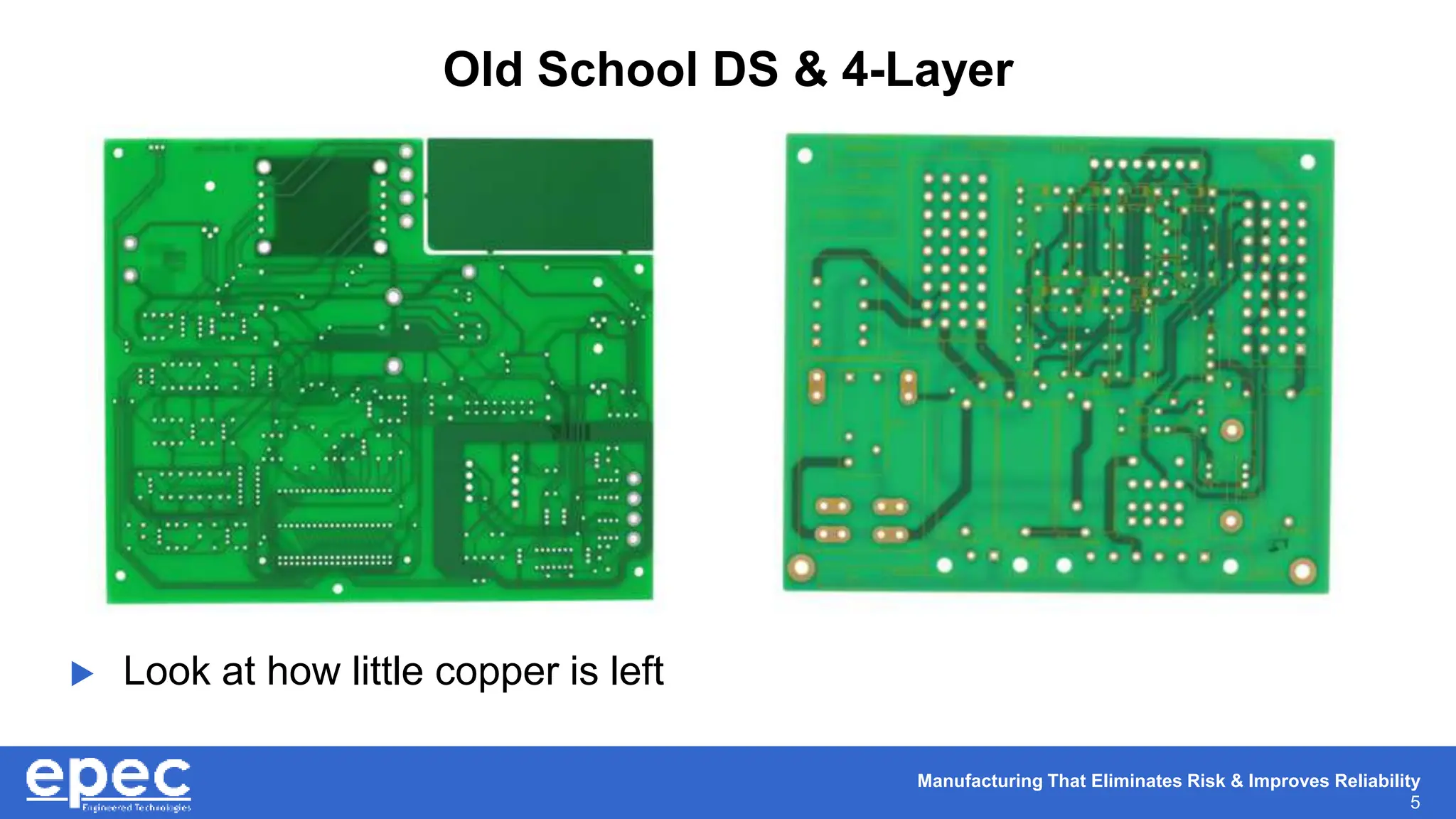

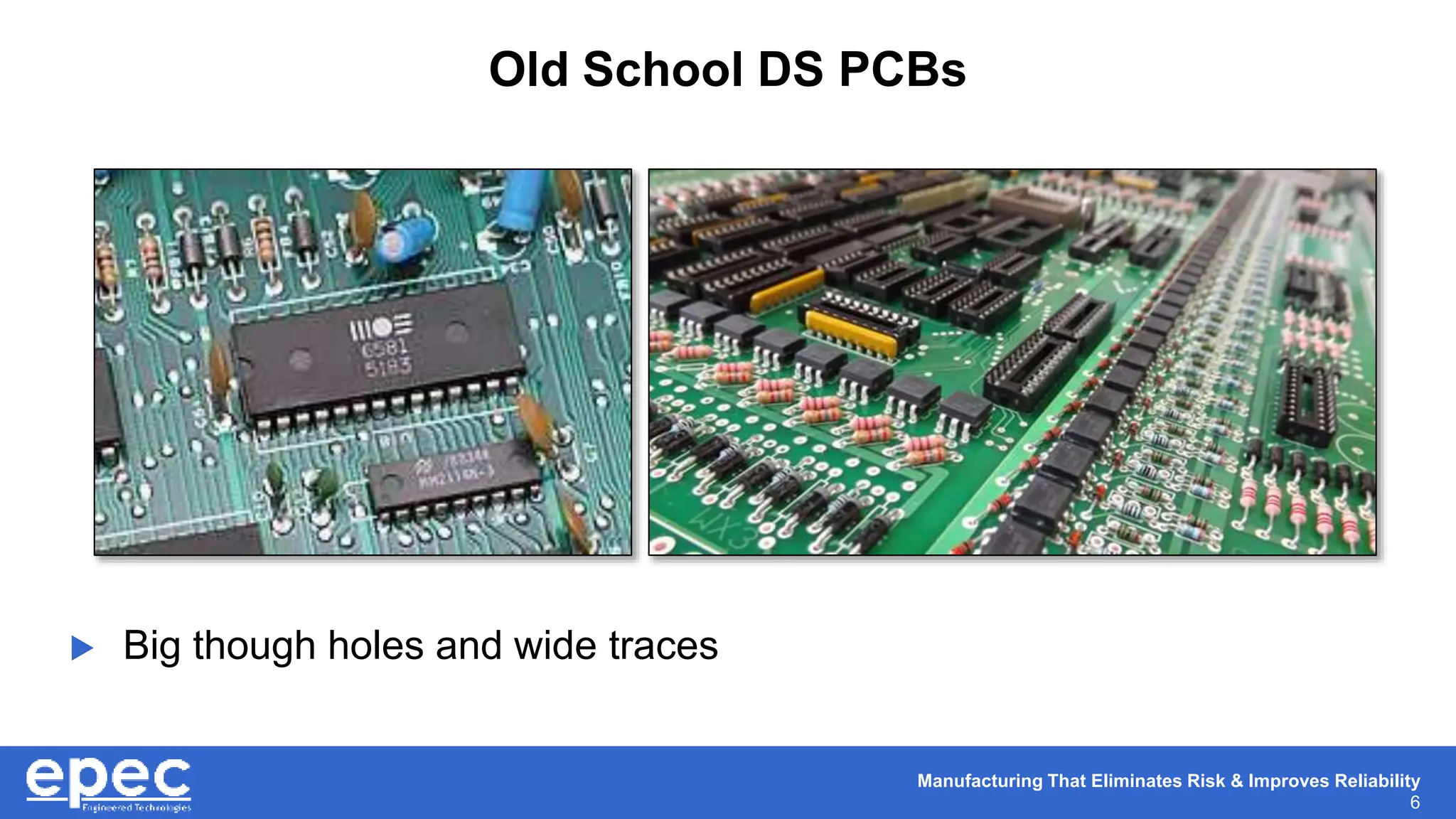

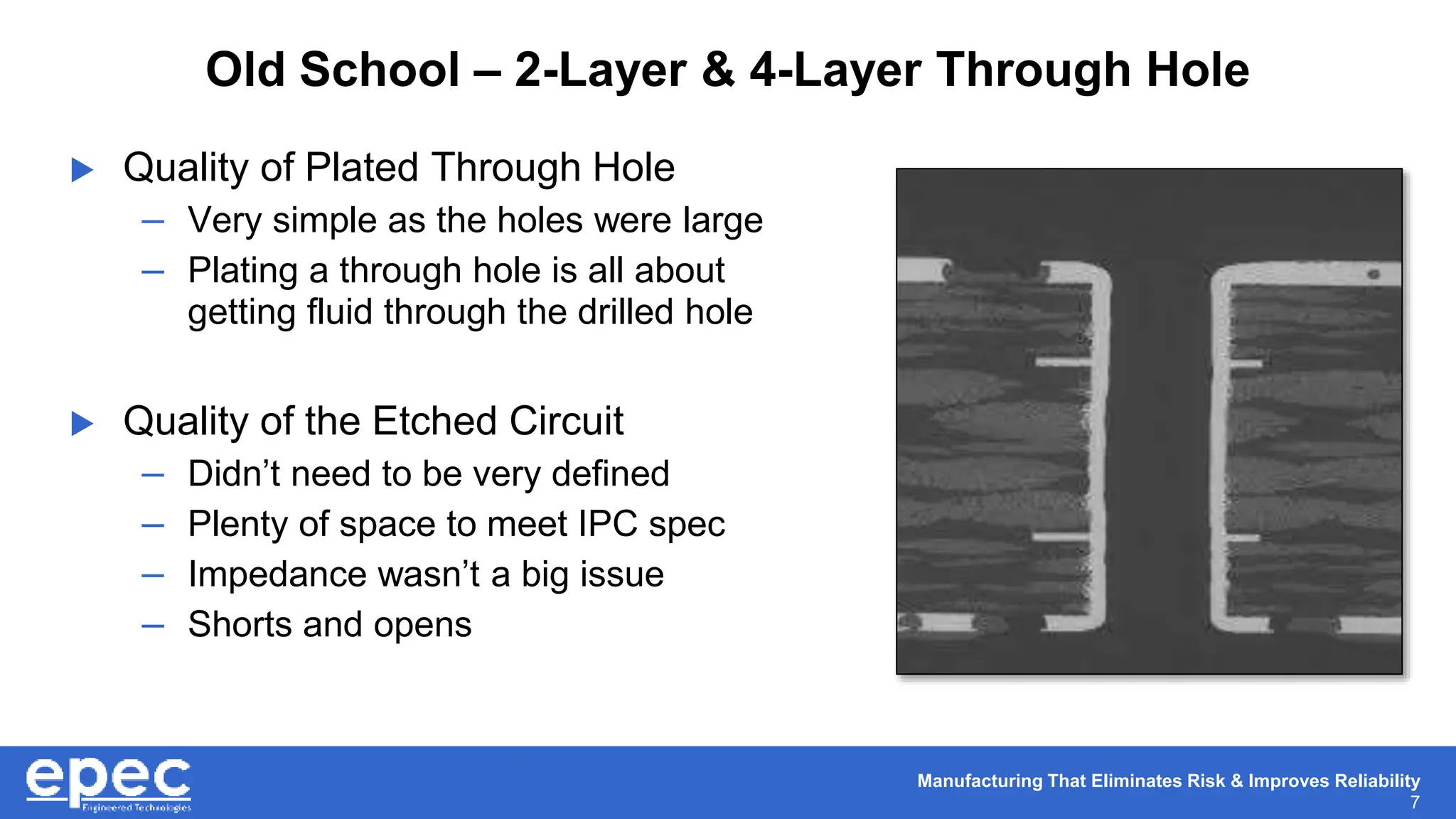

