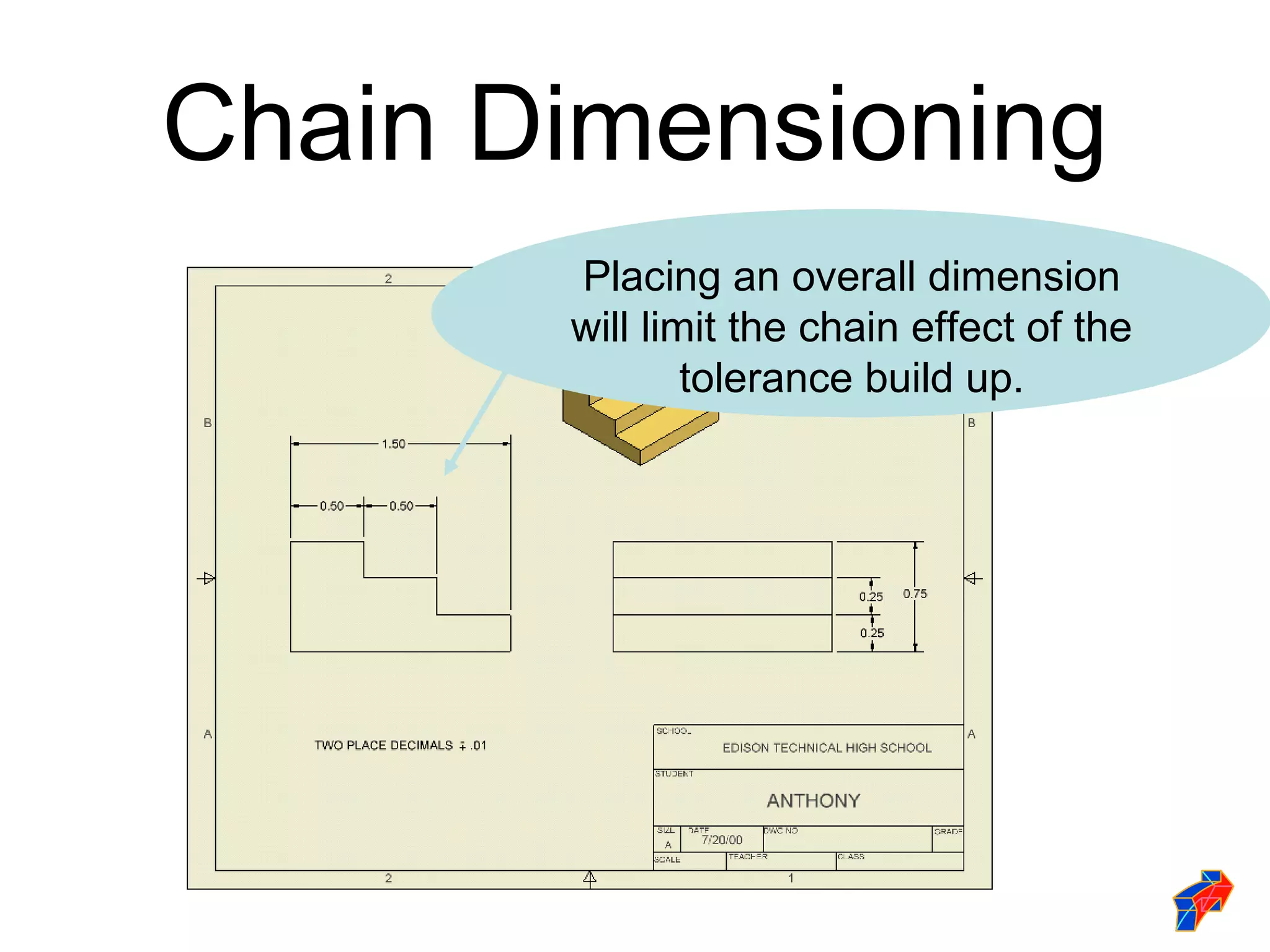

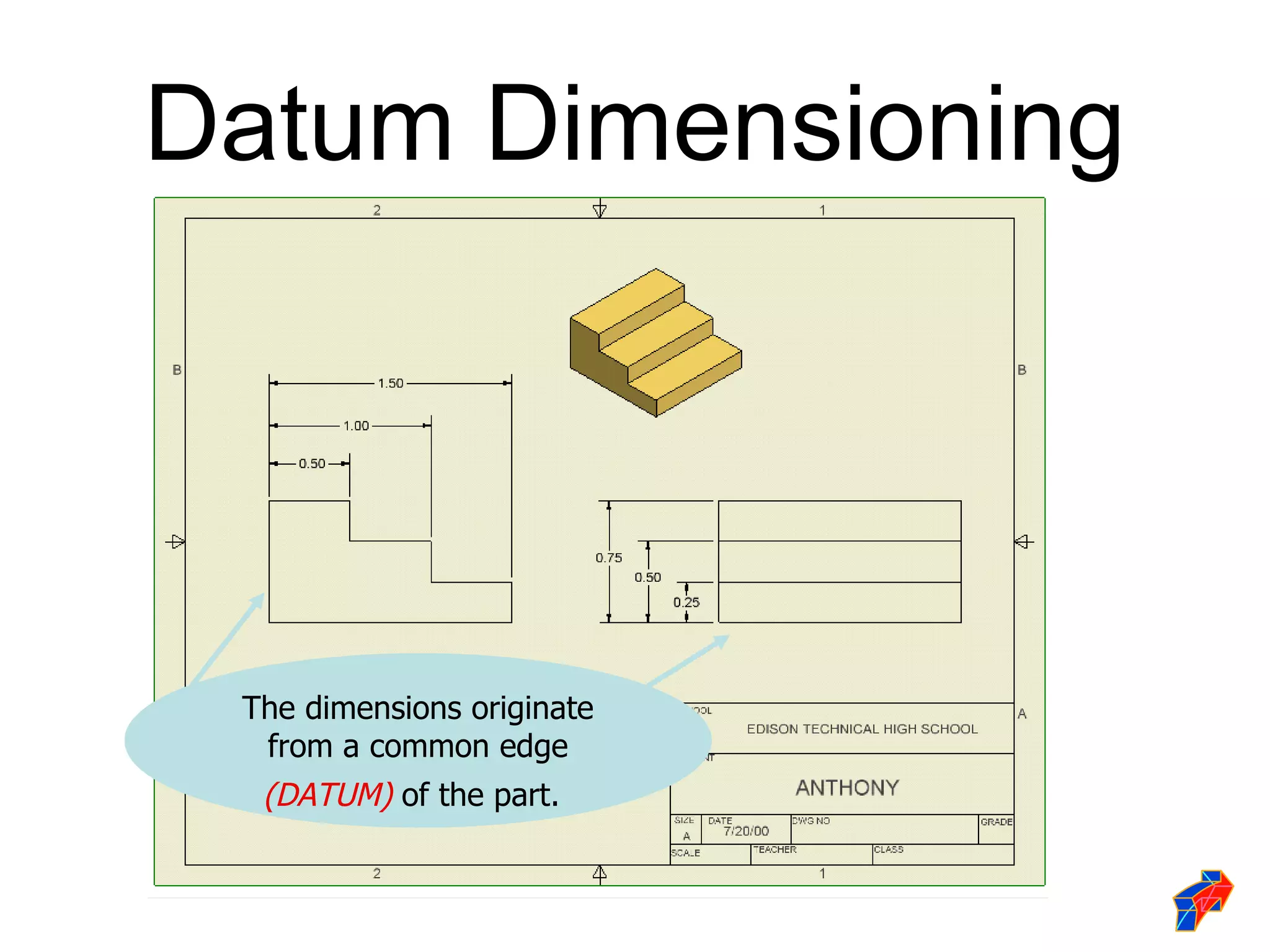

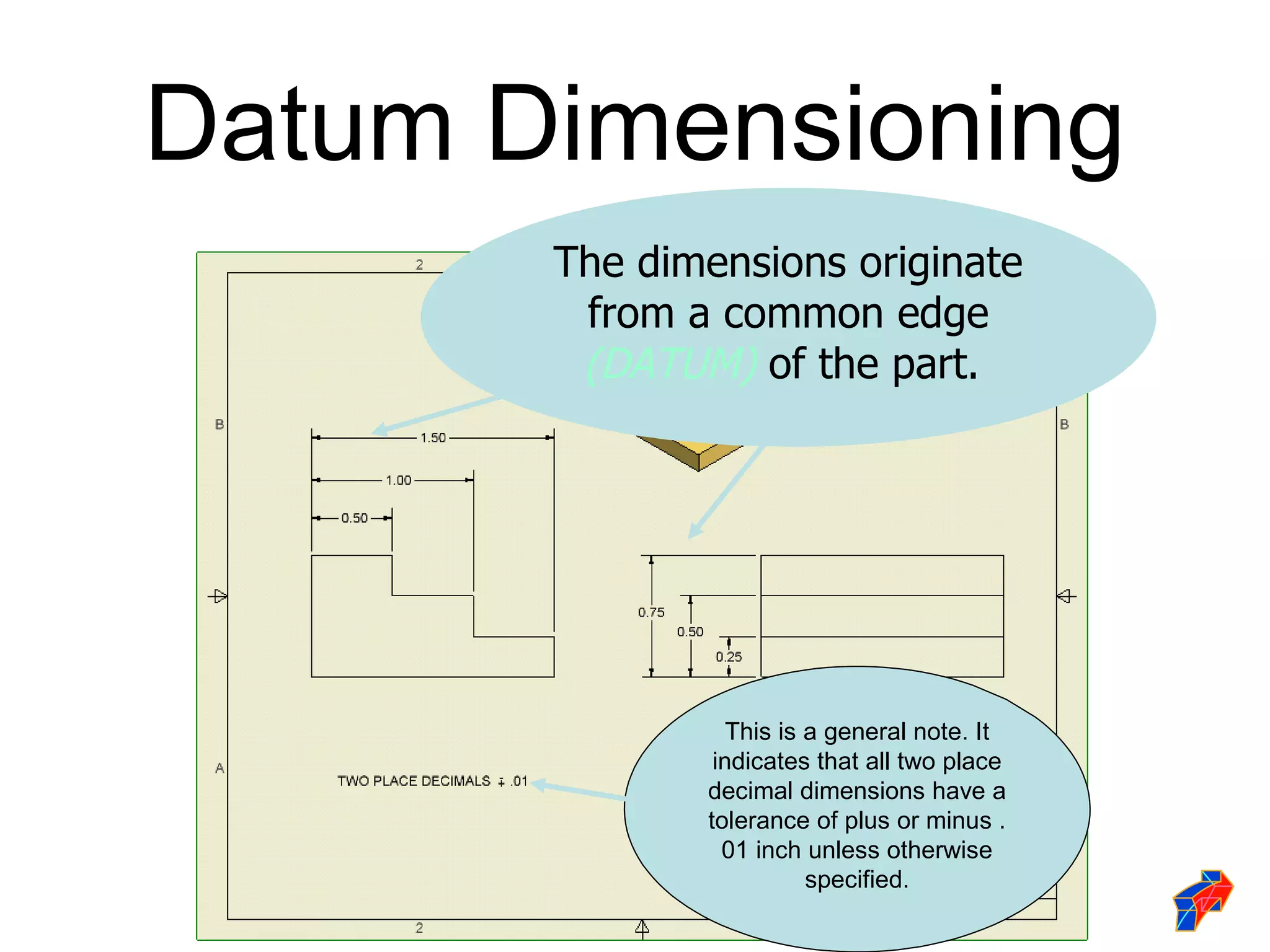

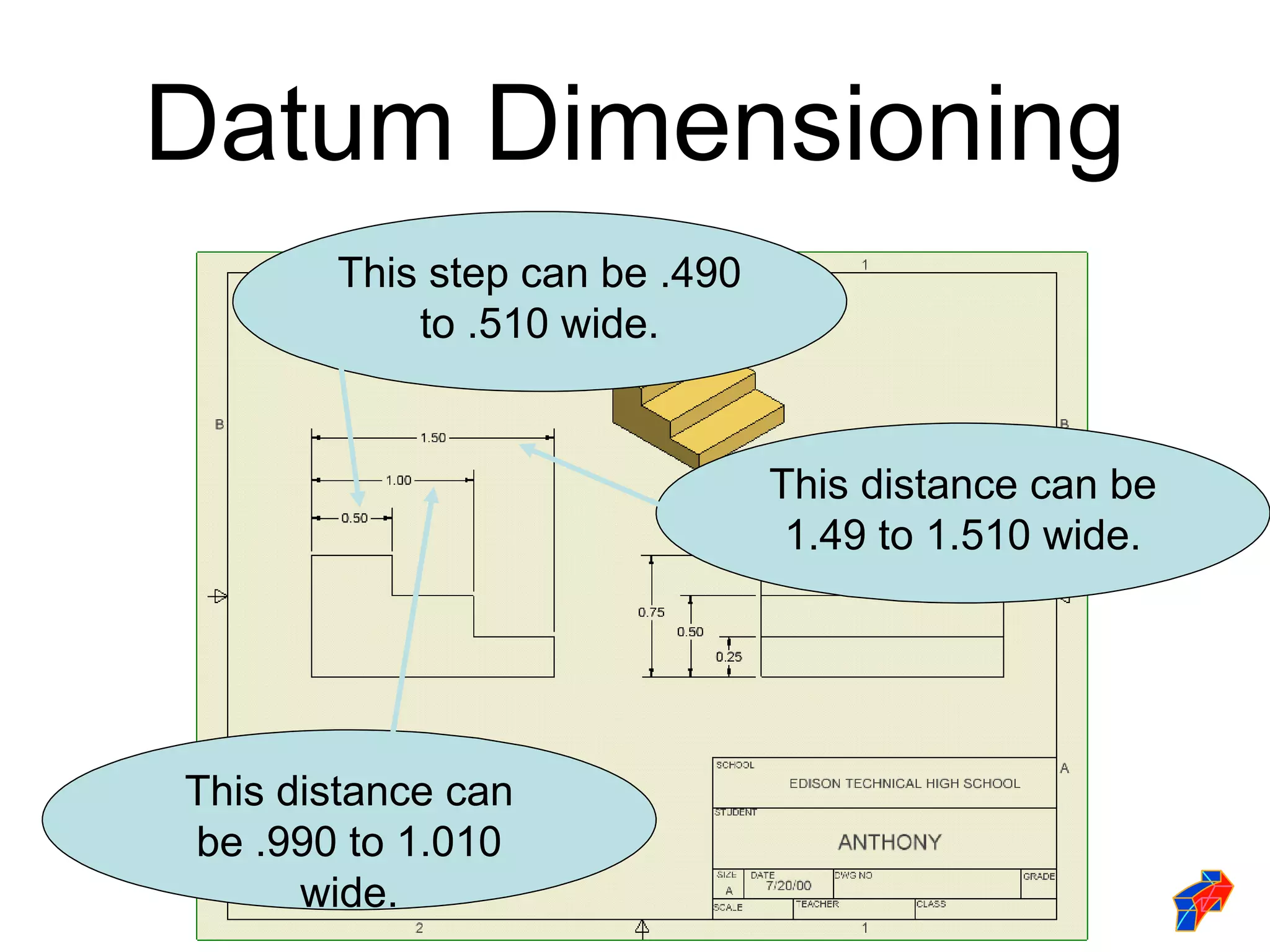

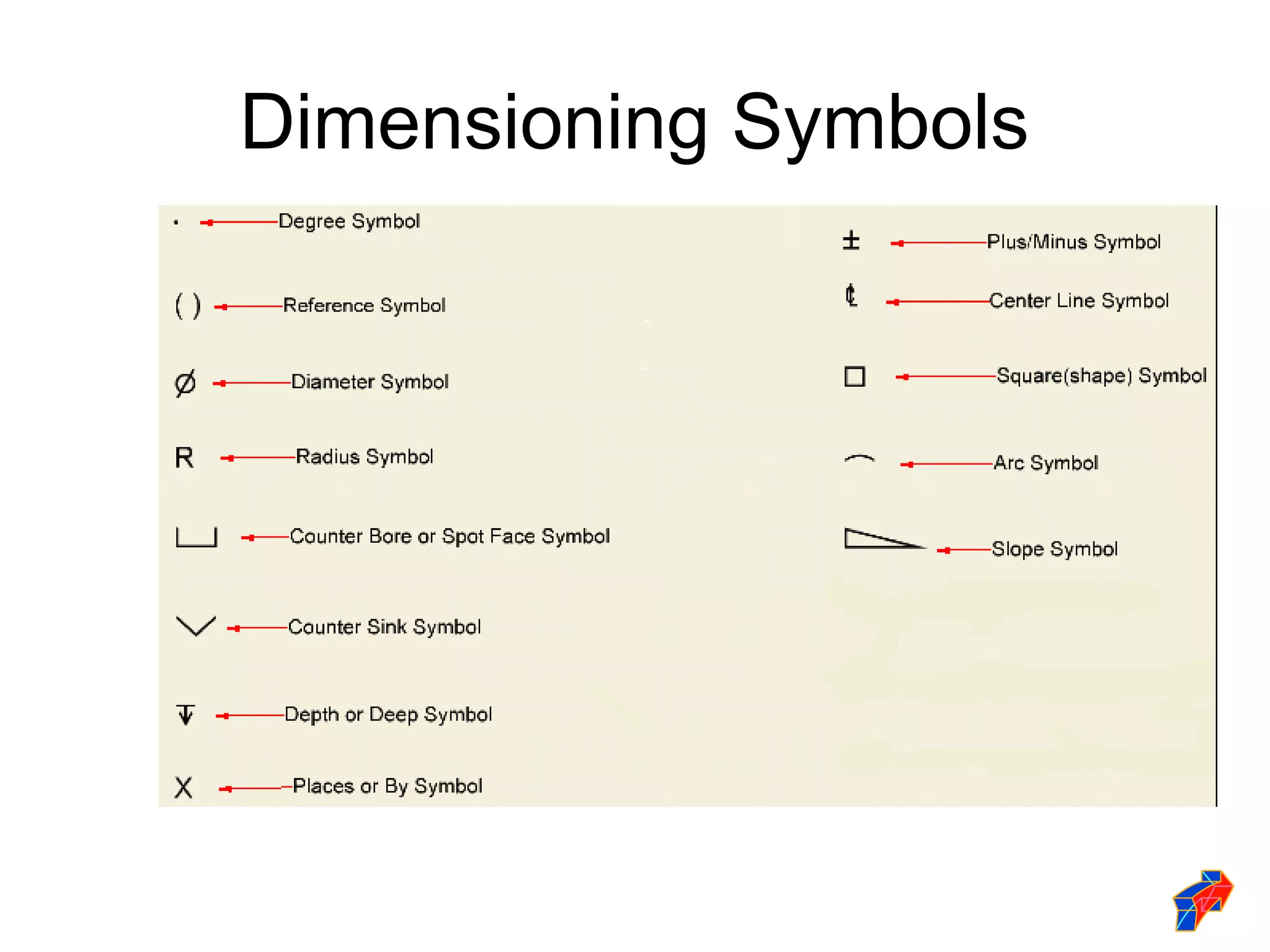

