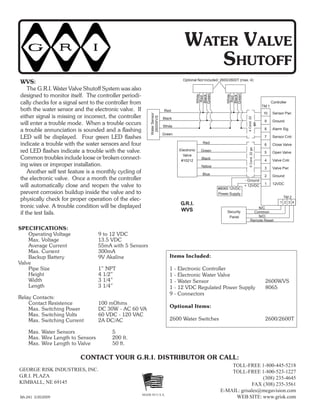

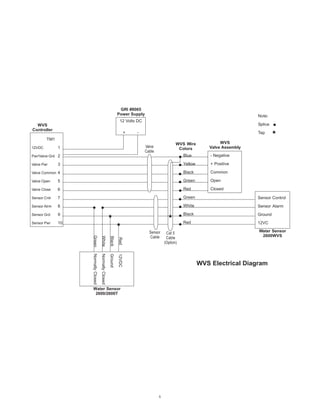

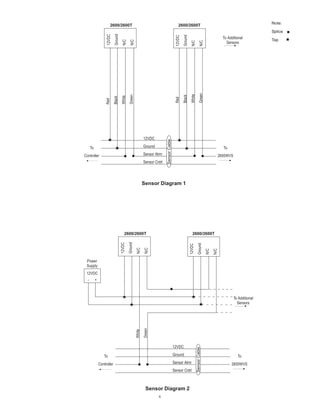

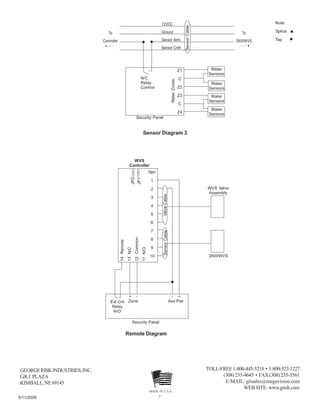

The document describes the G.R.I. Water Valve Shutoff System, which automatically shuts off the main water supply line when water is detected by sensors. The system includes an electronic controller that monitors multiple water sensors, controls an electronic water valve, and provides status indicators. When water is detected, the controller closes the valve and triggers an alarm. It can cover a large area when used with multiple sensors and has self-testing features to monitor operation.

![Water Valve Shutoff

WVS

Water Valve Shutoff

Monitors flooding from

leaking or broken water

line

Automatic control of

main water supply line

Form C Relay output for

external monitoring

devices

Visual and audible

status indicators

Automatic self testing

Covers large area when

used with multiple

sensors

Low voltage design with

battery backup

Product Specification PDF's

About PDF

GRI Water Valve Shutoff Product Specification PDF

GRI Water Valve Shutoff Instructions PDF

[Home] [Products] [What's New!] [Security Products] [Data Entry Peripherals] [Pushbutton Switches]

[Custom Engraved Keycaps] [Proximity Sensors] [Contact GRI] [About GRI]

file:///Z:/My Web Sites/grisk/specialty/water_valve_shutoff.html

Revised: Friday, September 13, 2013

Web design by The Computer Guy Copyright © 1997-2011](https://image.slidesharecdn.com/wvs-150603152733-lva1-app6891/75/GRI-WVS-Data-Sheet-1-2048.jpg)