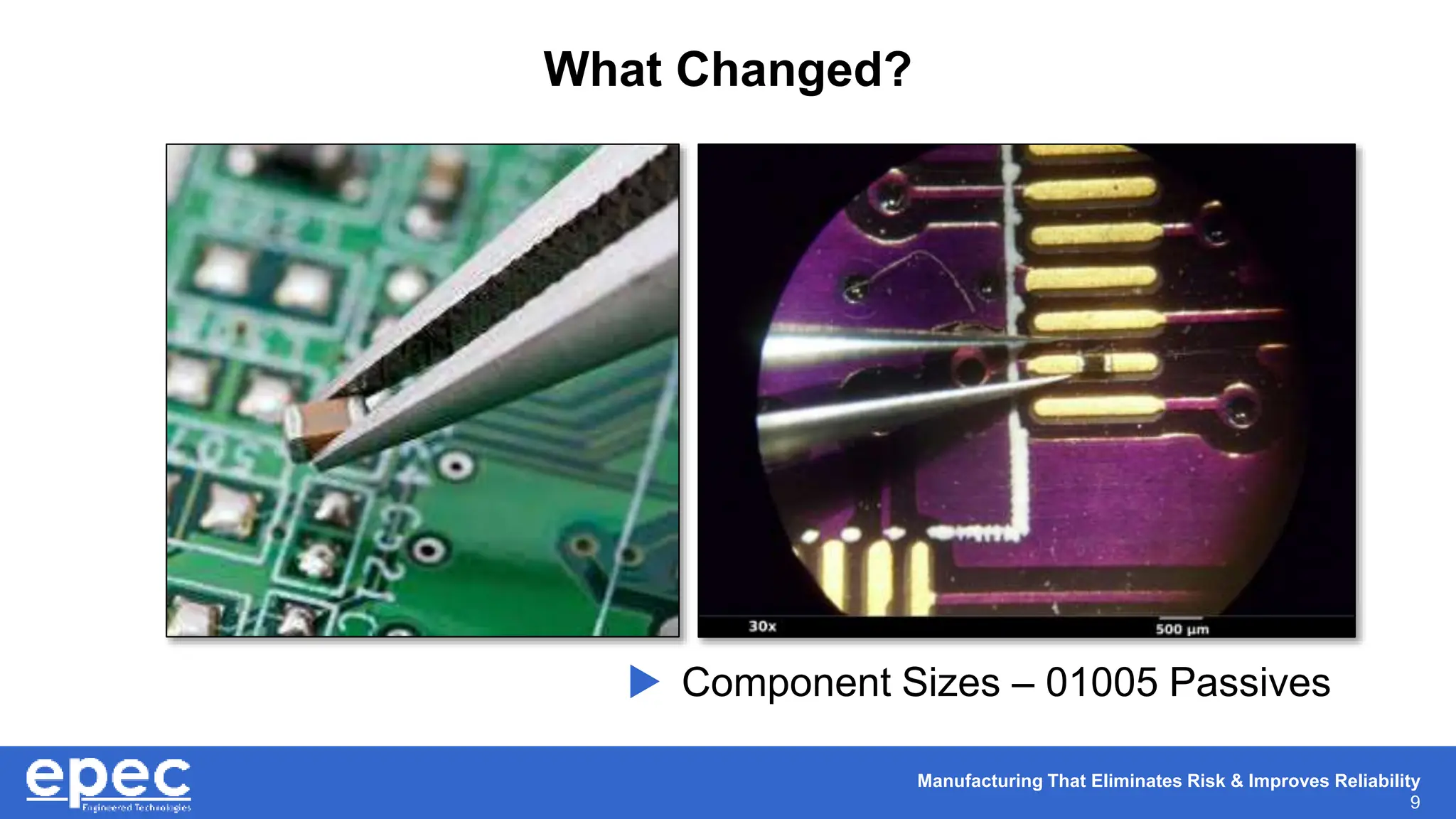

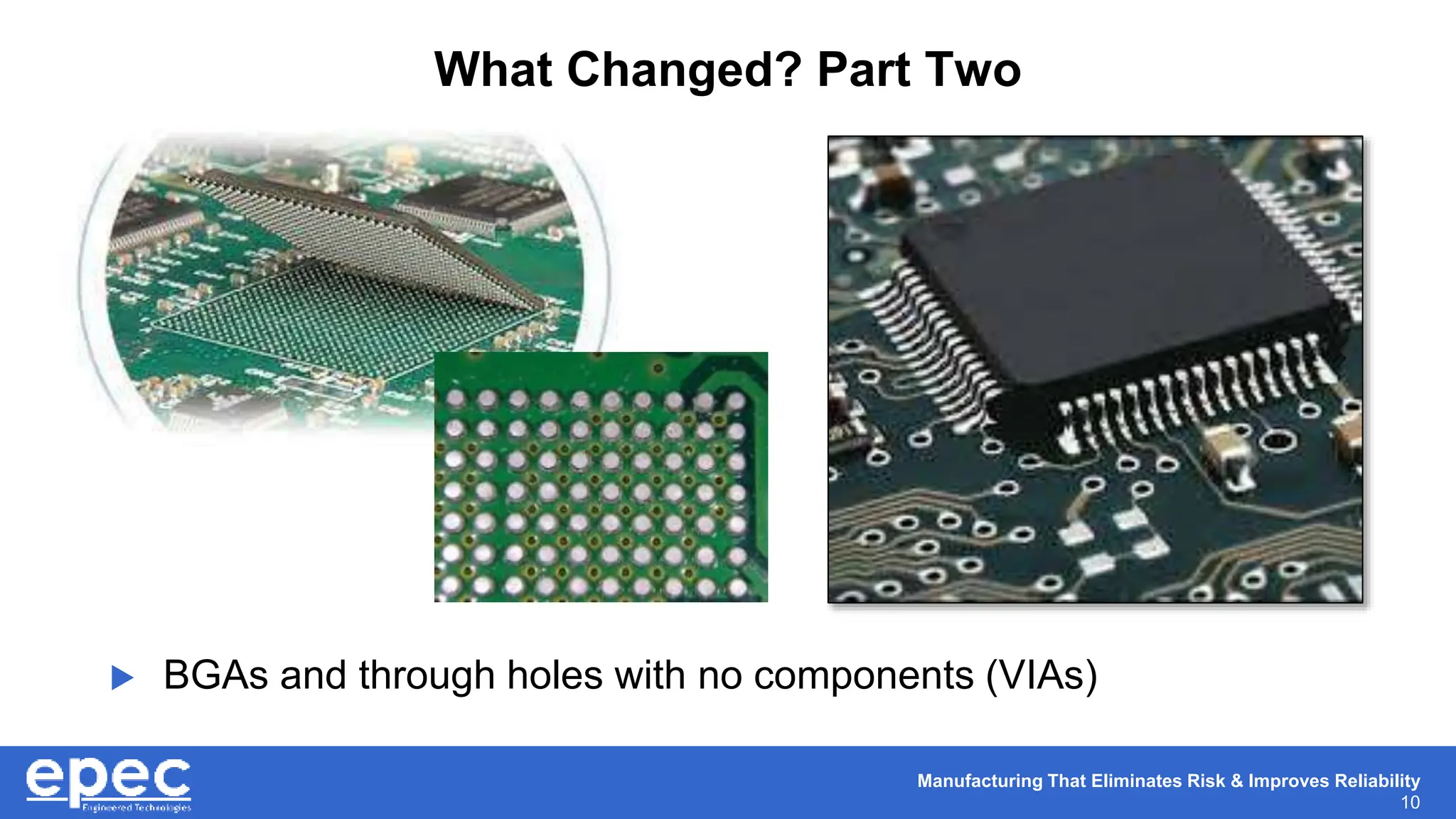

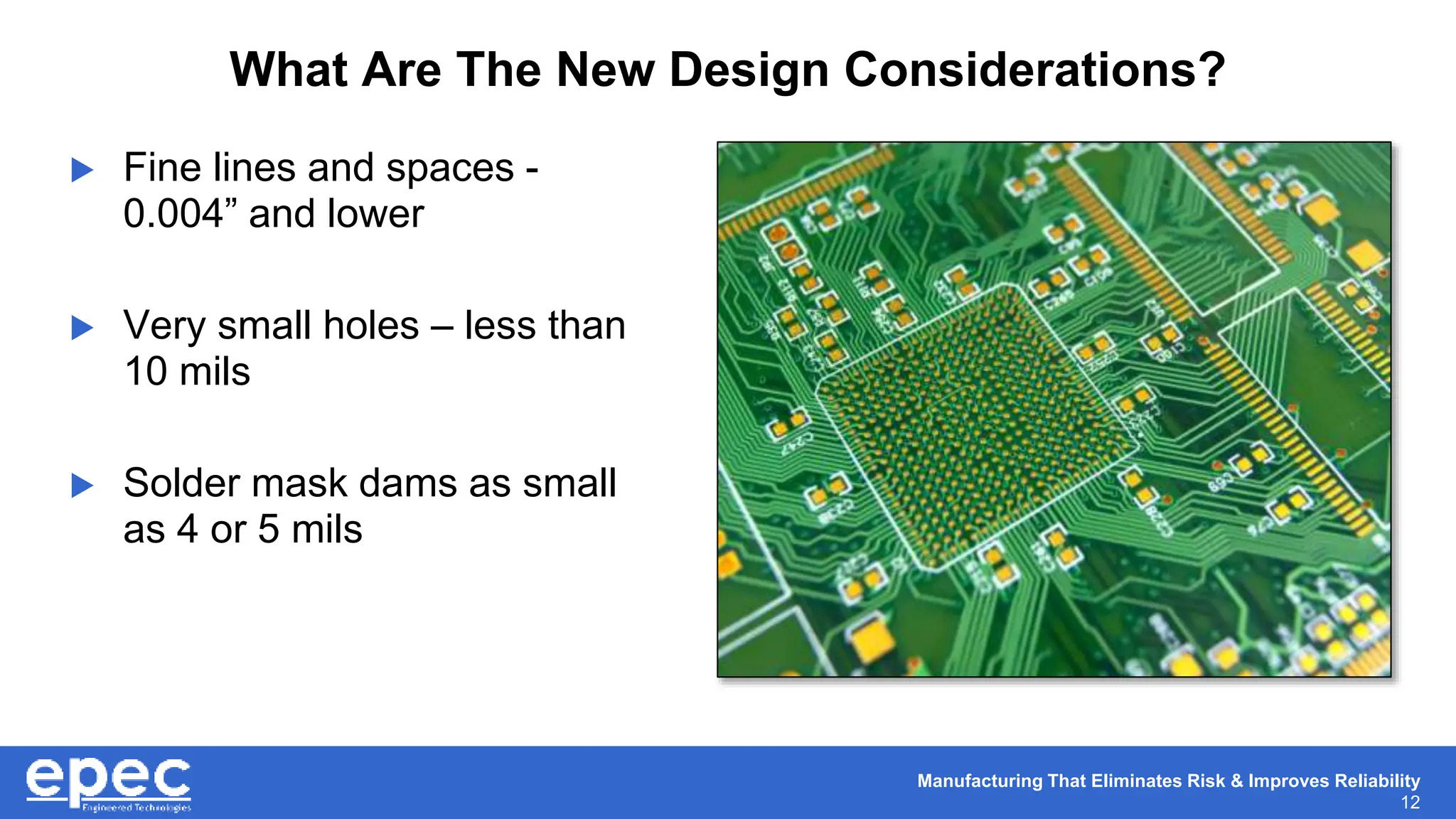

