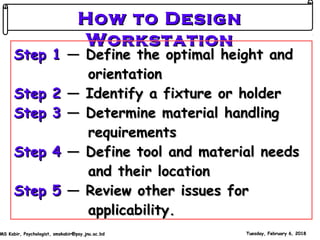

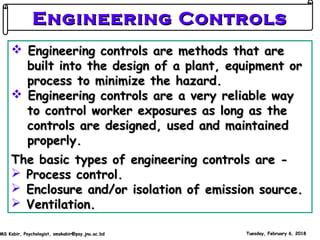

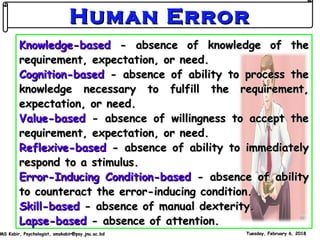

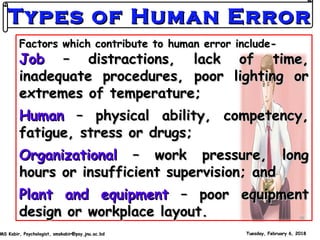

The document provides an overview of ergonomics in workplace design, emphasizing the importance of equipment, workstation, and environmental factors to enhance human performance and safety. It highlights methods for hazard control including engineering, administrative, and personal protective equipment, along with strategies to reduce human error. Additionally, it discusses managing human error by creating a culture of security and involving employees in safety practices.