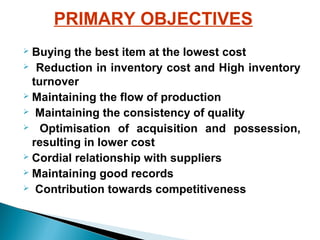

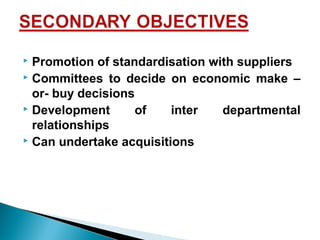

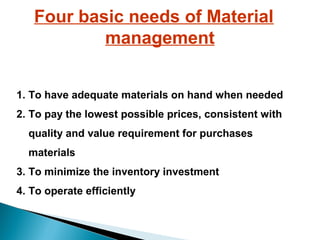

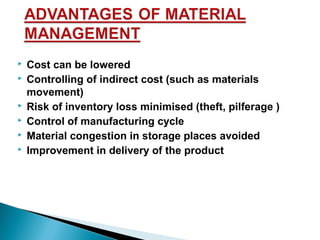

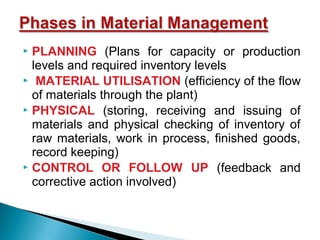

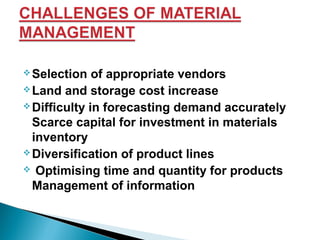

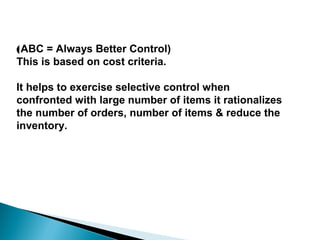

This document provides information on material management. It defines material management as planning, organizing, and controlling the flow of materials from initial purchase through operations to distribution. The objectives of material management include obtaining the right quality and quantity of supplies at the right time and place for the right cost. Material management aims to gain economy in purchasing and satisfy demand during replenishment periods while maintaining adequate reserve stocks.