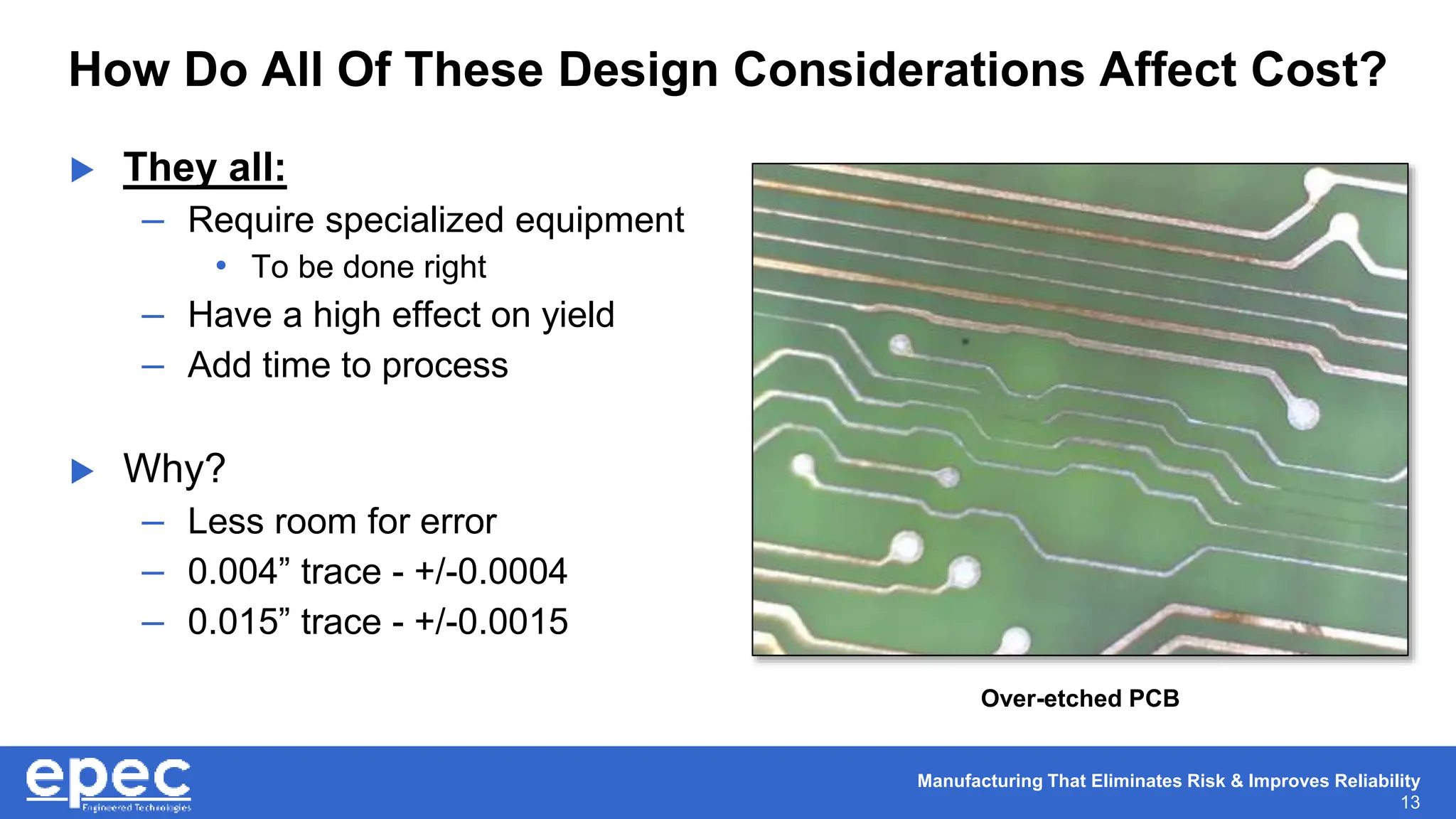

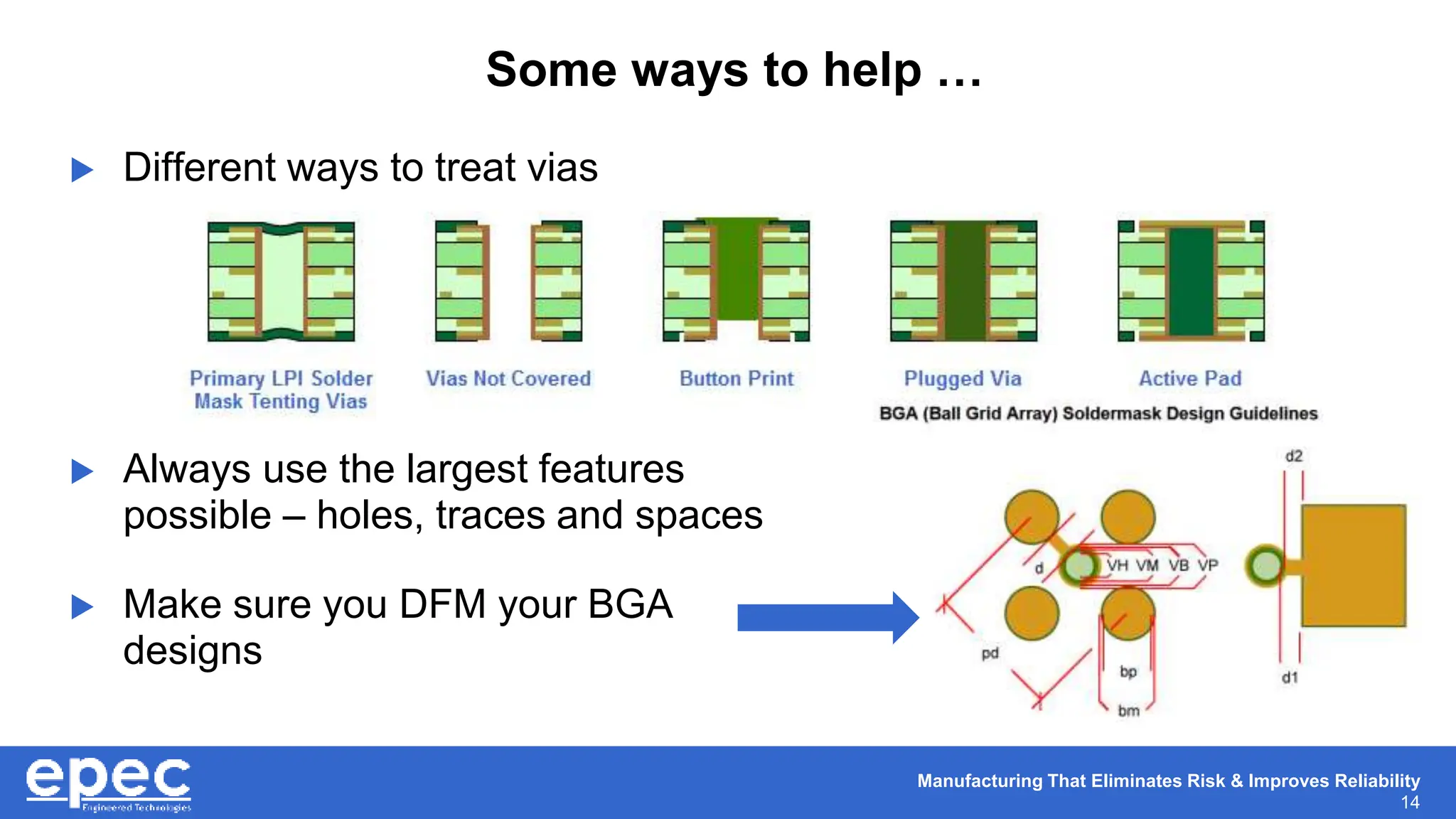

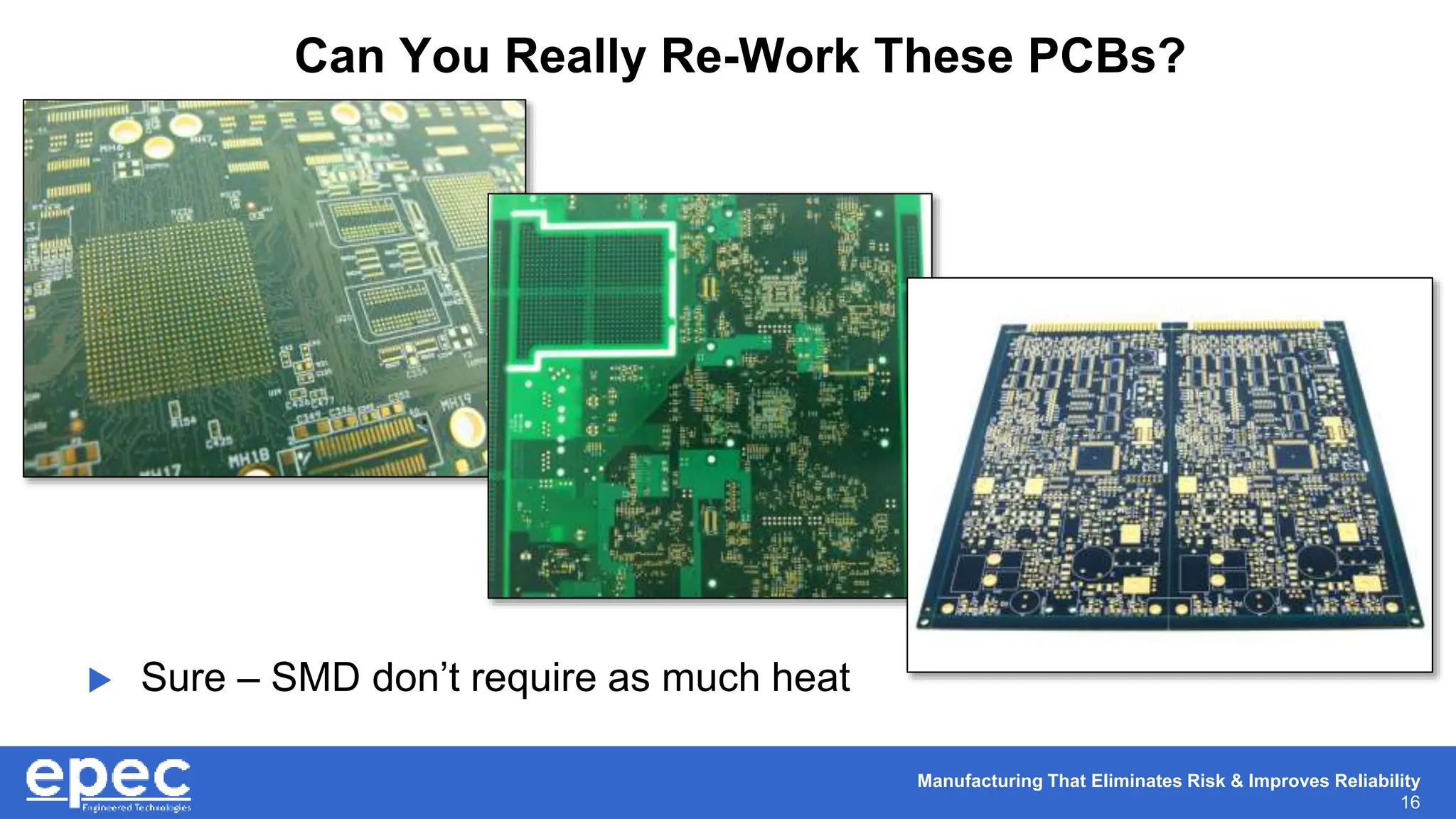

