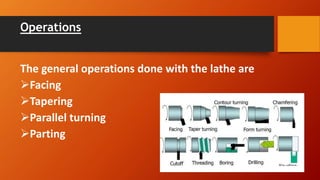

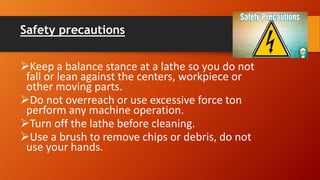

This document describes a lathe machine used in mechanical engineering. It discusses the history and purpose of lathes, common operations like facing, tapering, and parallel turning. Safety precautions are outlined. Dimensions and specifications provided for a mini wood lathe include a 3ft base, 180W motor, and RPM calculation. The objectives are to use local materials, reduce costs, encourage indigenous technology, and increase productivity.