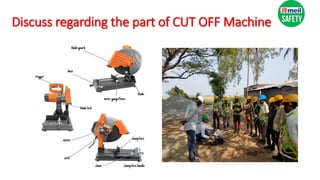

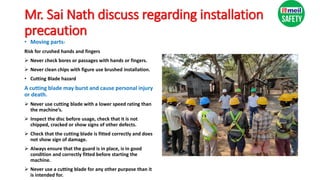

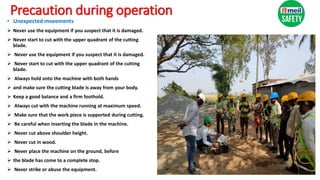

The document discusses safety precautions for operating a cutting machine. It outlines many hazards like moving parts that can crush hands, bursting cutting blades, unexpected movements, dust and fumes, projectiles, slipping or falling. It provides guidelines to reduce risks like never putting hands near moving parts, inspecting blades for defects, wearing proper protective equipment, and operating the machine correctly. The document emphasizes the machine should only be operated by qualified and trained persons wearing protective helmet, hearing protection, eye protection, gloves and boots. Operators should clean and inspect the machine daily before use.