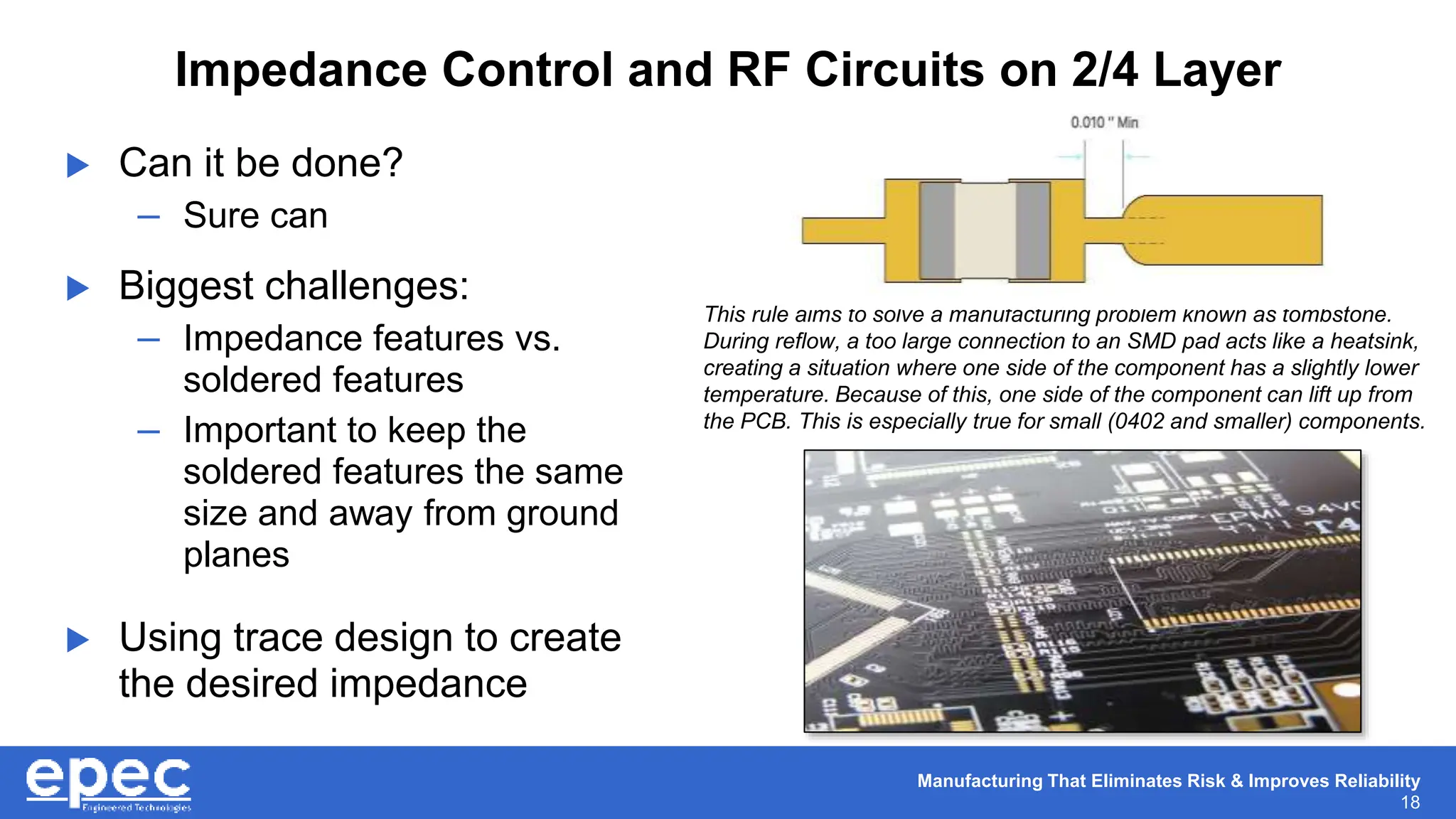

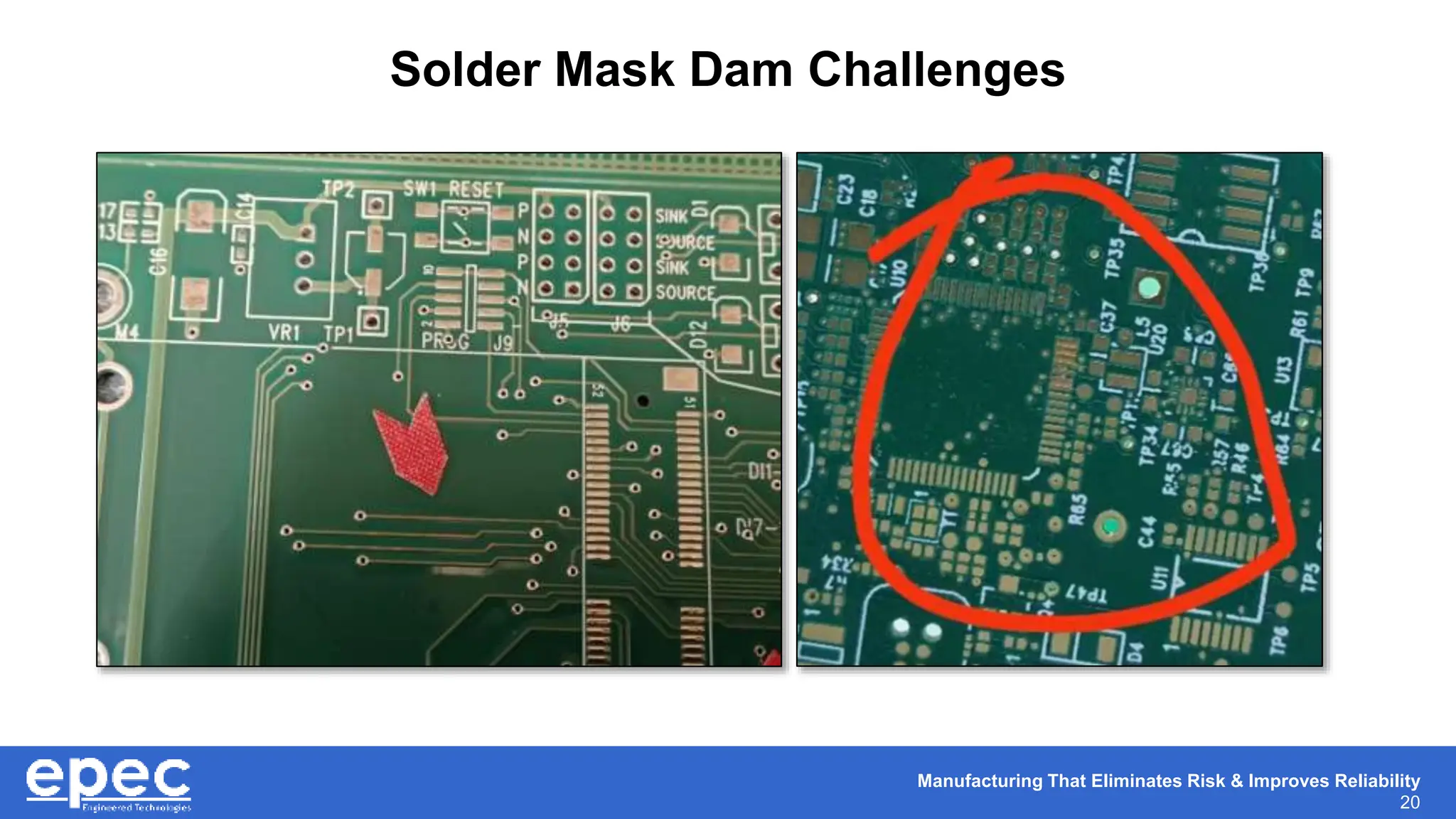

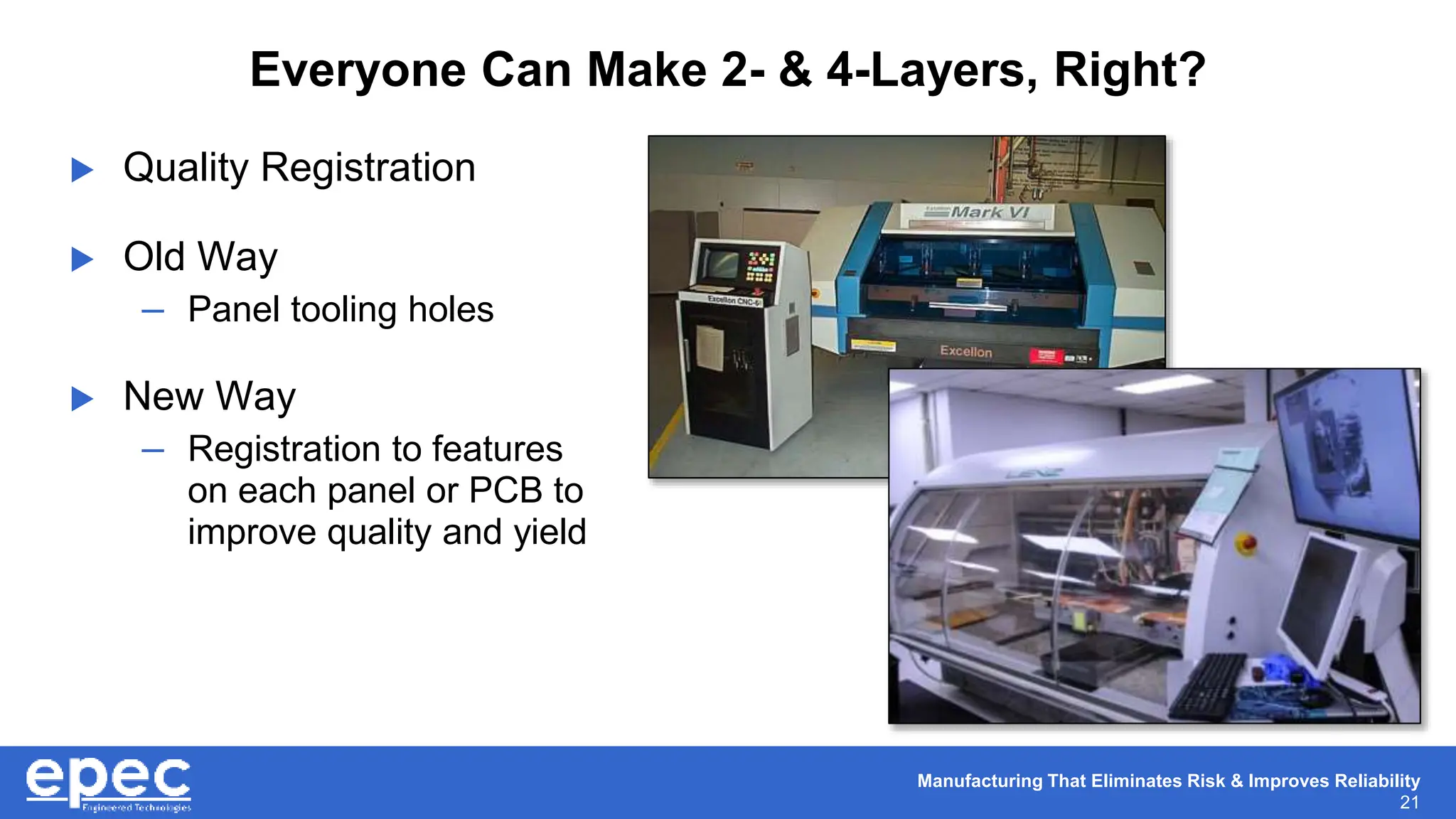