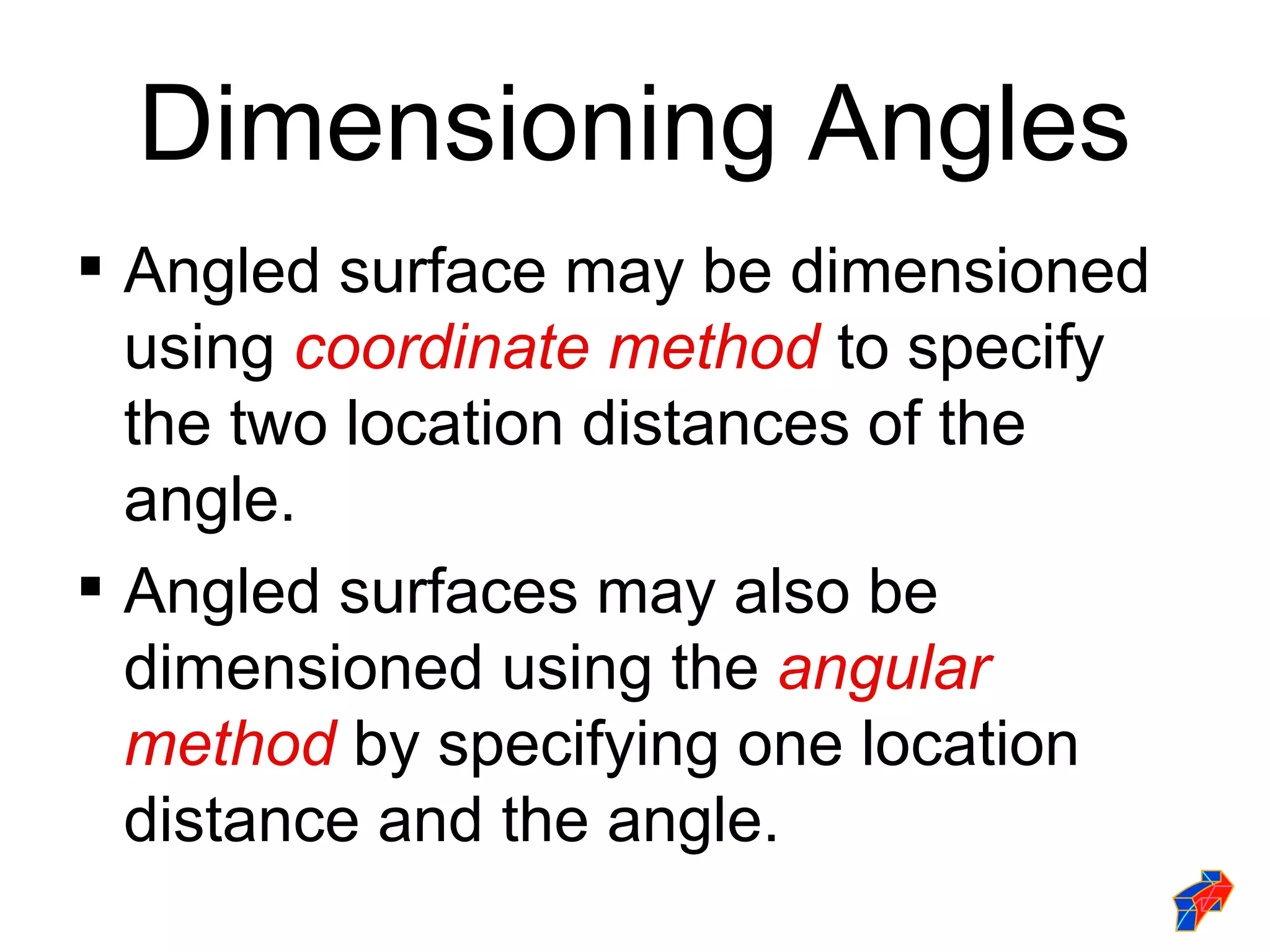

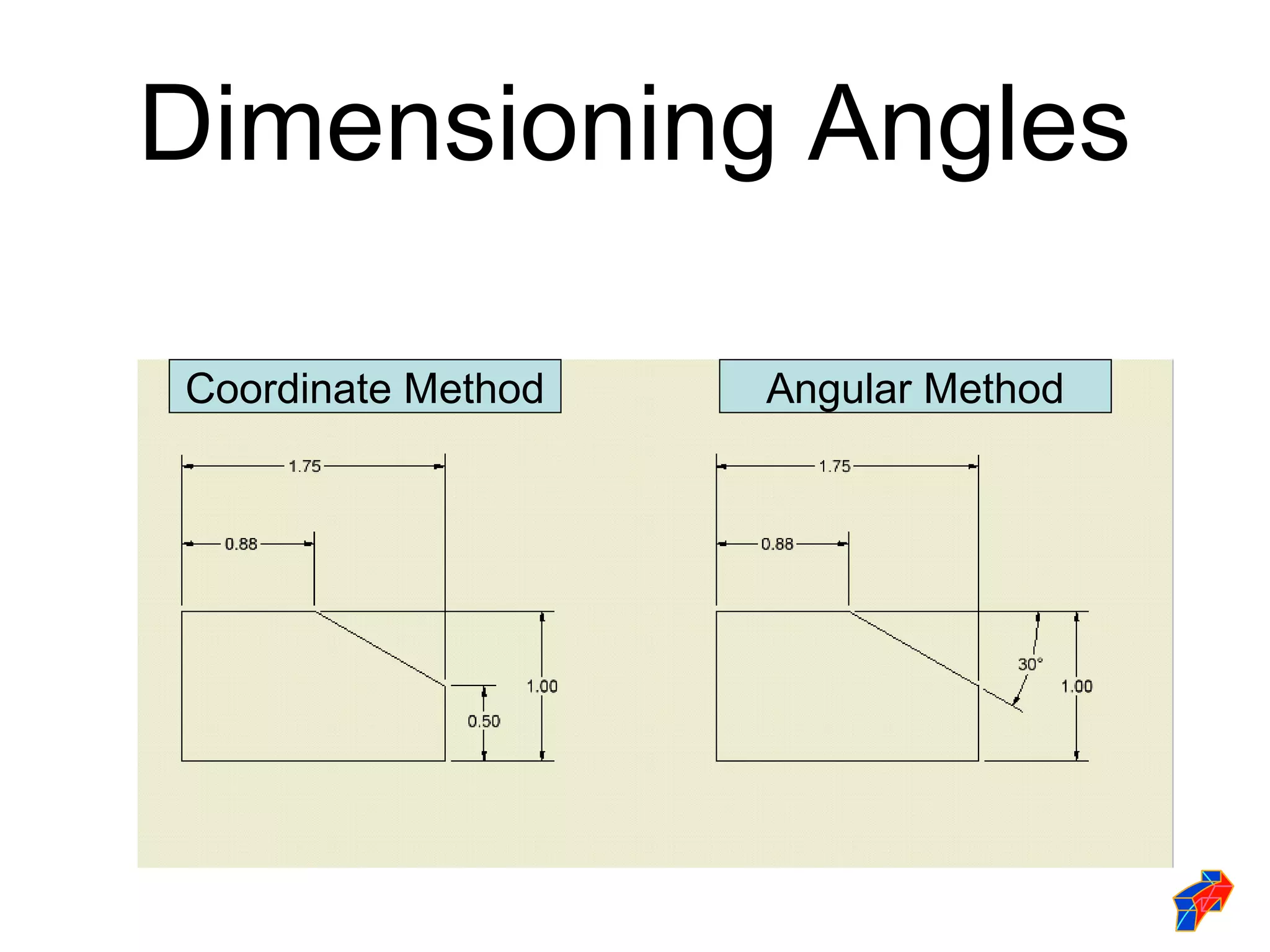

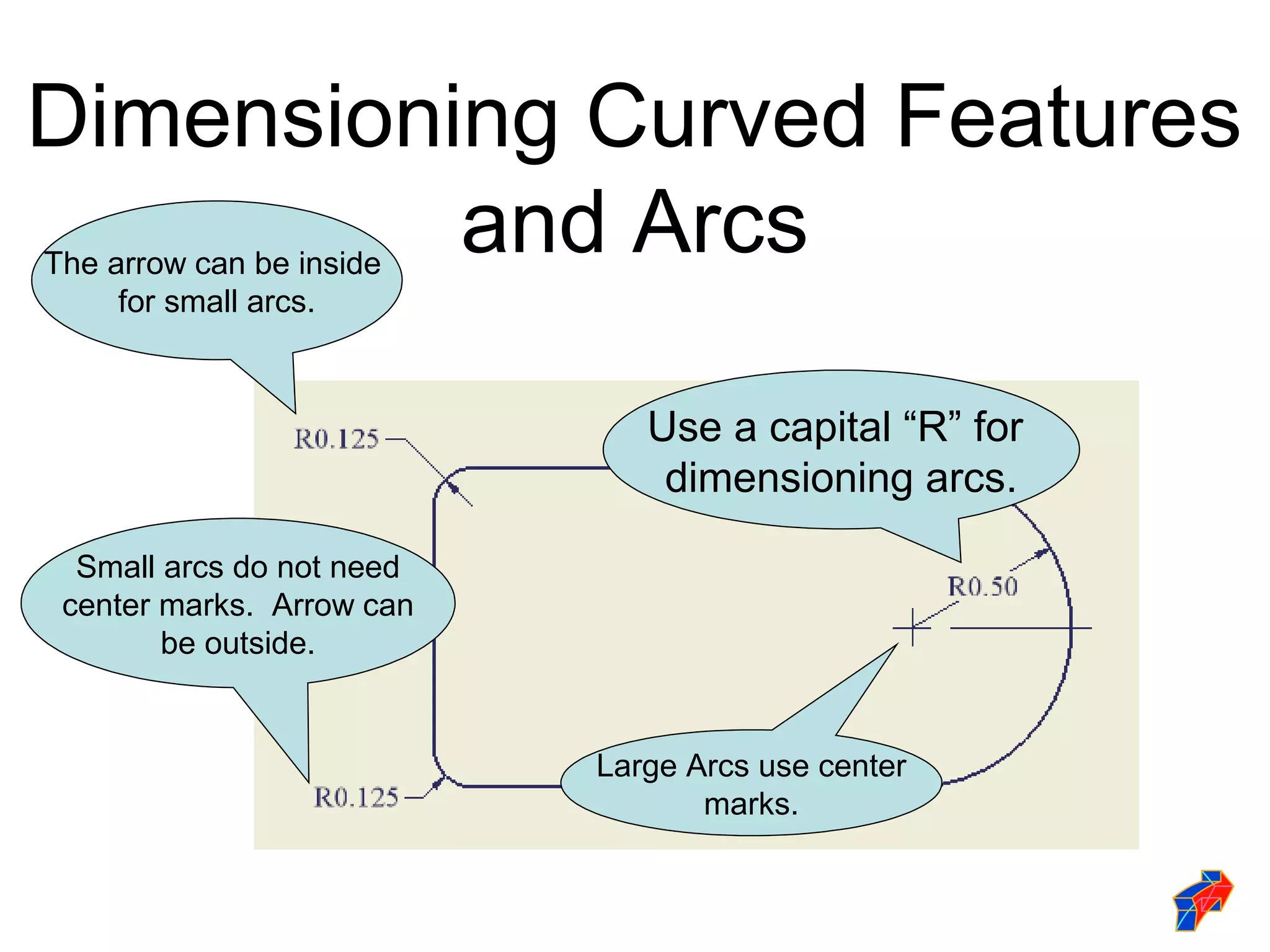

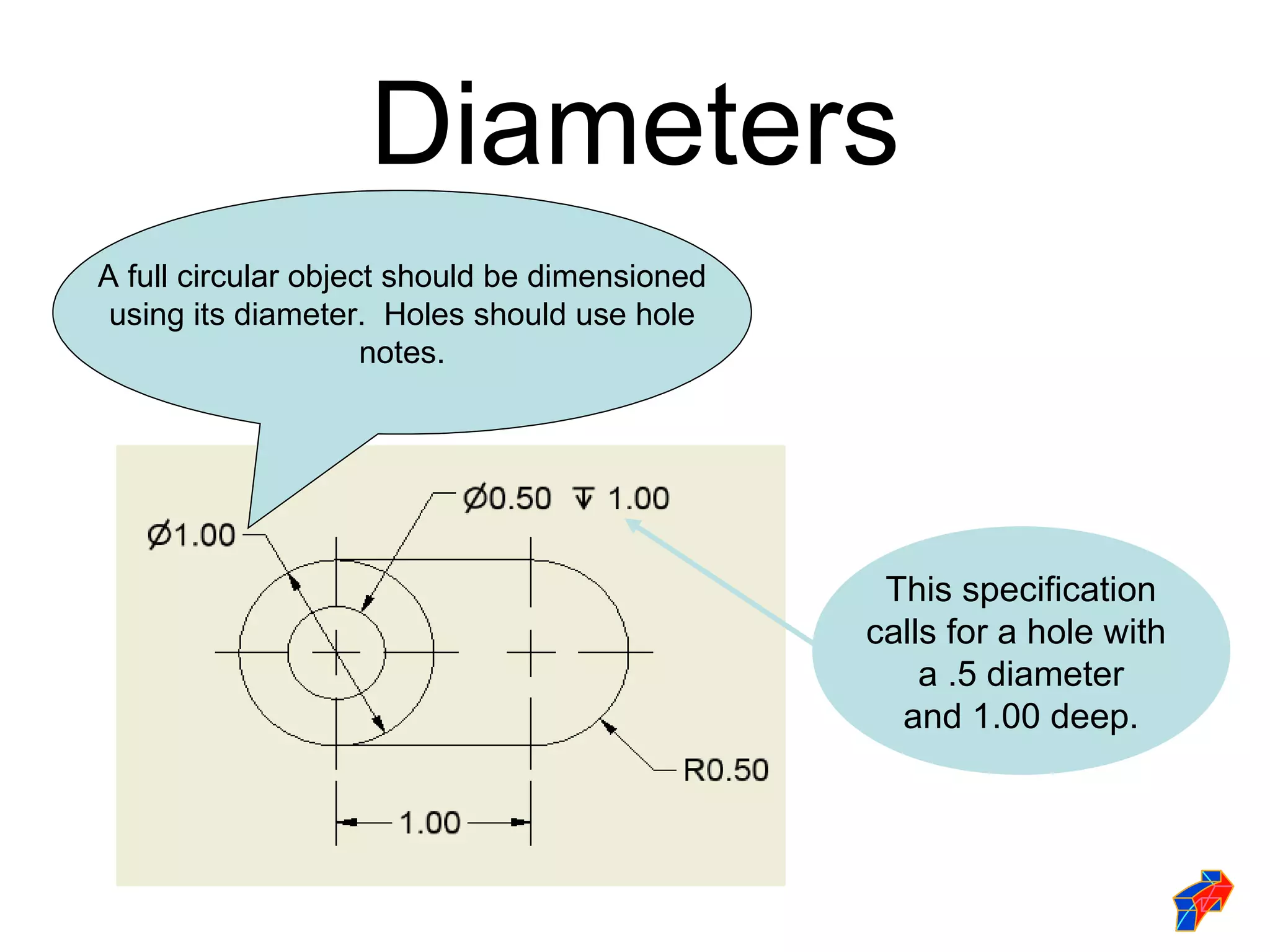

