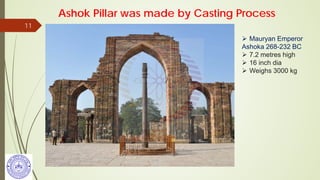

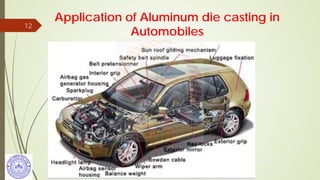

The document outlines the advantages and disadvantages of casting, highlighting its capability to create complex geometries, produce large parts, and suitability for mass production, while also noting mechanical limitations and safety hazards. It provides a historical context of casting, dating back to ancient civilizations, and mentions its application in various fields, including automotive and jewelry. Additionally, it emphasizes key areas for successful casting operations and includes references to instructional video content.