Well Unloading Solution - Winning Poster

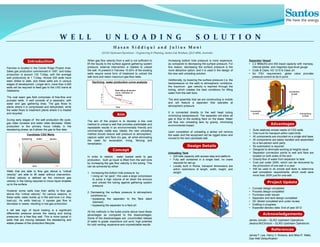

- 1. H a s a n S i d d i q u i a n d J u l i u s M o n i GLNG Upstream Operations – Engineering & Planning, Santos Ltd, Brisbane, QLD 4000, Australia W E L L U N L O A D I N G S O L U T I O N Fairview is located in the Comet Ridge Project Area. Sales gas production commenced in 1997, and today production is around 130 TJ/day, with the average well productivity at 1 TJ/day. Almost 200 wells have been drilled to date, and these wells are in various stages of development. Longer term, more than 4,000 wells will be required to feed gas to the LNG trains at Gladstone. The coal seam gas field comprises of free-flow and pumped wells. A well consists of a separator, with water and gas gathering lines. The gas flows to plants where it is compressed and dehydrated, while the water flows to treatment plants where it is treated and recycled. During early stages of the well production life cycle, gas rates increase and water rates decrease. Water production is the primary focus initially in the dewatering phase, as it allows the gas to flow later. Wells that are able to flow gas above a “critical velocity” are able to lift water without intervention. Critical velocity is defined as the minimum gas velocity in the tubing required to move liquid droplets up to the surface. However some wells lose their ability to flow gas above this “critical velocity”, for various reasons. In these wells, water builds up in the well bore (i.e. they load-up). As wells load-up, it causes gas flow to decrease or cease, resulting in lost gas production. A tell tale sign of liquid loading is a significant differential pressure across the casing and tubing pressures on a free flow well. This is more typical in wells that are moving between the dewatering and stable phases of the production lifecycle. IntroductionIntroduction Increasing bottom hole pressure is more expensive, as compared to decreasing the surface pressure. For this reason, decreasing the surface pressure is the more attractive option, and it is used in the design of the new well unloading solution. Additionally, by lowering the surface pressure (i.e. the backpressure on the well) to atmospheric conditions, the maximum gas velocity is reached through the tubing, which creates the best conditions for lifting water from the well bore. The skid assembly that we are constructing is mobile and will feature a separator that operates at atmospheric pressure. It is connected directly to the well head tubing minimizing backpressure. The separator will allow all gas to flow to the existing flare on the lease. Water will flow into unloading tank by gravity, minimizing environmental impact. Upon completion of unloading a tanker will remove the water and the equipment will be rigged down and moved to the next candidate well. Unloading Tank • 220 bbls capacity with access step and platform • Fully self contained in a single load, no crane required for set up • Locally built in Roma, transport dimensions are within restrictions of length, width, height, and weight Design DetailsDesign Details • Suits relatively simple needs of CSG wells • One truck for transport within road limits • All components are mounted on a single skid base • All components are easily handled and assembled by a two-person work party • No automation is required • Designed to eliminate working at heights issue • Separator connection points to well and flare are located on both sides of the skid • Gravity flow of water from separator to tank • Cost just under 200K, which can be recovered by the production of one well in a year • Will be used to do simple well tests to determine well completion requirements, which could save more than 200K just for one well AdvantagesAdvantages Project UpdateProject Update • Concept design completed • Process design completed • Purchase order issued • Separator and tank design completed • 3D- Model completed and under review • Drafting in progress • Expected delivery date: End of year 2012 AcknowledgementsAcknowledgements James Jonutis – GLNG Upstream Operations Jessica McClintock – GLNG Upstream Operations ReferencesReferences James F. Lea, Henry V. Nickens, and Mike R. Wells, Gas Well Deliquification Separator Vessel • 2.2 MMscf/d and 400 bwpd capacity with manway, internal ladder, and magnetic-type level gauge • Code & Class: AS 1210 & Class 2A • No PSV requirement, globe valve provides pressure control at tie-in point Connection to well Connection to well Connections to flare AimAim ConceptConcept The aim of the project is to develop a low cost method to unload a well that provides predictable and repeatable results in an environmentally friendly and commercially viable way. Ideally, the new unloading method should reduce well pressure to atmospheric, capture water and flare dry gas, all while eliminating the need for excavation, lining, fencing and remediation. In order to restore water loaded wells to gas production, built up liquid is lifted from the well bore by increasing the gas flow velocity in the tubing. This can be achieved by either: 1. Increasing the bottom hole pressure by: • Using an “air pack”; this uses a large compressor to pump a high volume of air down the annulus and unload the tubing against gathering system pressure 2. Decreasing the surface pressure to atmospheric conditions by: • bypassing the separator to the flare stack (banned) • bypassing the separator to a flare pit All the methods in the bullet points above have fewer advantages as compared to the disadvantages. Some of the disadvantages are: uncontrolled release of water to grade; expensive civil work; high potential for cold venting; expensive and unpredictable results. When gas flow velocity from a well is not sufficient to lift the liquids to the surface against gathering system pressure, external intervention is needed to unload the well. At present in Fairview 10-20% of the existing wells require some form of treatment to unload the well bore and reach maximum gas flow rates. Time R a t e Rate falling off decline curve, indication of loading Declining water production curve analysis time dewatering stable decline rates Candidate CSG Wells