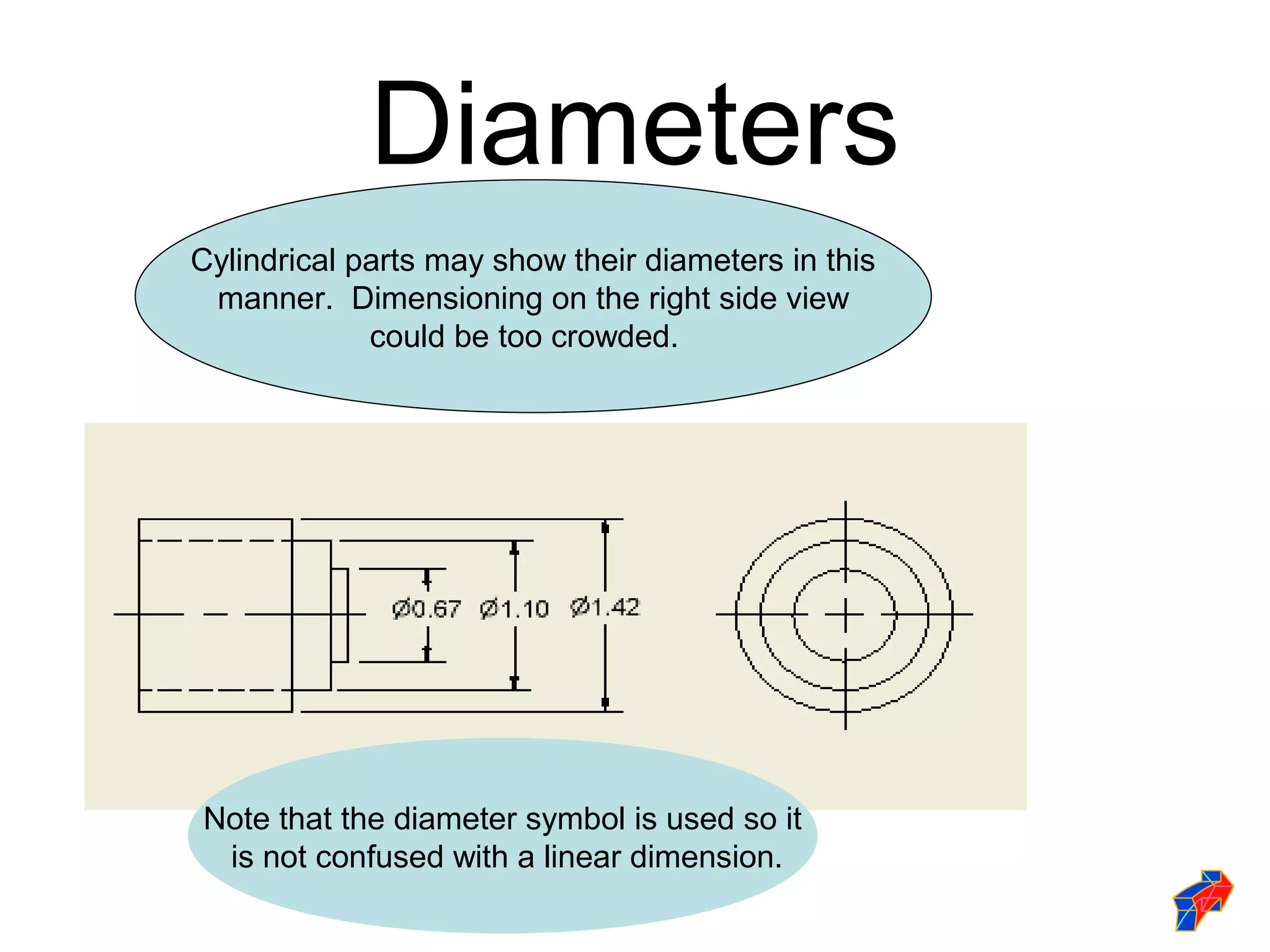

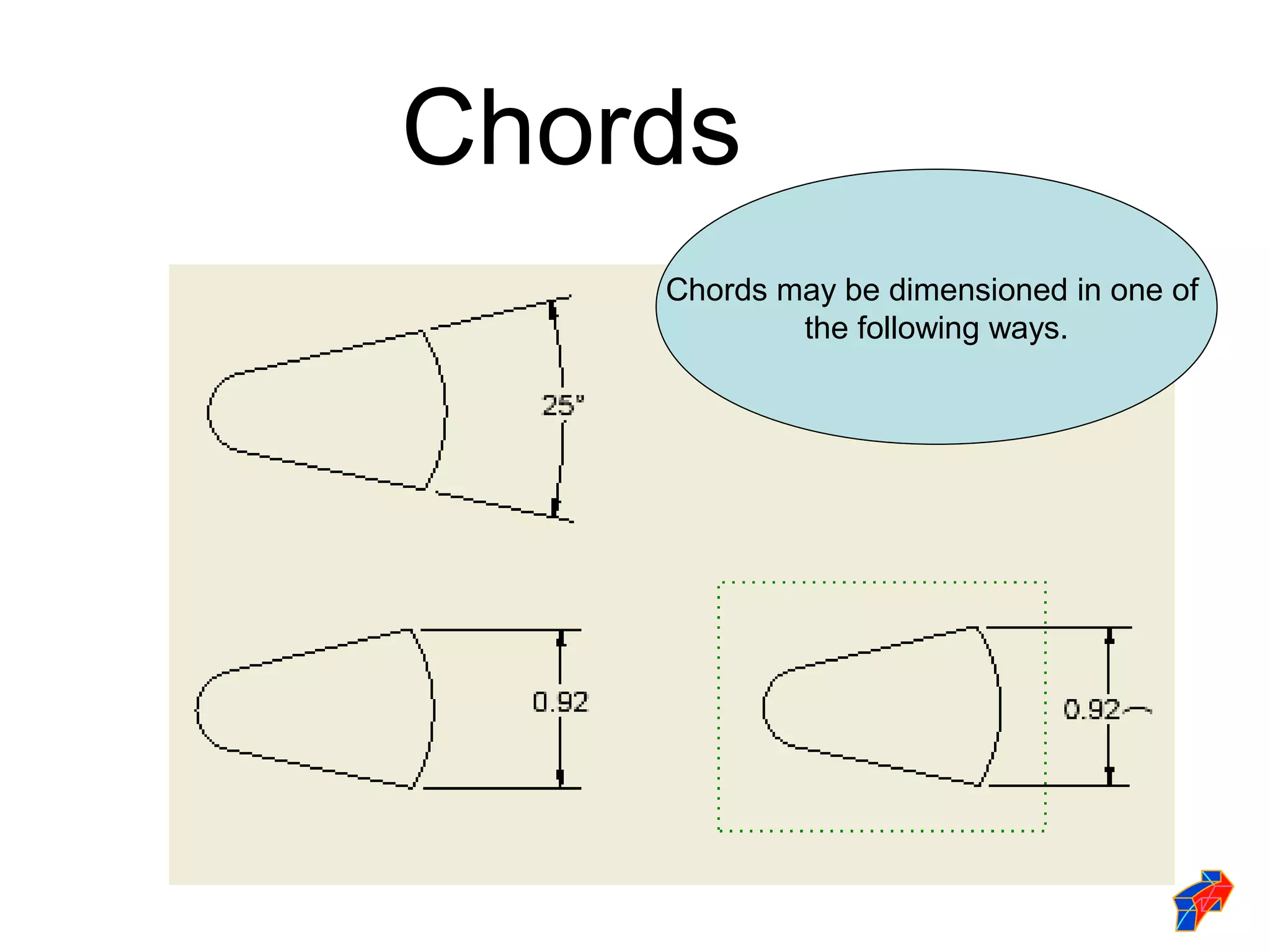

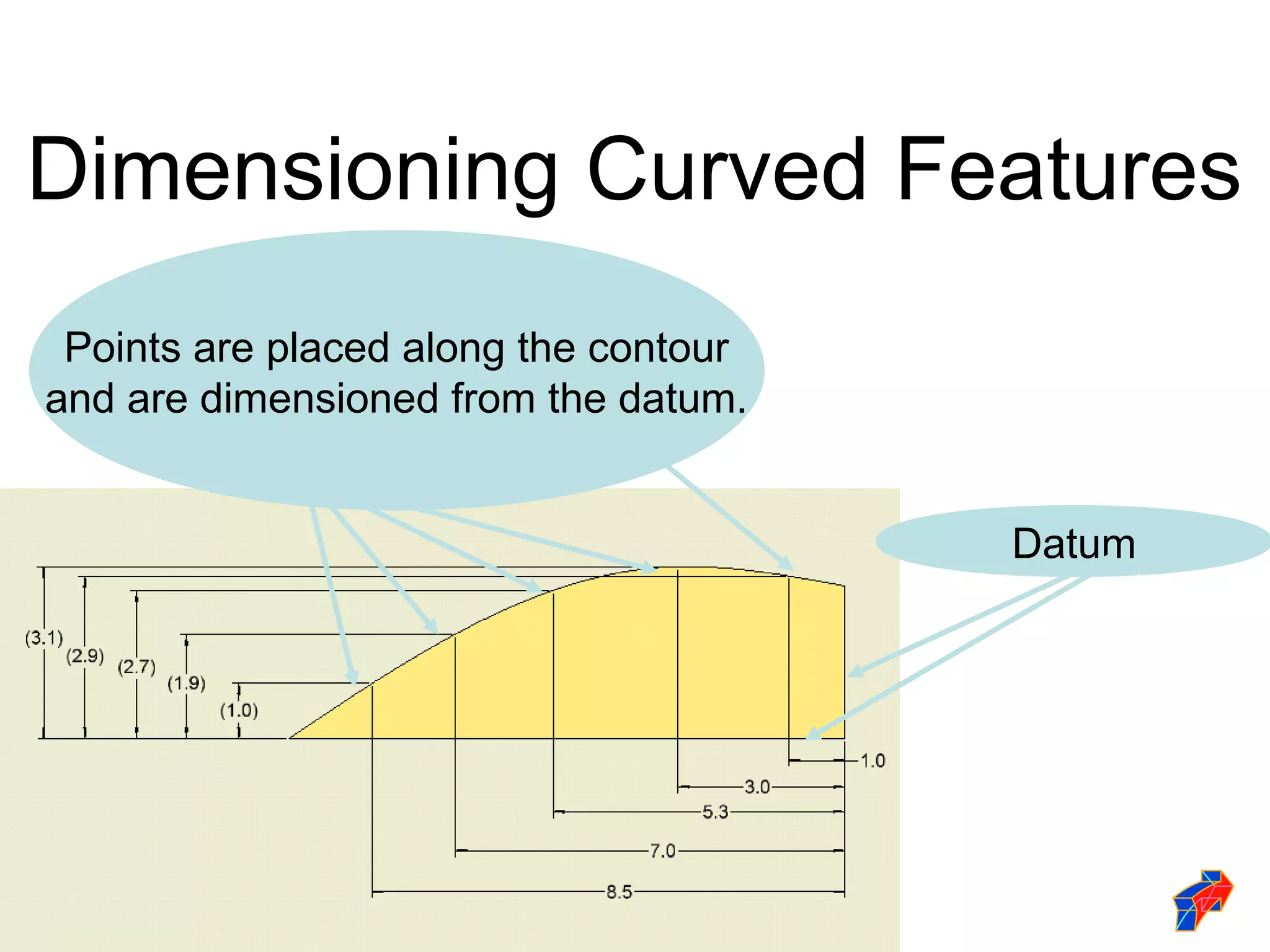

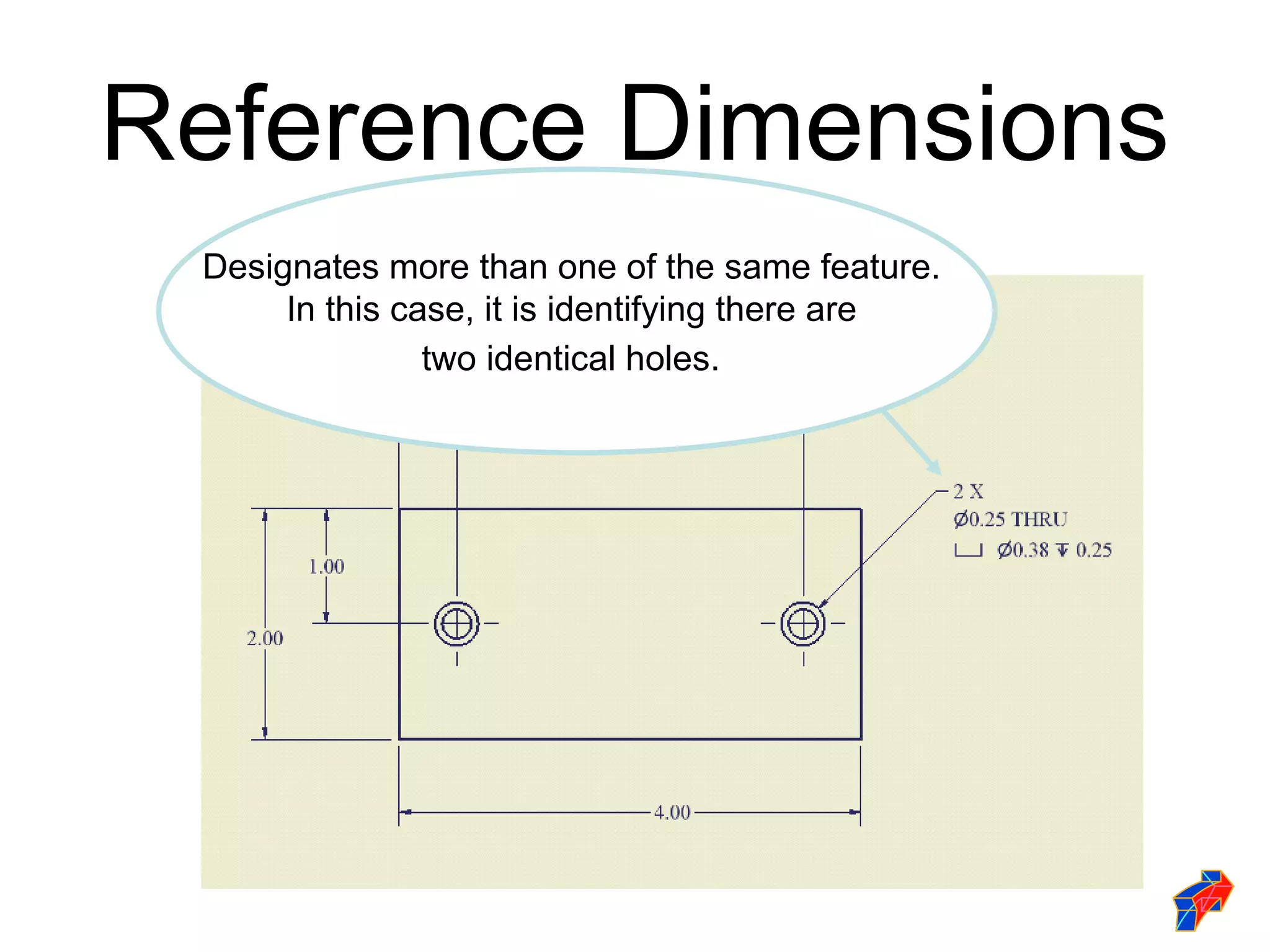

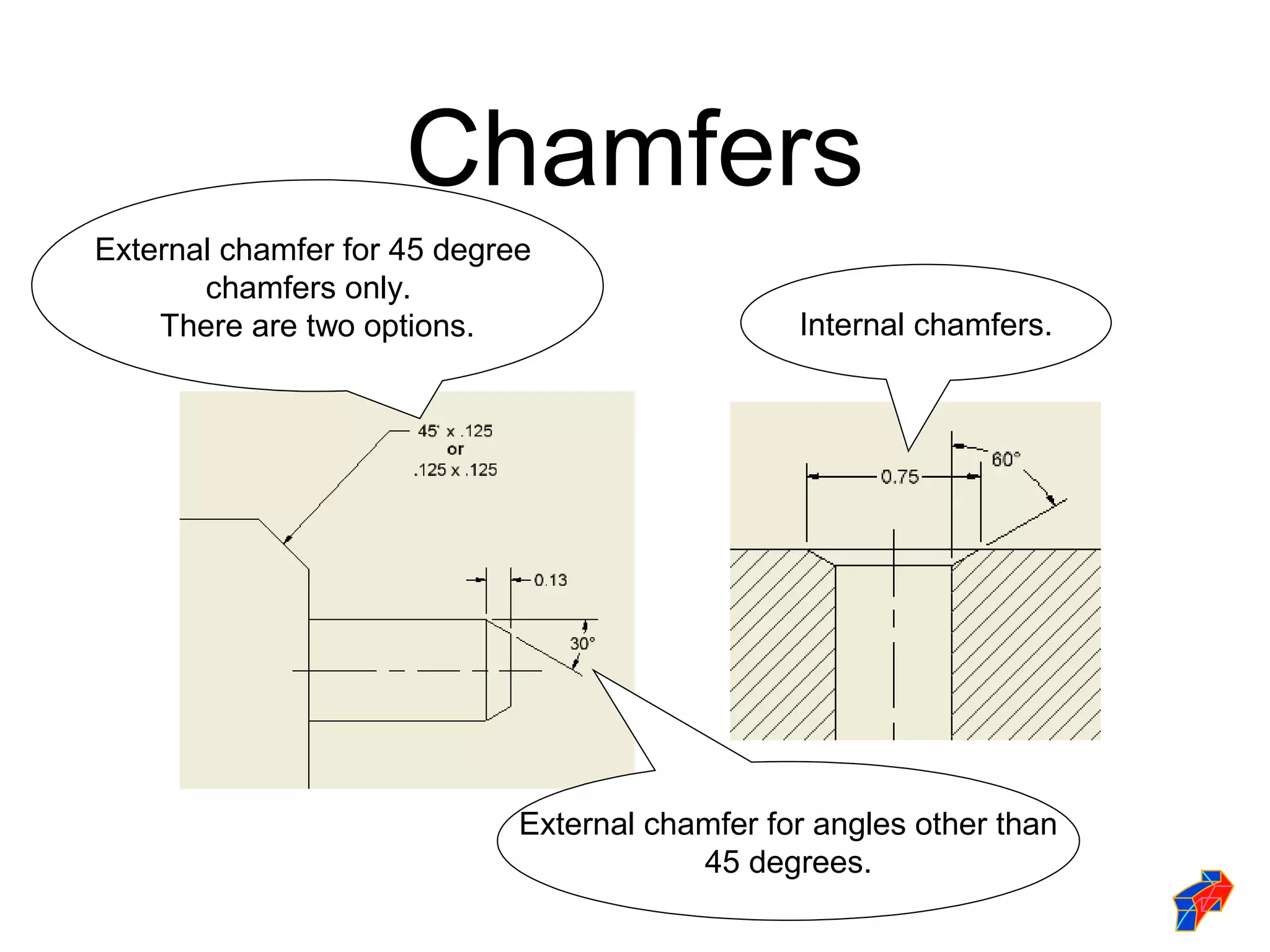

