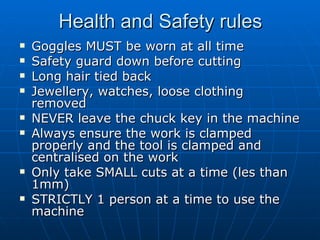

The document provides instructions for a lesson on using a metal lathe. It outlines the learning aims of drilling a hole, filing work, and turning down material on the lathe using measurement scales. It lists health and safety rules that must be followed when using the lathe, such as wearing goggles and ensuring only one person uses the machine at a time. It describes the process of facing off material by moving the tool directly along the face at an angle and keeping the speed fairly fast. It explains that turning down involves using a wedge-shaped tool to remove material by moving the tool along the work sideways using the carriage slide.