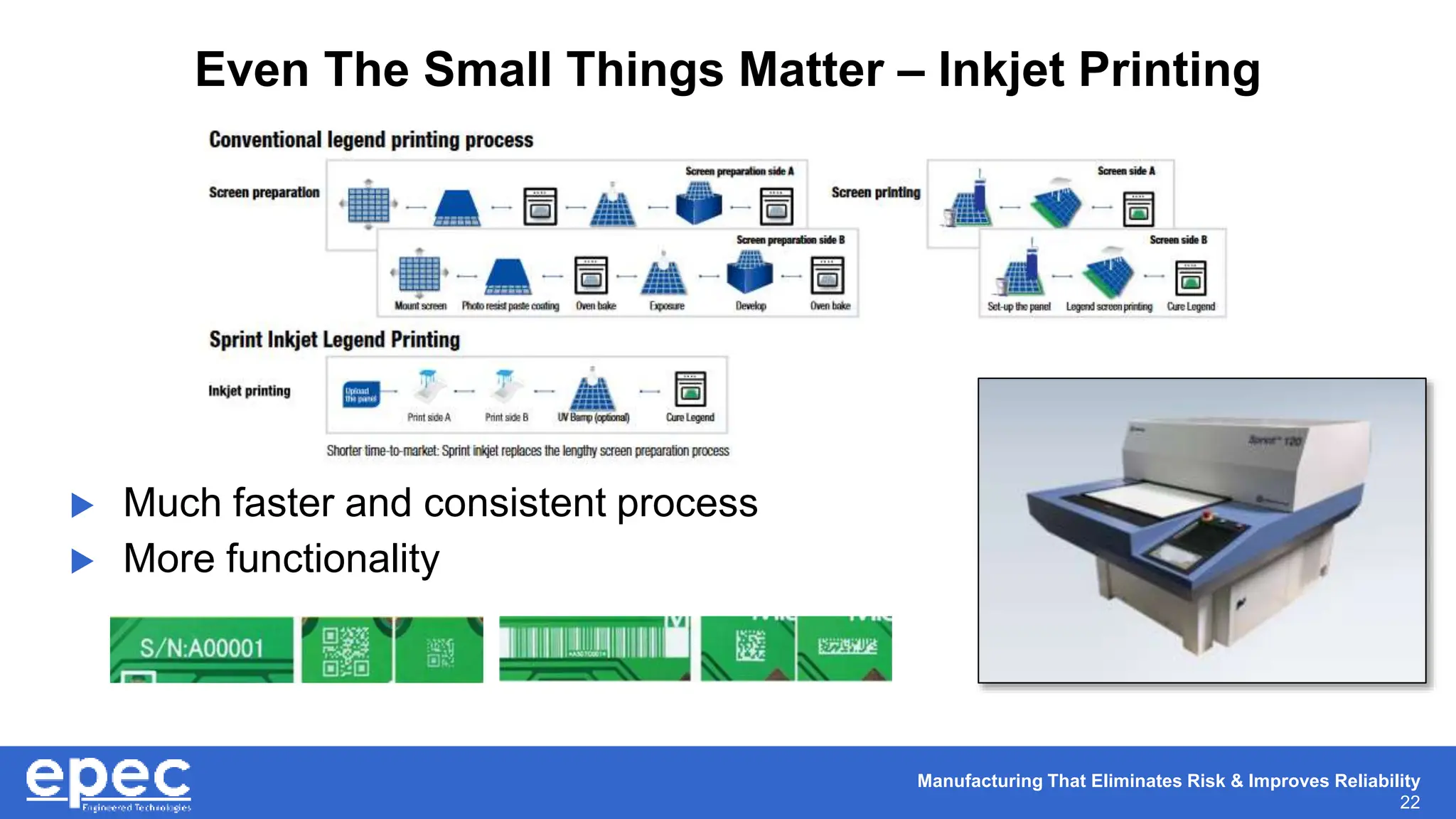

The document discusses the manufacturing process of low layer count PCBs, emphasizing the importance of material selection, design considerations, and technology advancements that influence cost and reliability. It highlights that not all fabricators are equally equipped to handle smaller features and tighter tolerances essential for modern designs. Additionally, it encourages utilizing fabricators' design for manufacturability (DFM) services during development to ensure quality.