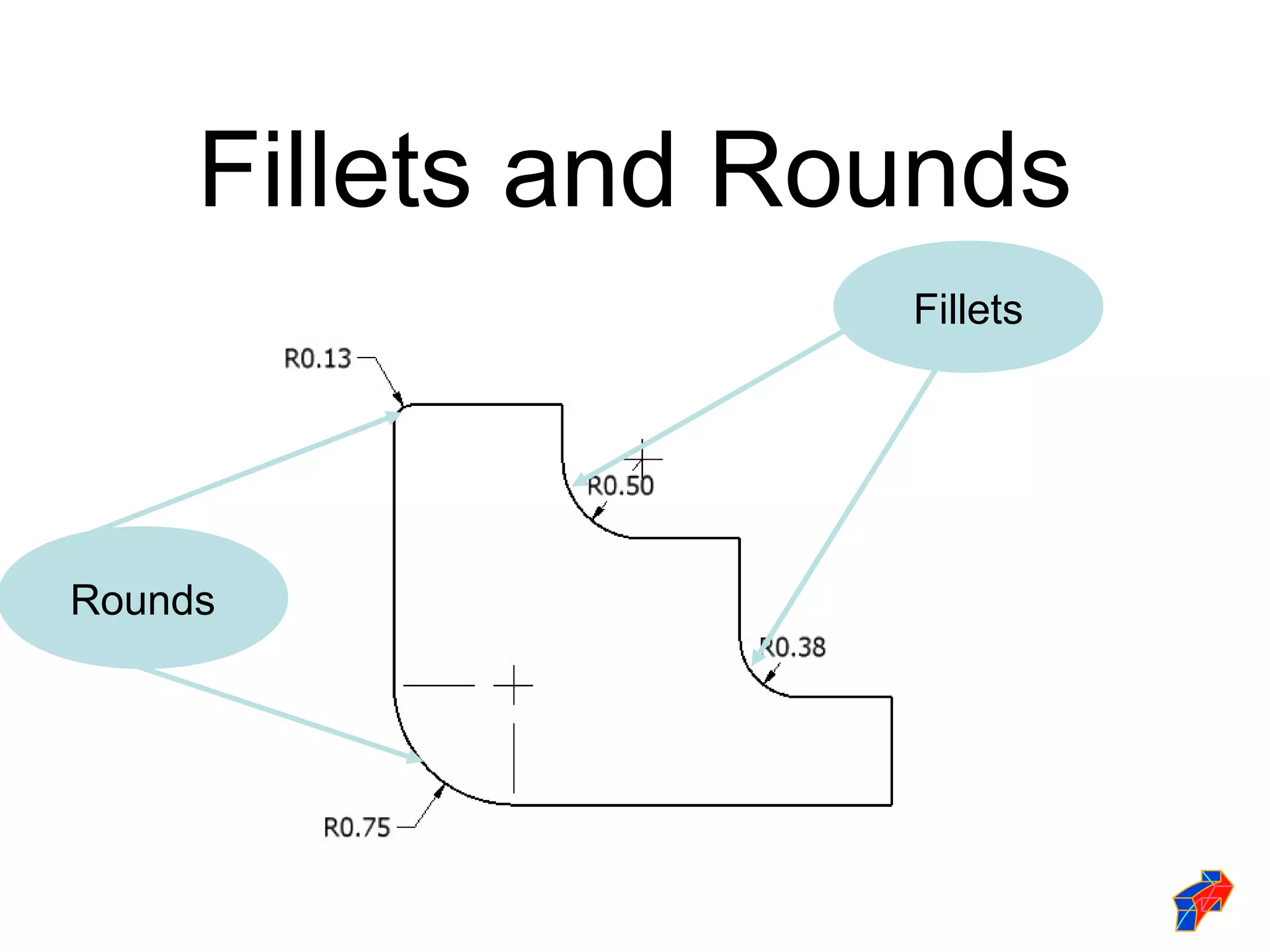

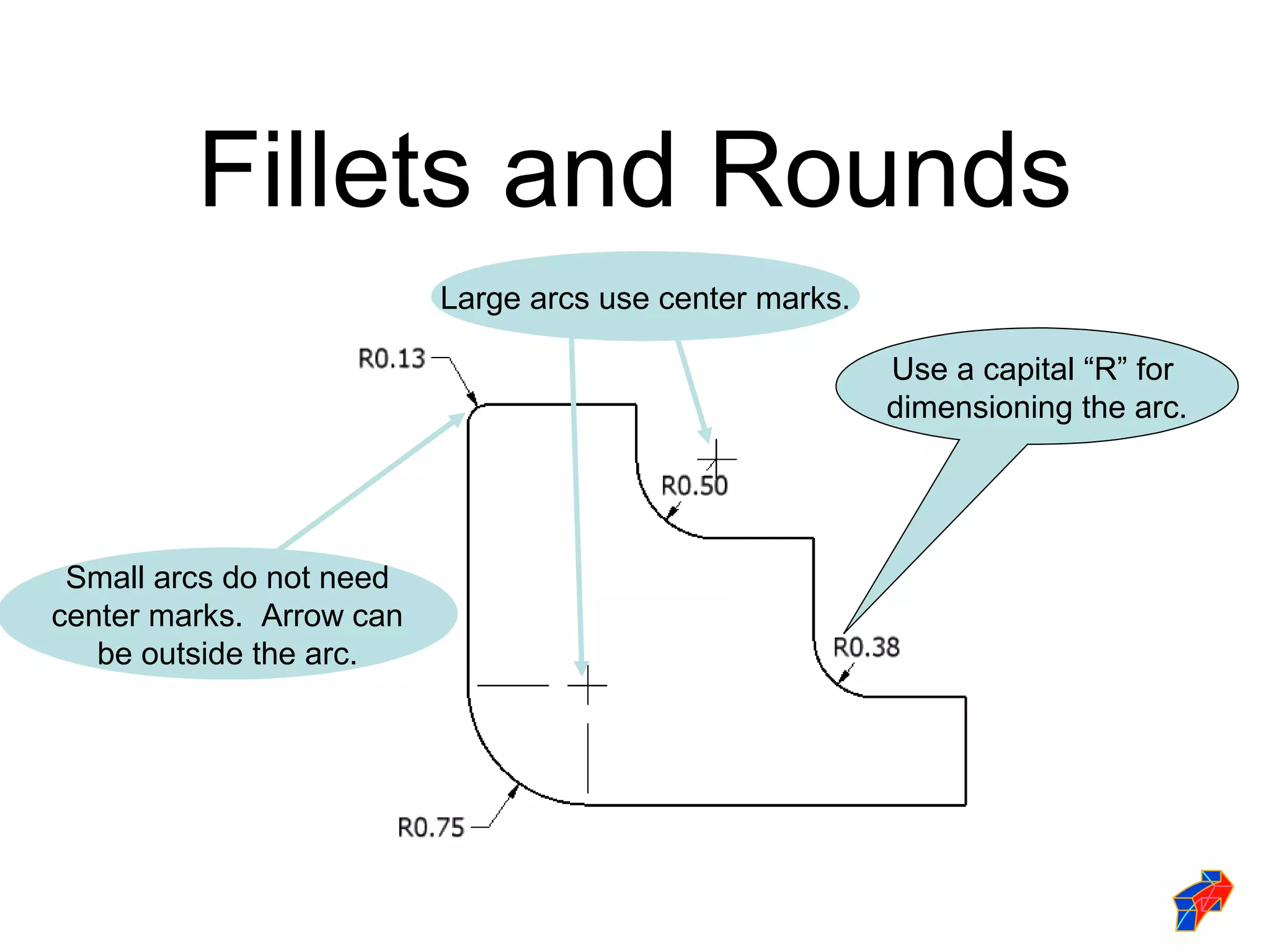

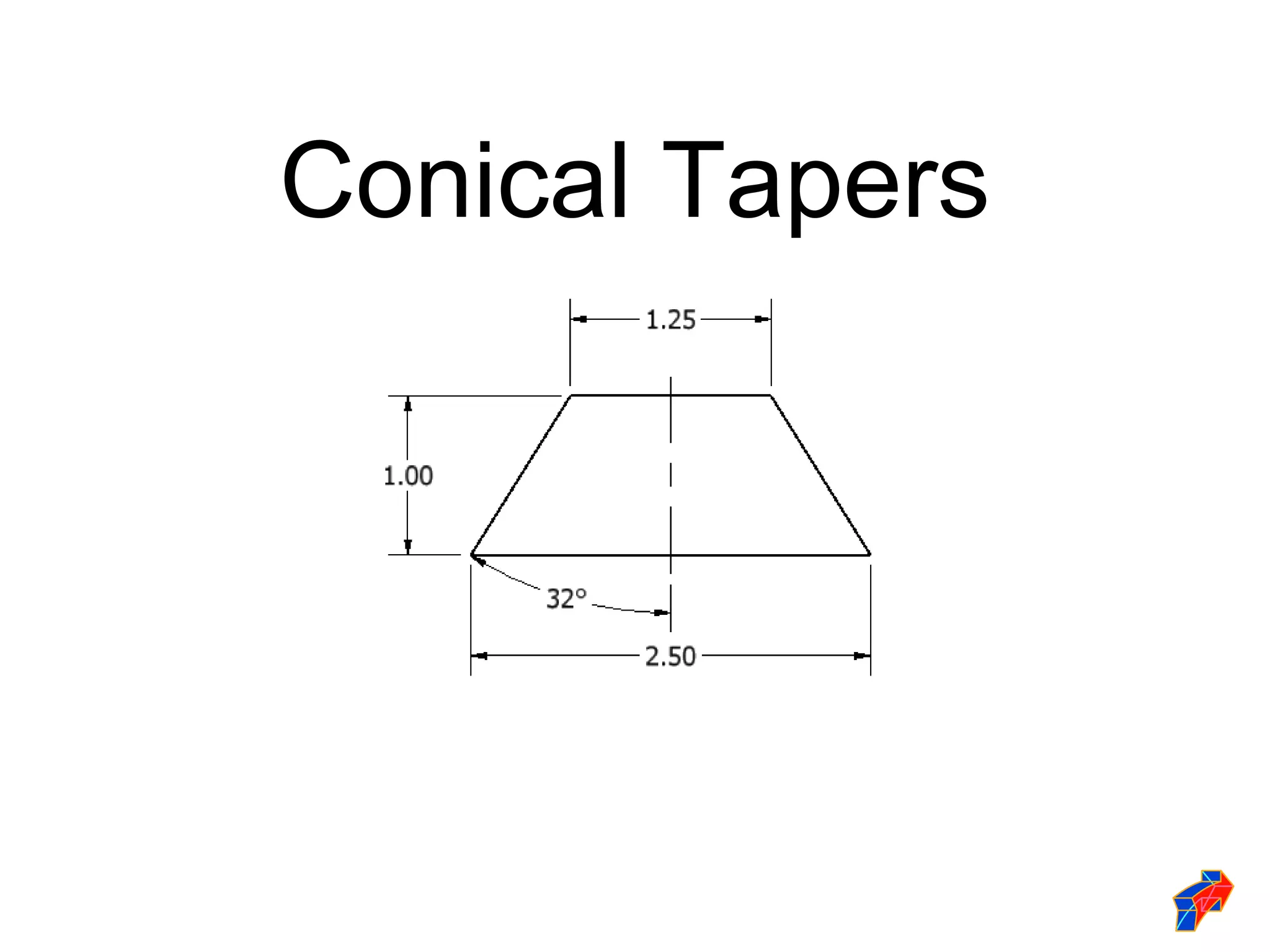

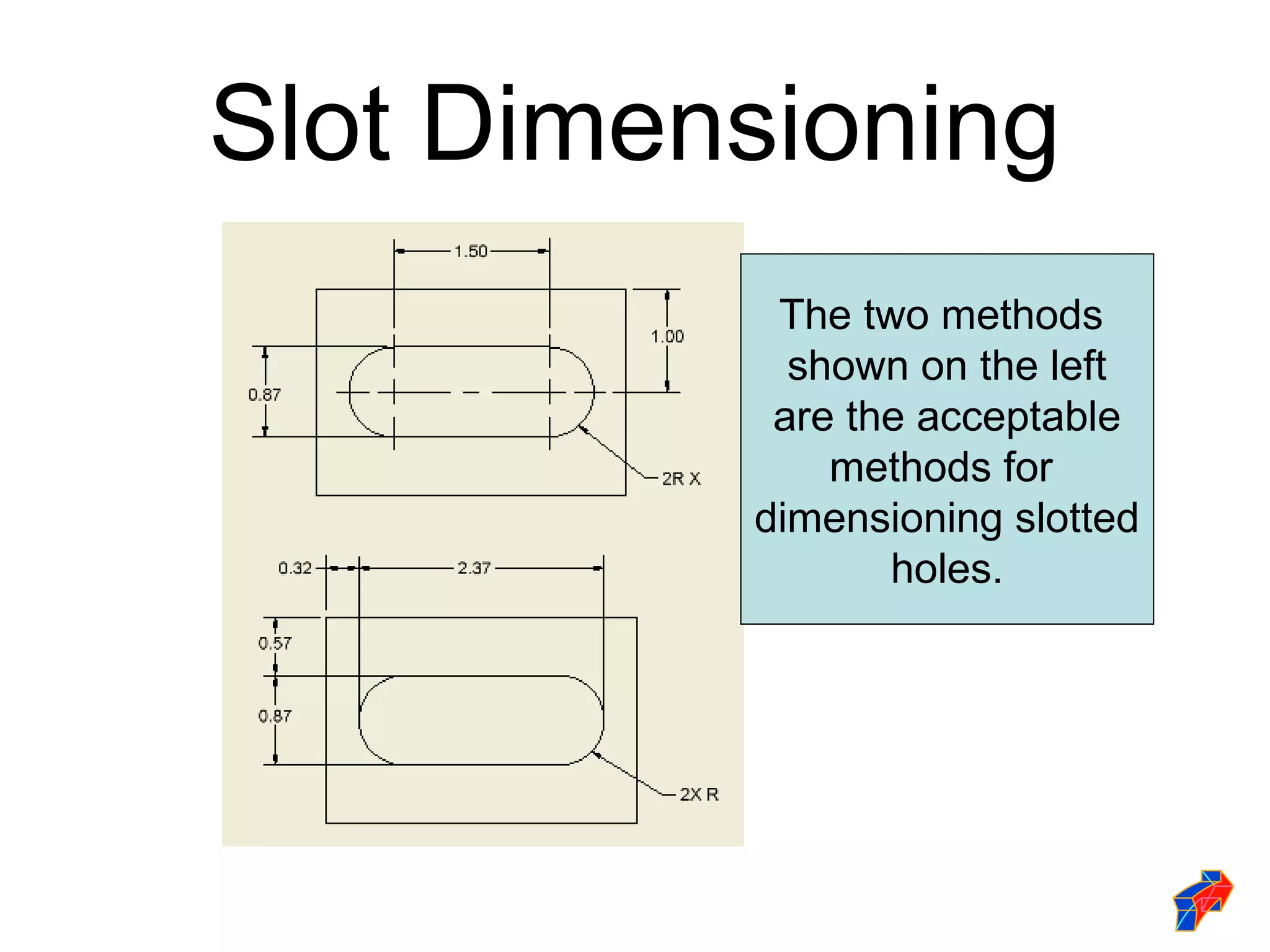

