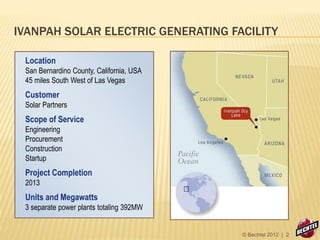

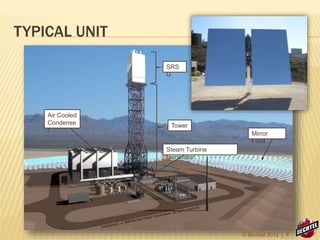

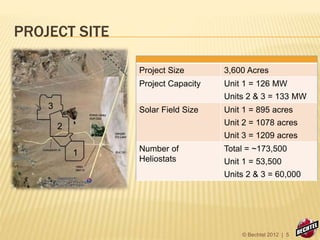

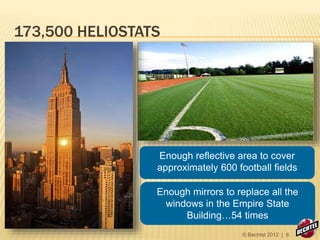

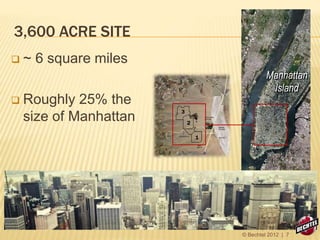

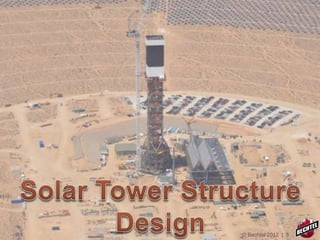

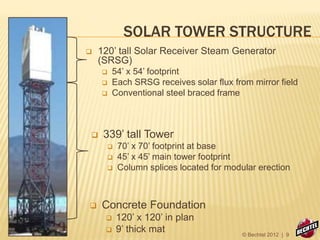

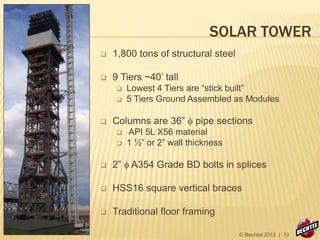

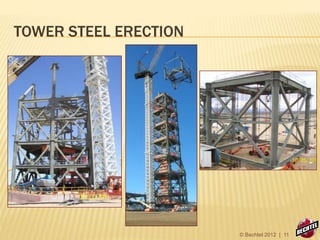

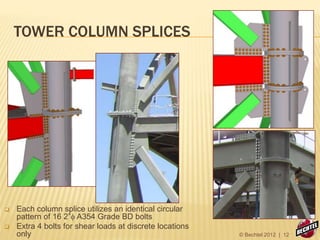

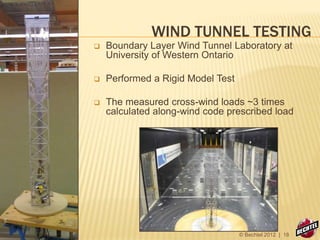

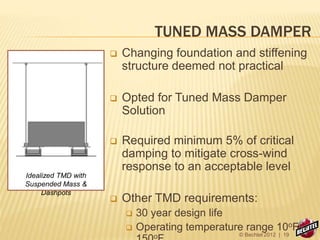

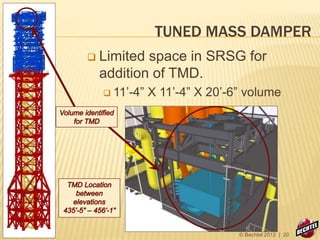

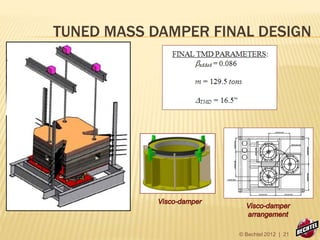

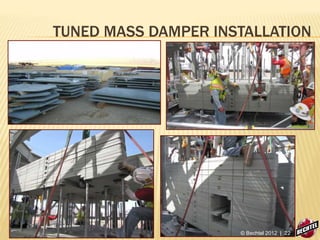

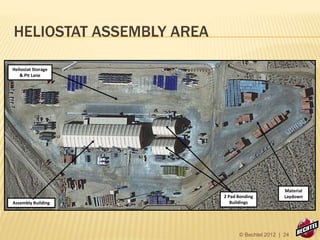

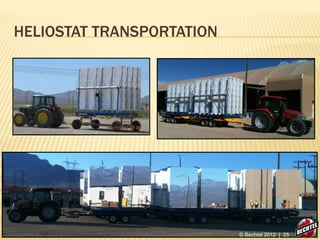

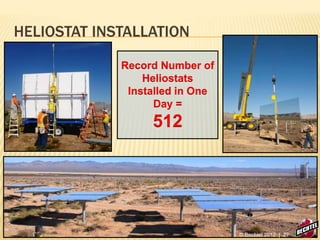

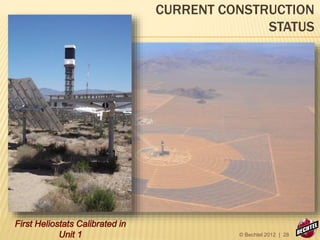

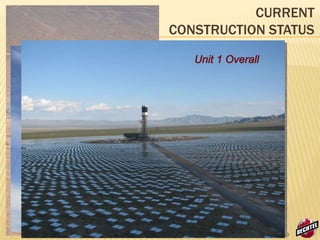

The document describes the Ivanpah Solar Electric Generating Facility, a solar thermal power plant located in California. It consists of 3 separate power plants using solar tower technology, with a total capacity of 392 megawatts. Over 173,000 heliostat mirrors focus sunlight onto boilers located on top of 340-foot towers, producing steam that drives electricity-generating turbines. The project required extensive engineering to address challenges like wind-induced vibration, and helps avoid thousands of tons of carbon emissions annually through clean solar power generation.