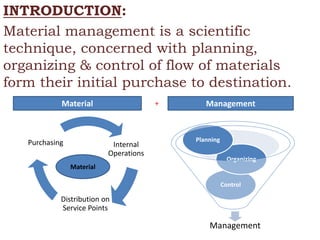

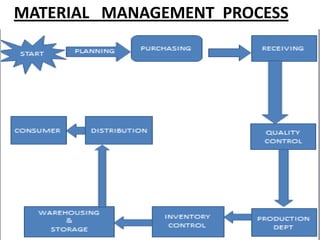

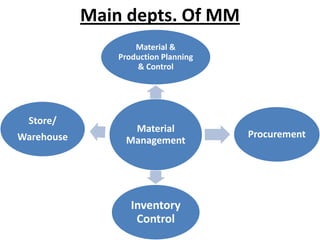

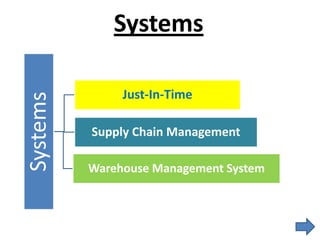

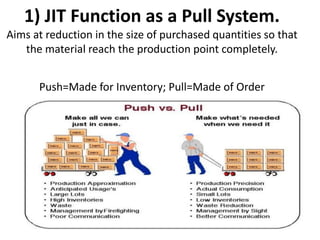

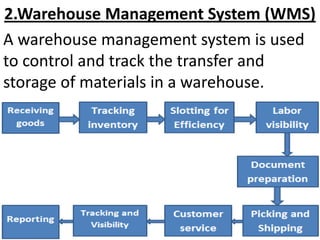

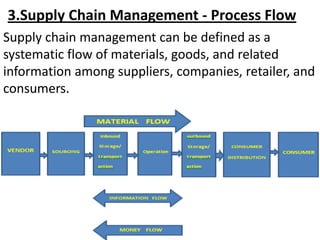

The document presents an overview of material management, covering its processes, functions, principles, and objectives, emphasizing its importance in planning, organizing, and controlling materials from procurement to delivery. It discusses main departments, systems like Just-in-Time and Supply Chain Management, as well as the benefits and challenges of implementing material management. The conclusion highlights the need for effective management to enhance efficiency and reduce costs in operations.