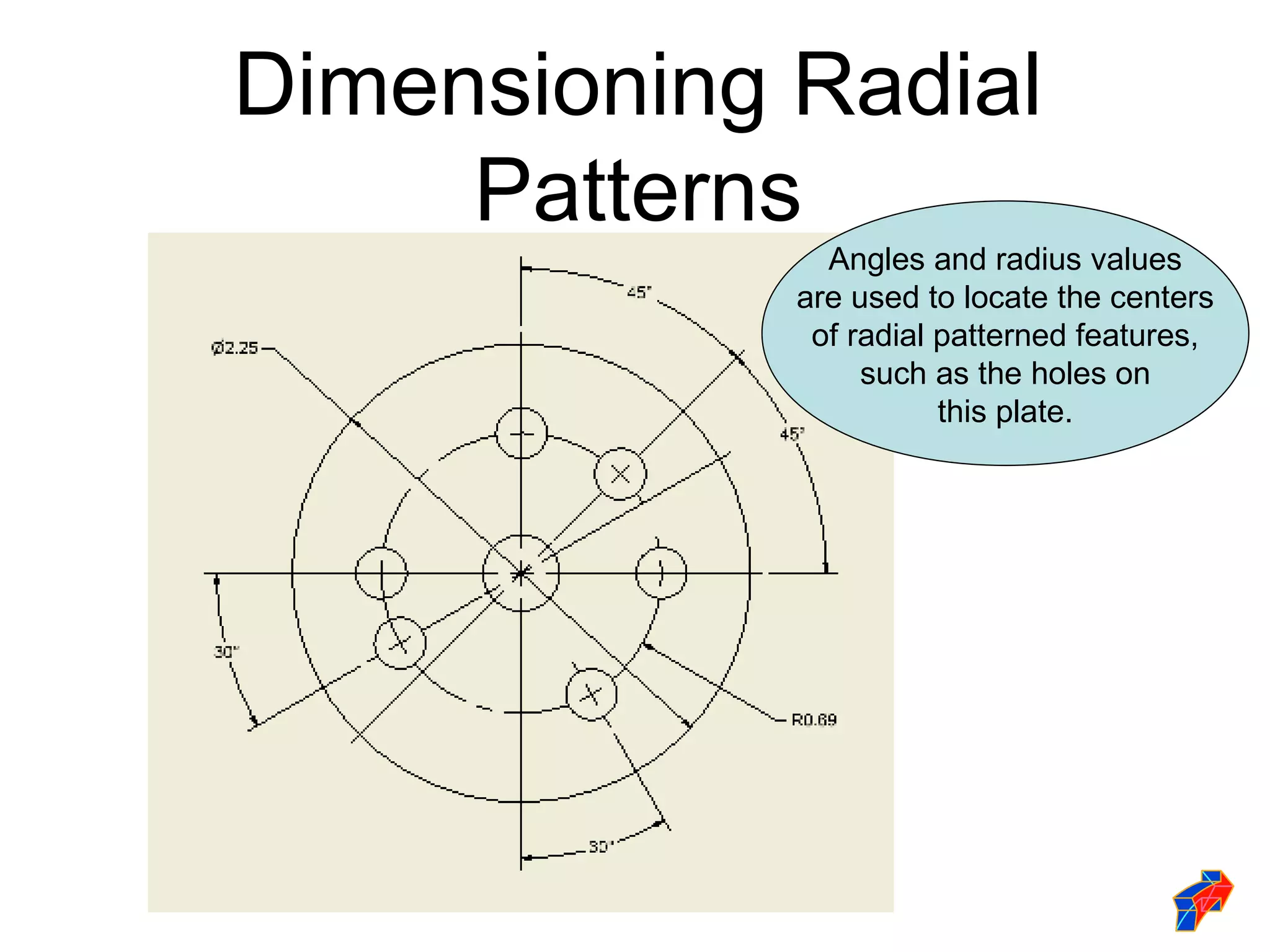

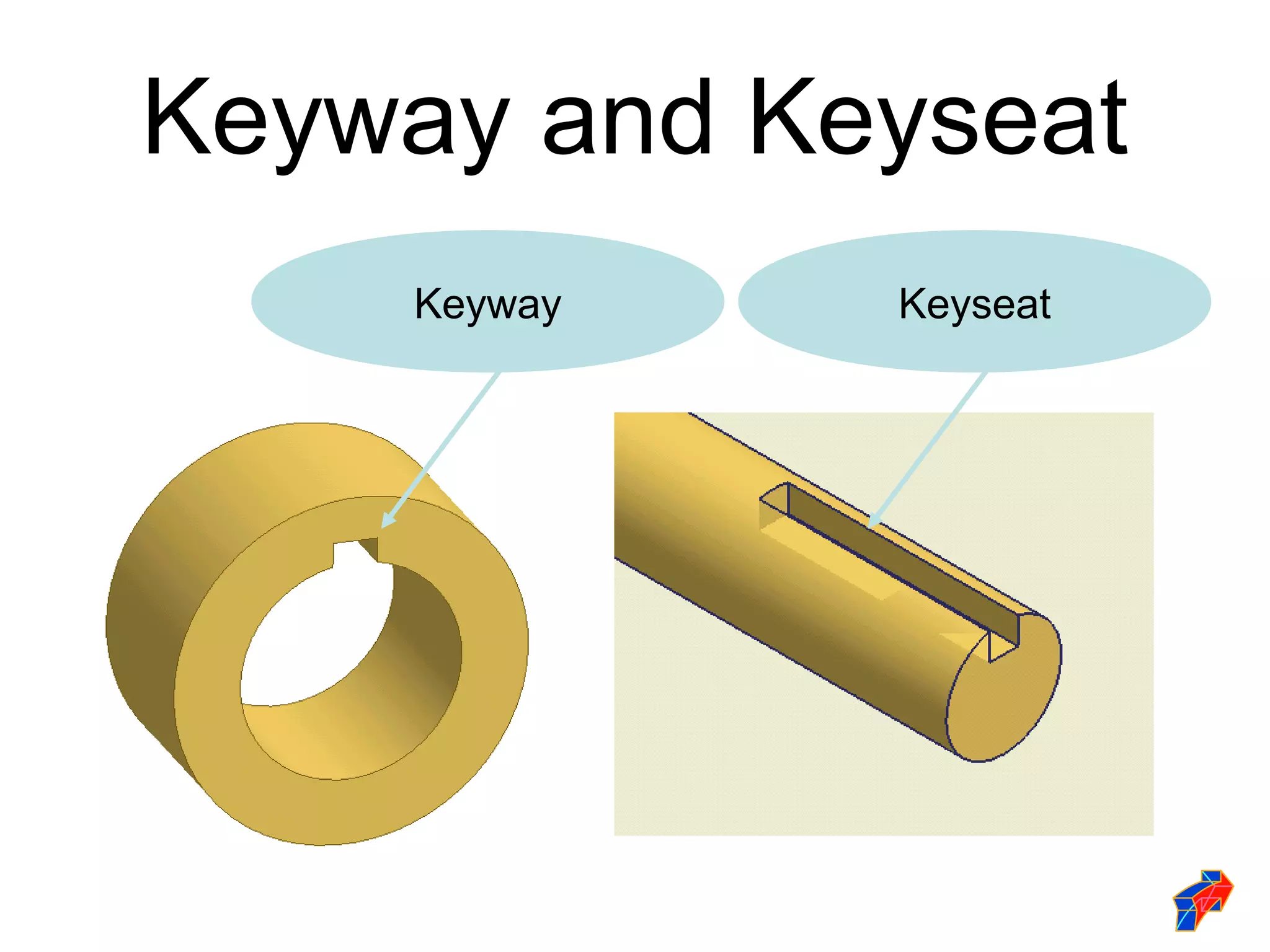

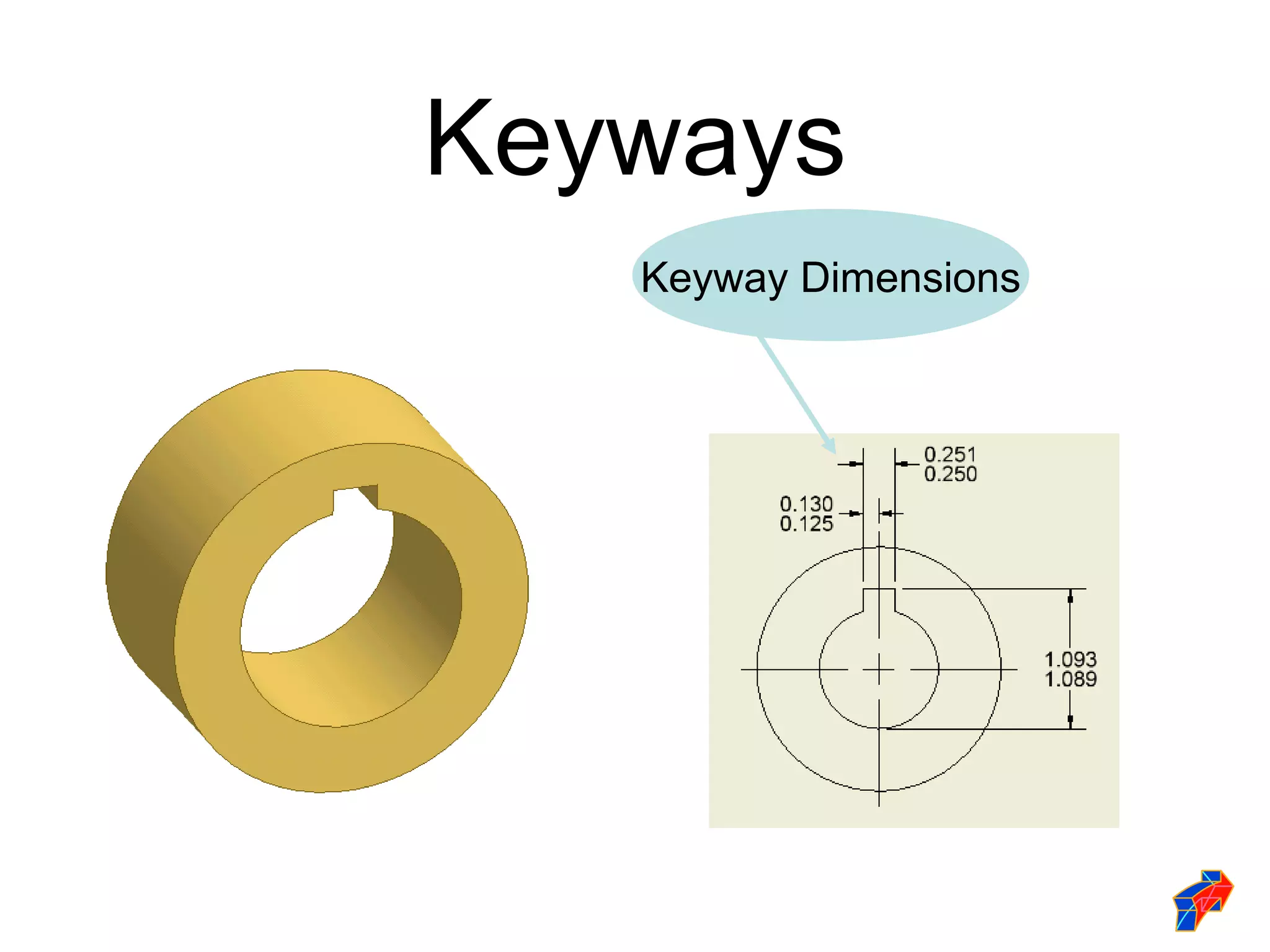

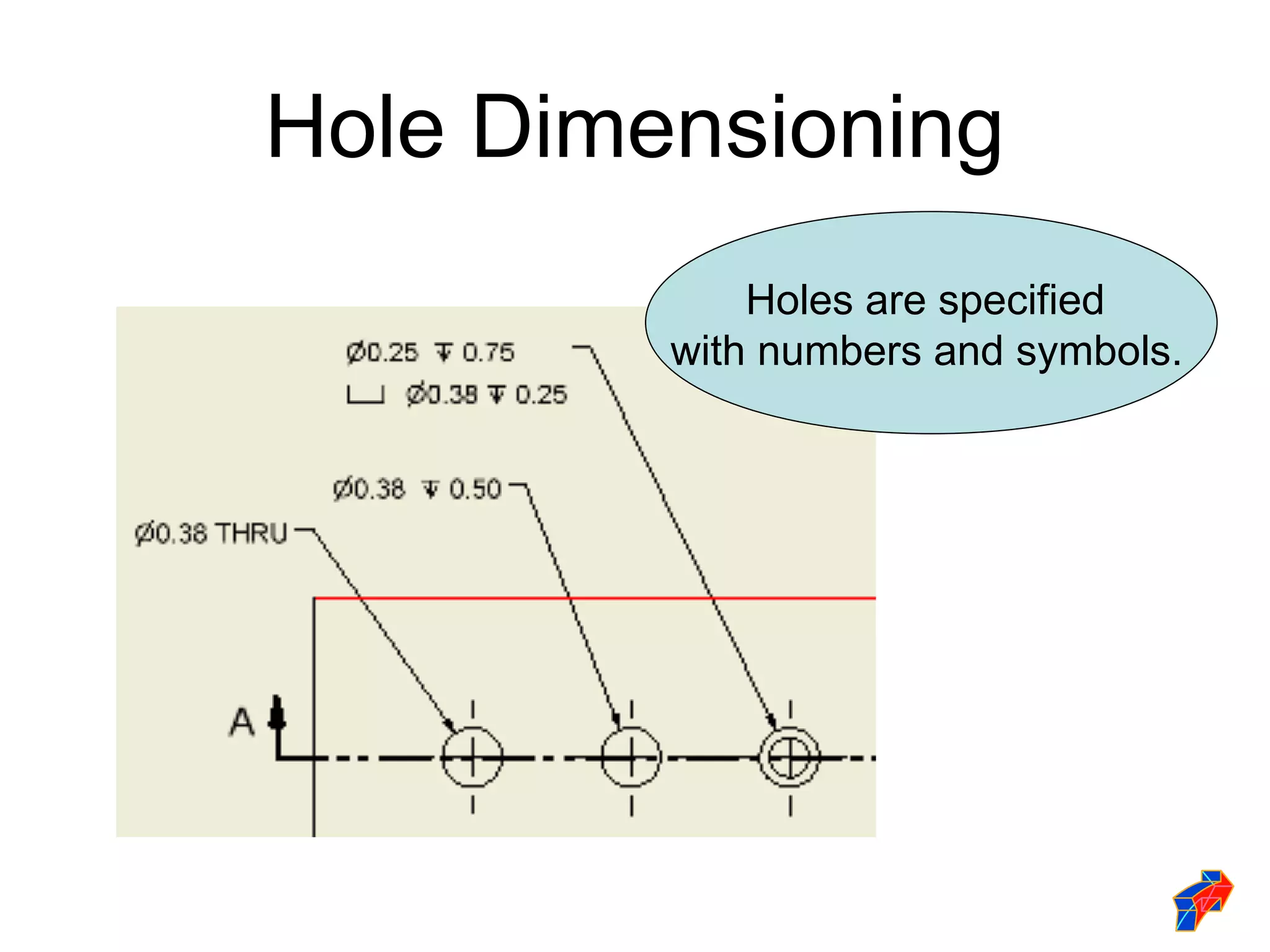

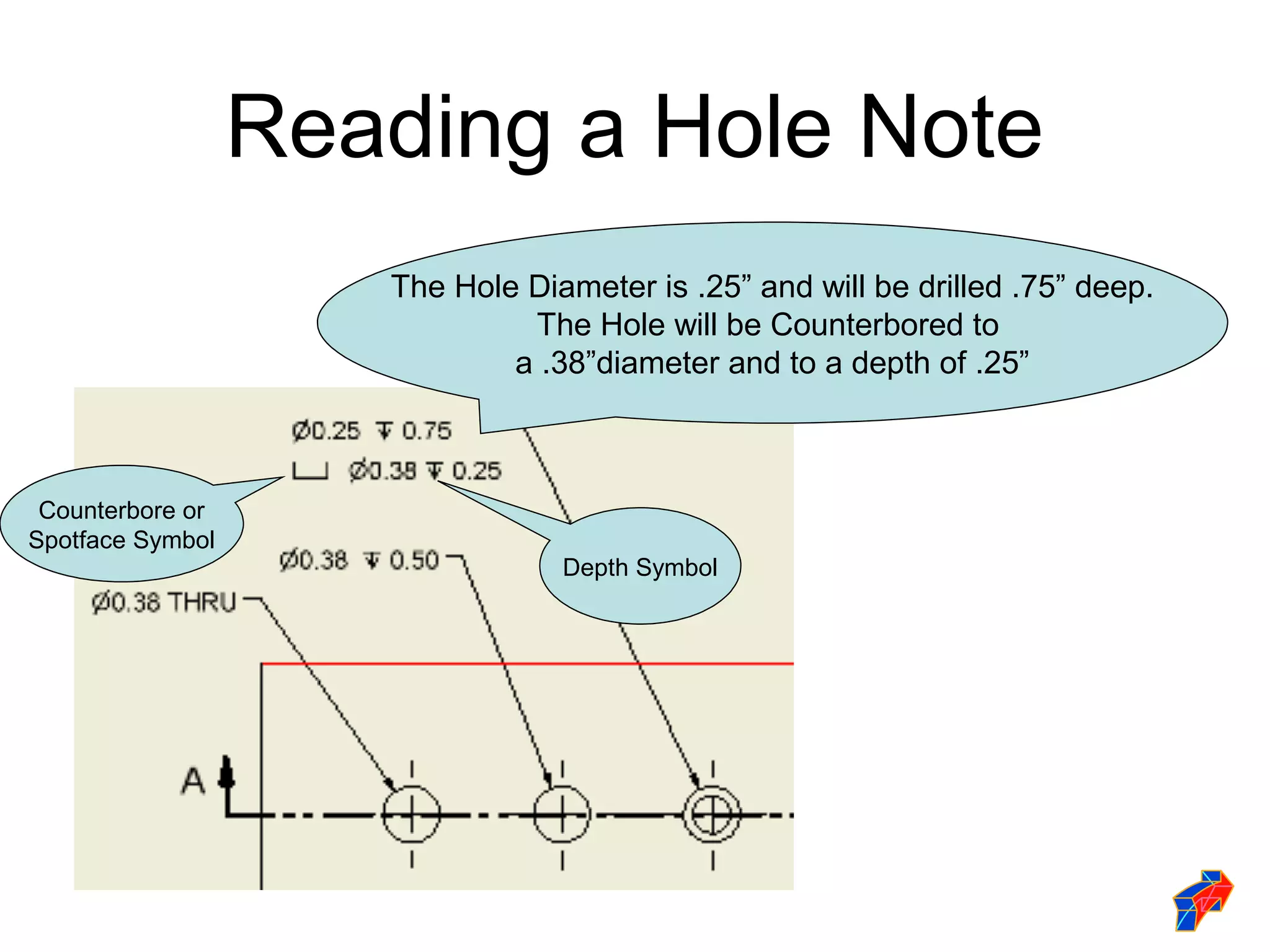

