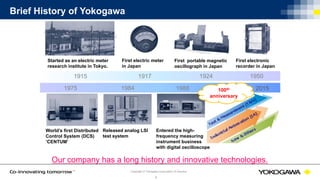

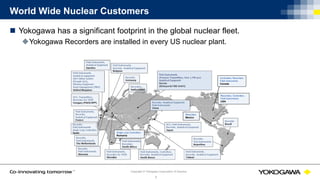

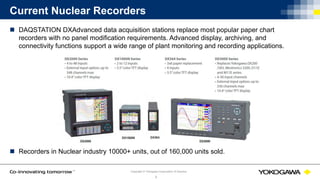

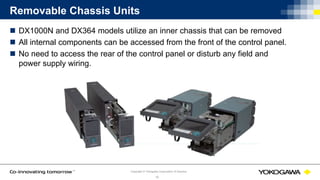

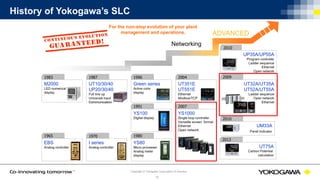

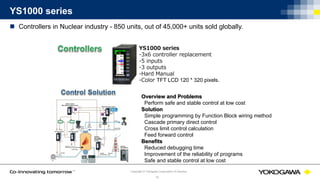

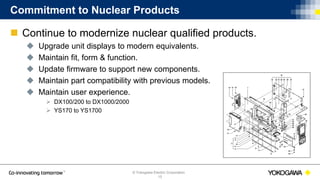

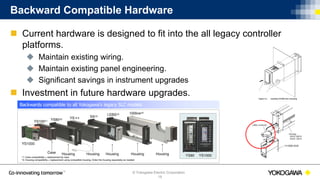

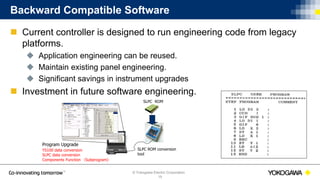

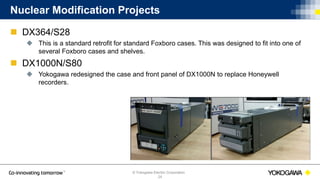

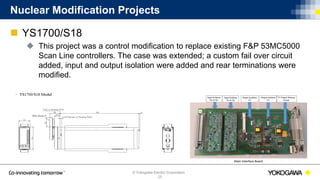

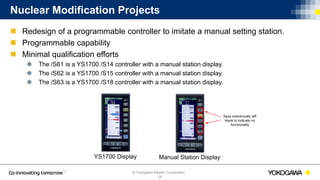

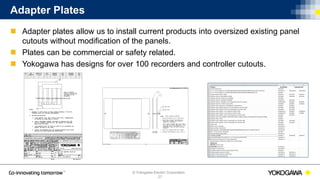

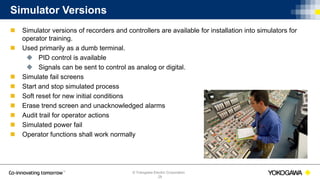

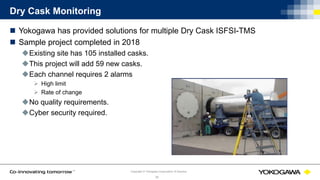

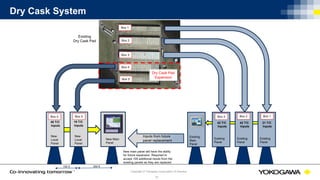

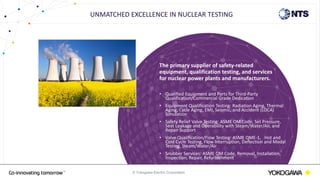

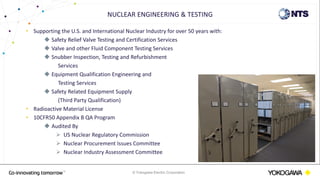

The document provides an overview of Yokogawa Electric Corporation's history, product offerings, and commitment to managing instrument obsolescence in the nuclear industry. It highlights their extensive experience, significant global footprint in nuclear applications, and modernization projects for various recording and control systems. Additionally, it emphasizes the importance of partnerships and continuous development to ensure safety and reliability in their products.