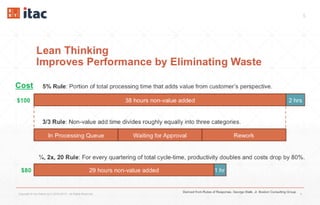

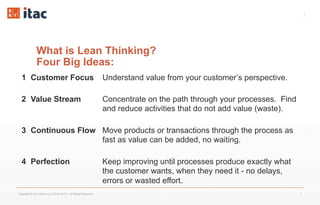

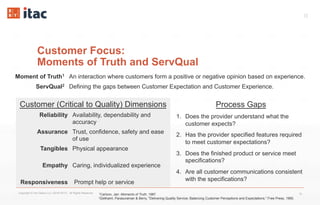

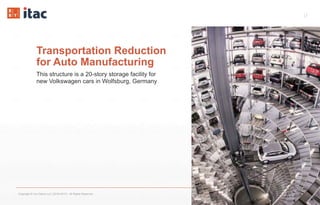

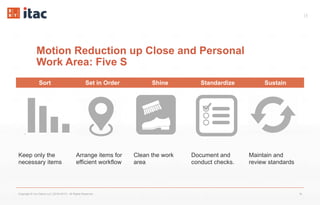

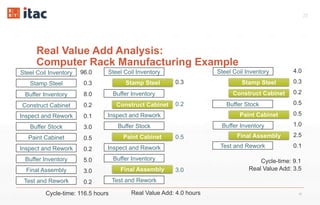

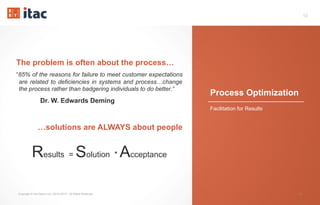

The document provides an overview of Lean Thinking concepts including customer focus, value streams, waste reduction, and continuous flow. It discusses building customer journey maps and identifying non-value added activities. The document also covers simulations and examples to illustrate key Lean principles like eliminating waste, applying the five S's, and conducting value stream analysis.