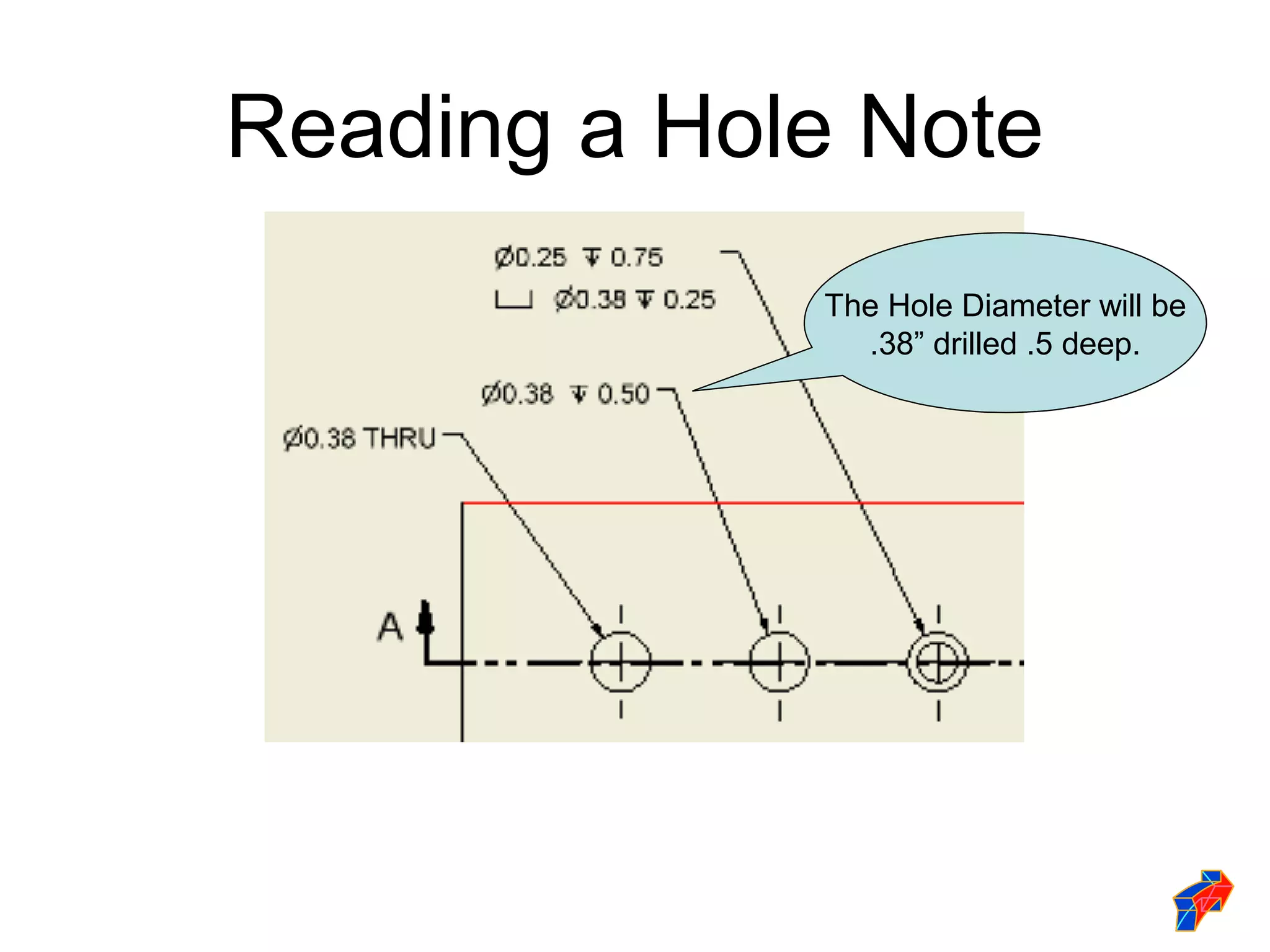

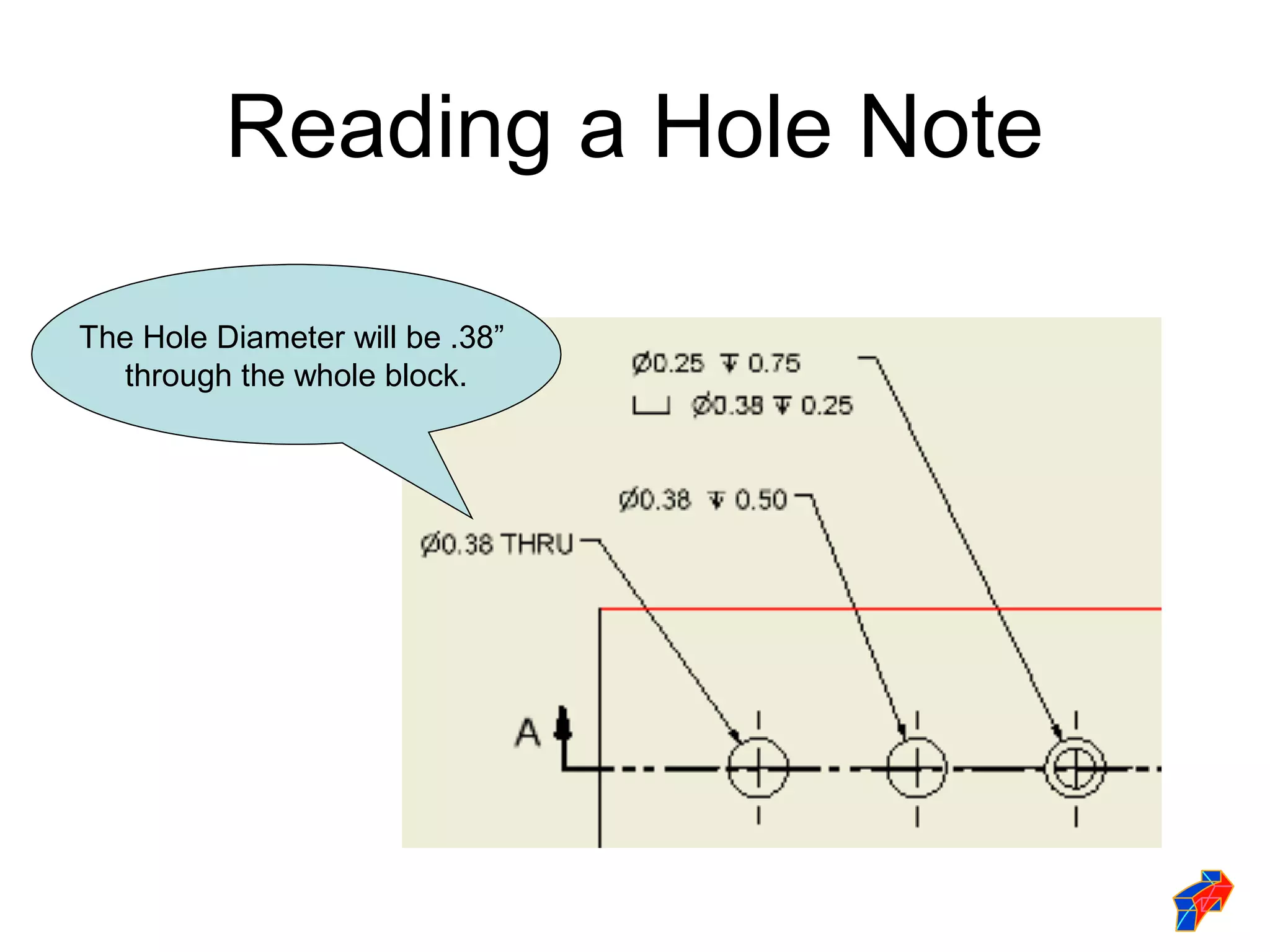

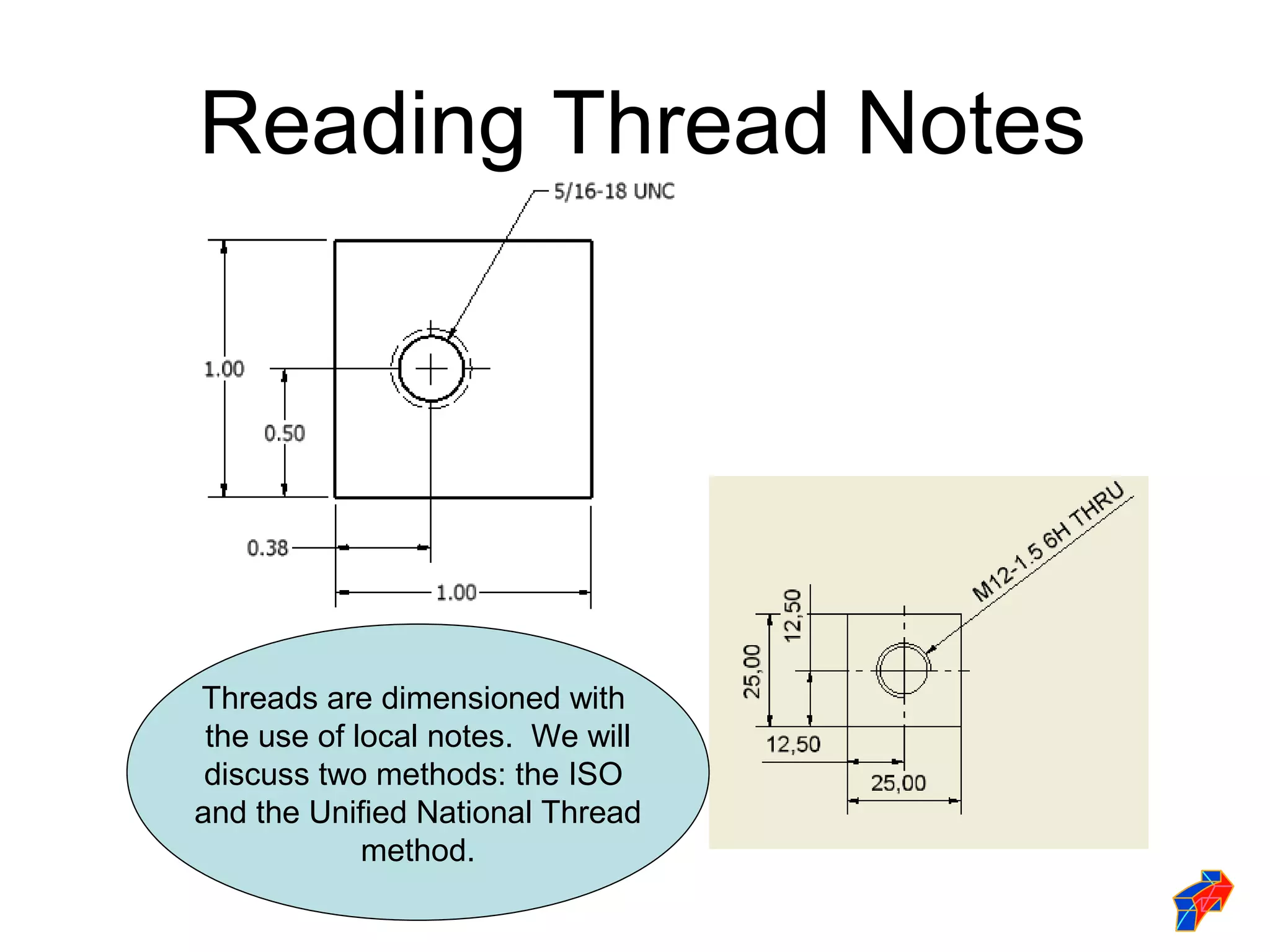

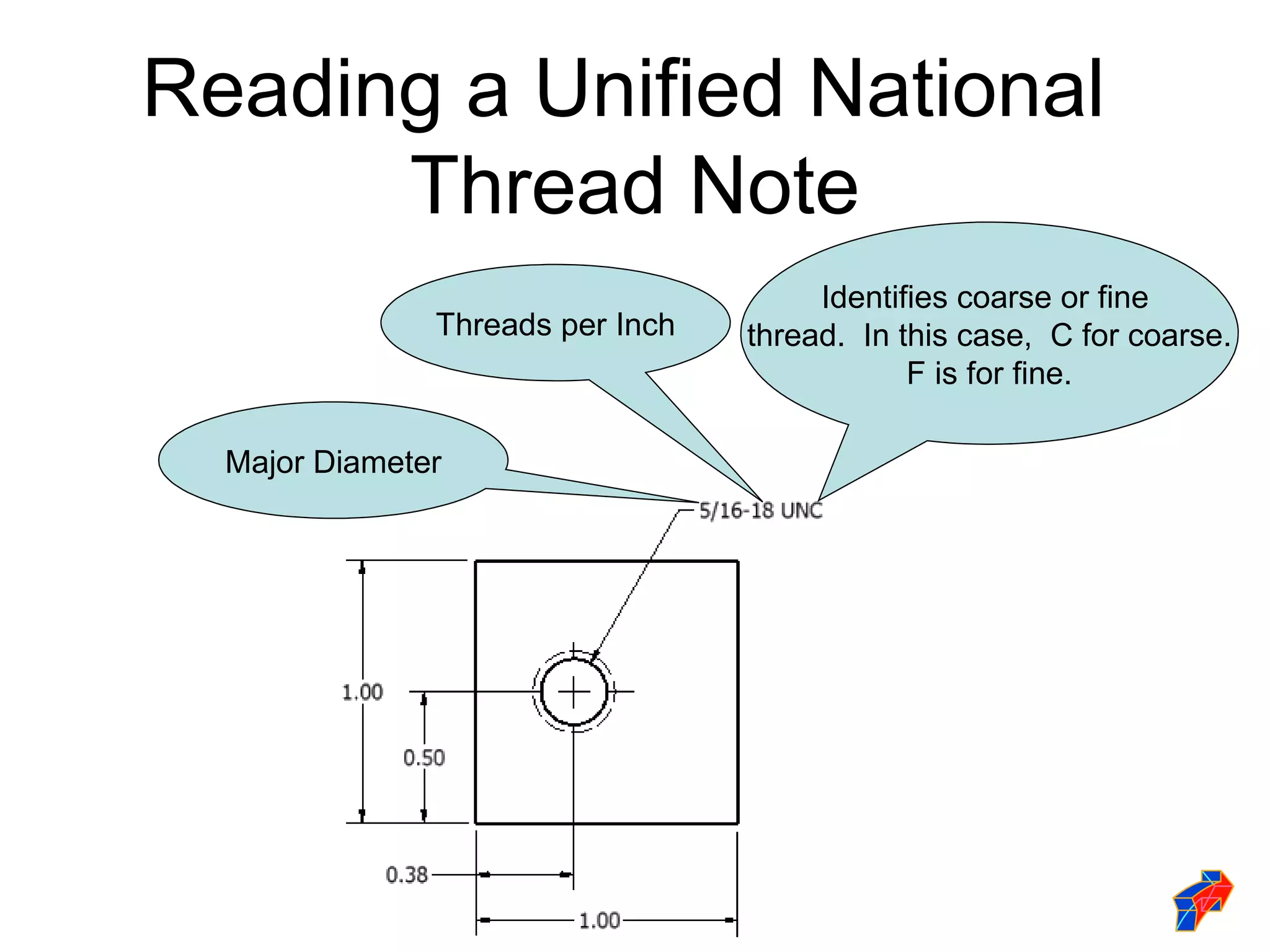

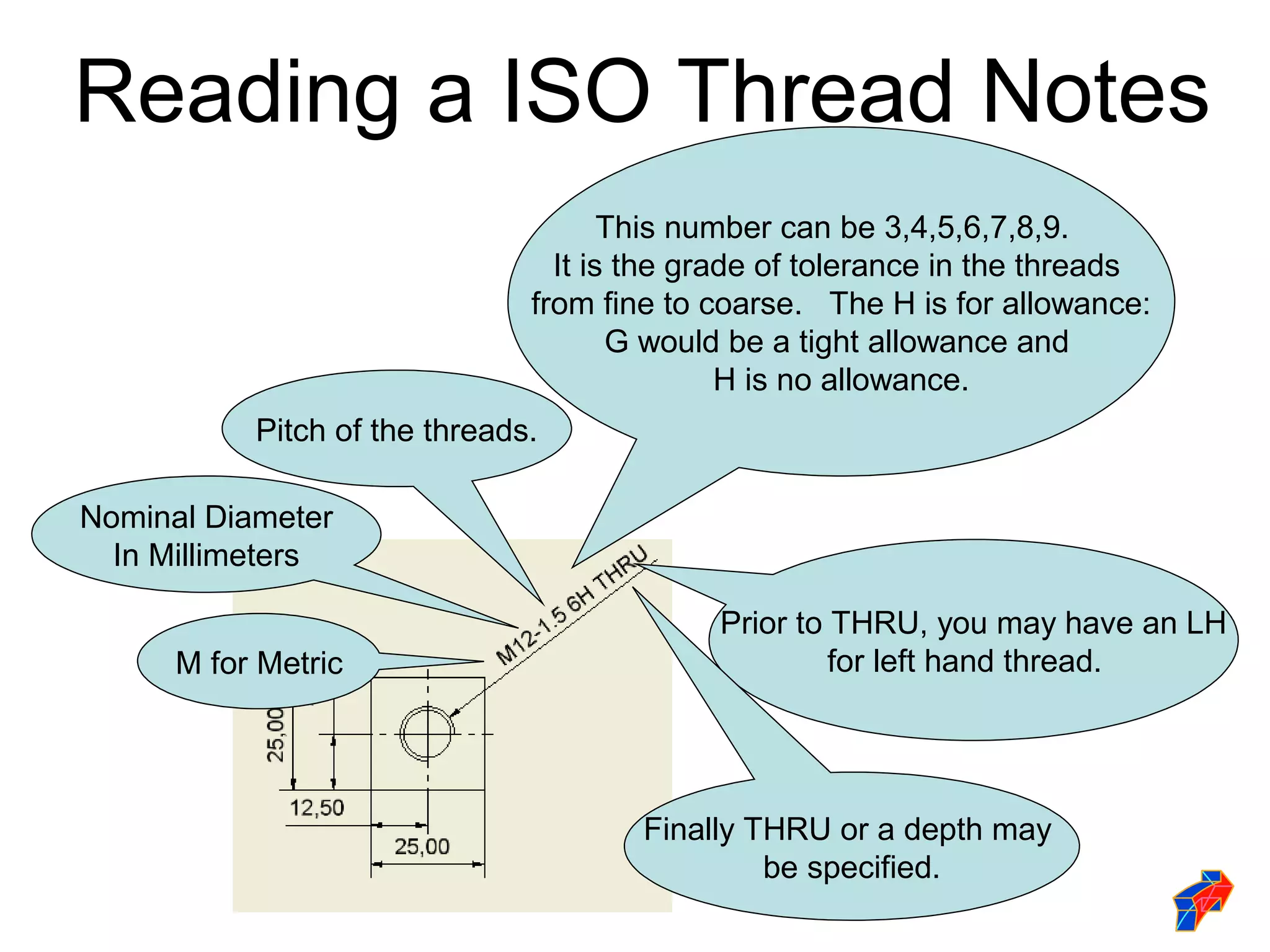

The document discusses dimensioning standards and practices. It covers topics such as dimensioning rules, types of dimensions, dimensioning methods like chain and datum dimensioning, and how to dimension different features including holes, threads, angles, and more. Standards organizations that set engineering standards are also identified, such as ANSI, ISO, DIN, and others.